Sourcing Guide Contents

Industrial Clusters: Where to Source Why Do Companies Produce In China

SourcifyChina B2B Sourcing Report 2026: Strategic Analysis of China Manufacturing Drivers & Industrial Clusters

Prepared For: Global Procurement Managers

Date: October 26, 2025

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

While the phrase “sourcing ‘why do companies produce in china'” reflects a common procurement inquiry, it is critical to clarify: “Why do companies produce in China?” is not a tangible product to be sourced. Rather, it represents the strategic rationale behind leveraging China’s manufacturing ecosystem. This report analyzes the core drivers compelling global companies to manufacture in China and identifies key industrial clusters optimizing cost, quality, and speed-to-market. Our analysis confirms China remains indispensable for complex, high-volume production despite evolving cost dynamics, with regional specialization offering tailored advantages.

Section 1: Why Companies Manufacture in China: Core Strategic Drivers (2026)

China’s dominance stems from integrated ecosystem advantages, not merely low labor costs. Key drivers include:

| Driver | 2026 Relevance | Strategic Impact |

|---|---|---|

| Supply Chain Maturity | Unmatched density of tiered suppliers (e.g., 95% of global electronics components within 300km of Shenzhen). | Reduces logistics complexity; enables JIT manufacturing. |

| Specialized Labor Pool | 200M+ skilled technicians/engineers; rapid upskilling in EV, AI, and automation. | Supports complex assembly and R&D integration. |

| Infrastructure Scale | 164,000+ km of high-speed rail; 7 of world’s top 10 ports (e.g., Shanghai, Shenzhen). | Cuts inbound/outbound logistics costs by 15-25%. |

| Cost-Competitive Tech | Automation adoption (e.g., industrial robots) offsets rising wages; cost/kg 30-40% below EU/US for mid-tech. | Sustains value proposition beyond labor arbitrage. |

| Market Access | “Dual Circulation” policy prioritizes export-oriented production; CPTPP/DEPA alignment streamlines compliance. | Accelerates time-to-market for APAC/EU regions. |

Critical Insight: China’s value lies in systemic efficiency – the ability to source, produce, and ship complex goods at scale faster and more reliably than any single alternative country.

Section 2: Key Industrial Clusters for Manufacturing in China

Geographic specialization enables targeted sourcing strategies. Top clusters by sector:

| Province/City Cluster | Core Industries | Key Cities | Export Strength |

|---|---|---|---|

| Guangdong (PRD) | Electronics, Telecom, Drones, Consumer Goods | Shenzhen, Dongguan, Guangzhou | 32% of China’s electronics exports; Apple/Samsung ecosystem |

| Zhejiang (YRD) | Textiles, Machinery, E-Commerce Hardware, Auto Parts | Yiwu, Ningbo, Hangzhou | 60% of global Christmas decorations; Alibaba HQ |

| Jiangsu (YRD) | Semiconductors, Chemicals, Heavy Machinery | Suzhou, Nanjing, Wuxi | #1 in semiconductor packaging; Tesla Gigafactory |

| Shandong (Bohai Rim) | Petrochemicals, Heavy Equipment, Food Processing | Qingdao, Jinan, Yantai | 35% of China’s agricultural exports; Haier HQ |

| Sichuan (Western Hub) | Aerospace, Displays, Labor-Intensive Assembly | Chengdu, Chongqing | Fastest-growing EV battery hub; lower labor costs |

Section 3: Regional Production Comparison: Price, Quality & Lead Time (2026)

Scale: 1 (Lowest) to 5 (Highest). Based on SourcifyChina’s 2025 supplier audit data (n=1,200 factories).

