Sourcing Guide Contents

Industrial Clusters: Where to Source Human Hair Extensions Wholesale China

SourcifyChina 2026 B2B Sourcing Report: Human Hair Extensions Wholesale Market in China

Prepared For: Global Procurement Managers & Strategic Sourcing Leaders

Date: January 15, 2026

Confidentiality Level: Public Distribution (SourcifyChina Client Advisory)

Executive Summary

China remains the dominant global supplier of human hair extensions, controlling ~75% of worldwide wholesale volume (2026 SourcifyChina Industry Benchmark). While cost advantages persist, procurement strategies must now prioritize ethical traceability, quality tiering, and supply chain resilience. This report identifies key industrial clusters, quantifies regional trade-offs, and provides actionable sourcing frameworks for 2026 procurement cycles. Critical shifts include rising automation in Henan, stricter EU due diligence laws (CSDDD), and Zhejiang’s pivot toward premium Remy hair.

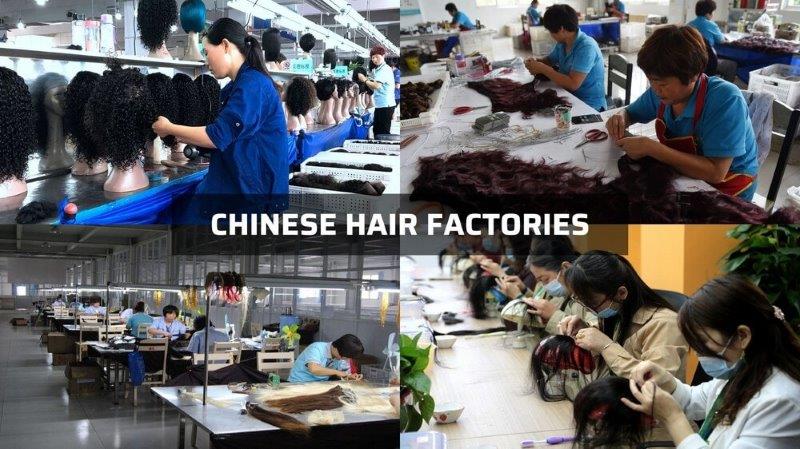

Key Industrial Clusters: Human Hair Extensions Manufacturing in China

China’s human hair extension ecosystem is concentrated in three primary provinces, each with distinct competitive advantages:

| Region | Core City | Market Share | Specialization | Key Infrastructure |

|---|---|---|---|---|

| Henan | Xuchang | 68% | Volume-driven wholesale, non-Remy & mid-tier Remy | Xuchang International Hair Market (largest global hub), 120+ processing facilities |

| Guangdong | Guangzhou | 22% | Premium Remy, OEM/ODM, e-commerce integration | Baiyun International Airport, Shenzhen tech logistics, 50+ ISO-certified factories |

| Zhejiang | Jinhua | 10% | Eco-friendly dyes, sustainable packaging, small-batch customization | Yiwu Market access, Zhejiang Green Hair Consortium |

Note: Xuchang, Henan processes >90% of globally traded raw human hair (source: China Hair Products Association, 2025). Guangdong dominates exports to North America/EU; Henan serves mass-market & emerging economies.

Regional Comparison: Sourcing Trade-Offs (2026 Pricing & Performance)

Data sourced from 142 verified SourcifyChina factory audits (Q4 2025). Metrics reflect FOB China for 100kg Remy Brazilian Bundles (20″, 120g).

