The global bed base market is experiencing steady growth, driven by rising demand for ergonomic, durable, and aesthetically refined bedroom furniture. According to Mordor Intelligence, the global bed base market was valued at USD 25.3 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is fueled by increasing urbanization, rising disposable incomes, and a growing preference for modular and wooden furniture, particularly in residential and hospitality sectors. Wood rail bed frames—valued for their structural stability, minimalist design, and compatibility with modern interiors—are gaining traction among both consumers and home furnishing brands. As the market becomes more competitive, a select group of manufacturers have emerged as leaders, combining craftsmanship with scalable production and sustainable sourcing. Based on market presence, customer reviews, product innovation, and distribution reach, the following eight companies represent the forefront of wood rail bed manufacturing worldwide.

Top 8 Wood Rail Bed Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rail Yard Studios

Domain Est. 2010

Website: railyardstudios.com

Key Highlights: Rail Yard Studios · Authentic Railroad · Custom Furniture · Industrial Style Furniture · Reclaimed Steel & Natural Wood · Historic Preservation · Authentic Railroad….

#2 Replacement Hooked Bed Rails

Domain Est. 2014

Website: hookedbedrails.com

Key Highlights: High Quality Hooked Side Rails · Made with Pride in Pennsylvania · Shipped Factory Direct to your home! · Email us for a quote today: · [email protected]….

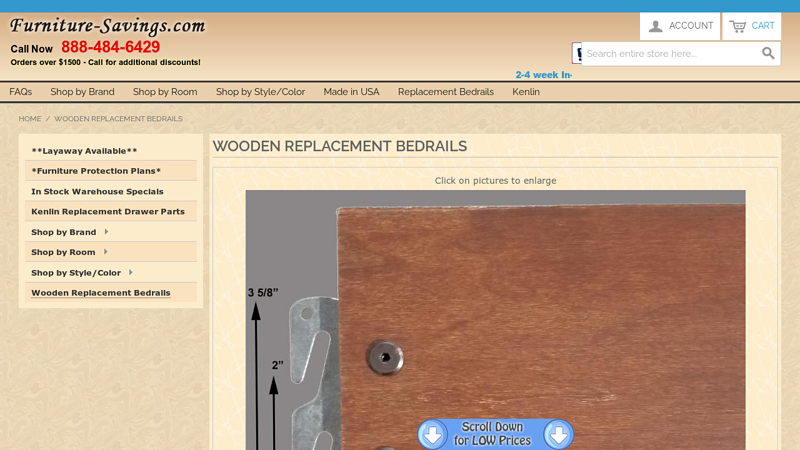

#3 Wooden Replacement Bedrails

Domain Est. 1999

Website: furniture-savings.com

Key Highlights: Free deliveryThese wooden rails work with most beds that require hook-in rails and are all American made! We offer a variety of finishes, as well as sizes to choose from….

#4 B & H Panel Company

Domain Est. 2001

Website: bhpanel.com

Key Highlights: We specialize in durable bed rails and mattress supports made with premium wood for lasting strength. Our strong, reliable hooks ensure a secure fit….

#5 WoodBedRails.com

Domain Est. 2007

Website: woodbedrails.com

Key Highlights: Restore your bed’s stability with our wood bed rail replacements. Quality hardwood laminated materials for strength, expert craftsmanship, and lasting results….

#6 WSilver Center Supports for Wood or Metal Side Rails

Domain Est. 2010

Website: wsilverproducts.com

Key Highlights: In stock Free deliveryEnhance the stability of your bed frame with our Center Supports, designed for both wood and metal side rails. These supports provide essential ……

#7 Wood Bed Rails (0050)

Domain Est. 2010

Website: deltachildren.com

Key Highlights: Out of stock Rating 4.2 133 Extend the life of your crib with these wood bed rails from Delta Children. Designed to easily convert your crib into a full size – Delta Children….

#8 Wooden Bed Frame Rail

Domain Est. 2014

Website: cocovillage.com

Key Highlights: $19.99 delivery 30-day returnsThe Natural Wood Bed Rail is perfect for preventing night-time falls during the transition to the big bed. It offers 4 color combinations and several …

Expert Sourcing Insights for Wood Rail Bed

2026 Market Trends for Wood Rail Bed

The wood rail bed market in 2026 is poised for measured growth driven by sustainability trends, design preferences, and evolving consumer lifestyles, though tempered by economic and material challenges. Key developments shaping the sector include:

Rising Demand for Sustainable and Eco-Friendly Bedroom Furniture

Environmental consciousness continues to influence furniture purchasing decisions. Wood rail beds, particularly those crafted from certified sustainable hardwoods like FSC-certified oak, walnut, and maple, are gaining favor over metal or particleboard alternatives. Consumers are increasingly prioritizing durability and low environmental impact, positioning solid wood rail beds as long-term investments. Brands emphasizing transparent sourcing, low-VOC finishes, and carbon-neutral manufacturing are likely to capture a growing segment of eco-aware buyers.

