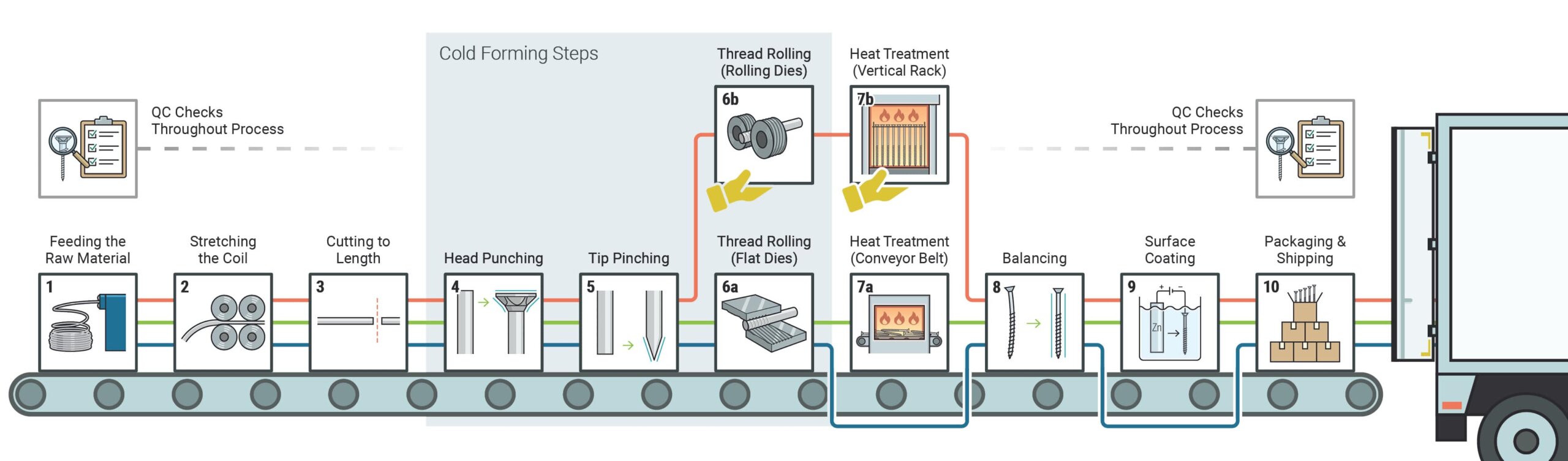

The global fasteners market, driven by steady demand from construction, automotive, and manufacturing sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2030, according to Grand View Research. Within this expansive market, wood screws represent a critical segment, with increasing investments in residential infrastructure and woodworking industries fueling demand for precision-engineered screw dimensions. As product quality and dimensional accuracy become key differentiators, a handful of manufacturers have emerged as leaders in producing standardized, reliable wood screw dimensions that meet international specifications. These top producers leverage advanced cold-forming technologies, stringent quality control, and material innovation to maintain tight tolerances and consistency across high-volume production. Based on market presence, manufacturing capabilities, and adherence to ISO and ANSI standards, the following eight companies stand out as the leading wood screw dimension manufacturers shaping the industry today.

Top 8 Wood Screw Dimension Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Star Drive Wood Screws – Screw Products, Inc.

Domain Est. 1999

Website: screw-products.com

Key Highlights: Screw Products Inc. specializes in star drive stainless steel and heat treated wood screws for decks, log homes, remodeling, kitchen cabinets, docks, ……

#2 Pro-Twist

Domain Est. 2003

Website: pro-twist.com

Key Highlights: Pro-Twist is an industry-leading manufacturer of professional-grade fasteners that are used for a wide variety of applications. Get started with us today!…

#3 Strong

Domain Est. 1995

Website: strongtie.com

Key Highlights: The Strong-Drive SDWS Timber screw is designed to provide an easy-to-install, high-strength alternative to through-bolting and traditional lag screws….