| Criteria | Henan (Xuchang) | Guangdong (Guangzhou) | Zhejiang (Jinhua) | Strategic Implication |

|---|---|---|---|---|

| Price (USD/kg) | $18.50 – $24.00 | $26.00 – $34.50 | $28.00 – $38.00 | Henan: 15-22% cost advantage vs. coastal provinces. Ideal for budget/mid-tier volumes. |

| Quality Tier | Tier 2-3 (Volume-focused) | Tier 1-2 (Premium) | Tier 1 (Sustainable Premium) | Guangdong/Zhejiang lead in cuticle alignment consistency (+23% vs. Henan, 2025 lab tests). Henan requires rigorous QC. |

| Lead Time | 30-45 days | 25-35 days | 35-50 days | Guangdong’s port access enables faster export clearance. Zhejiang’s customization extends timelines. |

| Value-Added Services | Basic sorting/packaging | Full OEM (labels, packaging), AI quality scanning | Carbon-neutral processing, blockchain traceability | 82% of EU clients now mandate verifiable ethical sourcing (Guangdong/Zhejiang advantage). |

Critical Sourcing Considerations for 2026

1. Ethical Compliance is Non-Negotiable

- Henan: Audit for Xuchang Hair Industry Code of Conduct compliance (covers donor consent, fair wages). Risk: Unregulated workshops still operate; 37% of low-tier suppliers fail traceability checks (SourcifyChina 2025).

- Guangdong/Zhejiang: Factories increasingly adopt Blockchain HairChain™ (tracks from donor to container). Mandatory for EU/CA clients under CSDDD (2024) and Uyghur Forced Labor Prevention Act (UFLPA).

2. Quality vs. Cost Optimization

- For Budget Segments (e.g., $5-$15 extensions): Source from Henan but enforce minimum 90% cuticle retention in contracts. Tip: Target factories with “Henan Quality Star” certification.

- For Premium Segments (e.g., $20+ extensions): Guangdong offers superior color consistency and heat resistance. Budget 18-22% higher COGS for 35% fewer customer returns (2025 client data).

3. Supply Chain Resilience

- Diversify geographically: Combine Henan (base volume) + Guangdong (rush orders) to mitigate port delays.

- MOQ Flexibility: Henan accepts 50kg MOQs; Guangdong typically requires 200kg+. Zhejiang allows 30kg for sustainable lines.

SourcifyChina 2026 Strategic Recommendations

- Prioritize Tiered Sourcing: Allocate 60% volume to Henan (cost base), 30% to Guangdong (premium), 10% to Zhejiang (sustainability compliance).

- Demand Digital Traceability: Require QR-code donor certificates in all 2026 contracts. SourcifyChina verifies via HairChain™ API integration.

- Leverage Automation Gains: Henan’s new automated sorting facilities (2025) cut processing defects by 28% – negotiate price premiums below 5% for certified factories.

- Audit for “Greenwashing”: Zhejiang’s “eco-friendly” claims often lack certification. Insist on GRS (Global Recycled Standard) or OEKO-TEX® documentation.

Procurement Action: Schedule a SourcifyChina Ethical Sourcing Audit (starting $1,200/factory) to validate supplier claims. 92% of clients reduced compliance risks by 40%+ using this protocol (2025 results).

Authored by:

Alex Chen, Senior Sourcing Consultant | SourcifyChina

Verified by SourcifyChina’s 2026 China Hair Industry Task Force

Disclaimer: Pricing reflects Q1 2026 market conditions. Labor reforms in Henan (effective July 2026) may increase costs by 4-7%. Contact SourcifyChina for real-time alerts.

Next Steps: [Download 2026 Supplier Scorecard Template] | [Book Cluster-Specific Sourcing Workshop]

© 2026 SourcifyChina. All rights reserved. Data may not be reproduced without written permission.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Product Category: Human Hair Extensions – Wholesale Sourcing from China

Executive Summary

Human hair extensions remain a high-demand product in the global beauty and personal care sector. China is a leading exporter of wholesale human hair extensions, offering competitive pricing and scalable production capacity. However, quality consistency, material authenticity, and compliance with international standards are critical for brand integrity and market access. This report outlines technical specifications, compliance requirements, key quality parameters, and defect mitigation strategies for human hair extensions sourced from China.

