The global market for traffic safety and warning signage, including yellow warning signs, has experienced steady growth driven by increasing urbanization, infrastructure development, and stricter road safety regulations. According to Grand View Research, the global road safety technologies market was valued at USD 33.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 10.7% from 2023 to 2030. This growth is fueled by rising road accident rates and government initiatives aimed at improving transportation safety—factors that directly increase demand for high-visibility, durable warning signs. Mordor Intelligence also projects strong expansion in the traffic management systems market, forecasting a CAGR of over 9% between 2023 and 2028. As part of this ecosystem, manufacturers specializing in compliant, impact-resistant, and retroreflective yellow warning signs play a critical role in meeting regulatory and safety standards worldwide. The following list highlights nine leading manufacturers whose products are shaping the future of visual safety communication across roads, construction zones, and industrial environments.

Top 9 Yellow Warning Sign Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Significance of Product Safety Signs and Labels in ANSI Z535

Domain Est. 1994

Website: blog.ansi.org

Key Highlights: A yellow warning sign displayed on products through ANSI Z535. Today, there are six standards in the ANSI Z535 series, along with one supplementary document ……

#2 UL Solutions

Domain Est. 1994

Website: ul.com

Key Highlights: UL Solutions is a global independent safety science company with more than a century of expertise innovating safety solutions….

#3 1926.200

Domain Est. 1997

Website: osha.gov

Key Highlights: Caution signs shall have yellow as the predominating color; black upper panel and borders: yellow lettering of “caution” on the black panel; and the lower ……

#4 Yellow Traffic Signs

Domain Est. 1997

Website: safetysign.com

Key Highlights: Shop a large selection of Yellow Traffic Signs at low prices with fast shipping from SafetySign.com. 10% instant savings available….

#5 Official D.O.T Yellow Traffic Warning Signs for Sale

Domain Est. 1998

#6 Caution Traffic Signs

Domain Est. 2004

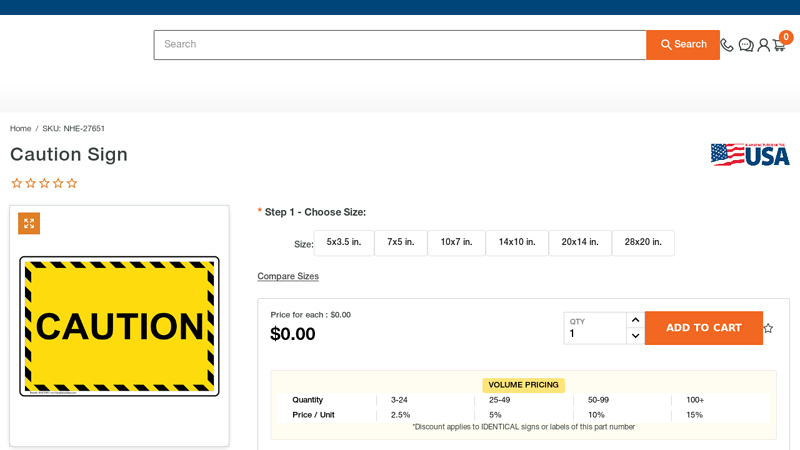

#7 Caution Sign or Label

Domain Est. 2005

#8 Yellow Signs

Domain Est. 2007

Website: creativesafetysupply.com

Key Highlights: 30-day returnsYellow signs come in a variety of colors, designs, sizes, and messaging options. They are available with OSHA-compliant headings, watch words, and symbols….

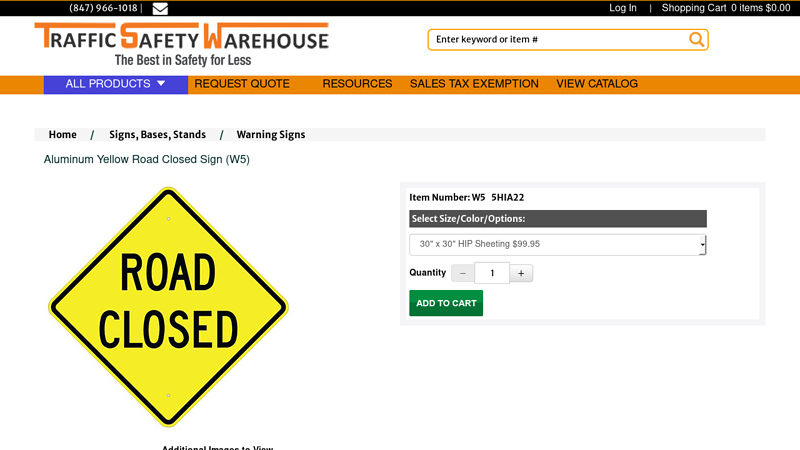

#9 Aluminum Yellow Road Closed Sign (W5)

