The global wire trenching machine market is experiencing steady growth, driven by rising investments in underground utility infrastructure, particularly in telecommunications, power distribution, and smart city development. According to a report by Mordor Intelligence, the underground utility construction equipment market—including trenching machinery—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This expansion is further supported by increasing demand for reliable, high-efficiency trenching solutions that minimize surface disruption and enhance installation speed. As urbanization accelerates and governments prioritize buried utility networks for safety and aesthetics, the need for advanced wire trenching machines has become critical. In this expanding landscape, several manufacturers have emerged as leaders, combining innovation, durability, and performance to meet evolving industry demands. Based on market presence, technological advancements, and equipment performance metrics, the following eight companies represent the forefront of wire trenching machine manufacturing worldwide.

Top 8 Wire Trenching Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 E-Z Trench Mfg. Inc.

Domain Est. 1998 | Founded: 1982

Website: eztrench.com

Key Highlights: Since 1982, we have been making durable and dependable trenching products for commercial use. Built to last, our trenchers will provide years of service….

#2 Cable Trenching Solutions

Domain Est. 2009

Website: kemroc.com

Key Highlights: Discover KEMROC’s advanced cable trenching solutions for efficient and precise trenching. Ideal for utility installations and micro trenching projects.Missing: wire manufacturer…

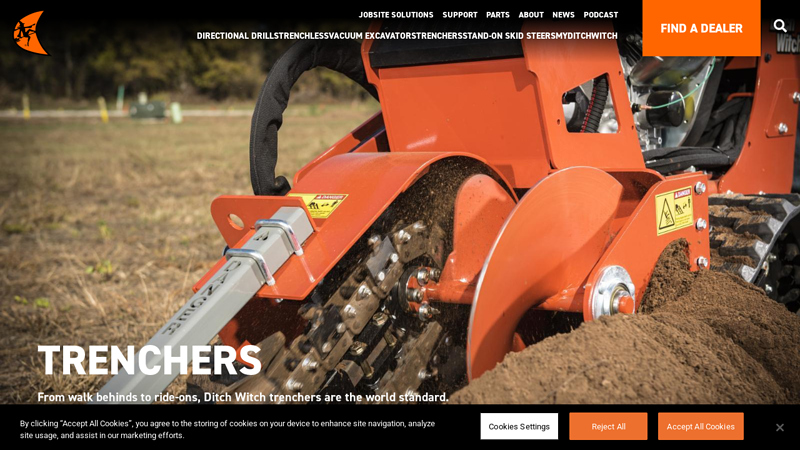

#3 Trenchers

Domain Est. 1996

Website: ditchwitch.com

Key Highlights: No matter what the job is, Ditch Witch trenchers are the world standard. Choose from walk-behinds, ride-ons, and micro trenching equipment….

#4 Energy Cables

Domain Est. 1997

Website: tesmec.com

Key Highlights: Tesmec trenchers are used for energy cables installation, especially in renewable energy plants, such as wind and solar farms….

#5 Trench Group

Domain Est. 2004

Website: trench-group.com

Key Highlights: Welcome to the Trench Group, an unstoppable force of positive change and sustainable innovation in the power transmission market….

#6 i

Domain Est. 2006

Website: helixesg.com

Key Highlights: The i-Trencher provides precise subsea trenching, designed for depths up to 2.7 meters with exceptional accuracy and efficiency….

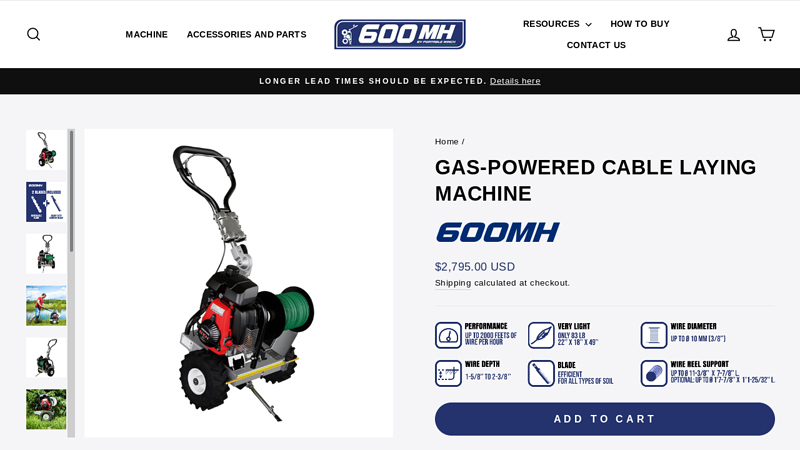

#7 gas

Domain Est. 2013

#8 Epiroc USA – Mining Equipment

Domain Est. 2017

Website: epiroc.com

Key Highlights: We provide innovative mining equipment, consumables and services for drilling and rock excavation. Whether the application is surface and underground mining ……