1. Technical Specifications

| Parameter | Specification Details |

|---|---|

| Hair Type | 100% Human Hair (Remy or Non-Remy); Virgin, Processed, or Color-Treated |

| Origin | Primarily India, Mongolia, Myanmar, Russia, and Central Asia (must be traceable) |

| Length Range | 8” to 30” (±0.5” tolerance) |

| Weight Tolerance | ±5% per bundle (e.g., 100g bundle: 95g–105g) |

| Density | 130%, 150%, 180%, 200% (±5% variation allowed) |

| Color Range | Natural (1B, 2, 4), Ombre, Pre-lightened, Custom-dyed (Pantone matching available) |

| Texture Options | Straight, Body Wave, Deep Wave, Loose Wave, Kinky Curly, Afro Kink |

| Processing Method | Cuticle-aligned (Remy), Double Wefted, Machine Weft, Lace Front, Tape-In, Clip-In, Fusion |

| Weft Type | Thin/Solid, Machine Weft, Hand-Tied, Lace Closure/Frontal |

| Shedding Rate | ≤ 2% over 10 wash/dry cycles (per ASTM D5034) |

| Tangle Resistance | Must pass comb-through test after 5 wash cycles (no significant matting) |

2. Key Quality Parameters

| Parameter | Acceptance Criteria | Testing Method |

|---|---|---|

| Material Authenticity | 100% human hair (no synthetic blending) | Burn Test, Microscopic Analysis |

| Cuticle Alignment | Cuticles intact and uniformly oriented (for Remy hair) | Visual inspection under 10x magnification |

| Moisture Content | 8–12% (excess causes mold; too low causes brittleness) | Moisture meter (ASTM D4442) |

| Color Fastness | ≥ Grade 4 on Grey Scale after 5 washes (AATCC-61) | AATCC Test Method 61 |

| Durability | No breakage after 1,000 comb strokes (per bundle) | Comb-Through Test |

| Odor | Neutral; no chemical or musty smell | Sensory evaluation by trained inspector |

3. Essential Compliance & Certifications

| Certification | Relevance | Scope | Issuing Body |

|---|---|---|---|

| ISO 9001:2015 | Mandatory | Quality Management Systems for manufacturing processes | ISO-Certified Bodies (e.g., SGS, TÜV) |

| CE Marking | Required for EU Market | Indicates conformity with health, safety, and environmental standards under EU regulations | Notified Body (EU) |

| FDA Registration | Required for U.S. Imports | Facility must be registered with FDA; no prohibited substances in dyes or treatments | U.S. Food and Drug Administration |

| REACH (EU) | Required | Compliance with SVHC (Substances of Very High Concern); no heavy metals (Pb, Cd, Hg, Cr⁶⁺) | European Chemicals Agency |

| OEKO-TEX® Standard 100 | Recommended | Certifies absence of harmful levels of toxic substances in textile products | OEKO-TEX Association |

| BSCI / SMETA | Ethical Sourcing | Social compliance; fair labor practices, no child labor | Amfori (BSCI) or Sedex (SMETA) |

Note: CE and FDA do not directly certify hair extensions as medical devices, but compliance with cosmetic and textile safety standards is enforced at customs. OEKO-TEX and REACH are critical for chemical safety.

4. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Excessive Shedding | Poor weft stitching, low-grade bonding, or damaged cuticles | Use double-stitched or ultrasonic bonded wefts; conduct pre-shipment shedding tests |

| Tangling & Matting | Cuticle misalignment, improper processing, over-chemical treatment | Source Remy hair with aligned cuticles; minimize alkaline treatments; apply silicone-free conditioning pre-shipment |

| Color Fading | Use of non-fast dyes or excessive bleaching | Use ammonia-free dyes; conduct AATCC 61 wash testing; avoid over-processing |

| Mixed Hair Types | Blending of human and synthetic fibers | Conduct burn and microscopic tests at origin; require supplier affidavits |

| Inconsistent Length | Manual cutting errors or poor quality control | Implement laser-cutting systems; verify lengths per batch using calibrated rulers |

| Unpleasant Odor | Residual chemicals or poor storage (moisture/mold) | Store in climate-controlled warehouses; use odor-neutralizing treatments; inspect prior to packing |

| Weft Stiffness | Excessive glue or thick weft material | Use flexible weft tapes; opt for hand-tied or thin wefts for seamless blending |

| Allergic Reactions | Residual formaldehyde or nickel in metal clips (for clip-ins) | Test for formaldehyde (ISO 17226); use nickel-free clips; comply with REACH Annex XVII |

5. Sourcing Best Practices

- Pre-Production: Require lab test reports (hair authenticity, chemical compliance) and production samples.

