The global demand for precision cleaning tools in industrial and electrical applications has fueled significant growth in the wire cleaning brush market. According to Mordor Intelligence, the Industrial Brushes Market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029, driven by rising automation, stringent quality standards, and increased maintenance requirements across power transmission, construction, and telecommunications sectors. As copper and fiber optic networks expand and electrical safety regulations tighten, reliable wire cleaning solutions have become essential for ensuring conductivity and preventing equipment failure. This sustained market expansion has spurred innovation and competition among manufacturers specializing in wire cleaning brushes—tools designed to remove oxidation, debris, and contaminants from electrical contacts and conductors. In this evolving landscape, identifying the top manufacturers offering high-performance, durable, and application-specific brushes is critical for engineers, procurement teams, and maintenance professionals aiming to optimize operational efficiency and compliance.

Top 10 Wire Cleaning Brush Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mill

Domain Est. 1997

Website: millrose.com

Key Highlights: Mill-Rose is the largest US manufacturer of twisted-wire brushes and the undisputed world market leader for industrial abrasive brushes….

#2 Brush Research Manufacturing

Domain Est. 1997 | Founded: 1958

Website: brushresearch.com

Key Highlights: World-Class manufacturer of FLEX-HONE® tools, industrial brushes, wire brushes and more since 1958! Made in USA. The FLEX-HONE® was invented by BRM’s founder ……

#3 Schaefer Brush

Domain Est. 1997

Website: schaeferbrush.com

Key Highlights: Schaefer Brushes are industrial quality, long-lasting, efficient cleaning tools designed to perform under heavy use by tradesmen, manufacturers and maintenance ……

#4 Twisted

Domain Est. 1998

Website: malinco.com

Key Highlights: Rating 5.0 (5) Brushes Corp., located in Cleveland, is a custom brush manufacturer equipped to supply nearly any twisted wire brush according to your specifications….

#5 Products

Domain Est. 2006

Website: tanisbrush.com

Key Highlights: At Tanis, we develop brush products to help you meet your goals. View and learn more about our vast array of industrial brushes offered here….

#6 Osborn brush

Domain Est. 1994

Website: osborn.com

Key Highlights: Global leading supplier of mechanical expert surface treatment solutions with customized high-quality abrasive brushes, cutting, grinding and polishing ……

#7 Brushtec

Domain Est. 1997

Website: brushtec.com

Key Highlights: Innovative design-work coupled with world class manufacturing allows Brushtec to work with all customers to create the perfect solution to their brushware ……

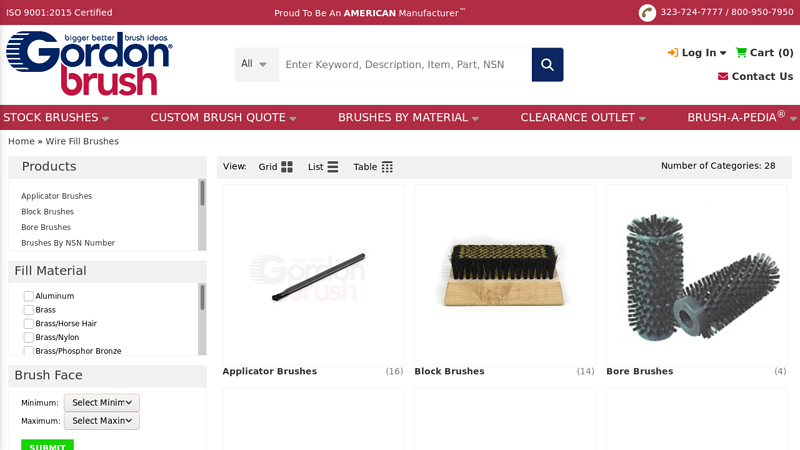

#8 Wire Fill Brushes

Domain Est. 1998

Website: gordonbrush.com

Key Highlights: 2–7 day deliveryGordon Brush has wire fill brushes for all applications: parts cleaning brushes, ESD brushes, flow thru brushes, scrubbers & more. Shop our site for bulk…

#9 Weiler Abrasives

Domain Est. 1999

Website: weilerabrasives.com

Key Highlights: Weiler Abrasives is the industry leader in manufacturing abrasive products and brushes for every application. View our product selection today!!…

#10 Wheel Brushes

Domain Est. 1999

Website: lessmann.com

Key Highlights: We manufacture all types of technical brushes. From the wheel brush and deburring brush, to the cup and bevel brushes and shank brushes to the hand brushes and ……

Expert Sourcing Insights for Wire Cleaning Brush

H2: Projected Market Trends for Wire Cleaning Brushes in 2026

The global market for wire cleaning brushes is anticipated to experience steady growth by 2026, driven by increasing industrial automation, rising demand for precision maintenance tools, and advancements in material technology. Several key trends are expected to shape the landscape of this niche yet essential segment of the industrial tooling market.

