The global wire markers market is experiencing steady growth, driven by increasing demand for cable management solutions across industrial, automotive, and electrical infrastructure sectors. According to Mordor Intelligence, the Electrical Markers market is projected to grow at a CAGR of over 5.2% during the forecast period of 2023–2028, fueled by rising investments in smart infrastructure and stringent regulatory requirements for electrical safety and labeling. Similarly, Grand View Research estimates that the broader cable management systems market, which includes wire markers, was valued at USD 12.7 billion in 2022 and is expected to expand at a CAGR of 7.1% from 2023 to 2030, underpinned by advancements in industrial automation and data center development. As reliability and traceability in electrical systems become critical, wire markers play an essential role in ensuring operational safety and maintenance efficiency. This growing demand has fostered a competitive landscape, with key manufacturers innovating in materials, durability, and labeling technology. Below are the top 10 wire markers manufacturers shaping the industry through product excellence, global reach, and technological advancement.

Top 10 Wire Markers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cable Markers Company

Domain Est. 1997

Website: cablemarkers.com

Key Highlights: Cable Markers Co., Inc. is a full service provider of industrial and commercial ID Products. We do it all! Everything from heat-shrinkable tubing, cable and ……

#2 Marking Services, Inc.

Domain Est. 1997

Website: markserv.com

Key Highlights: We have all the products to meet your electrical labeling needs including conduit & cable markers, wire labels, arc flash labels, switch plates, and more….

#3 Markers and cable management

Domain Est. 1999

Website: partex.nu

Key Highlights: At Partex we lead the world in industrial marking systems. We manufacture products for the identification of wires, cables, pipes and components….

#4 Homepage

Domain Est. 2000

Website: spectrumtech.com

Key Highlights: Spectrum Technologies is the world leader in laser wire marking and stripping technology for use in the manufacture of complex wire and cable harnesses….

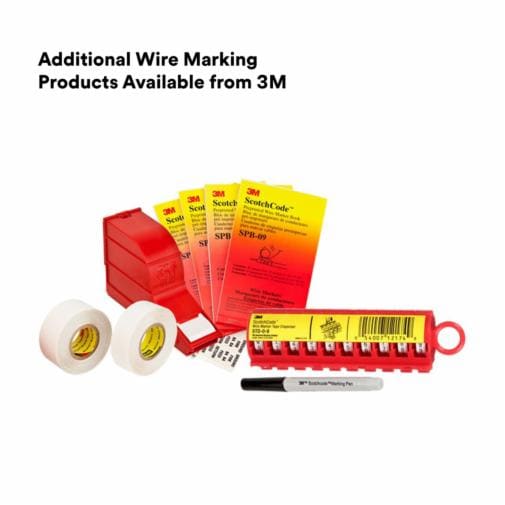

#5 3M Wire Markers

Domain Est. 1988

Website: 3m.com

Key Highlights: Products used for identification of wires and components….

#6 Cable markers and conductor markers

Domain Est. 1996

Website: weidmuller.com

Key Highlights: At Weidmüller, you will find a large selection of conductor and cable markers for marking cables, conductors and wires….

#7 Wire Labels and Cable Labels

Domain Est. 1998

Website: bradyid.com

Key Highlights: 1-day deliveryChoose from Brady’s variety of wire labels and cable labels to suit your identification needs, including self-laminating, heat shrink, wrap ……

#8 Wire and Cable Markers

Domain Est. 1998

Website: hellermanntyton.com

Key Highlights: Wire and Cable Markers: 4171 products in various materials ✓ Cable tags ✓ Heat shrink wire labels ✓ Cable markers ✓ Discover now!…

