The global wooden slat panel market is experiencing robust growth, driven by rising demand for sustainable interior design solutions and architectural aesthetics in both residential and commercial spaces. According to Mordor Intelligence, the global acoustic panels market—of which wooden slat panels are a key segment—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. Complementing this, Grand View Research valued the global interior wood products market at USD 117.4 billion in 2022 and forecasts a CAGR of 5.3% from 2023 to 2030, underpinned by increasing consumer preference for natural materials and energy-efficient building designs. As sustainability and biophilic design gain traction, wooden slat panels have emerged as a sought-after solution for their acoustic performance, thermal insulation, and visual appeal. With expanding applications in offices, hospitality venues, and modern homes, manufacturers are innovating to meet quality, customization, and eco-certification demands. In this competitive landscape, identifying leading wooden slat panel manufacturers—those combining craftsmanship, scalability, and technical expertise—is essential for architects, designers, and procurement professionals aiming to align performance with aesthetic vision.

Top 10 Wooden Slat Panel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oak Acoustic Wood Slat

Domain Est. 2003

Website: feltright.com

Key Highlights: Designed as an elegant sound dampening solution. Absorbs 55% of the sound waves they come in contact with. Reduces excess noise and eliminates echo….

#2 TerraMai

Domain Est. 2003

Website: terramai.com

Key Highlights: Custom sustainable wood millwork, expertly crafted for unique design applications. Slat panels made of. SPECIALTY MILLWORK. Handcrafted sustainable wood ……

#3 Acoustic Wood Slat Panels

Domain Est. 2012

Website: msisurfaces.com

Key Highlights: Acoustic Wood Slat Panels offer a serene and cozy ambiance in various shades, ranging from warm beige to rich browns, without the need for staining or sanding….

#4 Wooden slat wall, wall panels & acoustic panels » WoodUpp

Domain Est. 2015

Website: woodupp.com

Key Highlights: WoodUpp is innovative do-it-yourself wood wall panels, wooden slatwall & acoustic panels, developed so you can mount a wooden wall easily….

