The global woodworking pallets market is experiencing steady growth, driven by increasing demand from logistics, manufacturing, and retail sectors for durable, cost-effective, and reusable material handling solutions. According to a report by Mordor Intelligence, the wood pallet market was valued at USD 41.5 billion in 2023 and is projected to reach USD 51.3 billion by 2029, growing at a CAGR of 3.4% during the forecast period. This expansion is fueled by the continued preference for wooden pallets in heavy-duty transportation due to their strength, repairability, and compatibility with existing supply chain infrastructure. Additionally, sustainability initiatives and the rising adoption of recycled and certified wood materials are reshaping production standards across the industry. As demand evolves, a select group of manufacturers have emerged as leaders—combining scale, innovation, and efficiency to meet the growing needs of global commerce. These top nine woodworking pallet manufacturers represent the forefront of this resilient and adaptable sector.

Top 9 Woodworking Pallets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Conner Industries

Domain Est. 1998

Website: connerindustries.com

Key Highlights: Conner Industries provides industrial manufacturers with cost-effective protective packaging and service solutions that are tailored to fit your product….

#2 Girard Wood Products

Domain Est. 1998

Website: girardwoodproducts.com

Key Highlights: NEW PALLETS. Domestically Sourced Lumber, Built to last ; RECYCLED PALLETS. Sustainable, Efficient Cost-savings ; AS/RS PALLETS. High-performing. Ultra durable….

#3 UFP Industries

Domain Est. 1999

Website: ufpi.com

Key Highlights: UFP Industries supplies thousands of products that support the world’s physical infrastructure, advance major markets, and improve people’s lives….

#4 National Wooden Pallet and Container Association

Domain Est. 2000

Website: palletcentral.com

Key Highlights: The wooden pallet industry produces near zero waste. With nearly 2 billion pallets in use every day, we recover, repair, recycle at the highest rate compared ……

#5 Wholesale Pallets Ohio Supplier

Domain Est. 2000

Website: troymill.com

Key Highlights: Troymill is at the top among stock lumber and wholesale pallet companies. For the best lumber company near Cleveland Ohio, call today!…

#6 Pallet Management & Logistics

Domain Est. 2004

Website: tpai.com

Key Highlights: We manage all your pallet inventory & logistical needs. From sourcing, design & implementation we deliver a comprehensive solution tailored to fit your ……

#7 J&L Wood Products

Domain Est. 2005

Website: jlwoodproducts.com

Key Highlights: Custom manufactured pallets and crates from J&L Wood Products. Durable and reliable shipping solutions for your unique needs….

#8 Custom Forest Products

Domain Est. 2012

Website: customforestproducts.com

Key Highlights: The only local lean pallet company for your new and recycled pallet needs. Lean practices create better quality and shorter lead times….

#9 Wood Pallet Machine,Pallet Block Machine,Wood Pallet Making …

Domain Est. 2014

Website: palletmach.com

Key Highlights: PalletMach is a trustworthy name in manufacturing of wood pallet block machine. We can offer a perfect solution in pallet block production….

Expert Sourcing Insights for Woodworking Pallets

2026 Market Trends for Woodworking Pallets

The woodworking pallets market is poised for significant transformation by 2026, driven by sustainability mandates, technological advancements, and shifting supply chain dynamics. As industries seek durable, cost-effective, and eco-friendly material handling solutions, woodworking pallets are regaining prominence over plastic and metal alternatives in many sectors. Below are the key trends shaping the market outlook for 2026.

Sustainability and Circular Economy Driving Demand

Environmental regulations and corporate sustainability goals are accelerating the shift toward reusable and recyclable packaging. Woodworking pallets, primarily made from renewable softwood and hardwood, align well with circular economy principles. By 2026, demand will be bolstered by:

- Increased use of certified sustainable wood (e.g., FSC or PEFC) as compliance with ESG (Environmental, Social, and Governance) standards becomes mandatory in key markets like the EU and North America.

- Growth in pallet pooling and reconditioning services, reducing waste and extending product lifecycle. Companies like CHEP and LPR are expanding their networks, creating a stable secondary market.

- Carbon footprint reduction initiatives, where wood’s lower embodied energy compared to plastic alternatives makes it a preferred choice in carbon-conscious supply chains.

