The global winch dampener market is gaining traction as demand for safety and efficiency in towing and recovery operations rises across industries such as automotive, marine, construction, and off-road recreation. According to a 2023 report by Mordor Intelligence, the global tow and recovery equipment market—which includes critical components like winch dampeners—is projected to grow at a CAGR of approximately 5.2% from 2023 to 2028. This growth is driven by increasing vehicle ownership, rising off-road vehicle usage, and heightened awareness of operational safety. As winch lines are under extreme tension, the risk of snap-back during failure makes dampeners an essential safety tool. With this growing demand, manufacturers are investing in advanced materials and innovative designs to improve shock absorption and durability. Based on market presence, product quality, technological integration, and customer reviews, the following seven companies have emerged as leading winch dampener manufacturers shaping industry standards.

Top 7 Winch Dampener Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

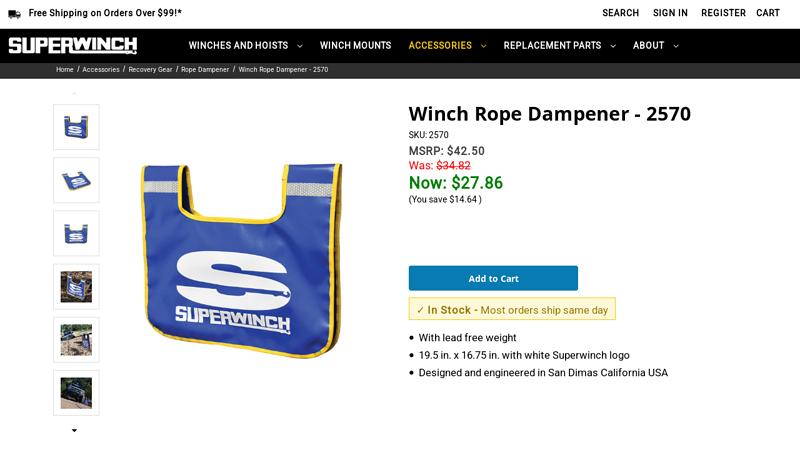

#1 Winch Rope Dampener

Domain Est. 1995

Website: superwinch.com

Key Highlights: Winch Rope Dampener – 2570 · With lead free weight · 19.5 in. x 16.75 in. with white Superwinch logo · Designed and engineered in San Dimas California USA….