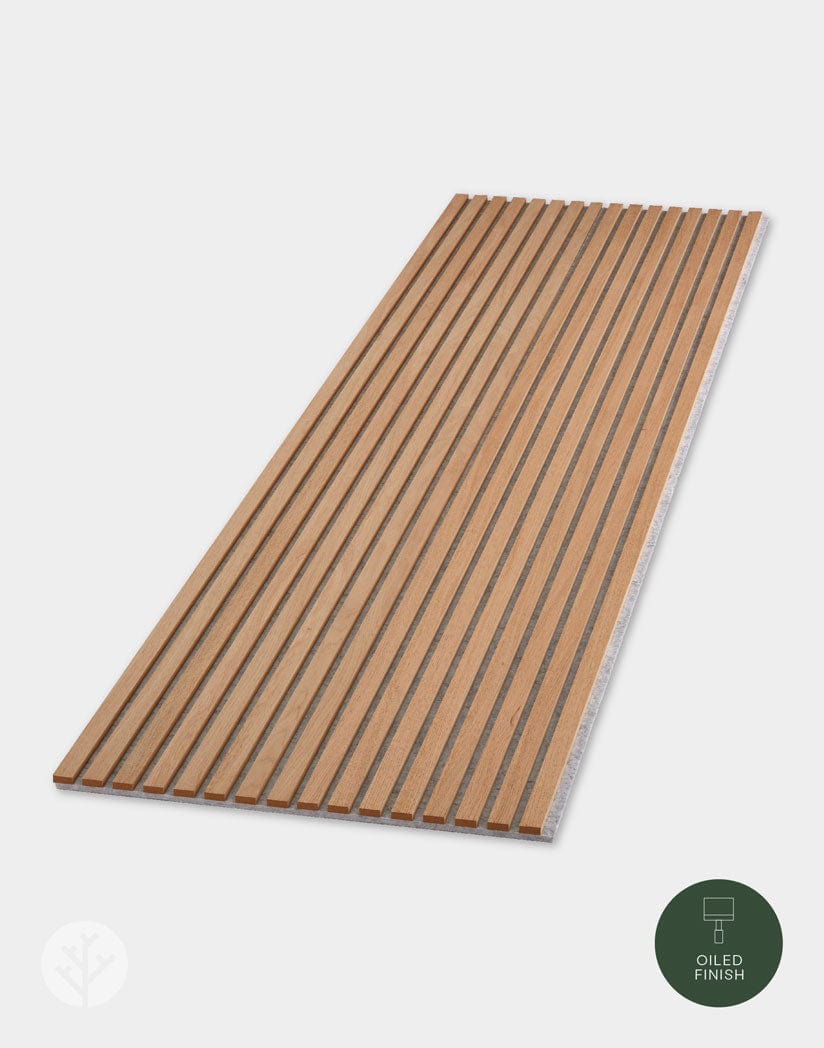

#5 Slat Wall Panels

Domain Est. 2021

#6 Acoustic Slat Wall Panel

Domain Est. 2022

Website: akuwoodpanel.com

Key Highlights: In stock Rating 4.9 (216) Featuring premium quality 3-sided wood veneer for better performance and aesthetic appeal. Made from eco-friendly materials and recycled felt….

#7 Slatta: Acoustic Wood Slat Panels

Domain Est. 2022

Website: materiallogiq.com

Key Highlights: Pre-engineered wood slat system available for quick delivery · Available in a variety of wood species and backer colors · Class A fire-rated for peace of mind ……

#8 Wooden Slat Wall, Wood Veneer & Acoustic Panels

Domain Est. 2023

Website: woodsonpanels.com

Key Highlights: Free delivery over $450 30-day returns…

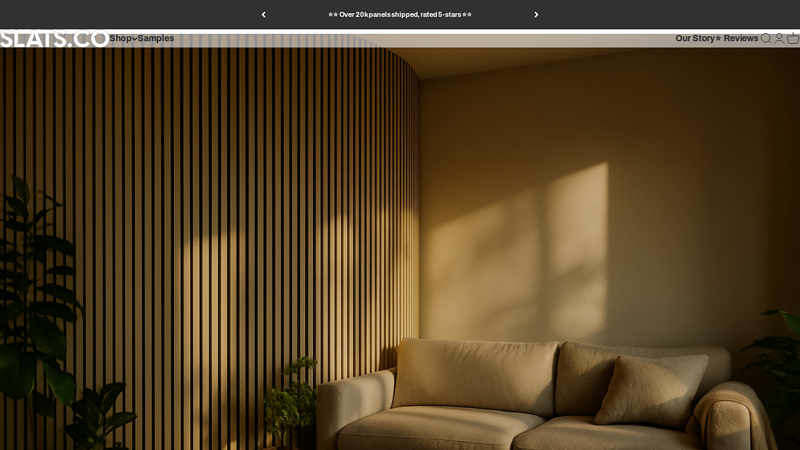

#9 Wood Slat Wall Panels for Modern Slatted Accent Walls & Interiors

Domain Est. 2023

Website: slats.co

Key Highlights: Transform your space with our handcrafted wood slat wall paneling. Our expertly crafted soundproof wood panels are made from sustainable natural white oak and ……

#10 slatsolution.com

Domain Est. 2023

Website: slatsolution.com

Key Highlights: Classic Slat Wood Panels. Our classic slat wood panels are constructed from solid wood, have a heavy-duty veneer wood finish, and seamless tongue and groove ……

Expert Sourcing Insights for Wooden Slat Panel

H2: 2026 Market Trends for Wooden Slat Panel

The wooden slat panel market is poised for significant evolution by 2026, driven by shifting consumer preferences, advances in sustainable design, and growing demand in both residential and commercial interiors. As architectural trends continue to favor natural materials and biophilic design, wooden slat panels are emerging as a go-to solution for aesthetic enhancement and functional acoustic performance.

One of the dominant trends shaping the 2026 market is the rising emphasis on sustainability. Consumers and businesses alike are prioritizing eco-friendly building materials, prompting manufacturers to source wood from certified forests, adopt low-VOC finishes, and incorporate recycled or reclaimed wood into slat panel production. This shift aligns with global green building standards such as LEED and WELL Certification, further boosting adoption in high-end commercial and hospitality projects.

Technological advancements are also transforming the wooden slat panel sector. By 2026, expect wider availability of pre-finished, modular slat systems that reduce installation time and labor costs. Integration with smart building systems—such as panels designed to conceal lighting, sensors, or HVAC components—will enhance functionality without compromising aesthetics.

Geographically, the Asia-Pacific region is anticipated to experience the fastest growth due to rapid urbanization, expanding middle-class populations, and a surge in premium retail and hospitality developments. North America and Europe will maintain strong demand, particularly in residential renovations and home office spaces influenced by the lasting hybrid work trend.