Technological Integration and Smart Pallets

While traditionally low-tech, woodworking pallets are being enhanced with digital capabilities to meet Industry 4.0 demands. By 2026:

- IoT-enabled smart pallets equipped with RFID tags or sensors will gain traction, allowing real-time tracking, temperature monitoring, and load management—especially in pharmaceuticals and perishable goods.

- Blockchain integration for supply chain transparency will increase trust in wood sourcing and pallet history, improving traceability from forest to end-user.

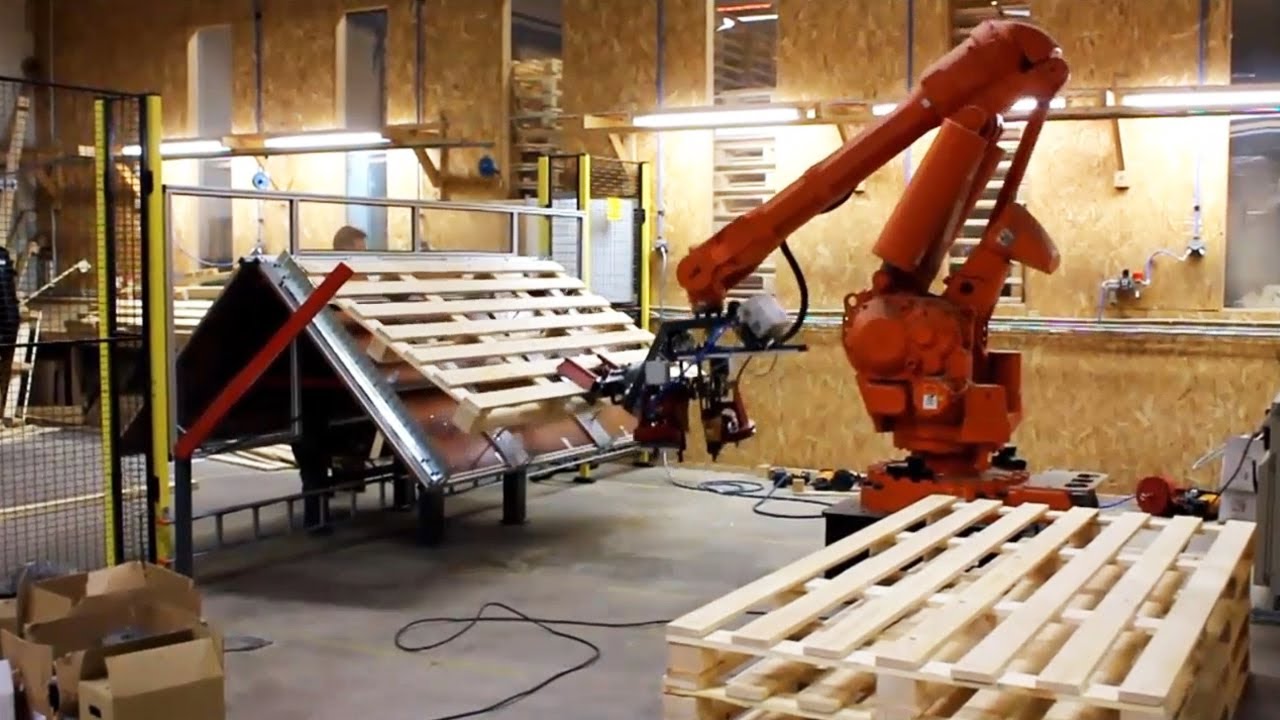

- Automation compatibility will drive design innovations, such as standardized dimensions and reinforced joints, to ensure seamless integration with automated warehouses and robotic handling systems.

Regional Shifts and Supply Chain Resilience

Geopolitical tensions and post-pandemic supply chain disruptions have prompted a reevaluation of logistics infrastructure. This is influencing woodworking pallet demand regionally:

- Nearshoring and regionalization in North America and Europe will boost local pallet manufacturing, reducing reliance on imported materials and increasing demand for domestically produced wooden pallets.

- Emerging markets in Asia-Pacific and Latin America will see rising industrialization and e-commerce growth, expanding the need for affordable, robust material handling solutions—favoring wood over pricier alternatives.

- Regulatory changes, such as ISPM 15 compliance for international shipments, will continue to shape production standards, with heat-treated wood pallets dominating export markets.

Material Innovation and Design Optimization

To compete with plastic and metal, the woodworking pallet industry is investing in performance improvements:

- Engineered wood products (e.g., laminated veneer lumber and plywood) will be increasingly used to enhance strength, durability, and moisture resistance without sacrificing recyclability.

