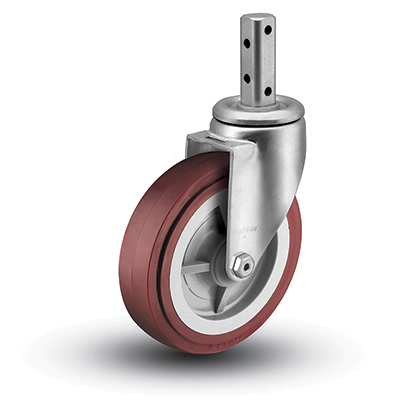

The global caster wheels market is experiencing robust growth, driven by increasing demand across industrial, logistics, healthcare, and retail sectors. According to a report by Mordor Intelligence, the caster market was valued at USD 3.8 billion in 2023 and is projected to reach USD 5.2 billion by 2029, growing at a CAGR of approximately 5.3% during the forecast period. This expansion is fueled by rising automation in material handling, infrastructure development, and the e-commerce boom, which has intensified warehouse operations requiring durable, high-performance casters. Among the various types, heavy-duty threaded stem casters are particularly sought after for their load capacity, ease of installation, and reliability in demanding environments. As demand surges, a select group of manufacturers have emerged as leaders, combining innovation, quality engineering, and global reach to dominate the space. Below are the top 10 manufacturers shaping the future of heavy-duty threaded stem casters.

Top 10 Heavy Duty Threaded Stem Casters Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Caster Threaded Stem Manufacturer and Supplier, Factory

Domain Est. 2022

Website: rizdacastor.com

Key Highlights: Our threaded stem casters are designed to provide smooth and seamless mobility for various industrial and commercial applications. Our threaded stem casters are ……

#2 DH Casters & Wheels

Domain Est. 2004

Website: dhcasters.com

Key Highlights: DH Caster’s is a manufacturer of threaded stem casters. We are an OEM Supplier and Wholesaler. Call us for a free quote!…

#3 Stem Casters

Domain Est. 1997

Website: globalindustrial.com

Key Highlights: 30-day returnsStem CastersStem casters make furniture or heavy equipment mobile and easy to maneuver. Available in threaded-neck, grip-neck, or grip ……

#4 Premium Casters and Wheels Supplier

Domain Est. 1999

Website: phcasters.com

Key Highlights: Explore a wide variety of reliable casters and wheels, including heavy duty swivel and rigid casters … Threaded Stem. Load Capacity. 0-120 LBS · 100-400 LBS ……

#5 Colson Caster Homepage

Domain Est. 1995

Website: colsoncaster.com

Key Highlights: Since 1885, Colson Caster’s quality lines of casters and wheels have defined the caster industry. Proudly made in the USA for over 130 years….

#6 Stainless Steel Casters, Swivel Brake & Replacement Wheels …

Domain Est. 1999

Website: allstatescasters.com

Key Highlights: Explore a wide selection of stainless steel casters, replacement caster wheels, cart and metal caster wheels, swivel brake casters, and medium-duty casters….

#7 Stem Mount Casters

Domain Est. 1999

Website: casterconnection.com

Key Highlights: 3–6 day delivery 30-day returnsBrowse our selection of light duty, stainless steel, electrostatic dissipative, swivel, rigid, non-marking, low-decibel, and ergonomic stem mount cas…

#8 Stem Casters

Domain Est. 2002

Website: castercity.com

Key Highlights: 1-day delivery 30-day returnsExplore Stem Casters at Caster City. Shop durable, high-quality casters and wheels for your needs with fast shipping. Order today!…