Design trends will continue to favor warm, organic textures, with oak, walnut, and teak remaining popular wood choices. However, engineered wood and wood-look composites are gaining traction as cost-effective, durable alternatives that mimic the appearance of solid wood while offering greater resistance to moisture and warping—making them ideal for use in kitchens, bathrooms, and high-traffic areas.

Finally, customization will be a key differentiator in the 2026 market. Consumers are increasingly seeking personalized interiors, leading to growth in made-to-order slat configurations, varied spacing, 3D patterns, and mixed-material installations (e.g., wood combined with metal or fabric).

In conclusion, the wooden slat panel market in 2026 will be defined by sustainability, innovation, and design flexibility, positioning it as a strategic element in modern interior architecture across global markets.

Common Pitfalls When Sourcing Wooden Slat Panels (Quality and Intellectual Property)

Sourcing wooden slat panels for architectural, interior design, or construction projects requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to project delays, cost overruns, legal disputes, and compromised aesthetics. Below are key pitfalls to avoid.

Poor Material Quality and Inconsistent Finishes

One of the most frequent issues in sourcing wooden slat panels is receiving products that fail to meet specified quality standards. This includes variations in wood grain, color inconsistencies, warping, splintering, or poor surface finishing. Low-quality panels may also use inferior adhesives or substrates, leading to delamination or structural failure over time. Sourcing from manufacturers without stringent quality control processes increases the risk of receiving substandard batches, especially when ordering large quantities.

Use of Non-Sustainable or Unverified Wood Sources

Many wooden slat panels are marketed as eco-friendly or sustainable, but without proper certifications (such as FSC or PEFC), the wood may originate from illegal or environmentally damaging sources. Buyers risk reputational damage and non-compliance with green building standards (e.g., LEED, BREEAM) if they fail to verify the chain of custody and sustainability claims of the wood used.

Lack of Fire, Moisture, and Durability Testing

Wooden slat panels intended for commercial or high-traffic environments must meet specific performance standards for fire resistance, humidity tolerance, and durability. Sourcing panels without certified test reports (e.g., ASTM, EN standards) can result in safety hazards or premature degradation—especially in areas with high moisture or fluctuating temperatures. Assuming all wood panels are suitable for interior use without verifying technical specifications is a common oversight.

Inadequate Attention to Intellectual Property Rights

Designers and architects often specify unique or custom wooden slat panel patterns that are protected by intellectual property rights. A major pitfall occurs when suppliers replicate patented or copyrighted designs without authorization. Buyers who unknowingly source counterfeit or IP-infringing products may face legal liability, cease-and-desist orders, or removal of installed panels, leading to costly replacements and project delays.

Failure to Secure Licensing for Proprietary Designs

Even when a design appears widely available, it may be protected under design patents or trademarked by the original creator. Sourcing panels based on such designs without obtaining proper licensing agreements exposes purchasers to infringement claims. This is especially prevalent with signature slat patterns used in high-profile architectural projects.

Ambiguous Contracts and Lack of IP Clauses

Procurement agreements that do not explicitly address ownership of design rights, usage permissions, or liability for IP violations leave buyers vulnerable. Without clear contractual terms, disputes over design ownership or unauthorized replication can escalate legally and financially. Always ensure contracts include IP indemnification clauses and define permitted use cases.

Overlooking Regional Manufacturing Standards and Compliance

Different countries have varying regulations regarding wood treatment, emissions (e.g., formaldehyde levels under CARB or E1 standards), and labeling requirements. Sourcing panels internationally without verifying compliance with local building codes can result in rejected shipments or non-compliant installations.

Conclusion

To avoid these pitfalls, conduct due diligence on suppliers, request material test reports, verify sustainability certifications, and consult legal experts when using or sourcing distinctive designs. Clear communication, detailed specifications, and robust contracts are essential to ensuring both high-quality products and IP compliance in wooden slat panel procurement.

Logistics & Compliance Guide for Wooden Slat Panel

Product Classification & HS Code

Wooden slat panels are typically classified under the Harmonized System (HS) Code 4418.90, which covers “Other builders’ joinery and carpentry of wood.” However, the exact code may vary based on composition (e.g., solid wood vs. engineered wood), country of import, and whether the product includes non-wood components. Always confirm the appropriate HS code with local customs authorities or a customs broker to ensure accurate tariff application and compliance.

