The global wire rope clamp market is experiencing steady growth, driven by rising demand across construction, maritime, oil & gas, and material handling industries. According to Mordor Intelligence, the wire rope market—which includes complementary components like clamps—is projected to grow at a CAGR of over 5.8% from 2024 to 2029. Similarly, Grand View Research reports that the industrial fasteners market, a broader segment encompassing wire rope clamps, is expected to expand at a CAGR of 5.6% during the same period, underpinned by increasing infrastructure development and industrial automation worldwide. With stringent safety standards and performance expectations shaping procurement decisions, identifying reliable manufacturers has become critical for end-users. This list highlights the top 10 wire rope clamp manufacturers recognized for product quality, innovation, global reach, and compliance with international standards such as ISO, ASME, and DIN.

Top 10 Wire Rope Clamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire Rope Clips

Domain Est. 2018

Website: baronhardware.com

Key Highlights: Wire Rope Clips … We are a manufacturer and distributor of industrial snaps and all types of connecting products and accessories meeting global quality ……

#2 to Loos & Co., Inc.

Domain Est. 1997

Website: loosco.com

Key Highlights: A recognized leader in the field of Mil-Spec hardware and wire rope fittings, our CNC parts supply to most major distributors and industries around the globe….

#3 Industrial Wire Rope Supply

Domain Est. 1997

Website: industrialrope.com

Key Highlights: Founded in the 1800s, our family-owned business provides Wire Rope, Wire Rope Fittings, Fiber Rope, Chain, Nylon Slings, and Wire Rope ……

#4 Wire Rope Clip

Domain Est. 1998

Website: suncorstainless.com

Key Highlights: This wire clip is precision cast and made from grade 304 stainless steel for maximum corrosion resistance and durability. It is ideal for marine and industrial ……

#5 Malleable Wire Rope Clips On Lexco Cable Manufacturers

Domain Est. 2002

Website: catalog.lexcocable.com

Key Highlights: Browse Malleable Wire Rope Clips in the Lexco Cable Manufacturers catalog including Item #,Name,To Fit Wire Rope Dia (in),Wt/100 pcs (lbs),Minimum Clips ……

#6 Wire Rope Clips and Cable Clamps

Domain Est. 2021

#7 Wire Rope Clips

Domain Est. 1995

Website: hubbell.com

Key Highlights: 30-day returnsDiscover our selection of Wire Rope Clips. Our product experts are here to assist you. Get in touch with our team now….

#8 Unirope

Domain Est. 1997

Website: unirope.com

Key Highlights: Unirope supplies superior wire rope and rigging products to the construction, automotive, and steel industries. ISO 9001-certified quality proudly serving ……

#9 Select™ Cable Clamps (Wire Rope Clips)

Domain Est. 2003

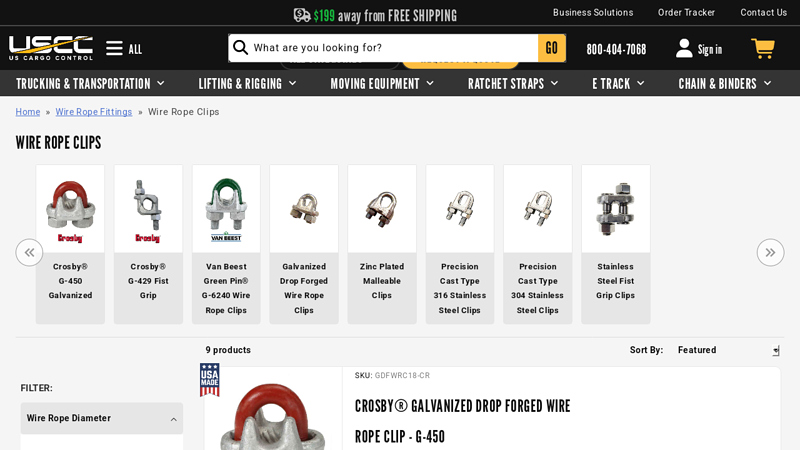

#10 Wire Rope Clips / Clamps

Domain Est. 2005

Website: uscargocontrol.com

Key Highlights: Free delivery over $199 60-day returnsUS Cargo Control offers a wide selection of galvanized, stainless steel, zinc & malleable wire rope clips / wire rope clamps for rigging jobs….