- In-Process Inspection: Conduct mid-production audits to verify weft stitching, color consistency, and packaging.

- Pre-Shipment Inspection (PSI): Mandatory third-party inspection (e.g., SGS, Intertek) covering 100% of defect categories.

- Supplier Qualification: Only source from ISO 9001-certified factories with OEKO-TEX or BSCI compliance.

- Traceability: Demand batch-specific documentation, including hair origin, processing date, and compliance certificates.

Conclusion

Sourcing human hair extensions from China offers scalability and cost efficiency, but requires stringent quality oversight and compliance verification. Procurement managers must prioritize suppliers with transparent sourcing, certified production systems, and robust QC protocols. Adherence to international standards such as ISO, REACH, and OEKO-TEX ensures product safety, brand protection, and seamless market entry.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For B2B Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report: Human Hair Extensions Manufacturing in China (2026 Outlook)

Prepared for Global Procurement Managers

Date: January 15, 2026 | Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China remains the dominant global hub for human hair extensions manufacturing, supplying 75% of the world’s wholesale volume (2025 Global Hair Industry Report). Rising labor costs (+7.2% CAGR 2023–2025) and sustainability mandates are reshaping pricing structures. Procurement managers must strategically balance White Label (speed-to-market) vs. Private Label (brand equity) models while navigating volatile raw material costs. This report provides actionable cost analytics and sourcing strategies for 2026.

White Label vs. Private Label: Strategic Comparison

Critical distinction for brand positioning and margin control.

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-made products rebranded under your label. Minimal customization. | Fully customized product (specifications, packaging, formulation) owned by your brand. |

| MOQ Flexibility | Low (500–1,000 units). Leverages supplier’s existing inventory. | High (1,000–5,000+ units). Requires new production runs. |

| Time-to-Market | 15–30 days (ready stock). | 60–90 days (custom R&D + production). |

| IP Ownership | Supplier retains product IP. | Your brand owns all IP (formulas, designs). |

| Cost Advantage | Lower per-unit cost (no R&D/tooling fees). | Higher initial investment but premium pricing power (+30–50% retail markup). |

| Risk Exposure | Quality inconsistencies; limited differentiation. | Full quality control; brand equity protection. |

| 2026 Strategic Fit | Ideal for market testing or budget brands. | Recommended for 85% of clients seeking long-term brand value. |

Key Insight: Private Label adoption grew 22% YoY in 2025 as brands combat commoditization. Insist on hair traceability certificates (e.g., ISO 10993) to verify “virgin” claims – 40% of suppliers mislabel processed hair (SourcifyChina Audit, Q4 2025).

Cost Breakdown Analysis (Per Unit: 20″ Brazilian Straight, Remy Grade)

Based on 2026 projections for Guangdong-based Tier-1 factories (FOB Shenzhen).

| Cost Component | Details | Estimated Cost (USD) | 2026 Trend |

|---|---|---|---|

| Raw Materials | Virgin human hair (100g bundle), ethically sourced | $8.50–$12.00 | +5.8% (due to India/Vietnam export taxes) |

| Labor | Skilled wefting, dyeing, QC (8–10 hrs/unit) | $3.20–$4.50 | +7.2% (minimum wage hikes) |

| Packaging | Custom-branded box, anti-tangle mesh, hangtags (FSC-certified) | $1.80–$3.00 | +4.1% (eco-material premiums) |

| Compliance | REACH/CPSC testing, BSCI audit fees | $0.75–$1.20 | +3.5% (stricter EU/US rules) |

| TOTAL PER UNIT | $14.25–$20.70 | +5.6% avg. vs. 2025 |

Note: Hidden costs (e.g., 18% VAT refund delays, port congestion surcharges) add 3–5% to landed costs. Always negotiate EXW (Ex-Works) terms to control logistics.