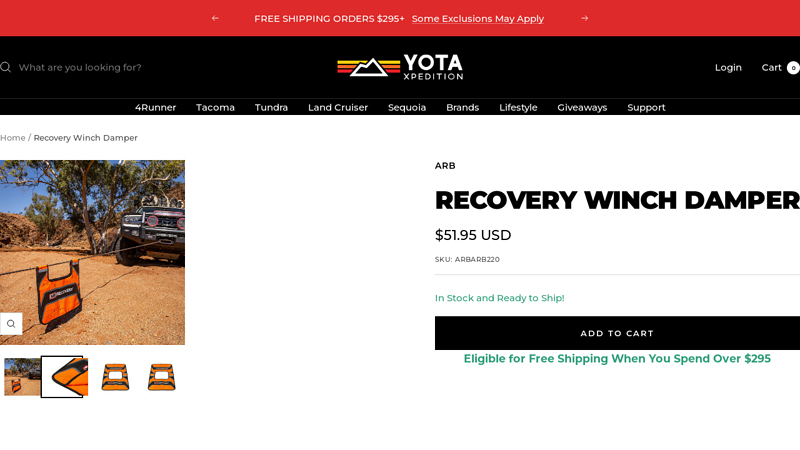

#2 Recovery Damper ARB220

Domain Est. 1998

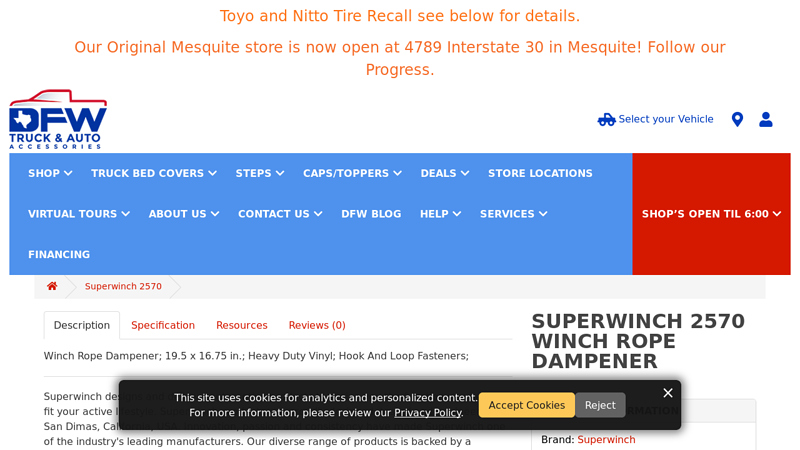

#3 Superwinch 2570 Winch Rope Dampener

Domain Est. 1999

Website: truckaccessorystore.com

Key Highlights: Free delivery 30-day returnsWinch Rope Dampener; 19.5 x 16.75 in.; Heavy Duty Vinyl; Hook And Loop Fasteners;. Superwinch designs and delivers automotive products that give you the…

#4 Superwinch Jeep Gladiator Winch Rope Dampener 2570

Domain Est. 2000

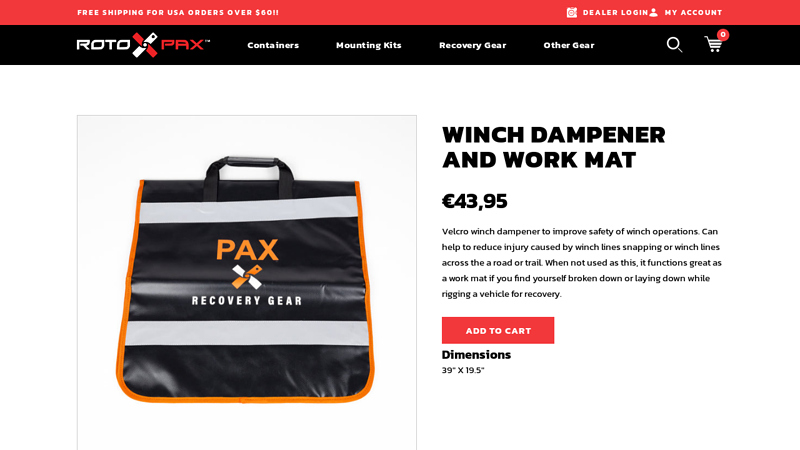

#5 Winch Dampener and Work Mat

Domain Est. 2008

Website: rotopax.com

Key Highlights: In stock Free deliveryVelcro winch dampener to improve safety of winch operations. Can help to reduce injury caused by winch lines snapping or winch lines across the a road or trai…

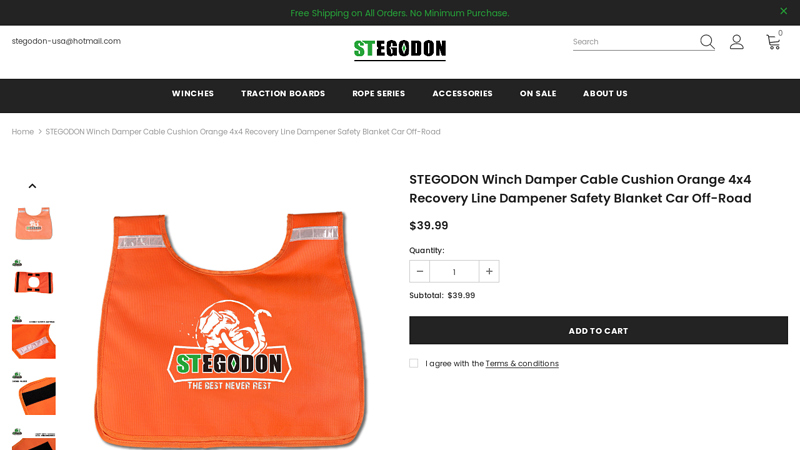

#6 STEGODON Winch Damper Cable Cushion Orange 4×4 Recovery …

Domain Est. 2019

#7 Recovery Winch Damper

Domain Est. 2022

Expert Sourcing Insights for Winch Dampener

H2: 2026 Market Trends for Winch Dampeners

The global market for winch dampeners is poised for significant evolution by 2026, driven by increasing industrial automation, safety regulations, and advancements in heavy machinery across key sectors such as offshore oil and gas, marine operations, construction, and renewable energy. As operational safety and equipment longevity become top priorities, the demand for effective load stabilization solutions like winch dampeners is expected to accelerate.

