The global wire nail making machine market is experiencing steady growth, driven by rising construction activities and infrastructure development worldwide. According to a report by Grand View Research, the global construction machinery market was valued at USD 168.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, with demand for fasteners and related manufacturing equipment playing a critical supporting role. Additionally, Mordor Intelligence projects the industrial machinery market in construction to grow significantly, citing increasing automation and demand for cost-efficient production methods in manufacturing fasteners. As one of the essential components in this ecosystem, wire nail machines are witnessing enhanced innovation and efficiency improvements from leading manufacturers. In this evolving landscape, selecting the right machinery partner is crucial for producers aiming to scale output, maintain quality, and reduce operational costs. Below, we spotlight the top 9 wire nail machine manufacturers shaping the industry through technological advancement, reliability, and global reach.

Top 9 Wire Nails Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Zeus Techno

Domain Est. 2001

Website: zeus-techno.com

Key Highlights: Producer of the smart, fast and reliable Wire Nail Making Machines with Manufacturing Execution System, including Wire Welding Collators and Thread Rollers….

#2 Wire Nail Making Machine Manufacturer In India

Domain Est. 2010

Website: ektanailmachine.com

Key Highlights: We are known for highly reliable, high-speed, low maintenance, easy to operate wire nail and wire drawing machine as well as ancillary machineries for Wire ……

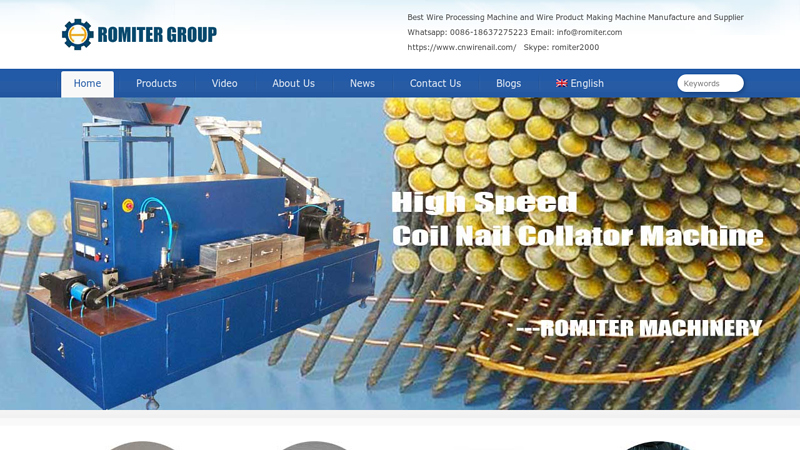

#3 Nail Machine, Nail Making Machine, Wire Drawing Machine

Domain Est. 2014

Website: cnwirenail.com

Key Highlights: Our Nail Making Machine adopts advanced technology and is able to produce both common steel nails and special shaped steel nail. Our Wire Mesh Welding Machine ……

#4 Gujarat Wire Products

Domain Est. 2015

Website: gujratwireproducts.com

Key Highlights: Heavy duty high speed nail making machine in GUJARAT · Rs 17,00,000 / Piece · Automatic High Speed Nail Making Machine N3 In Ladakh · Rs 3,90,000 / Piece….

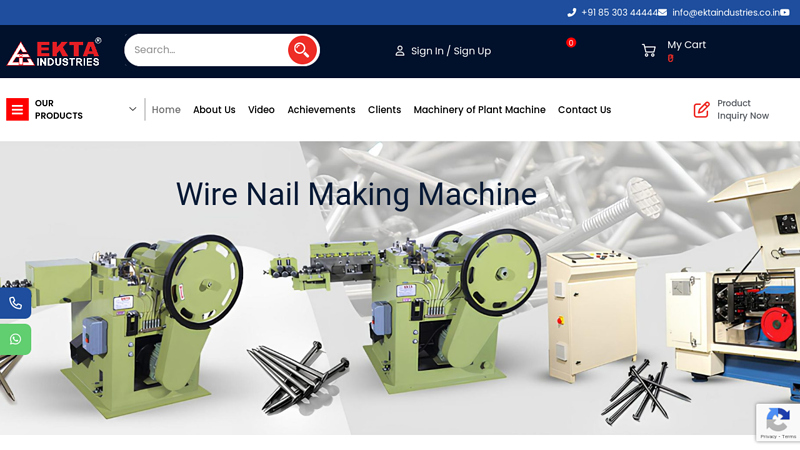

#5 Ekta Industries

Domain Est. 2018

Website: ektawirenailmachine.com

Key Highlights: Ekta Industries offers a wide and impressive range of High Speed Wire Nail Making Machine Hs-90, we Are manufacturer of wire nail making machine model EI-N25, ……