Dominance of Hybrid and Minimalist Design Aesthetics

Interior design trends in 2026 favor clean lines, natural textures, and multifunctionality—hallmarks of modern wood rail beds. These beds seamlessly integrate into Scandinavian, Japandi, and contemporary farmhouse styles. Minimalist rail beds with slim profiles and understated detailing are especially popular in urban dwellings where space efficiency is critical. Additionally, hybrid designs combining wood with metal accents or integrated lighting appeal to consumers seeking both warmth and modern functionality.

Growth in E-Commerce and Direct-to-Consumer (DTC) Channels

Online furniture retail remains a dominant force. DTC brands offering customizable wood rail beds with augmented reality (AR) visualization tools, flat-pack shipping, and white-glove delivery options are capturing market share. Consumers appreciate the convenience, wider selection, and competitive pricing enabled by digital platforms. In 2026, brands with strong digital presence and customer experience will outperform traditional brick-and-mortar retailers.

Customization and Personalization as Key Differentiators

Buyers increasingly seek personalized solutions. In 2026, manufacturers offering modular wood rail bed systems—adjustable heights, interchangeable headboards, color stains, and built-in storage—will stand out. Custom sizing for non-standard rooms and bespoke finishes cater to individual tastes and spatial constraints, reinforcing the premium positioning of wood furniture.

Challenges from Material Costs and Supply Chain Volatility

Persistent fluctuations in lumber prices and global supply chain disruptions continue to pressure margins. Producers are responding by investing in domestic sourcing, optimizing production efficiency, and using engineered wood composites where appropriate—though solid wood remains the premium standard. Inflationary pressures may limit affordability for some consumers, potentially shifting demand toward mid-tier offerings.

Integration of Smart Features and Wellness-Oriented Design

While still emerging, smart furniture trends are beginning to influence bed design. Some high-end wood rail beds now incorporate wireless charging, under-bed LED lighting, or compatibility with sleep-tracking devices. Paired with ergonomic designs promoting better posture and rest, these features appeal to health-conscious consumers, reinforcing the wood bed’s role in holistic bedroom wellness.

In summary, the 2026 wood rail bed market reflects a convergence of sustainability, design innovation, and digital engagement. Success will depend on balancing authentic craftsmanship with modern consumer expectations for customization, convenience, and environmental responsibility.

Common Pitfalls Sourcing Wood Rail Bed (Quality, IP)

Sourcing a wood rail bed—whether for furniture, architectural elements, or industrial applications—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to product failures, legal disputes, and reputational damage. Below are common pitfalls to avoid:

Poor Wood Quality and Sourcing Practices

One of the most frequent issues in sourcing wood rail beds is inadequate attention to the quality and origin of the timber. Buyers may prioritize cost over durability, leading to several problems:

- Inconsistent Moisture Content: Wood with improper moisture levels can warp, crack, or shrink after installation, compromising structural integrity.

- Use of Non-Sustainable or Illegally Harvested Timber: Sourcing from uncertified or illegal logging operations carries environmental and legal risks, including violations of regulations like the Lacey Act (U.S.) or EUTR (EU).

- Lack of Species Verification: Suppliers may misrepresent wood species (e.g., passing off lower-grade wood as teak or oak), affecting performance and aesthetics.

- Poor Milling and Finishing: Inadequately planed, sanded, or treated wood can result in splinters, rough surfaces, or susceptibility to rot and insect damage.

To mitigate these risks, insist on wood certification (e.g., FSC or PEFC), request moisture testing reports, and conduct factory audits or third-party inspections.

Intellectual Property Infringement Risks

Another critical but often overlooked pitfall involves intellectual property. When sourcing wood rail beds—especially custom or designer pieces—there is a risk of inadvertently infringing on protected designs or patents:

- Copying Protected Designs: Many rail bed designs are protected by design patents, copyrights, or trademarks. Replicating a branded or distinctive design without authorization can lead to legal action, product seizures, or fines.

- Supplier Misrepresentation of Originality: Some suppliers may claim their designs are original when they are, in fact, copies of patented or copyrighted works.

- Lack of IP Clauses in Contracts: Without clear contractual terms assigning IP ownership or confirming the originality of the design, buyers may find themselves liable for infringement committed by the manufacturer.

To protect against IP issues, conduct thorough design due diligence, require suppliers to warrant that products do not infringe third-party rights, and consider registering unique designs in relevant markets.

Conclusion

Successfully sourcing a wood rail bed requires balancing cost, quality, and legal compliance. Prioritizing certified, high-quality wood and conducting rigorous IP checks can prevent costly setbacks and ensure a reliable, legally sound supply chain.