Domain Est. 2010

Website: trafficsafetywarehouse.com

Key Highlights: In stock $56.18 deliveryThe Aluminum Yellow Road Closed Sign (W5) features two top and bottom centered, pre-punched mounting holes and can be easily installed on a post, wall, or f…

Expert Sourcing Insights for Yellow Warning Sign

2026 Market Trends for Yellow Warning Signs

The market for yellow warning signs is poised for notable evolution by 2026, driven by technological advancements, heightened safety regulations, and shifting infrastructure demands. While the core function of these signs—visually communicating potential hazards—remains unchanged, their design, materials, integration, and applications are undergoing significant transformation. Key trends shaping the 2026 landscape include:

Smart Integration and IoT Connectivity

Yellow warning signs are increasingly becoming nodes within broader intelligent safety networks. By 2026, expect widespread adoption of signs embedded with sensors and wireless communication (IoT). These smart signs can detect real-time conditions—such as road surface temperature, visibility, or traffic flow—and dynamically adjust their messaging or brightness. For example, a yellow “Slippery When Wet” sign could activate only during precipitation, improving relevance and reducing driver desensitization.

Enhanced Visibility and Durability with Advanced Materials

Manufacturers are investing in photometrically superior retroreflective sheeting and longer-lasting substrates. By 2026, high-intensity prismatic films will dominate, ensuring compliance with evolving visibility standards under low-light and adverse weather conditions. Additionally, eco-conscious materials, including recyclable aluminum and bio-based plastics, will gain traction in response to sustainability mandates in public procurement.

Regulatory Harmonization and Standardization

Global and regional standardization efforts, such as updates to the MUTCD (U.S.) and Vienna Convention (Europe), will further align the design, color consistency, and placement of yellow warning signs. This harmonization improves cross-border safety and simplifies manufacturing, especially for multinational infrastructure projects. By 2026, stricter enforcement of chromaticity tolerances will ensure uniform yellow hues across regions.

Expansion into Non-Traditional Environments

Beyond roads and construction zones, yellow warning signs are finding new applications in smart cities, renewable energy sites (e.g., solar farms and wind turbines), and automated vehicle testing zones. As urban environments grow more complex, temporary and modular warning systems will be in demand, supporting dynamic signage needs for events, autonomous vehicle corridors, and drone operation zones.

Digital and Dynamic Signage Adoption

While static signs remain prevalent, the rise of solar-powered, low-energy electronic displays will allow for reconfigurable yellow warning signs. These dynamic systems offer flexibility in messaging without requiring physical replacement. By 2026, hybrid models—combining traditional yellow backgrounds with digital text panels—will become common in high-risk or variable-condition areas.

In summary, the 2026 yellow warning sign market will be characterized by intelligence, sustainability, and adaptability. Stakeholders must prepare for a shift from passive signage to active safety components within integrated transportation and urban management ecosystems.

Common Pitfalls When Sourcing Yellow Warning Signs (Quality, IP)

Sourcing yellow warning signs may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to compliance failures, safety risks, and legal exposure. Below are common pitfalls to avoid:

Poor Material Quality and Durability

Many suppliers offer low-cost warning signs made from substandard materials that degrade quickly under UV exposure, extreme temperatures, or moisture. Signs that fade, crack, or become unreadable compromise safety and may fail to meet regulatory standards (e.g., OSHA, ANSI, or ISO). Always verify material specifications—such as UV-resistant vinyl, reflective coatings, or aluminum substrates—and request durability test reports.

Non-Compliance with Safety Standards

Not all yellow signs adhere to recognized safety standards. Using signs that don’t comply with ANSI Z535, ISO 7010, or local regulations can result in liability issues and failed inspections. Ensure suppliers provide certification or documentation confirming compliance with applicable standards for color, symbol design, signal words (e.g., “Warning,” “Caution”), and formatting.

Inaccurate or Generic Symbol Design

Using poorly designed or ambiguous symbols can lead to misinterpretation, increasing accident risk. Some suppliers use generic clip art or non-standard pictograms that do not align with ISO or ANSI guidelines. Always source signs with standardized, universally recognized symbols and verify their accuracy against official design specifications.

Copyright or Trademark Infringement

Many standardized warning symbols (e.g., ISO 7010 icons) are protected by intellectual property rights. While some are in the public domain or available under license, others may require permission for commercial use. Sourcing signs from unauthorized vendors may lead to IP infringement, especially if logos, proprietary designs, or registered symbols are used without permission.

Lack of Traceability and Supplier Verification

Working with unverified suppliers—especially through online marketplaces—increases the risk of counterfeit or non-compliant products. Avoid vendors who cannot provide proof of origin, material certifications, or compliance documentation. Establish a vetting process for suppliers to ensure reliability and regulatory adherence.