Expert Sourcing Insights for Wire Rope Clamp

H2: 2026 Market Trends for Wire Rope Clamps

The wire rope clamp market in 2026 is poised for steady growth, driven by sustained demand in core industries, evolving safety standards, and technological advancements. While not a rapidly disruptive sector, key trends are shaping its trajectory:

1. Steady Growth Driven by Industrial & Infrastructure Expansion:

Global investment in infrastructure (bridges, ports, energy projects) and continued activity in oil & gas, mining, and construction will underpin demand. Emerging economies, particularly in Asia-Pacific and Africa, will be significant growth drivers as they expand industrial capacity and transportation networks. The recovery and modernization of aging infrastructure in developed regions will also contribute to replacement demand.

2. Heightened Focus on Safety and Compliance:

Regulatory bodies (OSHA, ISO, national standards) are continuously emphasizing workplace safety. This drives demand for high-quality, certified wire rope clamps made from superior materials (e.g., forged steel, stainless steel) and manufactured to strict tolerances. End-users are increasingly prioritizing clamps with clear identification, traceability (batch/lot numbers), and documented compliance to meet stringent safety audits and insurance requirements, reducing liability.

3. Material Innovation and Corrosion Resistance:

Demand for corrosion-resistant solutions will grow, especially in marine, offshore, chemical processing, and coastal environments. This fuels the adoption of:

* Stainless Steel Clamps (304, 316): Dominant for superior corrosion resistance.

* Enhanced Coatings: Improved galvanization (e.g., hot-dip galvanized with thicker coatings) and specialized protective coatings for carbon steel clamps in less severe corrosive environments.

* Material Optimization: Development of high-strength, lightweight alloys remains a niche but potential area.

4. Shift Towards Value-Added Solutions and Branding:

The market is moving beyond commoditization. Leading manufacturers are differentiating through:

* Value-Added Services: Offering technical support, installation training, inspection guidelines, and customized solutions.

* Brand Trust: Establishing reputations for reliability, safety, and quality assurance.

* Product Differentiation: Introducing ergonomic designs, easier installation features, or specialized clamp types for specific applications.

5. Supply Chain Resilience and Regional Manufacturing:

Geopolitical tensions and past disruptions have prompted a focus on supply chain diversification. While China remains a major manufacturer, there’s a noticeable trend towards nearshoring or friend-shoring, particularly in North America and Europe. This aims to reduce lead times, mitigate risks, and ensure more reliable access to critical safety components, potentially benefiting regional manufacturers.

6. Digitalization and Traceability:

While not pervasive, the trend towards digitalization in industrial supply chains is impacting wire rope clamps. Implementing batch/lot tracking, QR codes linking to certificates of conformity (CoC), and digital inventory management systems is becoming more common for quality control and compliance, especially in regulated industries.

Conclusion:

The 2026 wire rope clamp market will be characterized by stable growth anchored in essential industrial needs, a paramount emphasis on safety and compliance, and increasing demand for higher-quality, corrosion-resistant materials. Success will favor manufacturers offering certified, reliable products supported by technical expertise and robust, resilient supply chains, moving beyond a purely price-based competition.

Common Pitfalls When Sourcing Wire Rope Clamps (Quality, IP)

Sourcing wire rope clamps involves critical considerations around quality and intellectual property (IP) that can significantly impact safety, performance, and legal compliance. Overlooking these aspects can lead to equipment failure, project delays, and legal disputes. Below are common pitfalls in both quality and IP domains:

Quality-Related Pitfalls

1. Prioritizing Low Cost Over Certified Quality

Choosing the cheapest available clamps often leads to substandard materials and poor manufacturing. Low-cost clamps may use inferior steel, lack proper heat treatment, or have inconsistent thread quality, increasing the risk of clamp slippage or failure under load.