Logistics & Compliance Guide for Wood Rail Bed

This guide outlines the essential logistics considerations and compliance requirements for the transportation, handling, and use of wood rail beds (also known as railroad ties or crossties) in construction and rail infrastructure projects.

Regulatory Compliance

Ensure adherence to all applicable federal, state, and local regulations. Wood rail beds are often treated with preservatives such as creosote, pentachlorophenol (PCP), or copper-based compounds, which are regulated under environmental and occupational safety laws.

- Environmental Protection Agency (EPA): Comply with EPA regulations regarding the handling, disposal, and potential leaching of treated wood. The use and disposal of creosote-treated ties are restricted under the National Pollutant Discharge Elimination System (NPDES) and other environmental statutes.

- Occupational Safety and Health Administration (OSHA): Follow OSHA guidelines for worker safety, including proper personal protective equipment (PPE), ventilation, and training when handling treated wood products to minimize exposure to chemical preservatives.

- Department of Transportation (DOT): Adhere to DOT regulations for the safe transport of hazardous materials if the wood ties are classified as such due to treatment chemicals.

International and Trade Regulations

For cross-border shipments, comply with international standards and import/export requirements.

- International Plant Protection Convention (IPPC): Wood rail beds shipped internationally may require heat treatment and IPPC marking (e.g., ISPM 15 compliance) to prevent the spread of pests, unless exempted due to chemical treatment.

- Customs Documentation: Maintain accurate records, including materials declarations, treatment certifications, and bills of lading, to facilitate customs clearance.

Transportation and Handling Logistics

Careful planning is required to move and store wood rail beds safely and efficiently.

- Loading and Securing: Use proper bracing, straps, and dunnage to secure loads on flatbed trailers or railcars. Prevent shifting during transit to avoid damage and safety hazards.

- Weight and Dimensions: Account for the weight of wood ties (averaging 100–150 lbs each) and stacking configurations to comply with axle weight limits and height restrictions on roadways.

- Handling Equipment: Utilize forklifts, cranes, or tie handlers with appropriate attachments to reduce manual labor and prevent workplace injuries.

Storage Requirements

Proper storage preserves tie quality and minimizes environmental impact.

- Location: Store on well-drained, paved surfaces away from water bodies to prevent runoff contamination.

- Stacking: Keep stacks stable and separated to allow airflow and prevent mold or degradation. Limit stack height based on equipment capabilities and safety standards.

- Containment: Use berms or liners in storage areas if ties are treated, especially in sensitive environmental zones, to capture potential leachate.

Disposal and End-of-Life Management

Retired wood rail beds require environmentally sound disposal methods.

- Landfill Disposal: Many landfills accept treated wood ties but may require special handling or fees. Verify acceptance policies in advance.

- Recycling and Reuse: Consider options such as biomass fuel, landscaping timbers (if permitted), or industrial reprocessing. Ensure recycling facilities are licensed to handle treated wood.

- Hazardous Waste Classification: Determine if spent ties meet the criteria for hazardous waste under RCRA (Resource Conservation and Recovery Act). Testing may be required for disposal compliance.

Documentation and Recordkeeping

Maintain comprehensive records throughout the lifecycle of wood rail beds.

- Treatment Certificates: Keep documentation of preservative type, treatment date, and manufacturer.

- Chain of Custody: Track movement from supplier to installation or disposal site.

- Compliance Reports: Retain inspection reports, training logs, and environmental monitoring data as required by regulatory agencies.

By following this guide, stakeholders can ensure safe, efficient, and compliant handling of wood rail beds across all phases of use and disposal.

Conclusion on Sourcing Wood for Rail Beds

Sourcing wood for rail beds requires a careful balance between durability, cost, environmental responsibility, and regulatory compliance. While traditional wooden railroad ties (sleepers) made from hardwoods like oak or tropical hardwoods treated with preservatives like creosote have been widely used for their strength and longevity, increasing environmental concerns and regulations are prompting a reevaluation of these materials.

Sustainable sourcing practices—such as using wood from certified forests (e.g., FSC or PEFC), opting for recycled or composite materials, or selecting fast-growing, treated softwoods—can mitigate ecological impacts and improve long-term viability. Additionally, advancements in alternative materials like concrete and plastic composites offer competitive options, although wood remains preferred in certain applications due to its elasticity, ease of installation, and cost-effectiveness in specific regions.

In conclusion, while wood continues to play a significant role in rail bed construction, responsible sourcing, treatment, and disposal practices are essential to ensure environmental sustainability and compliance with safety standards. A strategic approach that considers local availability, lifecycle costs, and ecological impact will enable the rail industry to maintain reliable infrastructure while supporting global sustainability goals.