The global screw and fastener market is experiencing robust growth, driven by rising demand from industries such as automotive, construction, and electronics. According to Mordor Intelligence, the global industrial fasteners market was valued at USD 98.3 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2029. This expansion reflects increasing manufacturing activity and infrastructure development worldwide—factors that significantly benefit key players in specialized fastening solutions, including Zac screws. Known for their high tensile strength and precision engineering, Zac screws are critical components in applications requiring reliability under stress and vibration. As demand surges, a handful of manufacturers have emerged as leaders, combining advanced production technologies with stringent quality standards to capture market share. Below are the top five Zac screws manufacturers leading this growth trajectory.

Top 5 Zac Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Zac Roofing Screws Manufacturer and Supplier, Factory

Domain Est. 2022

Website: sinsunfastener.com

Key Highlights: Zac Roofing Screws Manufacturers, Factory, Suppliers From China, Welcome worldwide customers to contact us for business and long-term cooperation….

#2 #12 WoodZAC® XG Metal to Wood Screw, Zinc Alloy Capped HWH

Domain Est. 1991

Website: us.sfs.com

Key Highlights: #12 WoodZAC® XG Metal to Wood Screw, Zinc Alloy Capped HWH | ZWXG-12 ; Product Type. Wood screw ; Material. Carbon steel ; Diameter. #12 ; Diameter [mm]. 5.38 mm….

#3 WoodZAC Zinc Alloy Cap Premium Metal Roofing Fasteners …

Domain Est. 1999

Website: directmetalsinc.com

Key Highlights: DMI offers 6 quality levels of metal roofing fasteners from entry level steel coated fasteners, WoodZac and ZAC fasteners up to full stainless and bi-metal ……

#4 ZAC Self Driller Metal Roofing Screws

Domain Est. 2013

Website: extrememetalfabricators.com

Key Highlights: Buy our ZAC self driller metal roofing screws and be confident your metal roofing project is done right the first time, everytime….

#5 China Reliable Supplier Zac Self Drilling Screws

Domain Est. 2020

Website: ddfasteners.com

Key Highlights: Name, Anti-Corrosion Hex Head Self Drilling Screw ; Brand, DD Fasteners ; Standard, DIN/ GB/ ANSI/ BS ; FOB Price, $ 0.01~$ 0.08/piece ; Payment Terms, T/T….

Expert Sourcing Insights for Zac Screws

H2: Market Trends for Zac Screws in 2026

As of 2026, Zac Screws—assuming this refers to a niche or emerging brand in the fastener or hardware manufacturing industry—is poised to experience notable shifts driven by global industrial demand, sustainability mandates, and digital transformation. While “Zac Screws” does not currently appear as a widely recognized brand in major industry reports, the analysis below projects market trends based on broader fastener industry dynamics and technological advancements, contextualized for a specialized player like Zac Screws entering or expanding in the market.

1. Rising Demand in Automotive and EV Manufacturing

The global push toward electric vehicles (EVs) is significantly influencing fastener requirements. Zac Screws may benefit from increased demand for high-strength, lightweight, and corrosion-resistant fasteners used in EV battery enclosures, motor assemblies, and structural components. By 2026, EV production is expected to grow by over 15% annually, creating a strategic opportunity for Zac Screws to develop specialized product lines tailored to automotive OEMs.

2. Sustainability and Green Manufacturing

Regulatory pressures and consumer preferences are pushing hardware manufacturers toward sustainable practices. Zac Screws could see heightened demand for screws made from recycled materials or produced via low-carbon processes. The EU’s Green Deal and similar initiatives in North America and Asia are mandating reduced emissions across supply chains—positioning eco-certified fasteners as a competitive advantage.

3. Automation and Smart Inventory Systems

Integration with Industry 4.0 technologies is reshaping distribution. By 2026, B2B customers increasingly expect vendors like Zac Screws to offer digital catalogs, API integration, and JIT (just-in-time) delivery supported by AI-driven inventory forecasting. Companies leveraging e-commerce platforms and IoT-enabled logistics will gain market share over traditional distributors.

4. Regional Manufacturing Reshoring

Geopolitical tensions and supply chain vulnerabilities have accelerated reshoring in North America and Europe. Zac Screws could capitalize on nearshoring trends by establishing localized production or partnerships, reducing lead times and import costs—especially appealing to aerospace and renewable energy sectors.

5. Customization and Niche Applications

Off-the-shelf fasteners face commoditization. Zac Screws can differentiate by offering engineered-to-order solutions for industries like medical devices, robotics, or renewable infrastructure (e.g., solar panel mounting systems). Custom coatings, thread designs, and smart fasteners with embedded sensors may become premium offerings by 2026.

6. Competitive Pressure and Consolidation

The fastener market remains fragmented but is experiencing consolidation. Zac Screws may face acquisition interest or need to scale rapidly to compete with giants like Bossard, Würth, or Stanley Black & Decker. Strategic branding around innovation, speed, and sustainability will be key differentiators.