- Lightweight yet strong designs will reduce shipping costs and improve handling efficiency, appealing to logistics and e-commerce sectors.

- Modular and collapsible pallets will gain popularity for returnable logistics, reducing transport volume during backhauls and improving space utilization.

Cost Pressures and Raw Material Volatility

Despite advantages, the market faces challenges:

- Fluctuations in lumber prices due to supply constraints, wildfires, or trade policies may impact profitability. By 2026, manufacturers will prioritize supply chain diversification and strategic inventory management.

- Labor costs and automation adoption in woodworking facilities will shape competitiveness, with advanced CNC machinery improving precision and reducing waste.

Conclusion

By 2026, the woodworking pallets market will be characterized by a strong emphasis on sustainability, digitization, and resilience. While challenges around raw materials and costs persist, innovation in design, technology, and circular business models will position wooden pallets as a strategic asset in global supply chains—particularly in industries prioritizing environmental performance and operational efficiency.

Common Pitfalls When Sourcing Woodworking Pallets (Quality and Intellectual Property)

Sourcing wooden pallets for woodworking projects—especially upcycling or repurposing—can be cost-effective and sustainable. However, several pitfalls related to quality and intellectual property (IP) can undermine your project’s success, safety, and legal compliance. Being aware of these issues helps ensure you make informed, responsible sourcing decisions.

Poor Wood Quality and Structural Integrity

One of the most frequent issues when sourcing used pallets is inconsistent or compromised wood quality. Many pallets have endured heavy use, exposure to the elements, or improper storage, leading to:

- Rot, mold, or insect damage: Compromises structural integrity and poses health risks.

- Excessive warping or splitting: Makes the wood difficult to work with and limits usable material.

- Nail damage and embedded metal: Increases risk of tool damage and injury during milling or sanding.

Always inspect pallets thoroughly before purchase or collection. Avoid those with visible decay, foul odors, or excessive moisture.

Unknown Chemical Treatments and Safety Hazards

Pallets may have been treated with chemicals to prevent pest infestation or prolong lifespan. The most concerning treatment is methyl bromide (MB), a toxic fumigant banned in many countries but still found on older or improperly labeled pallets.

- Look for the IPPC stamp: Legitimate pallets should bear an International Plant Protection Convention (IPPC) mark indicating treatment type.

- Avoid pallets marked “MB”: These were treated with methyl bromide and are unsafe for indoor or furniture use.

- Heat-treated (HT) pallets are safer: These are generally acceptable for woodworking, as they are kiln-dried rather than chemically fumigated.

Unknown treatments can release harmful off-gassing or contaminate finished projects, especially in living spaces.

Misinterpretation of the IPPC Stamp and Compliance

The IPPC stamp provides critical information about a pallet’s origin and treatment, but it’s often misunderstood or overlooked.

- Missing or altered stamps: Indicate non-compliance or potential theft, raising red flags about legality and safety.

- Fake or counterfeit stamps: Some pallets may have forged markings to appear compliant.

- Regional variations in standards: Regulations differ by country, so imported pallets may not meet local safety or environmental standards.

Always verify the stamp and understand its components (e.g., country code, producer number, treatment code) to assess suitability.

Intellectual Property and Branding Concerns

Repurposing pallets with visible branding, logos, or company markings can lead to unintended intellectual property (IP) issues.

- Logos and trademarks: Using wood that still displays a company’s brand could imply endorsement or lead to trademark infringement claims, especially in commercial products.

- Commercial resale risks: If you craft and sell items made from branded pallets, original companies may object to their logo being used without permission.

To avoid IP pitfalls:

– Sand or cut away visible branding.

– Avoid using wood with prominent logos in customer-facing products.

– When in doubt, seek legal advice or choose unbranded or generic pallets.

Sourcing from Restricted or Stolen Pallets

Many pallets are part of leasing or pooling systems (e.g., CHEP, PECO) and are not meant for resale or permanent removal.

- Trespassing or theft risks: Taking pallets from private property, warehouses, or shipping yards without permission is illegal.

- Traceability issues: Major pallet pools can track their assets; using stolen pallets may lead to legal action.

- Ethical sourcing: Ensure pallets are surplus, discarded, or legally available for reuse.

Always obtain pallets through legitimate channels—donations, recycling centers, or authorized resellers.