#6 Super Nail Machine

Domain Est. 2019

Website: supernailmachine.com

Key Highlights: Welcome To Super Nail Machine We manufacture, supply and export Wire Nail Making Machine, Polishing Barrel Drum, Automatic Cutter Grinder Machine, Wire Nail ……

#7 World Leading Nail Manufacturing Solutions

Domain Est. 1998

Website: enkotec.com

Key Highlights: World Leading supplier of wire nail manufacturing solutions. High-speed operations and high-quality output have defined ENKOTEC for over 40 years….

#8 Automatic Wire Nail Making Machine

Domain Est. 2008

Website: gujaratwireproducts.com

Key Highlights: Gujarat Wire Products excels in manufacturing Automatic Wire Nail Making Machines. These machines are designed for efficient and reliable nail ……

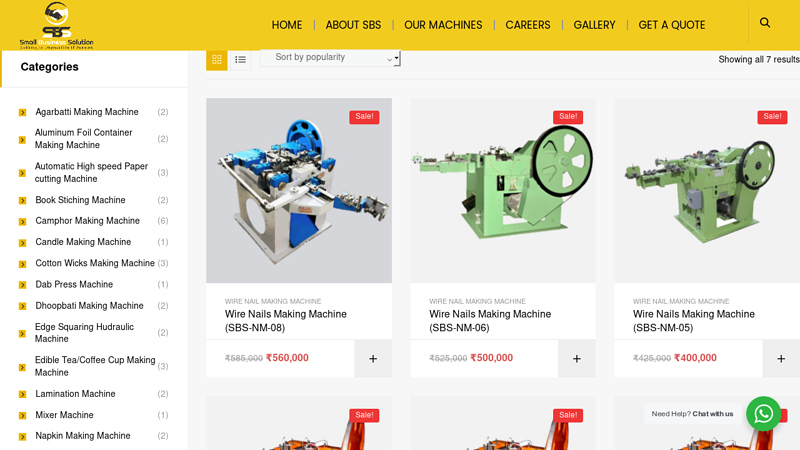

#9 Wire Nail Making Machine

Domain Est. 2013

Website: sbscompany.in

Key Highlights: ₹585,000 Original price was: ₹585,000. ₹560,000 Current price is: ₹560,000. Quick view. Add to wishlist. Compare. Get Best Price. Sale! Wire Nails Making ……

Expert Sourcing Insights for Wire Nails Machine

H2: 2026 Market Trends for Wire Nails Machines

The global wire nails machine market in 2026 is poised for steady growth, driven by construction expansion, infrastructure development, and advancements in manufacturing technology. Key trends shaping the industry include:

1. Rising Demand from Construction and Infrastructure Sectors

The primary driver for wire nails machines remains the global construction industry. Urbanization, housing projects, and government-backed infrastructure initiatives—especially in Asia-Pacific, Africa, and Latin America—are increasing the demand for fasteners. As a result, manufacturers are investing in efficient, high-capacity wire nail machines to meet growing output needs.

2. Technological Advancements and Automation

By 2026, automation and smart manufacturing are central to wire nail machine design. Machines with integrated PLC controls, IoT-enabled monitoring, and self-diagnostic features are becoming standard. These technologies improve precision, reduce downtime, and lower labor costs, making automated systems increasingly attractive to mid- and large-scale producers.

3. Shift Toward Energy Efficiency and Sustainability

Environmental regulations and rising energy costs are pushing manufacturers to adopt energy-efficient machines. In 2026, wire nails machine producers are focusing on reducing power consumption, minimizing material waste, and using recyclable components. This trend aligns with broader sustainability goals across the manufacturing sector.

4. Regional Market Diversification

While China remains a dominant manufacturer and exporter of wire nails machines, other regions—such as India, Turkey, and Mexico—are emerging as competitive production hubs. Localized manufacturing supports supply chain resilience and reduces dependency on imports, particularly in developing economies with growing construction demand.