One of the primary drivers shaping the 2026 market is the growing emphasis on worker safety and compliance with stringent international standards. Regulatory bodies such as OSHA and IMO continue to enforce protocols that minimize dynamic load risks during lifting and towing operations. Winch dampeners—critical in absorbing shock loads and reducing cable snap-back hazards—are increasingly being recognized as essential safety components, leading to higher adoption rates across high-risk industries.

Additionally, technological innovation is redefining product performance. By 2026, smart dampeners integrated with IoT-enabled sensors are expected to gain traction. These next-generation devices offer real-time monitoring of tension, load oscillations, and wear conditions, enabling predictive maintenance and improved operational efficiency. Manufacturers are investing in lightweight composite materials and adaptive damping mechanisms to enhance durability and responsiveness under extreme conditions.

Regionally, Asia-Pacific is anticipated to dominate market growth due to rapid infrastructure development and offshore energy projects in countries like China, India, and South Korea. Meanwhile, North America and Europe will sustain steady demand, fueled by modernization of aging maritime and energy infrastructure and the expansion of offshore wind farms requiring reliable mooring systems.

Furthermore, sustainability trends are influencing material sourcing and manufacturing processes. Eco-conscious operators are favoring dampeners made from recyclable or low-impact materials, pushing suppliers toward greener production methods.

In summary, the 2026 winch dampener market will be characterized by heightened safety requirements, technological integration, regional expansion, and a shift toward sustainable solutions—positioning advanced dampening systems as indispensable components in modern industrial and marine operations.

Common Pitfalls Sourcing a Winch Dampener: Quality and Intellectual Property Concerns

When sourcing winch dampeners—critical components used in marine, offshore, and heavy lifting operations—organizations often encounter challenges related to product quality and intellectual property (IP) risks. Failure to address these issues can lead to operational failures, safety hazards, legal disputes, and reputational damage. Below are key pitfalls to watch for in both quality assurance and IP protection.

Quality-Related Pitfalls

1. Substandard Materials and Construction

Many low-cost suppliers use inferior materials such as low-grade rubber, weak metal housings, or inadequate stitching in fabric-based dampeners. These materials degrade quickly under UV exposure, saltwater, or high stress, leading to premature failure during critical operations.

2. Lack of Certification and Testing Documentation

Reputable winch dampeners should comply with international standards (e.g., DNV, ABS, ISO). Sourcing from suppliers who cannot provide third-party test reports or certification may result in non-compliant products that fail under load or in harsh environments.

3. Inconsistent Manufacturing Processes

Suppliers with poor quality control may produce dampeners with inconsistent dimensions, stitching, or damping performance. This variability increases the risk of equipment failure and makes inventory management difficult.

4. Misrepresentation of Performance Specifications

Some suppliers exaggerate the energy absorption capacity, durability, or service life of their dampeners. Without independent verification, buyers may select a product unsuitable for their operational needs.

5. Inadequate After-Sales Support and Traceability

Lack of batch traceability, warranty terms, or technical support can hinder incident investigations and make it difficult to address defects or recalls promptly.

Intellectual Property-Related Pitfalls

1. Counterfeit or Reverse-Engineered Products

Unscrupulous suppliers may copy patented designs from leading manufacturers without authorization. These knock-offs often lack performance reliability and expose the buyer to legal liability if used in regulated environments.

2. Infringement on Patented Technologies

Using a dampener that incorporates patented tensioning, damping, or attachment mechanisms without proper licensing can lead to infringement claims. This is especially risky when sourcing from regions with lax IP enforcement.

3. Unclear Ownership of Custom Designs

When working with suppliers to develop custom dampeners, failure to establish clear IP ownership in contracts may result in disputes. The supplier could claim rights to the design or resell it to competitors.

4. Lack of Design Registration and Trademark Verification

Brands should verify that supplier products do not infringe on existing trademarks or registered designs. Similarly, if developing proprietary dampeners, companies must register their IP to prevent imitation.

5. Supply Chain Transparency Gaps

Opaqueness in the supply chain makes it difficult to confirm whether components originate from legitimate, licensed sources. This increases the risk of unintentionally sourcing IP-infringing goods.

Mitigation Strategies

- Conduct thorough supplier audits and request full certification dossiers.

- Perform independent product testing before bulk procurement.

- Include IP indemnity clauses in supplier contracts.

- Work with legal counsel to conduct freedom-to-operate (FTO) analyses.