#4 Screws

Domain Est. 1997

Website: fischer-international.com

Key Highlights: fischer offers a wide range of high-quality screws for professional users in wood construction, interior fittings and the drywall sectors. The screws are ……

#5 Wood Fasteners, Structural Deck Screws, LOK Line Products

Domain Est. 1998

Website: fastenmaster.com

Key Highlights: Here you can find all our products categorized on type of applications and projects, starting from decking, interior remodeling and new projects….

#6 Not Your Mama’s Wood Screw

Domain Est. 2002

Website: iccsafe.org

Key Highlights: Proprietary wood screws are typically formed from steel material; have a head, a threaded shank and a point; and are intended to be self-drilling….

#7 SPAX US

Domain Est. 2004

Website: spax.us

Key Highlights: Our Engineered Screws & Fasteners are manufactured and rigorously tested right here in the heart of America. Rely on us to help you drive the highest quality….

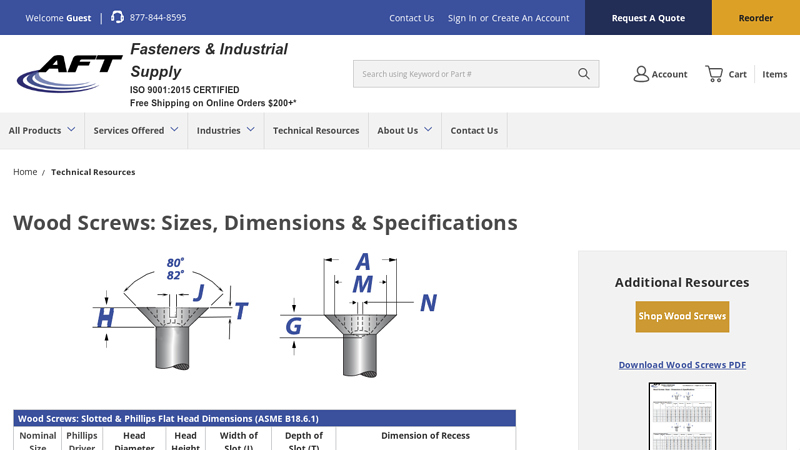

#8 Wood Screw Sizes, Dimensions & Specifications

Domain Est. 2008

Website: aftfasteners.com

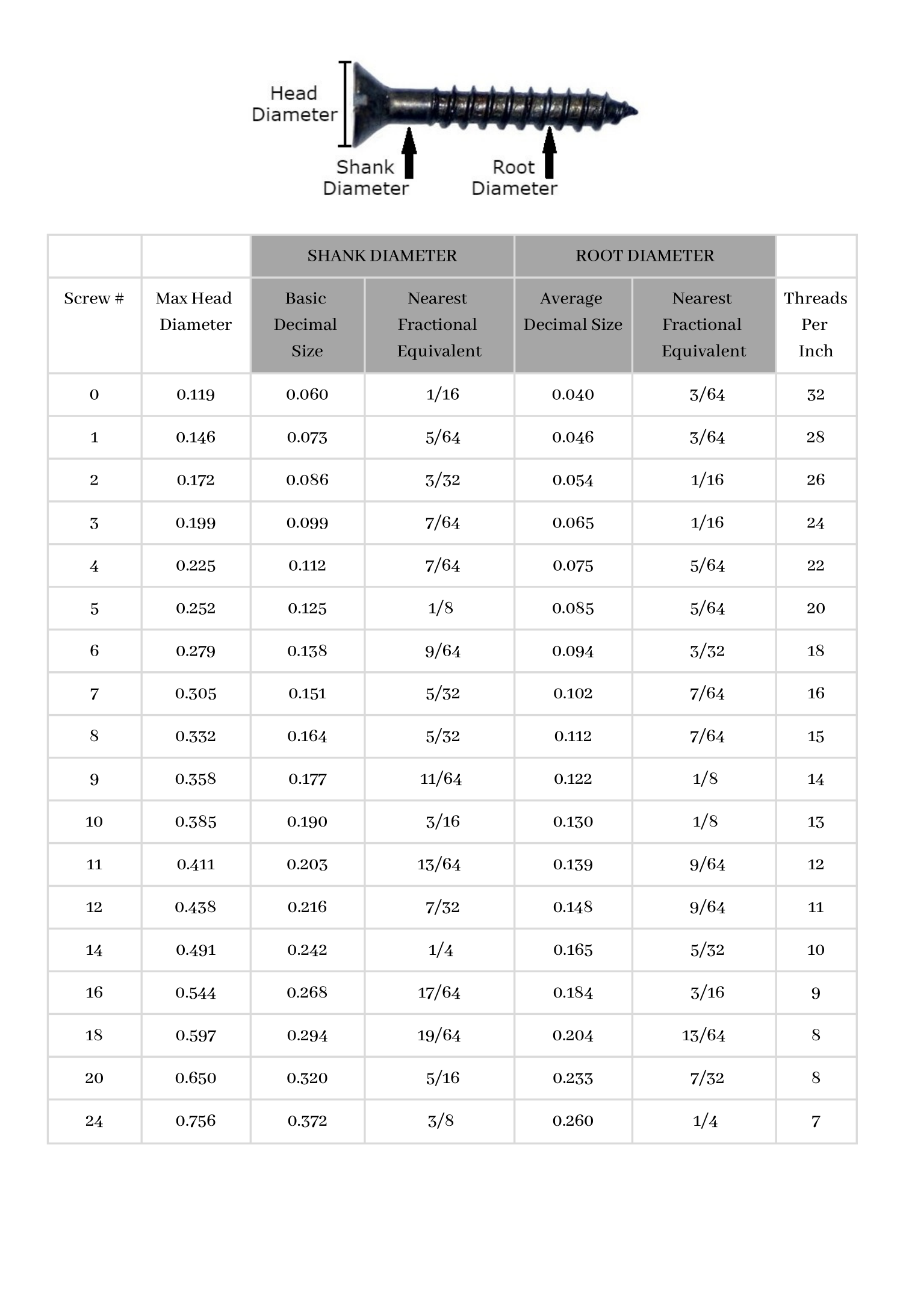

Key Highlights: AFT Fasteners provides a helpful resource on wood screw sizes, dimensions, tolerance on length, material, hardness, and strength. The wood screw size chart ……

Expert Sourcing Insights for Wood Screw Dimension

H2: 2026 Market Trends for Wood Screw Dimensions

The global wood screw dimension market is poised for notable evolution by 2026, shaped by technological advancements, shifting construction practices, and growing demand across residential, commercial, and industrial sectors. Key trends influencing wood screw dimensions in 2026 include standardization efforts, material innovations, regional construction dynamics, and sustainability demands.