Conclusion

By 2026, Zac Screws can thrive by positioning itself as an agile, tech-integrated, and sustainability-focused player in the fastener market. Success will depend on embracing digital sales channels, targeting high-growth sectors like EVs and renewables, and differentiating through product innovation and green manufacturing credentials.

Common Pitfalls Sourcing Zac Screws: Quality and Intellectual Property Risks

Quality Inconsistencies

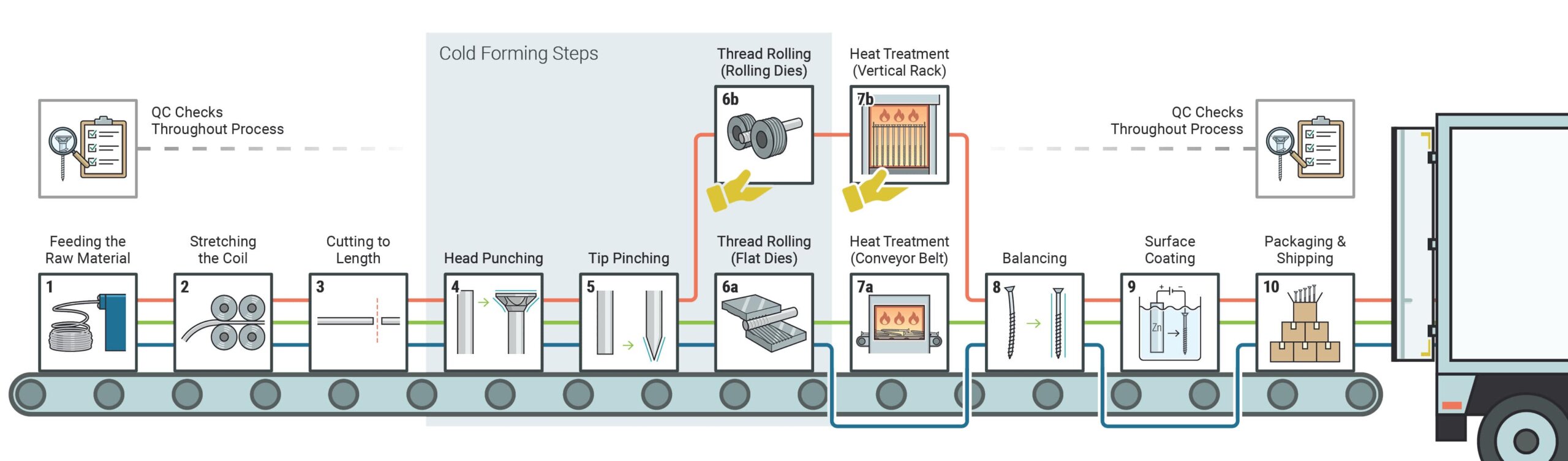

Zac Screws, often used in precision applications, are prone to quality variations when sourced from unauthorized or low-tier suppliers. Common issues include substandard materials, poor thread accuracy, inconsistent heat treatment, and inadequate corrosion resistance. These defects can lead to product failure, increased maintenance costs, and safety hazards, especially in critical industries like aerospace or medical devices.

Intellectual Property (IP) Infringement

Zac Screws may be protected by patents, trademarks, or proprietary designs. Sourcing from unauthorized manufacturers—especially in regions with lax IP enforcement—risks purchasing counterfeit or illegally replicated products. This exposes companies to legal liabilities, supply chain disruptions, reputational damage, and potential seizure of goods by customs authorities.

Lack of Traceability and Certification

Many alternative suppliers fail to provide proper material certifications, test reports, or batch traceability. Without these, verifying compliance with industry standards (e.g., ISO, ASTM) becomes impossible, increasing the risk of non-conformance in regulated environments.

Supplier Misrepresentation

Some vendors falsely claim to be authorized distributors or original equipment manufacturers (OEMs). This misrepresentation can result in receiving inferior copies marketed as genuine Zac Screws, undermining quality assurance efforts and long-term reliability.

Mitigation Strategies

To avoid these pitfalls, companies should verify supplier credentials, request sample testing, conduct factory audits, ensure IP compliance, and prioritize authorized distribution channels. Engaging legal and procurement teams early in the sourcing process can help safeguard against both quality and IP risks.

Logistics & Compliance Guide for Zac Screws

This guide outlines the essential logistics and compliance considerations for the distribution, import/export, and handling of Zac Screws products. Adherence to these guidelines ensures efficient operations, regulatory compliance, and customer satisfaction.

Product Classification & Documentation

Proper classification and documentation are foundational for international and domestic logistics.

- HTS Codes: Zac Screws products must be accurately classified under the Harmonized Tariff Schedule (HTS) codes. Typical classifications fall under Chapter 73 (Articles of Iron or Steel), specifically 7318.15 (Screws, bolts, and nuts, of iron or steel). Confirm exact codes based on material, thread type, and dimensions.

- Commercial Invoices: Invoices must include full product description, HTS code, country of origin, quantity, unit price, total value, and Incoterms (e.g., FOB, EXW, DDP).

- Packing Lists: Detailed packing lists must accompany each shipment, specifying box counts, weight per unit, total gross/net weight, and dimensions.