Expert Sourcing Insights for Wire Trenching Machine

2026 Market Trends for Wire Trenching Machines

The wire trenching machine market is poised for significant evolution by 2026, driven by technological advancements, increasing infrastructure demands, and a growing emphasis on efficiency and sustainability. Key trends shaping the industry include:

1. Accelerated Adoption of Electric and Hybrid Models

Environmental regulations and the push for carbon neutrality are accelerating the shift from traditional diesel-powered trenchers to electric and hybrid alternatives. By 2026, electric wire trenching machines are expected to capture a larger market share, particularly in urban and environmentally sensitive areas. Benefits such as reduced noise pollution, lower operating costs, and compliance with emission standards are driving adoption among utility contractors and municipal projects.

2. Integration of Smart Technology and Telematics

Wire trenching machines are increasingly equipped with IoT-enabled sensors, GPS tracking, and real-time telematics. By 2026, these smart features will become standard, allowing for remote monitoring of machine health, performance optimization, predictive maintenance, and enhanced job site safety. Fleet management platforms will enable contractors to improve operational efficiency and reduce downtime.

3. Growth in Telecommunications and 5G Infrastructure

The global rollout of 5G networks and expansion of fiber-optic broadband are fueling demand for precise and efficient underground cabling solutions. Wire trenching machines, especially compact and mini models, are essential for rapid deployment in urban and suburban areas. This infrastructure push, particularly in North America, Europe, and parts of Asia-Pacific, will remain a primary growth driver through 2026.

4. Emphasis on Compact and Versatile Equipment

With more projects taking place in congested urban environments and residential areas, compact wire trenchers that offer high maneuverability and minimal surface disruption are gaining favor. Manufacturers are focusing on designing lightweight, multi-functional machines capable of handling various soil types and trench depths, meeting the needs of diverse applications from landscaping to utility installation.

5. Rising Demand in Renewable Energy Projects

The expansion of solar farms, wind parks, and microgrid installations requires extensive underground cabling for power transmission. Wire trenching machines are critical for efficiently laying cables in these large-scale renewable projects. As investments in clean energy continue to rise globally, demand for trenching equipment tailored to these applications will grow steadily through 2026.

6. Regional Market Expansion and Localization

While North America and Europe remain strong markets due to ongoing infrastructure modernization, emerging economies in Asia, Latin America, and Africa are expected to see increased adoption. Localized manufacturing, favorable government policies, and public-private partnerships are facilitating market entry and driving regional growth.

In summary, the wire trenching machine market in 2026 will be defined by innovation, sustainability, and responsiveness to evolving infrastructure needs. Companies that invest in electric solutions, digital integration, and application-specific designs will be best positioned to capitalize on these dynamic trends.

Common Pitfalls When Sourcing Wire Trenching Machines: Quality and Intellectual Property Concerns

Sourcing wire trenching machines, especially from international or unfamiliar suppliers, carries significant risks related to both product quality and intellectual property (IP) protection. Overlooking these aspects can lead to operational inefficiencies, safety hazards, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Poor Build Quality and Performance Issues

Many low-cost trenching machines suffer from inferior materials and substandard manufacturing processes. Buyers may encounter machines with weak frames, underpowered engines, or poorly designed cutting mechanisms that fail prematurely under normal operating conditions. This results in frequent breakdowns, increased downtime, higher maintenance costs, and reduced project efficiency. Always verify material specifications, conduct factory audits, and request third-party quality inspections before placing bulk orders.

Lack of Safety Features and Non-Compliance

Some sourced machines lack essential safety certifications (such as CE, ANSI, or OSHA compliance) or fail to meet regional safety standards. This not only poses serious risks to operators but can also result in legal liabilities and project shutdowns. Ensure that the supplier provides valid test reports and certification documents, and confirm that the machine complies with the regulations of the target market.

Inadequate After-Sales Support and Spare Parts Availability

Suppliers, particularly those without established service networks, may offer little to no after-sales support. This becomes a critical issue when repairs are needed or spare parts must be replaced. Delays in obtaining compatible parts can halt operations entirely. Prioritize suppliers with documented service agreements, accessible technical support, and a reliable supply chain for spare components.

Counterfeit or IP-Infringing Designs

A major risk when sourcing from certain regions is purchasing machines that copy patented technology or bear counterfeit branding. These machines may replicate the appearance and functionality of well-known brands without proper licensing, exposing the buyer to legal action for using or distributing infringing equipment. Conduct thorough due diligence on the supplier’s design origins and request proof of IP ownership or licensing agreements.

Misrepresentation of Technical Specifications

Some suppliers exaggerate machine capabilities—such as trenching depth, speed, or fuel efficiency—to close sales. This misrepresentation can lead to the purchase of equipment unsuitable for the intended application. Always request real-world performance data, independent reviews, and, if possible, on-site demonstrations before finalizing procurement.