-

Expansion in Industrial and Manufacturing Sectors

As global manufacturing output rebounds post-pandemic and industrial automation intensifies, especially in automotive, aerospace, and electronics manufacturing, the need for reliable maintenance tools such as wire cleaning brushes will grow. These brushes are critical for removing debris, rust, and contaminants from wires, connectors, and intricate components, ensuring optimal performance and safety. The Asia-Pacific region, particularly China, India, and Southeast Asia, will remain a key growth driver due to rapid industrialization and infrastructure development. -

Shift Toward High-Performance and Specialized Brushes

By 2026, demand is expected to shift from generic wire brushes to specialized variants tailored for specific applications—such as anti-static brushes for electronics, stainless steel brushes for food processing or medical equipment, and non-sparking brushes for hazardous environments. This trend reflects heightened regulatory standards and the growing importance of precision in maintenance protocols. -

Adoption of Advanced Brush Materials and Coatings

Innovations in bristle materials—such as polymer-coated wires, tungsten carbide, and composite filaments—are enhancing brush durability, corrosion resistance, and cleaning efficiency. Manufacturers are increasingly investing in R&D to develop brushes that offer longer service life and reduced contamination risks, particularly in cleanroom and high-purity environments. -

Growth in Maintenance, Repair, and Operations (MRO) Spending

The MRO sector is projected to account for a significant share of wire brush consumption. Industries are prioritizing preventive maintenance to minimize downtime and extend equipment life. Wire cleaning brushes, as cost-effective and essential MRO tools, will benefit from this trend, especially in energy, transportation, and heavy machinery sectors. -

Sustainability and Eco-Friendly Manufacturing

Environmental regulations are pushing manufacturers to adopt greener production methods. By 2026, there will be a growing preference for recyclable brush components and sustainable manufacturing processes. Companies that emphasize eco-design and reduce waste in brush production are likely to gain a competitive edge. -

E-Commerce and Digital Distribution Channels

Online platforms and B2B e-marketplaces will play an increasingly important role in the distribution of wire cleaning brushes. Manufacturers and distributors are leveraging digital channels to reach smaller workshops, independent technicians, and international markets more efficiently. Enhanced product visibility, customer reviews, and online configurators will streamline procurement. -

Consolidation and Strategic Partnerships

The market may witness consolidation as larger industrial tool manufacturers acquire niche brush producers to expand their product portfolios. Strategic partnerships with OEMs and integration of brushes into bundled maintenance solutions could become common, enhancing customer value and brand loyalty.

In conclusion, the wire cleaning brush market in 2026 will be characterized by technological innovation, application-specific customization, and strong demand from industrial end-users. Companies that focus on quality, sustainability, and digital engagement are poised to lead in this evolving market.

Common Pitfalls Sourcing Wire Cleaning Brushes (Quality, IP)

Sourcing wire cleaning brushes involves several potential pitfalls, especially concerning product quality and Intellectual Property (IP) protection. Overlooking these areas can lead to substandard products, legal risks, and supply chain disruptions.

Quality-Related Pitfalls

-

Inconsistent Brush Filament Material: Sourcing from unreliable suppliers may result in brushes using inferior or incorrect filament types (e.g., non-abrasive or non-conductive filaments), reducing cleaning effectiveness or damaging sensitive wire surfaces.

-

Poor Core and Shank Construction: Low-quality metal cores may corrode, break, or fail to securely hold bristles, leading to brush failure during use and potential safety hazards.

-

Inadequate Dimensional Accuracy: Brushes that don’t meet exact diameter, length, or shank specifications can cause improper fit in machinery, reducing cleaning efficiency and increasing downtime.