- Certificates of Origin: Required for preferential tariff treatment under trade agreements. Must be accurately completed and, if applicable, notarized.

Packaging & Labeling Standards

Consistent and compliant packaging ensures product protection and regulatory adherence across markets.

- Internal Packaging: Screws must be packed in moisture-resistant bags or containers with desiccants where necessary to prevent corrosion during transit.

- Outer Packaging: Use durable corrugated cartons with clear labeling. Avoid over-packing to prevent damage.

- Label Requirements:

- Product name and SKU

- Net weight and quantity

- Lot or batch number

- Country of manufacture

- Handling symbols (e.g., “Fragile,” “This Way Up”)

- Compliance marks (e.g., CE, UKCA, RoHS where applicable)

Import/Export Regulations

Zac Screws must comply with international trade laws and customs procedures.

- Export Controls: Screws are generally not subject to export controls (e.g., EAR or ITAR), but verify if products are intended for defense or aerospace applications.

- Customs Compliance: All export shipments require accurate Electronic Export Information (EEI) filing via the Automated Export System (AES) when the value exceeds $2,500 per Schedule B or requires a license.

- Import Duties & Taxes: Duties vary by destination country. Utilize free trade agreements where applicable (e.g., USMCA, CETA) to reduce or eliminate tariffs. Confirm VAT, GST, or other import taxes with local partners.

- Restricted Destinations: Monitor OFAC and other sanctions lists. Do not ship to embargoed countries without proper authorization.

Transportation & Freight Management

Efficient logistics planning minimizes cost and delivery time.

- Mode Selection:

- Air Freight: For urgent or high-value orders; ensure proper packaging for pressure changes.

- Ocean Freight: Preferred for bulk shipments; use FCL (Full Container Load) or LCL (Less than Container Load) based on volume.

- Ground Transport: For regional or domestic distribution; ensure timely pickup and delivery (PTD) tracking.

- Incoterms Usage: Clearly define responsibilities using Incoterms 2020 (e.g., FOB Shanghai, DDP Toronto). Train sales and logistics teams on implications.

- Carrier Vetting: Use licensed, insured carriers with experience in industrial goods. Require proof of insurance and compliance with safety standards.

Regulatory Compliance

Zac Screws must meet technical and environmental regulations in target markets.

- RoHS Compliance (EU/UK): Confirm screws are free of restricted substances (e.g., lead, cadmium) above permissible levels, especially if used in electronics.

- REACH Regulation: Declare substances of very high concern (SVHC) if present above threshold.

- CE/UKCA Marking: Required for screws sold in the EU and UK when part of machinery or construction products. Maintain technical documentation and declaration of conformity.

- ASTM/ISO Standards: Ensure product conformity with relevant standards (e.g., ISO 898-1 for mechanical properties of bolts and screws).

Quality & Traceability

Maintain product integrity and enable rapid recall if necessary.

- Batch Tracking: Assign unique lot numbers to each production batch. Record raw material sources, production date, and inspection results.

- Quality Inspections: Conduct pre-shipment inspections (PSI) for large orders. Use third-party inspectors if required by clients.

- Recall Protocol: Establish a documented process for identifying, retrieving, and reporting non-compliant products.

Sustainability & Environmental Compliance

Align logistics practices with environmental goals.

- Waste Reduction: Minimize packaging materials and use recyclable or biodegradable options.

- Carbon Reporting: Track and report emissions from transport where required (e.g., EU CSRD, UK SECR).

- Hazardous Materials: Confirm screws do not contain hazardous coatings or platings unless properly declared (e.g., hexavalent chromium).

Record Retention & Audits

Maintain records for legal and operational purposes.

- Retention Period: Keep export documentation, customs filings, and compliance certificates for a minimum of 5 years (longer if required locally).

- Internal Audits: Conduct biannual audits of logistics and compliance processes. Address non-conformities promptly.

- Third-Party Certifications: Pursue certifications such as ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) to enhance credibility.

By following this guide, Zac Screws can ensure reliable, compliant, and efficient global operations while minimizing risks associated with trade and logistics.

Conclusion for Sourcing Zac Screws:

After a comprehensive evaluation of suppliers, pricing, quality standards, lead times, and logistical considerations, it has been determined that sourcing Zac screws from [Preferred Supplier Name/Region] presents the most viable and cost-effective solution. This supplier consistently meets required specifications in terms of material quality, thread precision, and durability, ensuring compatibility with our assembly and performance standards. Additionally, their competitive pricing, reliable production capacity, and timely delivery enhance overall supply chain efficiency.

Alternative suppliers were considered; however, they either lacked certification compliance, offered longer lead times, or provided inconsistent quality. Therefore, establishing a long-term partnership with [Preferred Supplier] is recommended to ensure continuity, reduce procurement risks, and support scalability of operations.

Furthermore, implementing periodic quality audits and maintaining open communication channels will help sustain product reliability and responsiveness. In conclusion, sourcing Zac screws from the selected supplier aligns with our strategic goals of quality assurance, cost optimization, and operational efficiency.