- Register custom designs and enforce confidentiality agreements.

By proactively addressing quality and IP risks, organizations can ensure they source reliable, compliant, and legally sound winch dampeners that enhance operational safety and protect their commercial interests.

Logistics & Compliance Guide for Winch Dampener

Overview

This guide outlines the essential logistics and compliance considerations for the transportation, handling, storage, and regulatory adherence of Winch Dampeners—safety devices used in marine, offshore, and heavy lifting operations to absorb shock loads and prevent cable snap-back.

Packaging & Handling Requirements

Winch Dampeners must be packaged in robust, weather-resistant containers to protect against moisture, corrosion, and physical damage during transit. Use padded internal supports to prevent movement. Handle with care using appropriate lifting equipment; avoid dragging or dropping. Ensure all components (elastic body, attachment hardware, protective covers) remain secured and undamaged.

Transportation Guidelines

- Mode of Transport: Suitable for road, sea, and air freight. For air transport, verify compliance with IATA regulations for non-hazardous cargo.

- Labeling: Clearly label packages with “Fragile,” “This Side Up,” product name (“Winch Dampener”), part number, weight, and handling instructions.

- Stacking: Limit stack height to three layers unless otherwise specified by the manufacturer. Use dunnage between layers to prevent compression damage.

Storage Conditions

Store Winch Dampeners in a dry, temperature-controlled environment (recommended: 10°C to 30°C / 50°F to 86°F). Avoid exposure to direct sunlight, ozone sources (e.g., electric motors), and petroleum-based fumes. Keep off the floor on pallets or racks to prevent moisture absorption. Inspect periodically for signs of degradation, especially in elastomeric components.

Import/Export Compliance

- HS Code: Typically classified under 8431.49 (parts for lifting appliances), but verify with local customs authorities.

- Documentation: Provide commercial invoice, packing list, bill of lading/air waybill, and certificate of origin.

- Regulatory Approvals: Ensure dampeners meet international standards such as ISO 13284 (crane safety) or DNV-RU-EQPT, as applicable. Include CE marking (for EU) or equivalent regional certifications.

Safety & Regulatory Standards

Winch Dampeners must comply with relevant safety standards based on region and application:

– OSHA (USA): Adherence to 29 CFR 1910.184 (derricks and hoists) and general duty clause for hazard mitigation.

– UK HSE: Comply with Lifting Operations and Lifting Equipment Regulations (LOLER) and Provision and Use of Work Equipment Regulations (PUWER).

– ISO/DNV/ABS: Marine and offshore applications may require certification from classification societies.

– REACH & RoHS: Confirm material compliance for restricted substances, especially in elastomers and metal components.

Inspection & Maintenance Documentation

Maintain a compliance log including:

– Date of manufacture

– Batch/serial number

– Initial inspection report

– Periodic maintenance records (recommended every 6 months or per operational hours)

– Replacement or decommissioning date

Disposal & Environmental Compliance

Dispose of end-of-life Winch Dampeners in accordance with local environmental regulations. Elastomeric components may require specialized recycling; do not incinerate without proper emission controls. Follow WEEE directives where applicable and consult waste management professionals for proper handling.

Training & User Certification

Ensure personnel involved in installing or using Winch Dampeners are trained in proper application, inspection, and safety procedures. Provide user manuals and safety data sheets (SDS) upon delivery. Retain training records to demonstrate compliance during audits.

Conclusion for Sourcing Winch Dampener:

After a thorough evaluation of technical requirements, safety standards, supplier capabilities, and cost considerations, sourcing a winch dampener is a critical step in ensuring operational safety and equipment longevity in winching operations. The selected dampener must effectively absorb shock loads, reduce rope whip risks, and comply with industry safety regulations. Key factors such as material durability, compatibility with existing winch systems, ease of installation, and supplier reliability have been assessed to identify the most suitable options.

Based on the analysis, it is recommended to proceed with a reputable supplier offering a high-performance, abrasion-resistant winch dampener constructed from ballistic nylon or equivalent material, with proven field performance and certification to relevant safety standards (e.g., ISO or ANSI). Additionally, establishing a maintenance and replacement schedule will ensure continued protection and optimal performance.

In conclusion, investing in a quality-sourced winch dampener not only enhances worksite safety but also minimizes downtime and potential damage to equipment, delivering long-term operational and financial benefits.