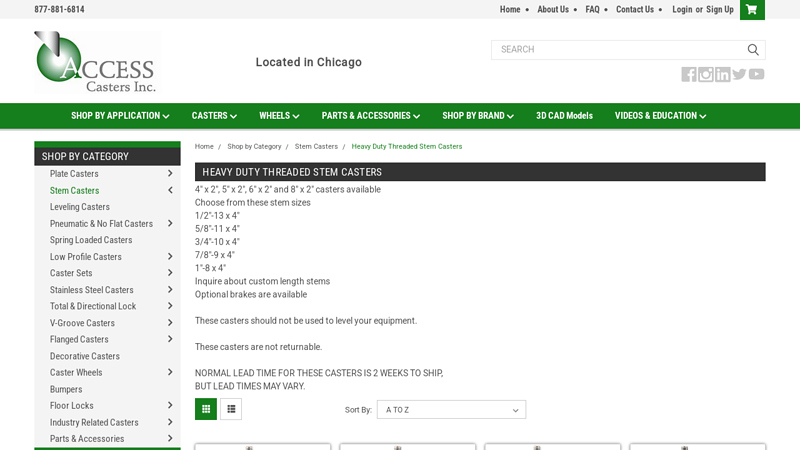

#9 Heavy Duty Threaded Stem Casters with 2″ wide wheels

Domain Est. 2003

Website: accesscasters.com

Key Highlights: 5–9 day delivery 30-day returnsHeavy duty threaded stem casters with capacities up to 900 pounds. Various stem sizes are available including 1/2″-13, 5/8″-11, 3/4″-10, 1″-8….

#10 CasterHQ

Domain Est. 2017

Website: casterhq.com

Key Highlights: We’re a trusted, family-owned company offering heavy-duty casters, premium oak dollies, hand trucks, and more for industrial and everyday needs….

Expert Sourcing Insights for Heavy Duty Threaded Stem Casters

H2: 2026 Market Trends for Heavy Duty Threaded Stem Casters

The global market for heavy-duty threaded stem casters is poised for steady growth and transformation by 2026, driven by industrial modernization, increased demand for material handling efficiency, and evolving manufacturing standards. These casters, known for their high load capacity and secure stem attachment, are essential in sectors such as manufacturing, warehousing, healthcare, and commercial equipment. Below are the key trends expected to shape the market landscape by 2026:

-

Increased Demand from E-Commerce and Logistics

The rapid expansion of e-commerce continues to fuel growth in warehouse automation and logistics infrastructure. Heavy-duty threaded stem casters are critical components in mobile racks, shelving units, and material transport carts. With supply chains prioritizing speed and durability, demand for robust, high-performance casters is rising—particularly those capable of supporting loads exceeding 1,000 lbs while maintaining smooth maneuverability. -

Shift Toward Ergonomic and Safety-Compliant Designs

Workplace safety regulations and ergonomic standards are becoming more stringent globally. By 2026, manufacturers are expected to focus on threaded stem casters with improved swivel locks, noise reduction features, and materials that minimize floor damage. Products compliant with ISO and OSHA standards will gain market preference, especially in Europe and North America. -

Material Innovation and Lightweight Durability

Advances in composite materials and high-strength alloys are allowing manufacturers to produce lighter yet stronger casters. Polyurethane tread wheels paired with forged steel or stainless steel stems offer corrosion resistance and extended service life—ideal for harsh environments like food processing, pharmaceuticals, and outdoor applications. This trend supports sustainability goals by reducing replacement frequency and waste. -

Growth in Automation-Integrated Applications

As industries adopt automated guided vehicles (AGVs) and collaborative robots (cobots), there is a growing need for casters that can support precise movement and integration with smart systems. While traditional threaded stem casters are less common in fully autonomous units, hybrid models with damping and alignment features are emerging for semi-automated industrial carts, creating new niche demand. -

Regional Market Expansion in Asia-Pacific

The Asia-Pacific region—particularly China, India, and Southeast Asia—is expected to be a key growth driver due to expanding manufacturing hubs and infrastructure development. Local production of industrial equipment is boosting demand for cost-effective, high-quality threaded stem casters, prompting global suppliers to establish regional manufacturing or distribution partnerships. -

Sustainability and Circular Economy Influence

Environmental concerns are prompting manufacturers to adopt eco-friendly production methods and recyclable materials. By 2026, leading brands may offer take-back programs or modular caster designs that allow for easy repair and component replacement, reducing the need for full-unit disposal. -

Customization and Specialized Applications

End-users are increasingly seeking customized caster solutions tailored to specific load, temperature, or environmental requirements. This includes high-temperature resistant models for foundries or anti-static variants for electronics manufacturing. Threaded stem casters with customizable thread sizes (e.g., 5/16”–18 UNC, ½”–13 UNC) will maintain relevance due to their ease of installation and interchangeability.

