The global demand for physical security solutions has surged in recent years, driven by rising concerns over asset protection, inventory control, and workplace safety across industries such as logistics, warehousing, manufacturing, and retail. According to Grand View Research, the global security market was valued at USD 117.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 9.8% from 2023 to 2030. A key segment within this expanding market is industrial security storage, where wire security cages play a critical role in securing high-value goods and restricting unauthorized access. With increasing investments in warehouse automation and supply chain resilience, the need for durable, customizable, and compliant storage solutions has never been greater. This growth trajectory, supported by ongoing industrialization and regulatory requirements, has fostered a competitive landscape of manufacturers specializing in high-quality wire security cages. Based on performance, innovation, customization capabilities, and market reach, the following nine manufacturers stand out as industry leaders in 2024.

Top 9 Wire Security Cage Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 WireCrafters ®

Domain Est. 1996

Website: wirecrafters.com

Key Highlights: WireCrafters provides our customers with creative solutions for their safety, security, and storage needs, while meeting commitments with exceptional ……

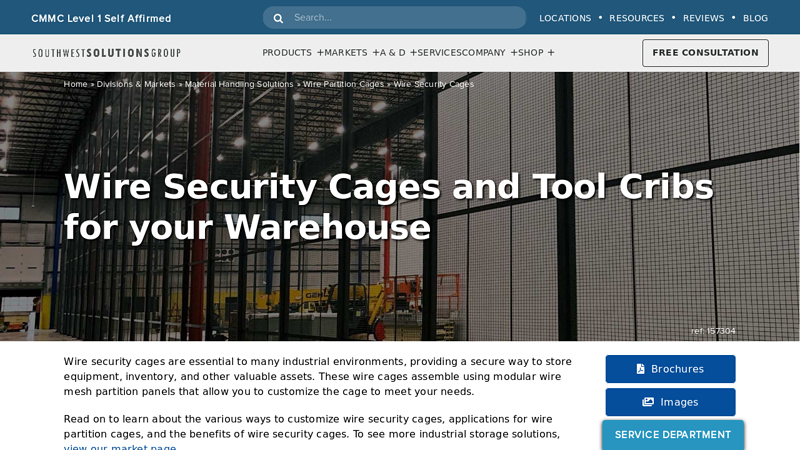

#2 Wire Security Cages

Domain Est. 1997

Website: southwestsolutions.com

Key Highlights: Wire security cages are wire wall panel systems used to secure inventory and valuable items in warehouses and industrial facilities….

#3 Preconfigured Wire Security Rooms

Domain Est. 1997

Website: globalindustrial.com

Key Highlights: Wire security rooms are specialized enclosures designed to provide secure and controlled access areas within industrial and commercial settings….

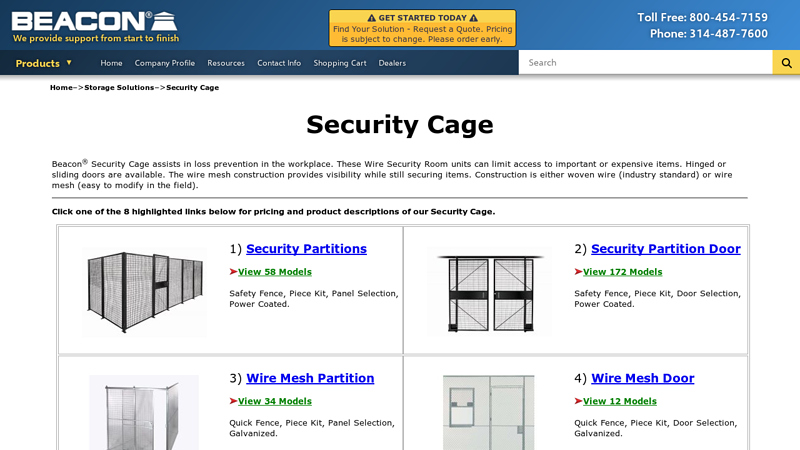

#4 Security Cage

Domain Est. 1998

Website: beacontechnology.com

Key Highlights: Beacon® Security Cage assists in loss prevention in the workplace. These Wire Security Room units can limit access to important or expensive items….

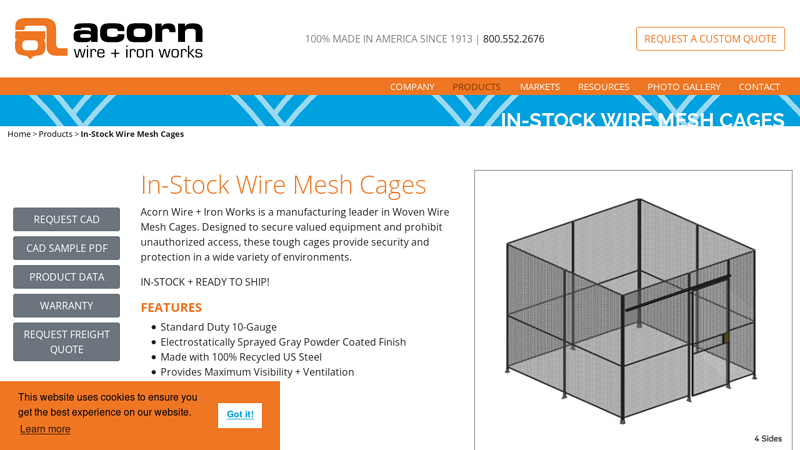

#5 In

Domain Est. 1999

Website: acornwire.com

Key Highlights: Acorn Wire + Iron Works is a manufacturing leader in Woven Wire Mesh Cages. Designed to secure valued equipment and prohibit unauthorized access….