Inconsistent Dimensions and Joinery Challenges

Pallets are built for logistics, not woodworking precision. Sourcing them often means dealing with:

- Variations in wood thickness and size: Requires extra time for planing, jointing, and sorting.

- Mixed wood species: Different densities and grain patterns can affect finishing and joinery.

- Poorly constructed pallets: Loose boards, broken stringers, or uneven surfaces reduce usable yield.

Factor in additional labor and material loss when planning projects using reclaimed pallet wood.

Conclusion

While woodworking with reclaimed pallets offers sustainability and cost benefits, due diligence is essential. Prioritize HT-treated, unbranded pallets with clear IPPC stamps, avoid chemically treated wood, and ensure ethical and legal sourcing. Addressing these quality and IP pitfalls upfront leads to safer, higher-quality, and legally sound woodworking projects.

Logistics & Compliance Guide for Woodworking Pallets

Understanding Wood Pallet Types and Materials

Woodworking pallets are primarily constructed from softwoods like pine or hardwoods such as oak, depending on strength and durability requirements. Key types include stringer pallets, block pallets, and custom designs tailored for specific load needs. Selecting the appropriate material and design ensures structural integrity during transport and compliance with industry standards.

ISPM 15 Compliance for International Shipping

All wood packaging material (including pallets) used in international trade must comply with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This requires heat treatment (HT) or fumigation (MB) to prevent the spread of pests. Certified pallets must bear a clearly marked IPPC stamp indicating the treatment method, country of origin, producer code, and certification body.

Domestic Regulations and Best Practices

Within the U.S. and other regions, while ISPM 15 does not apply to domestic shipments, best practices include using kiln-dried lumber to minimize moisture and prevent mold. Many industries follow voluntary standards set by the National Wooden Pallet and Container Association (NWPCA) to ensure quality, load capacity, and safety.

Load Capacity and Structural Integrity

Pallets must be rated for the intended load—static (storage), dynamic (handling), and racking (shelf) capacities. Exceeding these limits can lead to breakage, product damage, or workplace injuries. Regular inspection for cracks, loose boards, or protruding nails is essential for maintaining compliance and safety.

Repair and Reuse Guidelines

Repairing used pallets is common but must follow standardized procedures. Repaired pallets should retain their original load rating only if repairs meet NWPCA or equivalent standards. Components like broken stringers or damaged deck boards must be replaced using compatible materials, and repaired pallets should be re-inspected before reuse.

Chemical and Treatment Restrictions

Avoid the use of chemically treated wood (e.g., arsenic-based preservatives like CCA) for pallets, especially those used in food, pharmaceutical, or consumer goods supply chains. Heat-treated (HT) wood is preferred over methyl bromide (MB) fumigation due to environmental and health concerns, even where MB is still permitted.

Documentation and Traceability

Maintain records of pallet sourcing, treatment certification (e.g., ISPM 15 stamps), and repair logs. Traceability supports compliance audits and facilitates recalls if contaminated or non-compliant materials are identified in the supply chain.

Environmental and Sustainability Considerations

Opt for sustainably sourced wood certified by organizations like the FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative). Recycling and reconditioning programs reduce waste and support circular economy practices in the woodworking and logistics sectors.

Carrier and Warehouse Requirements

Different carriers and distribution centers have specific pallet specifications (e.g., GMA 48×40 pallets in the U.S.). Ensure pallets meet dimensional, weight, and cleanliness standards to avoid rejection. Non-compliant or damaged pallets may result in additional handling fees or shipment delays.

Incident Reporting and Non-Compliance Remediation

Establish protocols for reporting pallet failures, pest infestations, or compliance issues. Promptly remove non-compliant pallets from circulation, investigate root causes, and update procurement or handling practices to prevent recurrence.

In conclusion, sourcing woodworking pallets can be a cost-effective and sustainable solution for various projects, from furniture making to garden landscaping. By exploring diverse sources such as local businesses, recycling centers, online marketplaces, and pallet suppliers, woodworkers can access a steady supply of reusable materials. However, it is essential to prioritize safety by selecting heat-treated (HT) pallets over chemically treated (MB) ones, inspecting for structural integrity, and properly cleaning and preparing the wood before use. With responsible sourcing practices and a focus on quality, woodworkers can transform discarded pallets into valuable, eco-friendly creations while minimizing environmental impact and reducing material costs.