In summary, the 2026 market for heavy-duty threaded stem casters will be shaped by a convergence of industrial efficiency demands, safety standards, material innovation, and regional economic growth. While competition from alternative mounting types (e.g., plate or bolt hole) persists, the threaded stem design remains a preferred choice for applications requiring secure, tool-based attachment and high load integrity. Companies that invest in R&D, sustainability, and customer-specific solutions are likely to gain a competitive edge in this evolving market.

Common Pitfalls Sourcing Heavy Duty Threaded Stem Casters (Quality, IP)

Sourcing heavy-duty threaded stem casters requires careful consideration to avoid performance failures, safety hazards, and cost overruns. Overlooking key quality and IP (Ingress Protection) factors can lead to significant issues. Below are the most common pitfalls to watch for:

Inadequate Load Capacity Verification

One of the most frequent mistakes is selecting casters based on nominal or advertised load ratings without verifying real-world performance. Some suppliers inflate load capacities or fail to specify whether ratings are dynamic (in motion) or static (at rest). Always confirm the exact test standards used (e.g., ISO 22872) and ensure the combined load rating of all casters exceeds the total equipment weight by a safety margin (typically 20–30%).

Poor Material and Construction Quality

Low-cost casters may use inferior materials such as brittle zinc-plated stems, soft nylon wheels, or weak housings made from thin-gauge or recycled steel. These compromise durability, especially under shock loads or continuous use. Inspect for signs of poor welds, inconsistent machining, or lack of heat treatment on critical components like the swivel raceway and kingpin.

Misaligned IP Ratings for Operating Environment

Assuming all “industrial” casters are suitable for harsh environments is a critical error. Without a proper IP rating (e.g., IP55 or higher), casters can fail in wet, dusty, or washdown conditions. Moisture and debris ingress into the swivel mechanism or wheel bearings leads to corrosion, binding, and premature failure. Always match the IP rating to the specific environmental demands—such as food processing, outdoor use, or chemical exposure.

Incorrect Thread Specifications

Threaded stem casters come in various thread types (UNC, UNF, metric), sizes, and lengths. Using the wrong thread specification can result in improper installation, reduced clamping force, or stem breakage under load. Confirm the exact thread pitch, diameter, and engagement depth required by your equipment to ensure compatibility and mechanical integrity.

Overlooking Swivel Lead and Maneuverability

Heavy-duty doesn’t mean immovable—but poor swivel joint design can increase rolling resistance and operator fatigue. A short swivel lead (distance between the vertical swivel axis and the wheel center) can cause instability or scrubbing. Ensure the caster has an adequate swivel lead and precision ball or roller bearings to maintain smooth rotation under load.

Ignoring Regulatory and Industry Compliance

In regulated industries (e.g., healthcare, food & beverage, cleanrooms), non-compliant casters can lead to audit failures or safety violations. Verify that casters meet relevant standards such as FDA, USDA, or NSF for hygiene, and ensure materials are non-marking, non-sparking, or ESD-safe where required.

Relying Solely on Price as a Selection Criterion

Choosing the lowest-cost option often leads to higher total cost of ownership due to frequent replacements, downtime, and safety incidents. Invest in reputable suppliers with traceable quality control, certifications (e.g., ISO 9001), and product testing data to ensure long-term reliability and performance.

Avoiding these pitfalls ensures your heavy-duty threaded stem casters deliver safe, reliable, and long-lasting performance in demanding applications.

Logistics & Compliance Guide for Heavy Duty Threaded Stem Casters

Product Overview and Specifications

Heavy Duty Threaded Stem Casters are engineered for industrial applications requiring high load capacity, durability, and secure mounting. These casters feature threaded stems (typically 1/2″-13 UNC, 5/8″-11 UNC, or metric equivalents) designed to screw directly into pre-tapped holes in equipment frames or platforms. Common materials include forged steel, ductile iron, or reinforced nylon with thermoplastic or polyurethane wheels. Load ratings typically range from 800 lbs to over 2,000 lbs per caster, depending on size and construction.