2. Absence of Recognized Certifications

Failing to verify certifications such as ISO 9001, CE marking, or compliance with standards like ASME B30.26 or EN 13411-3 can result in non-compliant products. Without third-party validation, there’s no assurance of performance or safety under operational conditions.

3. Inconsistent Manufacturing Tolerances

Poorly manufactured clamps may have mismatched saddle and U-bolt dimensions, leading to uneven load distribution and premature wear. Inconsistent threading can also make installation difficult and compromise grip strength.

4. Inadequate Corrosion Resistance for Environment

Using standard carbon steel clamps in corrosive environments (e.g., marine or chemical settings) without specifying galvanized or stainless-steel variants leads to rapid degradation and reduced service life.

5. Lack of Traceability and Documentation

Suppliers who cannot provide mill test reports, material certifications, or batch traceability make it difficult to verify quality or conduct root cause analysis in case of failure.

IP-Related Pitfalls

1. Sourcing Counterfeit or IP-Infringing Products

Purchasing clamps that mimic well-known branded designs (e.g., Yale, Crosby) without authorization violates trademark and design patents. This exposes buyers to legal liability, seizure of goods, and reputational damage.

2. Unlicensed Use of Proprietary Designs

Some clamp designs (e.g., dual-saddle clamps or specific safety mechanisms) are protected by utility patents. Using generic versions that replicate these features without licensing can result in infringement claims.

3. Ambiguous Supplier IP Agreements

Failing to clarify IP ownership in supplier contracts—especially when customizing clamps—can lead to disputes over design rights, reverse engineering, or unauthorized resale of proprietary specifications.

4. Ignoring Regional IP Enforcement Variability

Sourcing from regions with lax IP enforcement increases the risk of receiving counterfeit or copied products, even if the supplier appears legitimate. This undermines safety and legal compliance.

5. Overlooking Design Rights in Private Labeling

When branding generic clamps under a private label, companies may inadvertently use designs protected by third-party IP, leading to potential litigation if the original design is patented or trademarked.

Avoiding these pitfalls requires due diligence in supplier vetting, verification of certifications, clear contractual terms, and awareness of both technical standards and intellectual property rights.

Logistics & Compliance Guide for Wire Rope Clamps

Product Overview

Wire rope clamps are essential hardware components used to secure the ends of wire ropes, forming eyes or loops, and ensuring load integrity in lifting, rigging, and tensioning applications. Proper logistics handling and regulatory compliance are critical to ensure safety, performance, and legal adherence.

International Shipping & Handling

- Packaging Requirements: Wire rope clamps must be packed in moisture-resistant, durable containers (e.g., sealed plastic bags inside corrugated cardboard or wooden crates) to prevent corrosion during transit.

- Labeling: Packages should be clearly labeled with product name, size, material grade, quantity, batch/lot number, and handling instructions (e.g., “Protect from Moisture,” “Do Not Drop”).

- Hazard Classification: Wire rope clamps are generally non-hazardous and not subject to dangerous goods regulations (e.g., IATA, IMDG) unless coated with hazardous substances. Confirm material safety data sheets (MSDS/SDS) for coatings or platings.

- Export Documentation: Include commercial invoice, packing list, and bill of lading. For regulated markets, provide a certificate of origin and conformity documentation.

Regulatory Compliance

- Material Standards: Ensure clamps comply with recognized international standards such as:

- ASTM A474 (Standard Specification for Carbon Steel Wire Rope Clips)

- ASME B30.26 (Rigging Hardware)

- ISO 492:2014 (Steel wire rope fittings — U-bolt type rope clamps)

- Load Certification: Provide load test certificates where required, especially for lifting applications. Proof load testing should be documented per ASME or ISO requirements.