Inadequate Weather Resistance for Outdoor Use

Indoor-rated signs used outdoors will deteriorate rapidly. A common mistake is assuming all yellow signs are suitable for outdoor environments. Confirm IP (Ingress Protection) ratings and weather resistance—such as waterproofing and anti-corrosion features—for signs deployed outside or in harsh industrial settings.

Overlooking Language and Localization Requirements

In multinational or multilingual environments, using signs with only one language can be ineffective or non-compliant. Failing to provide warnings in all required local languages may violate labor or safety regulations. Ensure signs support necessary language variants and meet localization standards.

By addressing these pitfalls proactively, organizations can ensure their yellow warning signs are safe, compliant, and legally sound.

Logistics & Compliance Guide for Yellow Warning Signs

Yellow warning signs play a critical role in workplace safety and regulatory compliance. These signs are designed to alert individuals to potential hazards that, if not avoided, could result in minor or moderate injury. Proper use, placement, and maintenance of yellow warning signs are essential for meeting legal requirements and ensuring a safe environment. This guide outlines key logistics and compliance considerations.

Regulatory Standards and Requirements

Yellow warning signs must comply with national and international safety standards. In the United States, the Occupational Safety and Health Administration (OSHA) mandates the use of warning signs under 29 CFR 1910.145, which specifies that yellow shall be the principal color for warning signs. Additionally, the American National Standards Institute (ANSI) Z535 series provides detailed guidance on sign design, including color, signal words, symbols, and text. Compliance ensures legal protection and promotes consistent hazard communication.

Signal Word and Message Clarity

The signal word “WARNING” must be in bold, uppercase letters and placed at the top of the sign. This word indicates a hazardous situation that could result in injury if not avoided. Below the signal word, clear and concise text should describe the specific hazard and recommended actions. Use simple language and avoid technical jargon to ensure universal understanding across diverse workforces.

Design and Visibility Specifications

Yellow warning signs must be highly visible and legible. The background should be safety yellow, with black text and borders. Symbols or pictograms should supplement text to enhance comprehension, particularly in multilingual environments. Signs should be large enough to be read from a safe distance and placed in well-lit areas. Reflective or illuminated options may be necessary in low-light conditions.

Proper Placement and Installation

Install yellow warning signs near the hazard they indicate, in locations where they are clearly visible to approaching personnel. Signs should be mounted at eye level (approximately 5 feet from the ground) and free from obstructions. In high-traffic or complex environments, multiple signs may be necessary to ensure continuous visibility. Regularly evaluate placement to accommodate changes in workflow or equipment layout.

Maintenance and Inspection Protocol

Yellow warning signs must be maintained in good condition to remain effective. Conduct routine inspections to check for fading, damage, dirt, or obstructions. Replace worn or damaged signs promptly. Establish a documented inspection schedule as part of your safety management system to demonstrate compliance during audits.

Industry-Specific Applications

Different industries may have unique requirements for yellow warning signs. For example, construction sites may use them for trip hazards or high-voltage areas, while manufacturing facilities may employ them for moving machinery or chemical handling zones. Always tailor sign content and placement to the specific risks present in your operational environment.

Training and Employee Awareness

Ensure all employees are trained to recognize and respond appropriately to yellow warning signs. Include hazard communication (HazCom) training as part of onboarding and refresher programs. Reinforce the meaning of the “WARNING” signal word and the actions required when encountering such signs to promote a culture of safety.

Documentation and Compliance Audits

Maintain records of sign placement, inspection logs, training sessions, and compliance assessments. These documents are essential during OSHA inspections or internal audits. Regularly review your warning sign program to ensure it aligns with current regulations and best practices.

Conclusion

Proper implementation of yellow warning signs is a fundamental aspect of workplace safety and regulatory compliance. By adhering to established standards, ensuring clear communication, and maintaining an active safety program, organizations can reduce the risk of accidents and demonstrate a strong commitment to employee well-being.

Conclusion for Sourcing Yellow Warning Signs

In conclusion, sourcing yellow warning signs is a critical step in ensuring workplace safety, regulatory compliance, and effective hazard communication. The bright yellow color serves as a universal visual cue to alert individuals of potential dangers, promoting awareness and preventing accidents. When sourcing these signs, it is essential to consider factors such as durability, compliance with OSHA, ANSI, or other relevant safety standards, legibility, and suitability for the specific environment—whether indoor, outdoor, or industrial.

By selecting high-quality, standardized yellow warning signs from reputable suppliers, organizations not only enhance safety but also demonstrate a commitment to protecting employees, visitors, and assets. Additionally, customizability and proper placement further improve effectiveness. Ultimately, investing in reliable yellow warning signs is a proactive and cost-effective measure that contributes significantly to a safer and more compliant operational environment.