5. Customization and Multi-Functionality

Demand for customized nail types (e.g., ring shank, screw nails, specialized coatings) is increasing. Modern wire nail machines are being designed with modular tooling and adjustable settings to produce diverse nail specifications on a single platform, offering greater flexibility to producers.

6. Competitive Pricing and Market Consolidation

Intense competition is driving innovation and cost reductions. Smaller manufacturers are either forming alliances or being acquired by larger players to scale up production and enhance R&D capabilities. This consolidation is expected to streamline the market and improve product quality.

7. Digital Integration and Industry 4.0 Adoption

Leading wire nails machine manufacturers are embracing Industry 4.0 principles. Features such as remote monitoring, predictive maintenance, and data analytics are being integrated into machine systems, enabling real-time performance tracking and improved operational efficiency.

In summary, the 2026 wire nails machine market reflects a transformation toward smarter, greener, and more adaptable manufacturing solutions. Companies that prioritize innovation, sustainability, and regional market responsiveness are likely to lead the evolving landscape.

Common Pitfalls When Sourcing Wire Nails Machines (Quality and Intellectual Property)

Sourcing a Wire Nails Machine from international suppliers—particularly from regions with less stringent manufacturing oversight—can present significant risks. Overlooking key factors related to quality and intellectual property (IP) can lead to costly delays, substandard production, legal disputes, and reputational damage. Below are common pitfalls to avoid:

Inadequate Quality Verification

Many buyers rely solely on supplier claims or online catalogs without conducting thorough due diligence. Machines may appear identical on paper, but build quality, material specifications, and component reliability vary widely. Poorly manufactured machines often suffer from frequent breakdowns, inconsistent nail output, and high maintenance costs.

Lack of On-Site Factory Audits

Skipping on-site inspections or third-party quality checks increases the risk of receiving counterfeit or reconditioned equipment sold as new. Without witnessing the machine in operation or verifying the production environment, buyers cannot assess true craftsmanship or adherence to international standards.

Ignoring Component Quality

The performance of a wire nail machine depends heavily on critical components like motors, bearings, cutting dies, and control systems. Suppliers may cut costs by using inferior or unbranded parts, leading to premature wear and reduced machine lifespan. Always verify the brand and origin of major components.

Overlooking Technical Documentation and Standards Compliance

Suppliers may not provide comprehensive manuals, electrical schematics, or safety certifications (e.g., CE, ISO). Lack of proper documentation impedes installation, troubleshooting, and compliance with local regulations, potentially resulting in operational delays or legal issues.

Intellectual Property (IP) Infringement Risks

Many low-cost machines on the market are direct copies of patented designs from reputable manufacturers. Purchasing such machines can expose buyers to IP litigation, especially if the machines are imported into countries with strong IP enforcement. Even unintentional use of infringing equipment may result in fines or seizure of assets.

No IP Warranty or Legal Protection

Suppliers in some jurisdictions rarely offer IP indemnity clauses in contracts. Without contractual protection, buyers assume full liability for any IP violations, leaving them vulnerable to claims from original equipment manufacturers (OEMs).

Poor After-Sales Support and Spare Parts Availability

Low-cost machines often come with limited or no after-sales service. When breakdowns occur, sourcing genuine spare parts becomes difficult and expensive. Some suppliers vanish after delivery, leaving buyers stranded without technical support or training.

Misleading Performance Claims

Suppliers may exaggerate production capacity, nail size range, or automation levels. Without verified test reports or live demonstrations, buyers risk investing in machines that fail to meet production requirements.

Currency and Payment Risks

Advancing large payments without escrow or milestone-based release increases financial exposure. If the machine fails to meet specifications or is never delivered, recovering funds can be extremely difficult, especially across borders.

Failure to Conduct Background Checks on Suppliers

Not verifying a supplier’s legitimacy, business history, or customer references can result in dealing with fraudulent entities or intermediaries with no real manufacturing capability. Use trade verification services and request proof of past installations.

To mitigate these risks, always prioritize transparency, conduct technical due diligence, insist on IP compliance, and use secure payment methods. Engaging a local agent or sourcing partner with industry expertise can significantly improve sourcing outcomes.