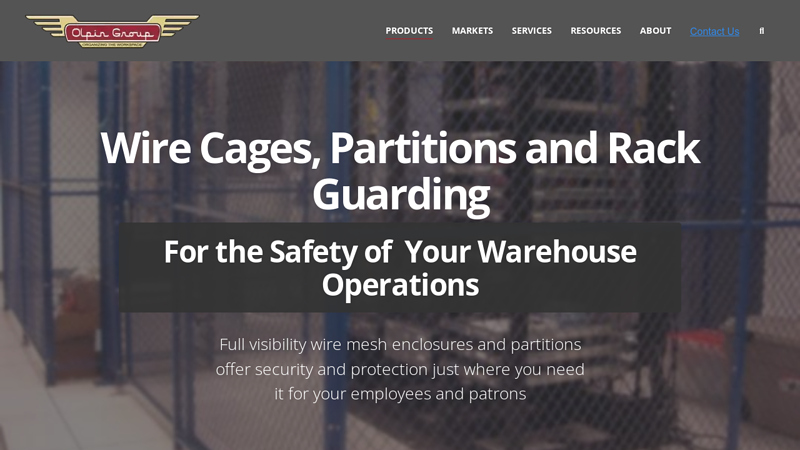

#6 Wire Security Cages Storage

Domain Est. 2004

Website: olpingroup.com

Key Highlights: Wire cages avert theft of equipment, tooling, and finished goods. It’s flexible design allows for multiple configurations to accommodate all types of spaces….

#7 Wire Cages – Security Where You Need it Most

Domain Est. 2004

Website: pattersonpope.com

Key Highlights: Secure gear, tools, and inventory with wire cages—durable, flexible enclosures that bring order and protection to any space….

#8 Custom Wire Security Cages

Domain Est. 2014

Website: apexwireworks.com

Key Highlights: Apex Iron Works’ custom and modular wire mesh security cages help you protect inventory, reduce theft, restrict access in authorized areas, and enhance safety….

#9 Security Caging

Domain Est. 2019

Website: securitycaging.com

Key Highlights: With our modular, customizable security cage system, build wire cages of any size or configuration. Our partitions are fully framed wire mesh panels that bolt ……

Expert Sourcing Insights for Wire Security Cage

2026 Market Trends for Wire Security Cages

The global market for wire security cages is poised for significant evolution by 2026, driven by advancements in materials, increased demand for physical security, and integration with smart technologies. This analysis explores key trends shaping the wire security cage industry in the coming years.

Rising Demand Across Industrial and Commercial Sectors

Wire security cages continue to be essential in warehousing, retail, manufacturing, and logistics. By 2026, the growing need for asset protection, inventory control, and workplace safety is expected to boost demand. E-commerce expansion, in particular, is fueling the construction of new distribution centers where secure storage and segregation of goods using wire cages are standard practice. Additionally, regulatory requirements for safety compliance in industrial environments are reinforcing the adoption of compliant security enclosures.

Technological Integration and Smart Security Solutions

A defining trend by 2026 is the integration of smart technologies into traditional wire cages. Manufacturers are increasingly embedding IoT sensors, access control systems, and RFID tracking within cage structures. These enhancements allow for real-time monitoring, automated inventory tracking, and remote access management. Smart cages connected to centralized security platforms offer improved operational efficiency and reduce the risk of theft or unauthorized access.

Emphasis on Modular and Customizable Designs

Flexibility is becoming a key selling point. Modular wire security cages that can be easily reconfigured or expanded are gaining popularity, especially in dynamic environments like distribution centers and retail backrooms. By 2026, customization—ranging from size and mesh density to anti-climb features and corrosion-resistant finishes—will be a major competitive differentiator. Businesses are seeking solutions tailored to their specific spatial and security needs, driving innovation in design and manufacturing.

Sustainability and Eco-Friendly Materials

Environmental concerns are influencing material choices. Galvanized steel and powder-coated finishes remain dominant due to durability, but there is a growing shift toward recyclable materials and sustainable production methods. By 2026, manufacturers that emphasize low-carbon footprints, recyclability, and longer product lifecycles are expected to gain market share, particularly in regions with strict environmental regulations.