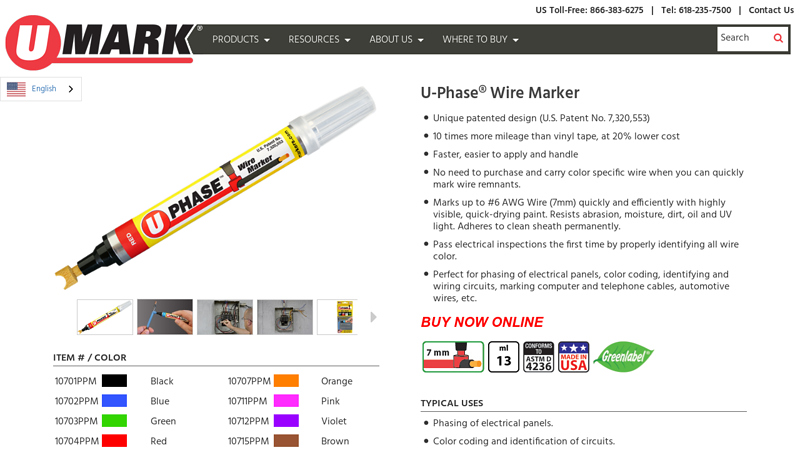

#9 U

Domain Est. 2004

Website: umarkers.com

Key Highlights: Marks up to #6 AWG Wire (7mm) quickly and efficiently with highly visible, quick-drying paint. Resists abrasion, moisture, dirt, oil and UV light. Adheres to ……

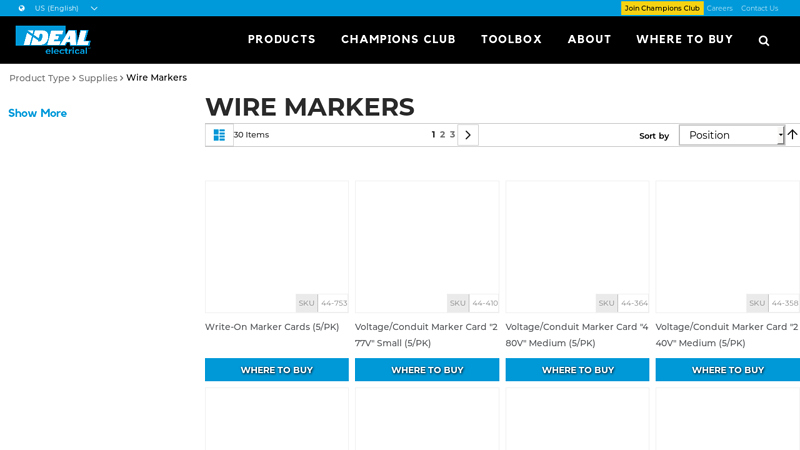

#10 Wire and Voltage & Conduit Markers

Domain Est. 2012

Website: idealind.com

Key Highlights: 30-day returnsA variety of wire markers and voltage/conduit markers. Our Wire Marker Booklets are a convenient pocket size. They offer a non-smear blade ……

Expert Sourcing Insights for Wire Markers

2026 Market Trends for Wire Markers

Rising Demand in Automation and Industrial IoT

By 2026, the integration of automation and the Industrial Internet of Things (IIoT) will significantly influence the wire marker market. As smart factories expand globally, the need for precise and durable wire identification in complex control systems will grow. Wire markers will increasingly be required to support high-density wiring in programmable logic controllers (PLCs), robotics, and sensor networks. Manufacturers will respond by offering markers compatible with automated marking systems and designed for long-term readability in industrial environments.

Shift Toward Sustainable and Eco-Friendly Materials

Environmental regulations and corporate sustainability goals are driving a shift toward eco-conscious products in the electrical supply sector. By 2026, wire marker producers will prioritize recyclable, halogen-free, and low-smoke materials—especially for use in public infrastructure, transportation, and green buildings. Labels made from biodegradable polymers or using solvent-free printing technologies will gain market share, aligning with global ESG (Environmental, Social, and Governance) standards.

Advancements in Printing and Customization Technologies

Digital printing and on-demand labeling solutions will revolutionize wire marker personalization. By 2026, businesses will increasingly adopt portable and desktop label printers capable of producing high-resolution, weather-resistant markers in real time. Cloud-based design software will enable engineers to generate custom labels with barcodes, QR codes, or asset IDs, enhancing traceability and maintenance efficiency in large-scale electrical installations.

Growth in Renewable Energy and EV Infrastructure

The global push for clean energy and electric vehicle (EV) adoption will boost demand for wire markers in solar farms, wind turbines, and EV charging stations. These applications require markers that withstand extreme temperatures, UV exposure, and chemical corrosion. By 2026, specialized wire markers with enhanced durability and compliance with international standards (e.g., UL, IEC) will see increased deployment in renewable energy projects and transportation electrification.