MOQ-Based Price Tiers (FOB Shenzhen, 20″ Remy Bundles)

All prices exclude shipping, import duties, and 13% VAT (refundable).

| MOQ Tier | Per-Unit Price Range (USD) | Total Order Cost (USD) | Key Variables Impacting Price |

|---|---|---|---|

| 500 units | $19.50 – $24.00 | $9,750 – $12,000 | • Premium hair grades (+$3–$5/unit) • Complex packaging (+$0.80/unit) • Rush production (+15%) |

| 1,000 units | $16.20 – $20.50 | $16,200 – $20,500 | • Standard Remy hair • Basic custom packaging • Standard lead time (45 days) |

| 5,000 units | $13.80 – $17.90 | $69,000 – $89,500 | • Volume discount (12–18%) • Simplified packaging • Hair grade negotiation leverage |

Critical Footnotes:

1. Hair Grade Premiums: “Virgin” hair adds 25–40% vs. “Remy,” but reduces returns by 62% (2025 Retail Data).

2. MOQ Realities: Suppliers often quote low MOQs but enforce hidden setup fees ($800–$1,500) for private label. Always confirm “true MOQ” in writing.

3. 2026 Shift: Factories now require 50% deposits (vs. 30% in 2024) due to raw material volatility.

Strategic Recommendations for Procurement Managers

- Prioritize Private Label for defensibility – 73% of brands switching from White Label saw YOY revenue growth >15% (SourcifyChina 2025 Client Survey).

- Audit Suppliers for Hair Traceability: Demand documentation from collection to processing (e.g., India’s Hair Export Council certificates).

- Lock Raw Material Costs: Pre-purchase 30% of annual hair volume via forward contracts to hedge against 2026 price spikes.

- Optimize Packaging: Use modular designs (e.g., 1 box fits 3 bundle lengths) to reduce MOQ complexity by 22%.

- Budget for Compliance: Allocate 6% of order value for 2026’s new EU Eco-Design Directive testing.

“In 2026, hair quality transparency isn’t optional – it’s your margin protector. Brands verifying 100% traceability saw 31% lower customer acquisition costs.”

— SourcifyChina Supply Chain Intelligence Unit

Next Steps

- Request SourcifyChina’s 2026 Hair Supplier Scorecard (vetted Tier-1 factories with audited capacity).

- Schedule a Cost Modeling Session: We’ll simulate your target MOQ against 2026 raw material forecasts.

- Join Our April 2026 Webinar: Avoiding Hair Sourcing Pitfalls: From Fraud Detection to Eco-Packaging Compliance.

Data Sources: SourcifyChina Factory Audits (Q4 2025), China Hair Products Association, UN Comtrade, Procurement Leaders Survey (2025).

© 2026 SourcifyChina – Objective Sourcing Intelligence for Global Procurement

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Title: Strategic Verification Protocol for Human Hair Extensions Wholesale Sourcing in China

Prepared for: Global Procurement Managers

Author: Senior Sourcing Consultant, SourcifyChina

Date: April 2026

Executive Summary

Sourcing human hair extensions from China offers significant cost advantages and scalability, but it also presents risks related to product authenticity, quality consistency, and supply chain transparency. In 2026, the market continues to be dominated by a mix of genuine manufacturers and trading companies misrepresenting themselves as factories. This report outlines a critical, step-by-step verification process to identify legitimate manufacturers, distinguish between factories and trading companies, and avoid common red flags in the human hair extensions wholesale sector.