Regional Market Growth and Expansion

While North America and Europe maintain strong demand due to mature logistics and industrial sectors, the Asia-Pacific region is projected to be the fastest-growing market by 2026. Rapid urbanization, infrastructure development, and rising investments in warehousing in countries like India and Vietnam are contributing to increased adoption of wire security cages. Government initiatives to improve supply chain security are further accelerating market penetration.

Competitive Landscape and Innovation

The market is becoming increasingly competitive, with both established manufacturers and new entrants focusing on innovation. Key players are investing in R&D to develop lightweight, high-strength wire cages with improved aesthetics and security features. Partnerships with security technology firms are also emerging, allowing for bundled offerings that combine physical barriers with digital monitoring systems.

Conclusion

By 2026, the wire security cage market will be shaped by a convergence of physical security needs, digital integration, and sustainability. Businesses that adapt to these trends—offering smart, modular, and eco-conscious solutions—will be well-positioned to capture growth in an evolving global landscape.

Common Pitfalls When Sourcing Wire Security Cages (Quality and Intellectual Property)

Logistics & Compliance Guide for Wire Security Cage

This guide outlines the essential logistics considerations and compliance requirements for the safe, efficient, and lawful handling, transportation, and installation of Wire Security Cages. Adherence to these guidelines ensures product integrity, worker safety, and regulatory compliance throughout the supply chain.

Product Handling and Storage

Wire Security Cages must be handled with care to prevent deformation, damage to protective coatings, or safety hazards. Always lift using appropriate slings or forklift attachments under the base frame—not by the mesh panels. Store cages on flat, level surfaces indoors or under protective cover to avoid moisture exposure, which can lead to rust or corrosion, especially for non-galvanized or coated models. Stack only if designed for multi-level stacking and use protective spacers to prevent abrasion between units.

Transportation Requirements

Secure Wire Security Cages firmly to transport vehicles using straps, chains, or load-locking systems to prevent shifting during transit. Overhang beyond the vehicle bed must comply with local transportation regulations (e.g., marking with flags or lights if exceeding limits). Ensure loads are evenly distributed and do not exceed axle weight limits. Use edge protectors to prevent strap damage to cage coatings. For international shipments, comply with International Maritime Dangerous Goods (IMDG) Code if applicable, though standard wire cages typically are non-hazardous.

Packaging and Labeling

Wire Security Cages are often shipped in flat-pack or pre-assembled configurations. All components must be securely bundled and protected with corner guards, plastic wrap, or wooden skids. Clearly label each package with: product name, model number, quantity, weight, handling instructions (e.g., “This Side Up”, “Forklift Only”), and any hazardous material warnings if coatings contain regulated substances. Include compliance marks such as CE, UKCA, or others as applicable based on destination market.

Regulatory Compliance

Wire Security Cages must meet relevant safety and construction standards depending on jurisdiction and application. In the European Union, compliance with EN 13201 (luminaires) or EN 12600 (impact resistance) may apply if used in public or high-risk areas. In the United States, adherence to OSHA standards for workplace safety (29 CFR 1910) and IBC (International Building Code) for structural installations is required. Verify local fire codes, especially if cages enclose electrical equipment or restrict emergency egress.

Installation and Site Safety

Installation must follow manufacturer instructions and be performed by trained personnel using appropriate PPE. Ensure anchoring to floors or walls meets load-bearing requirements and uses approved fasteners. Confirm that cages do not obstruct emergency exits, fire sprinklers, or safety signage. Post-installation, conduct a safety inspection to verify structural integrity, proper grounding (if electrically conductive), and compliance with site-specific safety protocols.

Documentation and Certification

Maintain all compliance documentation, including test reports, material safety data sheets (MSDS), CE/UKCA declarations of conformity, and installation certifications. Provide end-users with operation and maintenance manuals, including inspection schedules and replacement guidelines. Keep records for traceability and audit purposes, particularly in regulated environments such as pharmaceuticals, aerospace, or government facilities.

Environmental and Disposal Considerations

Wire Security Cages are typically fabricated from recyclable steel or aluminum. At end-of-life, disassemble and segregate materials for proper recycling in accordance with local waste management regulations (e.g., WEEE or ELV directives in the EU). Avoid open burning or landfill disposal where recycling is available. Coatings or surface treatments may require special handling—consult local environmental agencies for disposal guidelines.

Conclusion for Sourcing Wire Security Cages:

In conclusion, sourcing wire security cages requires a strategic approach that balances durability, security, cost-efficiency, and compliance with industry standards. After evaluating various suppliers, materials, and design specifications, it is evident that selecting high-quality, tamper-resistant wire cages from reputable manufacturers ensures long-term protection of assets, operational efficiency, and safety. Key considerations such as galvanized or powder-coated finishes, appropriate mesh size, secure locking mechanisms, and customizability should guide procurement decisions. Additionally, building strong relationships with reliable suppliers who offer warranty support and on-time delivery enhances supply chain reliability. By prioritizing these factors, organizations can effectively secure valuable inventory, tools, or equipment while optimizing total cost of ownership and maintaining a safe working environment.