-

Standardization and Harmonization of Dimensions

By 2026, increased harmonization of wood screw dimensions—driven by ISO and ASTM standards—is expected to streamline manufacturing and distribution. The push for uniformity in diameter, length, thread pitch, and head types will enhance compatibility across fastening systems, particularly in international construction and furniture assembly. This trend benefits large-scale contractors and DIY consumers alike by reducing inventory complexity and minimizing installation errors. -

Rise in Demand for Specialized and Custom Sizes

While standardization dominates, there is a parallel surge in demand for customized wood screw dimensions tailored to niche applications such as engineered wood products (e.g., cross-laminated timber), modular housing, and high-end cabinetry. Longer and thicker screws (e.g., 4–6 inches with coarse threads) are gaining traction in structural timber framing, while micro-dimensions (<1 inch) are seeing growth in precision woodworking and furniture markets. -

Influence of Engineered Wood and Mass Timber Construction

The rapid adoption of mass timber in commercial construction is a major driver shaping screw dimensions. These materials require screws with specific length-to-diameter ratios and optimized thread designs to ensure load-bearing integrity. By 2026, manufacturers are expected to offer dimensionally optimized screws—such as 3.5″ to 5″ variants with dual-thread technology—to meet the mechanical demands of glued-laminated timber (glulam) and nail-laminated timber (NLT) systems. -