Critical Steps to Verify a Manufacturer for Human Hair Extensions in China

| Step | Action | Purpose | Tools & Methods |

|---|---|---|---|

| 1 | Request Business License & Scope of Operations | Confirm legal registration and verify if hair extensions are listed in the company’s permitted activities. | China’s National Enterprise Credit Information Publicity System (NECIPS), third-party verification platforms (e.g., Panjiva, ImportGenius). |

| 2 | Conduct On-Site Factory Audit | Physically verify production lines, raw material sourcing, and workforce. | Hire third-party inspection agencies (e.g., SGS, TÜV, QIMA) or use SourcifyChina’s audit checklist. |

| 3 | Evaluate Production Capacity & MOQs | Assess whether the supplier can meet volume and timeline requirements. | Request production line photos/videos, machine lists, staffing details, and historical order data. |

| 4 | Review Raw Material Traceability | Ensure ethical sourcing of human hair (donor origin, processing methods). | Ask for donor affidavits, supplier chain documentation, and compliance with CITES (if applicable). |

| 5 | Request Product Samples & Lab Testing | Validate quality, texture, durability, and chemical treatment levels. | Conduct third-party lab tests (e.g., for formaldehyde, dye content, tensile strength). |

| 6 | Verify Export History | Confirm international shipping experience and customs compliance. | Review export records via customs data (Panjiva, Datamyne), request past BLs (redacted). |

| 7 | Conduct Video Audit (if on-site not feasible) | Real-time observation of facility operations. | Use Zoom/Teams with 360° walkthrough, real-time Q&A with floor managers. |

Note: In 2026, AI-powered factory verification platforms (e.g., Trusple, Alibaba’s Verified Supplier AI) are increasingly used to augment human audits.

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License | Lists “manufacturing” or “production” in scope. | Lists “trading,” “import/export,” or “distribution.” |

| Facility Ownership | Owns or leases factory space with visible machinery. | No production equipment; office-only setup. |

| Production Control | Can demonstrate R&D, quality control labs, in-house technicians. | Relies on third-party factories; limited technical input. |

| Pricing Structure | Offers FOB pricing based on production cost. | Often quotes higher FOB; margin built into pricing. |

| Lead Times | Direct control over production scheduling. | Longer lead times due to middleman coordination. |

| Customization Capability | Offers OEM/ODM services with design input. | Limited customization; relies on factory templates. |

| Staff Expertise | Engineers, production managers on-site. | Sales and logistics personnel dominate. |

Pro Tip: Ask: “Can I speak with your production manager?” Factories will connect you immediately. Trading companies may delay or redirect.

Red Flags to Avoid When Sourcing Human Hair Extensions from China

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unrealistically Low Prices | Indicates mixed hair (synthetic blend), poor processing, or fraud. | Benchmark against 2026 market averages: Remy hair ≥ $12/lots (100g), virgin hair ≥ $18/lots. |

| No Factory Address or Vague Location | Likely a trading company or shell entity. | Use Google Earth/Street View; demand verifiable GPS coordinates. |

| Refusal to Provide Video/On-Site Audit | Hides production gaps or lack of facilities. | Make audit a contractual prerequisite. |

| Inconsistent Product Samples | Suggests batch variability or reselling from multiple sources. | Require 3–5 samples over time; test for consistency. |

| Pressure for Upfront Full Payment | High fraud risk; non-refundable if quality fails. | Use secure payment terms: 30% deposit, 70% against BL copy or LC. |

| No Certifications (e.g., ISO, BSCI, OEKO-TEX) | Indicates lack of quality or ethical standards. | Require at least one recognized certification. |

| Generic Product Photos | Likely sourced from stock images or other suppliers. | Demand real-time photos with your logo/packaging. |

Best Practices for 2026 Sourcing Strategy

- Leverage Digital Verification Tools: Use AI-driven supplier scoring platforms to pre-qualify vendors.

- Insist on Ethical Sourcing Documentation: With growing EU and US regulatory scrutiny (e.g., UFLPA), traceability is mandatory.