Packaging Requirements

To ensure safe transport and prevent damage:

– Casters should be individually wrapped in protective plastic or foam sleeves.

– Group packaging in sturdy corrugated cardboard boxes with internal dividers to prevent movement.

– Use edge protectors and corner boards for palletized shipments.

– Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” as appropriate.

– Include desiccant packs in sealed packaging to prevent corrosion in humid environments.

Shipping and Handling Guidelines

- Use standard pallets (48″ x 40″) secured with stretch wrap or strapping for bulk shipments.

- Stack no more than 5 layers high unless specified otherwise by manufacturer load limits.

- Forklifts or pallet jacks must engage pallets fully to avoid tipping.

- Avoid exposure to moisture during transit; use enclosed trucks or containers.

- Clearly label each shipment with SKU, quantity, weight, and destination.

International Shipping and Documentation

For cross-border shipments:

– Provide commercial invoice, packing list, and bill of lading.

– Include product HS Code (typically 8716.80.00 for casters and wheels).

– Specify country of origin, material composition, and declared value.

– Comply with destination country’s import regulations (e.g., FDA, CE, or UKCA as applicable).

– For shipments to the EU, ensure compliance with REACH and RoHS directives regarding hazardous substances.

Regulatory Compliance

- RoHS (EU/UK): Ensure materials (especially plastics and coatings) are free from restricted substances (e.g., lead, cadmium, PBB, PBDE).

- REACH (EU): Confirm no SVHCs (Substances of Very High Concern) above threshold limits.

- Proposition 65 (California, USA): Provide warnings if components contain listed chemicals.

- OSHA/ANSI (USA): Comply with workplace safety standards for load-bearing equipment.

- TSCA (USA): Certify compliance with Toxic Substances Control Act for chemical content.

Certifications and Testing

- Provide load test certification (e.g., 1.5x or 2x rated load test reports).

- Include ISO 9001 certification for quality management (if applicable).

- Wheel material certifications (e.g., FDA-compliant polyurethane for food-grade environments).

- Anti-static or conductive certifications if used in ESD-sensitive areas (e.g., ANSI/ESD S20.20).

Storage Recommendations

- Store in a dry, temperature-controlled environment (40°F–90°F / 5°C–32°C).

- Keep away from direct sunlight, ozone sources, and corrosive chemicals.

- Elevate pallets off concrete floors to prevent moisture absorption.

- Rotate stock using FIFO (First In, First Out) to avoid material degradation.

Installation and User Compliance

- Ensure mounting threads match equipment specifications (size, pitch, depth).

- Apply thread locker (e.g., Loctite 242) to prevent loosening under vibration.

- Torque stem to manufacturer-recommended specifications during installation.

- Inspect regularly for wear, corrosion, or thread damage in compliance with OSHA or workplace safety programs.

Environmental and Disposal Considerations

- Follow local regulations for disposal of metal and plastic components.

- Recycle casters through approved metal and plastic recycling facilities.

- Do not incinerate polyurethane wheels—hazardous fumes may result.

- Comply with WEEE (EU) if integrated into electrical equipment.

Customer Support and Documentation

- Provide multilingual installation guides and compliance certificates.

- Maintain online access to technical drawings, load charts, and safety data sheets (SDS).

- Offer product traceability (batch/lot numbers) for quality and recall management.

Summary

Adhering to these logistics and compliance guidelines ensures safe handling, regulatory approval, and reliable performance of Heavy Duty Threaded Stem Casters across global markets. Always consult manufacturer specifications and local regulations to maintain full compliance.

In conclusion, sourcing heavy-duty threaded stem casters requires careful consideration of load capacity, material quality, wheel type, and environmental compatibility to ensure optimal performance and longevity. Selecting casters from reputable suppliers who adhere to industry standards helps guarantee durability and safety in demanding applications. Additionally, verifying exact specifications—such as stem size, thread type, and wheel composition—ensures a proper fit and reliable operation. By prioritizing strength, precision, and supplier reliability, businesses can enhance equipment mobility, improve operational efficiency, and reduce maintenance costs over time.