Consolidation and Regional Market Expansion

The wire marker market will experience consolidation among key players seeking broader product portfolios and global reach. At the same time, emerging markets in Asia-Pacific, Latin America, and Africa will drive growth due to urbanization and infrastructure development. Localization of production and distribution networks will become critical, with suppliers focusing on cost-effective, region-specific solutions tailored to local electrical codes and installation practices.

Common Pitfalls When Sourcing Wire Markers (Quality, IP)

Sourcing wire markers may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to operational failures, safety hazards, and legal risks. Below are common pitfalls to avoid:

Poor Material Quality and Durability

Low-grade materials in wire markers can degrade quickly when exposed to heat, chemicals, UV light, or mechanical stress. This leads to fading, cracking, or disintegration—making identification difficult and increasing the risk of miswiring. Always verify that markers are made from durable, industry-appropriate materials (e.g., vinyl, polyester, or heat-shrink tubing) and meet environmental ratings for the intended application.

Inadequate Print Legibility and Longevity

Substandard printing methods or inks can result in smudged, faded, or illegible text over time. This compromises safety and maintenance efficiency. Ensure markers use laser or thermal printing with high-resolution, permanent marking that resists abrasion, solvents, and temperature extremes.

Non-Compliance with Industry Standards

Using wire markers that don’t comply with standards such as UL, CSA, IEC, or MIL-SPEC can result in failed inspections or non-compliance in regulated environments. Confirm that sourced products carry necessary certifications and are tested for flame resistance, dielectric strength, and other safety parameters.

Misrepresentation of IP (Intellectual Property) Rights

Some suppliers may offer wire markers that mimic branded products (e.g., Panduit, HellermannTyton) but infringe on trademarks or patented designs. Sourcing counterfeit or cloned products exposes your company to legal liability and risks supply chain disruptions. Always purchase from authorized distributors or verify IP compliance directly with the manufacturer.

Lack of Traceability and Documentation

Reputable wire markers should come with traceable lot numbers, material data sheets, and compliance documentation. Absence of these can be problematic during audits, recalls, or quality investigations. Ensure suppliers provide full documentation to support product integrity and regulatory compliance.

Inconsistent Sizing and Fit

Poorly manufactured markers may have inconsistent inner diameters or lengths, leading to loose fits or difficulty installing on wires. This reduces reliability and increases labor time. Test samples for dimensional accuracy and compatibility with common wire gauges before bulk procurement.

Overlooking Environmental and IP Ratings

For harsh environments, wire markers may need specific Ingress Protection (IP) ratings or resistance to oils, acids, or extreme temperatures. Assuming standard markers are sufficient without verifying environmental compatibility can result in premature failure. Confirm environmental ratings match the application’s requirements.

By addressing these pitfalls early, organizations can ensure reliable, safe, and legally compliant wire identification systems.

Logistics & Compliance Guide for Wire Markers

Overview

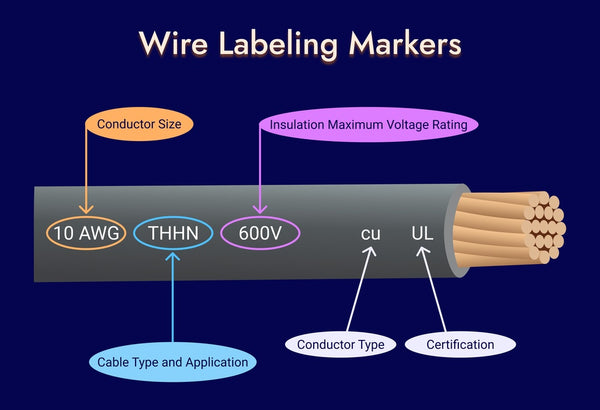

Wire markers are essential components in electrical and industrial applications, used to identify wires and cables for safety, maintenance, and regulatory compliance. Proper logistics and adherence to compliance standards ensure product reliability, traceability, and legal conformity across supply chains and installations.