- CE Marking (EU): For sale in the European Union, wire rope clamps used in lifting equipment must comply with the Machinery Directive (2006/42/EC) or Lifts Directive (2014/33/EU), requiring CE marking and a Declaration of Conformity.

- UKCA Marking (UK): Post-Brexit, UKCA marking may be required for sale in Great Britain. Verify current UK regulations.

- OSHA & ANSI (USA): In the U.S., compliance with OSHA 1910.184 (Ropes) and ANSI/ASME B30.26 is mandatory for rigging hardware safety.

Import Requirements by Region

- United States: No import license required for standard wire rope clamps. However, ensure compliance with Customs and Border Protection (CBP) regulations and provide Harmonized System (HS) code 7312.90.90 (Other articles of iron or steel used for ropes).

- European Union: Subject to CE marking and conformity assessment. Importers must verify compliance with EU Construction Products Regulation (CPR) if used in construction applications.

- Canada: Comply with Canadian Standards Association (CSA) Z243.200-16 (Rigging Equipment) and provide documentation for Canada Border Services Agency (CBSA).

- Australia: Must meet AS 3569.0 (Mechanical properties and dimensions of steel bolts and nuts) and be registered in the Australian Building Codes Board (ABCB) system if used in structural applications.

Storage & Inventory Management

- Environmental Conditions: Store in a dry, indoor environment to prevent rust and degradation. Avoid exposure to saltwater, chemicals, or high humidity.

- Shelf Life: While metal clamps have a long shelf life, inspect periodically for corrosion, thread damage, or deformation before use.

- Traceability: Maintain batch-level traceability through inventory systems to support recalls or audits.

Quality Assurance & Documentation

- Inspection Protocols: Conduct incoming and outgoing inspections per ISO 2859 (Sampling procedures for inspection by attributes).

- Mill Test Reports (MTRs): Provide MTRs for raw materials (e.g., carbon steel, stainless steel) to verify chemical composition and mechanical properties.

- Compliance Certificates: Offer certificates of compliance (CoC) confirming adherence to applicable standards upon request.

Safety & End-User Compliance

- Installation Guidelines: Include clear instructions for correct installation (e.g., proper torque, orientation of the U-bolt, minimum number of clamps per diameter).

- Training & Warnings: Distribute safety warnings—improper use can lead to catastrophic failure. Recommend use only by qualified personnel following OSHA or equivalent safety practices.

- Recall Preparedness: Maintain a product recall plan in accordance with regional regulatory requirements (e.g., EU RAPEX, U.S. CPSC coordination if applicable).

Sustainability & Environmental Compliance

- RoHS & REACH (EU): Confirm that clamps (especially plated or coated versions) comply with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations.

- Waste Management: Provide guidance on end-of-life disposal. Steel clamps are recyclable; advise users to follow local scrap metal recycling protocols.

Summary

Proper logistics and compliance management for wire rope clamps involves adherence to international standards, accurate documentation, safe handling, and regional regulatory alignment. Ensuring product conformity and traceability supports safety, legal compliance, and customer trust across global supply chains.

Conclusion for Sourcing Wire Rope Clamps:

Sourcing wire rope clamps requires careful consideration of quality, specifications, supplier reliability, and compliance with industry standards such as ISO, ASME, or OSHA. These clamps play a critical role in ensuring the safety and integrity of wire rope assemblies in lifting, rigging, and structural applications. Selecting the right clamp—based on material (typically forged steel or stainless steel), size compatibility, and mechanical strength—is essential to prevent failures and maintain operational safety.

It is advisable to partner with reputable suppliers who provide certified products, consistent quality control, and technical support. Evaluating cost-effectiveness should not compromise safety; therefore, the lowest price should not be the sole deciding factor. Implementing a structured sourcing process that includes supplier audits, product testing, and long-term performance monitoring will help ensure reliable and safe operations. In conclusion, a strategic and safety-driven approach to sourcing wire rope clamps is vital for both operational efficiency and workplace safety.