Phytosanitary Requirements

Wood products are subject to international phytosanitary regulations to prevent the spread of pests and diseases. Wooden slat panels must comply with International Standards for Phytosanitary Measures No. 15 (ISPM 15) if made from raw wood (including solid wood components). This requires:

– Heat treatment (HT) or fumigation (MB) of wood packaging materials and solid wood components over 6mm thick.

– Marking with the official ISPM 15 stamp showing country code, producer number, and treatment type.

– Panels made entirely from processed wood (e.g. plywood, MDF, particleboard) may be exempt. Confirm with the importing country’s plant protection organization.

Import/Export Documentation

Ensure accurate and complete documentation for smooth customs clearance:

– Commercial Invoice (detailing product description, value, quantity, and HS code)

– Packing List (including dimensions, weight per package, and total shipment weight)

– Bill of Lading (for ocean freight) or Air Waybill (for air freight)

– Certificate of Origin (may be required for preferential tariffs under trade agreements)

– Phytosanitary Certificate (if applicable, issued by national plant protection authority)

– Import Declaration and any country-specific permits

Packaging & Marking

- Use durable, moisture-resistant packaging to prevent damage during transit.

- Clearly label each package with:

- Product description (“Wooden Slat Panel”)

- Quantity and dimensions

- Net and gross weight

- Handling instructions (e.g., “This Side Up,” “Fragile”)

- ISPM 15 mark (if applicable)

- Manufacturer and recipient details

Transportation Considerations

- Wooden slat panels are susceptible to warping, cracking, or moisture damage. Use enclosed, climate-controlled containers when shipping over long distances or in high-humidity environments.

- Secure panels vertically or flat with adequate spacing to avoid pressure marks and allow airflow.

- Avoid exposure to rain or direct sunlight during loading/unloading.

- For international shipping, choose freight forwarders experienced in handling wood products and compliance documentation.

Country-Specific Regulations

Regulations vary by destination. Key examples:

– United States: Enforced by USDA APHIS. ISPM 15 compliance mandatory for solid wood components. Lacey Act requires declaration of wood species and origin to combat illegal logging.

– European Union: Requires compliance with EU Timber Regulation (EUTR), mandating due diligence to ensure wood sourcing is legal. ISPM 15 applies. Some countries restrict certain wood species.

– Australia & New Zealand: Strict biosecurity controls. Wooden items may require pre-shipment treatment and inspection. Refer to the Department of Agriculture, Fisheries and Forestry (Australia) or MPI (New Zealand) for requirements.

– China: Requires phytosanitary certificate and may inspect for pests. ISPM 15 compliance is enforced.

Environmental & Sustainability Compliance

- Ensure wood sourcing complies with sustainability standards such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification).

- Maintain chain-of-custody documentation if marketing panels as sustainably sourced.

- Be prepared to provide proof of legal harvest and processing, especially under regulations like the U.S. Lacey Act or EU EUTR.

Labeling & Safety Data

- Label finished products with manufacturer details, country of origin, material composition (e.g., wood type, finishes used), and care instructions.

- If coatings or adhesives are used, provide Safety Data Sheets (SDS) upon request, especially for commercial or industrial customers.

- Comply with indoor emissions standards (e.g., CARB Phase 2 in the U.S., E1 in the EU) for formaldehyde if using composite wood materials.

Returns & Reverse Logistics

- Establish clear return policies for damaged or non-conforming goods.

- Inspect returned wooden slat panels for pest infestation or contamination before reintroducing into inventory.

- Follow biosecurity protocols for disposal or recycling of non-reusable wood materials.

Summary

Successful logistics and compliance for wooden slat panels require attention to international wood packaging rules, accurate documentation, proper handling, and adherence to destination-specific regulations. Partnering with experienced customs brokers and freight providers can mitigate risks and ensure timely delivery while maintaining compliance.

In conclusion, sourcing wooden slat panels requires a careful balance of quality, sustainability, cost, and design compatibility. It is essential to partner with reliable suppliers who offer certified, sustainably harvested materials, ensuring both environmental responsibility and long-term durability. Factors such as wood species, finish options, dimensional consistency, and customization capabilities should align with the project’s aesthetic and functional requirements. Additionally, considering lead times, shipping logistics, and after-sales support contributes to a smooth procurement process. By conducting thorough research and due diligence, businesses and designers can secure high-quality wooden slat panels that enhance interior or exterior spaces while meeting budgetary and sustainability goals.