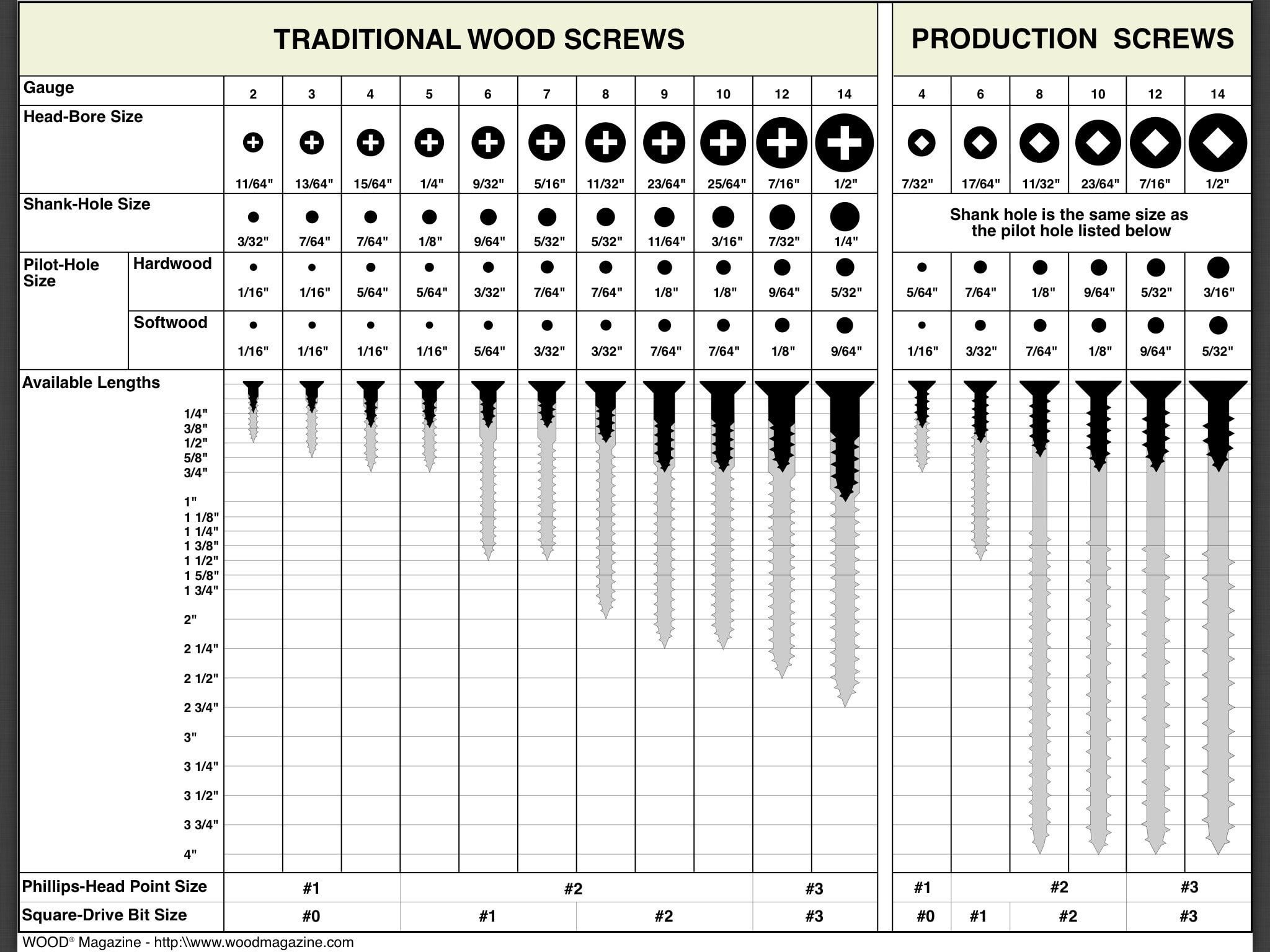

Regional Variations in Preferred Dimensions

Regional construction practices continue to influence screw size preferences. In North America, #8 and #10 diameter screws in 1.25″ to 3.5″ lengths remain dominant due to framing standards. In contrast, European markets exhibit a preference for metric dimensions (e.g., 4.0 mm, 5.0 mm diameter) and self-tapping variants, driven by prefabricated housing trends. Asia-Pacific regions are seeing a shift toward smaller, high-precision screws for furniture and interior fit-outs, reflecting urbanization and space optimization. -