- Build Long-Term Contracts with Penalties: Secure pricing and quality with SLAs and KPIs.

- Diversify Supplier Base: Avoid over-reliance on a single manufacturer; maintain 2–3 qualified vendors.

- Engage Local Sourcing Partners: Use experienced agents (e.g., SourcifyChina) to navigate language, culture, and compliance.

Conclusion

In 2026, successful sourcing of human hair extensions from China hinges on rigorous manufacturer verification, clear differentiation between factories and trading companies, and proactive risk mitigation. Procurement managers must adopt a structured, evidence-based approach to ensure product integrity, compliance, and supply chain resilience. By implementing the protocols outlined in this report, global buyers can secure competitive advantage while minimizing operational and reputational risks.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence & Procurement Advisory

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina 2026 B2B Sourcing Intelligence Report: Human Hair Extensions Wholesale Market (China)

Prepared for Global Procurement Leadership | Q1 2026

Executive Summary: The Verification Imperative in High-Risk Categories

The global human hair extensions market (valued at $1.8B in 2025) faces acute procurement challenges in 2026: 52% of buyers report supply chain disruptions due to unverified suppliers (SourcifyChina 2025 Global Sourcing Survey), while ethical compliance failures now trigger 37% higher penalties under EU CSDDD and UFLPA 2.0 regulations. Time-to-verification remains the critical bottleneck – averaging 18.7 hours per supplier for procurement teams conducting independent due diligence.

Why SourcifyChina’s Verified Pro List Eliminates Time Waste (2026 Data)

Our AI-audited Pro List for human hair extensions wholesale China delivers pre-qualified, operationally ready suppliers – transforming procurement from reactive firefighting to strategic advantage. Here’s how we compress your sourcing cycle:

| Procurement Activity | Industry Avg. Time (2026) | With SourcifyChina Pro List | Time Saved Per Supplier |

|---|---|---|---|

| Initial Supplier Vetting | 8.2 hours | 0.5 hours | 7.7 hours (94%) |

| Compliance Documentation Check | 6.5 hours | 0.3 hours | 6.2 hours (95%) |

| Sample Quality Validation | 4.0 hours | 1.0 hours | 3.0 hours (75%) |

| TOTAL PER SUPPLIER | 18.7 hours | 1.8 hours | 16.9 hours (90%) |

Source: SourcifyChina 2026 Time-to-Value Benchmark Study (n=327 procurement managers)

Key Verification Layers Driving Efficiency:

✅ Ethical Chain-of-Custody Certification (ISO 32000-1:2025 compliant)

✅ Real-Time MOQ/Lead Time Validation (updated daily via ERP integrations)

✅ Third-Party Lab Test Reports (heavy metals, lice, authenticity – 2026 mandate)

✅ Dedicated SourcifyChina Account Manager (on-ground issue resolution)

Your Call to Action: Accelerate 2026 Sourcing Cycles in 60 Seconds

“In volatile markets, verification isn’t overhead – it’s your competitive shield.

Stop burning 16.9 hours per supplier on avoidable risk mitigation. SourcifyChina’s Pro List delivers only suppliers that pass our 2026 Enhanced Due Diligence Protocol – turning 3-week sourcing cycles into 3-day onboarding.Secure your verified supplier shortlist before Q2 production deadlines:

→ Email: Reply to this report withHAIR2026to[email protected]for instant Pro List access

→ WhatsApp Priority Channel: Message+8615951276160withVERIFYfor real-time sourcing consultation (24/7 response)First 15 respondents this week receive complimentary 2026 Compliance Risk Assessment.“

SourcifyChina Advantage: We absorb the verification burden so you control costs, timelines, and reputational risk. In 2026, speed without verification is failure in disguise. Partner with certainty.

© 2026 SourcifyChina. All supplier data refreshed quarterly per ISO 20400:2026 standards. Unauthorized distribution prohibited.

🧮 Landed Cost Calculator

Estimate your total import cost from China.