Logistics & Compliance Guide for Wire Nails Machine

Overview

This guide outlines the essential logistics and compliance considerations for the international shipment, import, and operation of a Wire Nails Machine. Adhering to these guidelines ensures smooth transit, regulatory compliance, and operational safety.

Packaging and Handling

Proper packaging is critical to prevent damage during transit.

– Securely crate the machine using wooden or metal-reinforced packaging.

– Use anti-vibration mounts and protective padding to safeguard sensitive components.

– Clearly label packages with “Fragile,” “This Side Up,” and handling instructions.

– Include lifting points in the design for safe loading/unloading using forklifts or cranes.

Transportation Modes

Select the most suitable transport method based on destination, cost, and delivery time.

– Sea Freight: Ideal for heavy machinery; use Full Container Load (FCL) or Roll-on/Roll-off (RoRo) as appropriate.

– Air Freight: Faster but costly; suitable for urgent, lightweight components.

– Land Transport: Use flatbed trucks for domestic or regional movement; ensure route compatibility with machine dimensions and weight.

Export Documentation

Accurate documentation ensures customs clearance and legal compliance.

– Commercial Invoice

– Packing List

– Bill of Lading (for sea) or Air Waybill (for air)

– Certificate of Origin

– Export License (if required by the exporting country)

– Technical specifications and HS code (typically 8462.21 or 8462.29 for mechanical forming machines)

Import Regulations

Comply with the destination country’s import requirements.

– Verify applicable tariffs and import duties using the correct HS code.

– Obtain necessary import permits or licenses.

– Confirm compliance with local industrial safety and environmental standards.

– Some countries may require pre-shipment inspection certificates.

Customs Clearance

Facilitate smooth customs processing.

– Submit complete documentation in advance.

– Appoint a licensed customs broker in the destination country.

– Be prepared for possible physical inspection of the machine.

– Pay all assessed duties and taxes promptly.

Electrical and Safety Compliance

Ensure the machine meets regional safety and electrical standards.

– Confirm voltage, frequency, and plug compatibility (e.g., 220V/50Hz vs. 110V/60Hz).

– Provide CE marking (for EU), UKCA (for UK), or UL/cUL certification (for North America) as required.

– Include safety manuals, emergency stop diagrams, and protective device specifications.

Installation and On-Site Compliance

Prepare for safe setup and operation.

– Ensure site meets machine foundation, ventilation, and power supply requirements.

– Follow manufacturer’s installation guidelines and involve certified technicians.

– Conduct risk assessments and comply with local occupational health and safety regulations (e.g., OSHA in the U.S., HSE in the UK).

– Train operators on safe usage and maintenance procedures.

After-Sales and Warranty Considerations

Support compliance throughout the machine lifecycle.

– Provide multilingual user manuals and maintenance guides.

– Ensure spare parts availability and service support in the destination region.

– Maintain records for warranty claims and regulatory audits.

Environmental and Disposal Regulations

Adhere to environmental standards during operation and end-of-life.

– Follow local rules for oil, lubricant, and metal waste disposal.

– Comply with WEEE (Waste Electrical and Electronic Equipment) directives if applicable.

– Consider recycling or refurbishment options for decommissioned machines.

Conclusion

Effective logistics planning and strict compliance with international and local regulations are essential for the successful delivery and operation of a Wire Nails Machine. Partner with experienced freight forwarders, customs brokers, and technical consultants to ensure all requirements are met efficiently and safely.

Conclusion for Sourcing a Wire Nails Machine:

Sourcing a wire nail making machine is a strategic investment that significantly impacts production efficiency, product quality, and long-term profitability. After evaluating various suppliers, machine specifications, automation levels, and after-sales support, it is clear that selecting the right machine requires a balance between initial cost and long-term reliability. Machines from reputable manufacturers offering advanced automation, durable construction, and proven performance deliver better return on investment through consistent output, reduced downtime, and lower maintenance costs.

Furthermore, considerations such as raw material compatibility, nail size range, production speed, and ease of operation should align with specific business needs. Partnering with a supplier that provides technical training, spare parts availability, and responsive customer service ensures smooth integration and sustained operation.

In conclusion, a well-researched and thoughtful procurement process will lead to the acquisition of a high-performance wire nail machine that enhances productivity, meets market demands, and positions the business for scalable growth in the competitive fastener industry.