Material Innovations Impacting Dimensional Design

Advancements in screw materials—such as carbon steel with improved coatings, stainless steel, and bio-based composites—are influencing dimensional tolerances. Enhanced corrosion resistance allows for slimmer designs without sacrificing strength, enabling longer screws with smaller diameters (e.g., 3.5″ x #6). This miniaturization trend supports aesthetic and functional needs in high-end architectural applications. -

Sustainability and Lightweighting

Environmental regulations are pushing manufacturers to reduce material use without compromising performance. As a result, optimized screw dimensions—lighter yet stronger through geometric efficiency—are emerging. Hollow-core or variable-pitch designs may become more prevalent by 2026, reducing raw material consumption and transportation emissions. -

Growth in E-Commerce and Consumer Influence

The rise of online retail platforms is reshaping consumer access to diverse screw dimensions. DIY enthusiasts now demand multi-pack assortments with a wide range of lengths and gauges, encouraging manufacturers to expand product ranges. This democratization of access is driving innovation in packaging and labeling, emphasizing dimensional clarity and application-specific guidance.

In summary, the 2026 wood screw dimension landscape will be defined by a dual movement: global standardization for efficiency and customization for performance. As construction methodologies evolve and sustainability gains priority, screw dimensions will increasingly reflect a balance between mechanical necessity, material innovation, and environmental responsibility.

Common Pitfalls in Sourcing Wood Screw Dimensions (Quality, IP)

Sourcing wood screws with precise dimensions while ensuring quality and protecting intellectual property (IP) can present several challenges. Overlooking these pitfalls may result in product failure, supply chain disruptions, or legal complications.

Inconsistent Dimensional Tolerances

Suppliers, especially those from low-cost regions, may not adhere strictly to international standards (e.g., ISO, ANSI). Variations in thread pitch, head diameter, or screw length can lead to assembly issues, reduced holding strength, or incompatibility with pre-drilled holes or automated equipment.

Compromised Material Quality

To reduce costs, some manufacturers may use substandard materials or misrepresent alloy compositions. This affects critical performance factors like tensile strength, corrosion resistance, and durability. Without proper certification (e.g., material test reports), buyers risk receiving screws prone to snapping or rusting prematurely.

Inadequate Surface Treatment and Coating

Improper or inconsistent plating (e.g., zinc, chrome, or black oxide) can compromise corrosion resistance. Some suppliers may apply thin or uneven coatings that wear off quickly. Verifying coating thickness and adherence to standards like ASTM B633 is essential but often overlooked.

Lack of Traceability and Certification

Many suppliers fail to provide documentation such as Certificates of Conformance (CoC), material certifications, or test reports. This lack of traceability makes it difficult to verify quality claims or respond effectively to product failures or audits.

Intellectual Property Risks in Design Specifications

When sharing detailed screw blueprints or proprietary designs with potential suppliers, there is a risk of IP theft—especially in regions with weak IP enforcement. Suppliers may replicate the design for other customers or sell them on the gray market without authorization.

Poor Communication of Technical Requirements

Ambiguities in specifications—such as unclear callouts for drive type, thread type (wood vs. machine), or head style—can result in incorrect products being manufactured. Misunderstandings due to language barriers or lack of engineering oversight exacerbate this issue.

Overlooking Production Capacity and Process Control

Even if samples meet specifications, a supplier’s mass production may not maintain consistency. Without robust quality management systems (e.g., ISO 9001), process variations can lead to batch-to-batch inconsistencies in dimensions and performance.

Failure to Audit Suppliers On-Site

Relying solely on paper certifications or sample testing without conducting on-site audits can hide poor manufacturing practices. Hidden issues like outdated machinery, untrained staff, or inadequate quality control procedures may only surface after large orders are received.