Hidden Costs from Warranty Limitations

While a machine may appear cost-effective upfront, vague or limited warranty terms can lead to unexpected expenses. Some suppliers exclude critical components from coverage or require parts to be returned to their home country for repair. Clarify warranty scope, duration, and support logistics in the contract to avoid financial surprises.

Failure to Protect Your Own IP in Custom Designs

If you’re sourcing custom-designed trenching machines, failing to secure intellectual property rights through proper contracts can result in the supplier replicating and reselling your design to competitors. Use robust Non-Disclosure Agreements (NDAs) and clearly define IP ownership in development agreements to safeguard proprietary innovations.

Avoiding these pitfalls requires a proactive sourcing strategy that emphasizes supplier vetting, legal safeguards, and performance validation. Investing time in due diligence reduces long-term risks and ensures reliable, compliant, and innovative equipment procurement.

Logistics & Compliance Guide for Wire Trenching Machine

Overview

This guide outlines key logistics and compliance considerations for the transportation, operation, and maintenance of a wire trenching machine. Adhering to these guidelines ensures safe deployment, regulatory compliance, and efficient project execution.

Transportation and Logistics Planning

Ensure the wire trenching machine is properly prepared for transport. This includes securing all moving parts, draining or stabilizing fluids if required, and confirming that the machine dimensions and weight comply with road transport regulations. Use certified flatbed trailers with appropriate tie-down points and follow local and international transport laws (e.g., ADR for hazardous materials, if applicable). Coordinate with transport providers experienced in heavy equipment logistics.

Regulatory Compliance

Verify that the machine meets applicable safety and emissions standards in the target region. In the EU, compliance with the Machinery Directive (2006/42/EC) and CE marking is mandatory. In the U.S., adhere to OSHA regulations and ANSI B71.4 standards for trenching equipment. Ensure noise emissions, exhaust standards (e.g., EPA Tier 4), and electrical safety certifications are up to date.

Site Access and Preparation

Assess the job site for accessibility, ground stability, and overhead/underground utility clearances before mobilization. Obtain necessary permits for digging and trenching operations. Confirm that the machine’s size and ground pressure are suitable for the terrain to prevent environmental damage or operational hazards.

Operator Certification and Training

Only trained and certified operators should operate the wire trenching machine. Training must cover equipment-specific controls, emergency procedures, and trenching safety protocols (e.g., preventing cave-ins). Maintain training records and ensure compliance with local labor and safety regulations.

Environmental and Safety Compliance

Implement erosion and sediment control measures during trenching to comply with environmental protection regulations (e.g., EPA Stormwater Pollution Prevention Plan). Conduct routine safety inspections and adhere to lockout/tagout (LOTO) procedures during maintenance. Use personal protective equipment (PPE) as required.

Documentation and Record Keeping

Maintain comprehensive records including equipment manuals, maintenance logs, transport documentation, compliance certificates (e.g., CE, EPA), operator certifications, and incident reports. These documents may be required for audits or regulatory inspections.

Import and Customs Clearance (International Use)

For cross-border operations, ensure compliance with customs regulations. Provide necessary documentation such as commercial invoices, packing lists, certificates of origin, and conformity assessments. Be aware of import duties, taxes, and restrictions on machinery components.

Decommissioning and Return Logistics

Plan for the safe demobilization of the machine at the end of the project. Clean equipment to prevent the spread of invasive species or contaminants, especially when moving between regions. Arrange return transportation following the same compliance and safety standards as initial delivery.

Emergency and Contingency Procedures

Develop a site-specific emergency response plan addressing potential hazards such as utility strikes, equipment failure, or personnel injury. Ensure communication systems are in place and that local emergency services are aware of the equipment on-site.

Conclusion for Sourcing a Wire Trenching Machine:

After a thorough evaluation of project requirements, site conditions, budget constraints, and long-term operational needs, sourcing a wire trenching machine emerges as a strategic and cost-effective solution for efficient cable and utility installation. The machine significantly improves productivity, ensures consistent trench quality, and reduces labor costs and project timelines compared to manual trenching methods.

By selecting a trenching machine with the appropriate cutting depth, width, mobility, and power source—whether hydraulic, gasoline, or electric—organizations can enhance precision and adaptability across various terrains and soil types. Additionally, considering factors such as maintenance requirements, operator safety, and environmental impact ensures sustainable and responsible operations.

Ultimately, investing in the right wire trenching machine not only supports current infrastructure demands but also strengthens scalability and reliability for future projects. Proper supplier vetting, warranty consideration, and training support further ensure long-term success, making the procurement of a trenching machine a valuable step toward operational excellence in utility and telecommunications deployment.