-

Lack of Performance Testing: Suppliers may not conduct or provide evidence of performance testing under real-world conditions (e.g., RPM tolerance, debris removal efficiency), resulting in brushes that fail in operation.

-

Inconsistent Coating or Plating: For corrosion-resistant brushes, inconsistent or thin plating (e.g., nickel or zinc) can compromise durability, especially in harsh environments.

IP-Related Pitfalls

-

Unlicensed Copying of Patented Designs: Some suppliers may reproduce patented brush configurations or mounting designs without authorization, exposing buyers to infringement claims and supply chain liabilities.

-

Use of Counterfeit Branding: Purchasing brushes labeled with well-known brand names without authorization risks receiving counterfeit goods and potential legal action for IP violations.

-

Lack of Design Ownership Clarity: When custom brushes are developed, failure to secure IP rights via contracts may result in the supplier retaining design ownership, limiting exclusivity and future sourcing options.

-

Insufficient Documentation for Compliance: Absence of IP certificates, design registration proofs, or freedom-to-operate (FTO) analyses increases legal risk, particularly in regulated industries.

-

Third-Party IP Infringement in Components: Even if the overall brush appears original, key components (e.g., specialized filament technology) might infringe on third-party patents, creating downstream liability.

Avoiding these pitfalls requires thorough supplier vetting, clear contractual IP agreements, and rigorous quality assurance protocols during the sourcing process.

Logistics & Compliance Guide for Wire Cleaning Brush

Product Classification and Documentation

Ensure accurate product classification under the appropriate Harmonized System (HS) code, typically falling under 9603.90 for mechanical appliances for cleaning. Maintain comprehensive technical documentation, including product specifications, material composition (e.g., brass or stainless steel bristles, plastic or wooden handle), and safety data sheets (SDS) if applicable. Confirm that all packaging and labeling include essential details such as product name, SKU, country of origin, net weight, and manufacturer information.

International Shipping and Customs Clearance

Prepare complete shipping documentation including commercial invoice, packing list, and bill of lading or air waybill. Declare the correct HS code and value to avoid customs delays. Be aware of import regulations in target markets; some countries may require additional certifications or conformity assessments for hand tools. Ensure compliance with Incoterms (e.g., FOB, DDP) clearly defined in purchase agreements to allocate responsibilities for shipping, insurance, and duties.

Regulatory Compliance

Verify compliance with regional safety and environmental standards. In the EU, ensure conformity with REACH and RoHS directives, particularly regarding restricted substances in metals and plastics. In the US, comply with CPSIA if marketed for consumer use, and adhere to OSHA guidelines for workplace safety if used in industrial settings. Check for any specific tool-related regulations in destination countries, such as labeling in local language or conformity marks (e.g., CE, UKCA).

Packaging and Handling Requirements

Package wire cleaning brushes securely to prevent damage during transit, using durable materials that minimize movement. Clearly label packages as “Fragile” if necessary and include handling icons per international standards (e.g., ISTA). Avoid over-packing to reduce waste and shipping costs while ensuring product protection. Use recyclable or sustainable packaging materials where possible to meet environmental compliance goals.

Storage and Inventory Management

Store wire cleaning brushes in dry, temperature-controlled environments to prevent corrosion of metal bristles. Organize inventory using a first-in, first-out (FIFO) system to maintain product quality. Monitor shelf life if packaging includes moisture-sensitive components. Implement barcode or RFID tracking for efficient inventory control and traceability across the supply chain.

End-of-Life and Environmental Considerations

Provide guidance for proper disposal in accordance with local regulations. Metal components may be recyclable; advise customers to separate materials where feasible. Comply with extended producer responsibility (EPR) schemes if applicable in regions such as the EU. Minimize environmental impact by designing for durability and repairability, reducing the need for frequent replacement.

In conclusion, sourcing a wire cleaning brush requires careful consideration of factors such as brush material, bristle type, size, application needs, and quality standards. Selecting the right supplier is equally important to ensure reliability, consistency, and compliance with industry requirements. By evaluating vendors based on reputation, customization capabilities, cost-effectiveness, and lead times, businesses can secure a dependable supply of wire cleaning brushes that enhance operational efficiency and maintain high cleaning performance. Ultimately, a well-informed sourcing decision contributes to improved product quality, reduced downtime, and long-term cost savings.