Logistics & Compliance Guide for Wood Screw Dimensions

Understanding and adhering to the correct wood screw dimensions is critical not only for product performance but also for smooth logistics operations and regulatory compliance across international markets. This guide outlines key considerations related to sizing standards, packaging, labeling, transportation, and regulatory requirements.

Standardized Dimension Specifications

Wood screws must conform to established dimensional standards to ensure compatibility, safety, and regulatory acceptance. Key standards include:

- ANSI/ASME B18.6.1 (United States): Governs the dimensions, thread types, head styles, and drive types for wood screws. Includes specifications for nominal diameter, length, thread pitch, and head dimensions.

- ISO 1580 (International): Specifies dimensions for slotted cheese head wood screws.

- ISO 1581 (International): Covers dimensions for slotted countersunk flat head wood screws.

- DIN 97 (Germany) and BS 93 (UK): National standards that may still be referenced in certain regions.

Ensure all screws are manufactured and documented according to the applicable standard for the destination market.

Packaging and Labeling Requirements

Proper packaging and labeling are essential for logistics efficiency and compliance:

- Net Quantity Declaration: Packages must clearly state the number of screws or total weight (e.g., “100 pcs” or “1 kg”). Units must comply with local measurement laws (metric vs. imperial).

- Dimensional Labeling: Include key dimensions on packaging: diameter (e.g., #8, M4), length (e.g., 1.5″, 40 mm), thread type (coarse/fine), and head style (e.g., Phillips flat head).

- Material and Finish: Label material composition (e.g., steel, stainless steel) and finish (e.g., zinc-plated, black oxide) for corrosion resistance and environmental compliance.

- Barcoding and SKU: Use standardized barcodes (e.g., UPC, EAN) and SKUs for inventory tracking and customs documentation.

Import/Export Compliance

International shipments of wood screws may be subject to the following:

- HS Code Classification: Use the correct Harmonized System (HS) code. Common codes include:

- 7318.15: Screws and bolts, whether or not with nuts or washers, of iron or steel.

- Local customs authorities may require sub-classifications based on material, thread, or use.

- Country-Specific Regulations: Some countries regulate fasteners for structural or safety reasons. Verify compliance with local building codes (e.g., ICC in the U.S., CE marking in the EU).

- RoHS and REACH (EU): Ensure screws (especially coatings) comply with restrictions on hazardous substances.

- TSCA (U.S.): Verify compliance with Toxic Substances Control Act, particularly for chemical treatments or platings.

Transportation and Handling

- Unit Load Optimization: Package screws in standardized containers or boxes to maximize pallet space and minimize damage.

- Moisture Protection: Use moisture-resistant packaging (e.g., vacuum sealing, desiccants) to prevent rust, especially for carbon steel screws.

- Hazard Classification: Wood screws are generally non-hazardous, but coated or treated screws may require documentation if chemical content exceeds thresholds.

Quality Assurance and Documentation

- Certificates of Compliance (CoC): Provide CoC confirming adherence to dimensional and material standards.

- Test Reports: Include tensile strength, thread accuracy, and coating thickness reports when required by customers or regulators.

- Traceability: Maintain batch-level traceability for recalls or audits.

Summary

Accurate wood screw dimensions are not only vital for engineering fit but also for ensuring compliance with packaging, labeling, and customs regulations. Adhering to international standards, providing clear documentation, and understanding destination-specific requirements will streamline logistics and reduce the risk of shipment delays or rejections.

In conclusion, sourcing the appropriate wood screw dimensions requires careful consideration of several key factors, including the type of wood, the load requirements, the thickness of the materials being joined, and the desired holding strength. Standard dimensions such as diameter (gauge), length, and thread type should align with the specific application to ensure optimal performance and durability. Referring to industry standards and manufacturer specifications helps in selecting the right screw size, while prototyping or testing can validate the choice in practical scenarios. Ultimately, selecting the correct wood screw dimensions contributes to the structural integrity, longevity, and overall success of woodworking and construction projects.