Regulatory Compliance Requirements

Wire markers must meet various international and regional standards depending on application and industry. Key compliance standards include:

– UL (Underwriters Laboratories) – Markers used in North America must often carry UL recognition (e.g., UL 224 for heat-shrink tubing).

– CSA (Canadian Standards Association) – Required for use in Canada; often harmonized with UL standards.

– RoHS (Restriction of Hazardous Substances) – Ensures markers are free from lead, mercury, cadmium, and other restricted substances (EU Directive 2011/65/EU).

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) – Applies to chemical content in marker materials within the EU.

– NFPA 70 (National Electrical Code) – Specifies requirements for wire identification in electrical installations in the U.S.

– IEC 60446 / IEC 60445 – International standards for color coding and identification of electrical conductors.

Manufacturers and distributors must provide compliance documentation (e.g., Certificates of Compliance, Material Safety Data Sheets) with each batch.

Material & Environmental Compliance

- Ensure wire marker materials are flame-retardant, abrasion-resistant, and suitable for operational environments (e.g., high temperature, UV exposure, oil resistance).

- Confirm halogen-free options are available for applications requiring low smoke zero halogen (LSZH) performance, especially in enclosed spaces like transit or data centers.

- Validate shelf life and storage conditions (e.g., temperature, humidity, light exposure) to maintain print legibility and material integrity.

Packaging & Labeling Standards

- Package wire markers in labeled, resealable bags or dispensers to prevent contamination and ensure organization.

- Include clear labeling on packaging with:

- Product type and specifications (size, color, material)

- Lot number and manufacturing date

- Compliance marks (UL, CSA, RoHS, etc.)

- Storage instructions and shelf life

- Use multilingual labeling when distributing internationally.

Shipping & Handling Logistics

- Store wire markers in a dry, cool environment away from direct sunlight and extreme temperatures.

- Avoid compression or mechanical stress during transport to prevent deformation of heat-shrink or pre-sleeved markers.

- Use appropriate protective packaging (e.g., rigid boxes, padded inserts) for air or ground shipment.

- Maintain chain-of-custody documentation for traceability, especially in regulated industries (aerospace, medical, defense).

Inventory Management & Traceability

- Implement lot traceability systems to track materials from supplier to end-use.

- Conduct periodic audits to verify stock integrity and expiration dates.

- Use barcode or RFID tagging for high-volume inventory tracking in warehouses and distribution centers.

Import/Export Considerations

- Verify customs classification (HS Codes) for wire markers (e.g., 3926.30 for plastic labels).

- Prepare commercial invoices, packing lists, and certificates of origin for international shipments.

- Confirm adherence to import regulations in destination countries, including electrical safety and chemical compliance.

Disposal & Sustainability

- Follow local regulations for disposal of non-conforming or expired wire markers.

- Where possible, recycle plastic-based markers through approved e-waste or plastic recycling programs.

- Choose suppliers committed to sustainable manufacturing practices and reduced environmental impact.

Best Practices Summary

- Source wire markers from certified, reputable suppliers with full compliance documentation.

- Train personnel on proper handling, storage, and application methods.

- Regularly audit compliance and logistics procedures to ensure ongoing adherence to standards.

- Maintain up-to-date records for audits, recalls, or regulatory inspections.

By following this guide, organizations can ensure safe, compliant, and efficient use of wire markers throughout their lifecycle—from procurement to disposal.

Conclusion for Sourcing Wire Markers

Sourcing wire markers is a critical step in ensuring electrical systems are safely, efficiently, and reliably maintained. High-quality wire markers enhance identification, reduce the risk of errors during installation and servicing, and support compliance with industry standards and safety regulations. When selecting a supplier, key factors such as material durability, legibility, environmental resistance, compatibility with wire types, and ease of application must be carefully evaluated.

Additionally, considering cost-effectiveness, availability, and customization options contributes to long-term operational efficiency. Whether sourcing from local suppliers or international manufacturers, establishing relationships with reputable vendors who provide consistent quality and timely delivery is essential. Ultimately, investing in the right wire markers from a reliable source improves system integrity, minimizes downtime, and supports safer working environments across electrical, industrial, and automation applications.