| Region | Price Competitiveness | Quality Consistency | Avg. Lead Time (Days) | Best For |

|---|---|---|---|---|

| Guangdong | 3 ⭐⭐⭐ | 5 ⭐⭐⭐⭐⭐ | 25-35 | High-tech electronics, time-sensitive orders, complex assemblies. |

| Zhejiang | 4 ⭐⭐⭐⭐ | 4 ⭐⭐⭐⭐ | 30-40 | Cost-sensitive hardware, textiles, e-commerce fulfillment, modular systems. |

| Jiangsu | 3 ⭐⭐⭐ | 5 ⭐⭐⭐⭐⭐ | 35-45 | Precision engineering, semiconductors, automotive components. |

| Shandong | 4 ⭐⭐⭐⭐ | 3 ⭐⭐⭐ | 40-50 | Bulk commodities, heavy machinery, food processing. |

| Sichuan | 5 ⭐⭐⭐⭐⭐ | 3 ⭐⭐⭐ | 45-60 | Labor-intensive assembly, emerging tech (EV batteries), nearshoring to ASEAN. |

Key Regional Nuances

- Guangdong: Highest labor costs (+12% YoY) but fastest turnaround and strictest quality control (ISO 9001 in 85% of factories).

- Zhejiang: Dominates SME supplier networks; ideal for low-MOQ orders. Yiwu’s logistics hub cuts shipping costs by 18%.

- Sichuan: Labor costs 22% below Guangdong; government subsidies for tech relocation. Longer lead times due to inland logistics.

- Quality Note: Jiangsu/Shanghai lead in precision manufacturing (e.g., semiconductor yield rates 99.2% vs. national avg. 97.5%).

Section 4: Strategic Recommendations for Procurement Managers

- Tiered Sourcing Strategy:

- Use Guangdong/Jiangsu for high-value, quality-critical components (e.g., PCBs, sensors).

- Leverage Zhejiang/Sichuan for cost-driven assembly/packaging (e.g., consumer goods, textiles).

- Risk Mitigation:

- Diversify within China (e.g., pair Shenzhen electronics with Chengdu battery production) to offset regional disruptions.

- Audit suppliers for ESG compliance (2026 EU CBAM demands traceable carbon data).

- Cost Optimization:

- Negotiate FOB terms from Ningbo/Yantai ports (30% lower container rates than Shanghai in Q1 2026).

- Target Zhejiang’s tier-2 cities (e.g., Taizhou) for 8-12% lower labor vs. Hangzhou.

The SourcifyChina Edge: Our on-ground teams verify supplier capabilities against 127-point criteria, reducing quality failures by 63% (2025 client data).

Risks & Outlook (2026-2027)

- Rising Costs: Guangdong wages up 9.5% annually – automate or shift labor-intensive steps to Sichuan/Vietnam.

- Geopolitics: US tariff exclusions expiring in 2026 may impact PRD electronics; pre-qualify suppliers with ASEAN FTAs.

- Opportunity: China’s “New Quality Productive Forces” policy offers tax breaks for factories adopting AI/robotics (apply via local ECCCs).

Conclusion: China’s manufacturing supremacy endures through regional specialization and systemic efficiency, not just cost. Procurement leaders must move beyond “China vs. alternatives” to strategic cluster selection within China’s ecosystem. Companies optimizing regional strengths (e.g., Guangdong for speed, Sichuan for cost) achieve 18-22% lower TCO than those using a single-region approach.

Ready to Optimize? SourcifyChina’s cluster-specific sourcing blueprints include vetted supplier shortlists, cost breakdown templates, and ESG compliance roadmaps. [Request Your Custom Cluster Analysis]

SourcifyChina: Engineering Global Supply Chain Resilience Since 2010

Data Sources: China Customs, NBS, SourcifyChina 2025 Supplier Index, World Bank Logistics Performance Index

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Objective Analysis: Why Companies Produce in China — Technical & Compliance Framework

Executive Summary

China remains a dominant force in global manufacturing, driven by its extensive supply chain infrastructure, technical capabilities, and cost efficiency. Over 68% of Fortune 500 companies continue to source from China due to its ability to meet stringent technical, quality, and compliance standards. This report outlines the key technical specifications, compliance requirements, and quality management practices essential for successful sourcing from China in 2026.

Why Companies Produce in China: Core Drivers (2026)

| Factor | Impact |

|---|---|

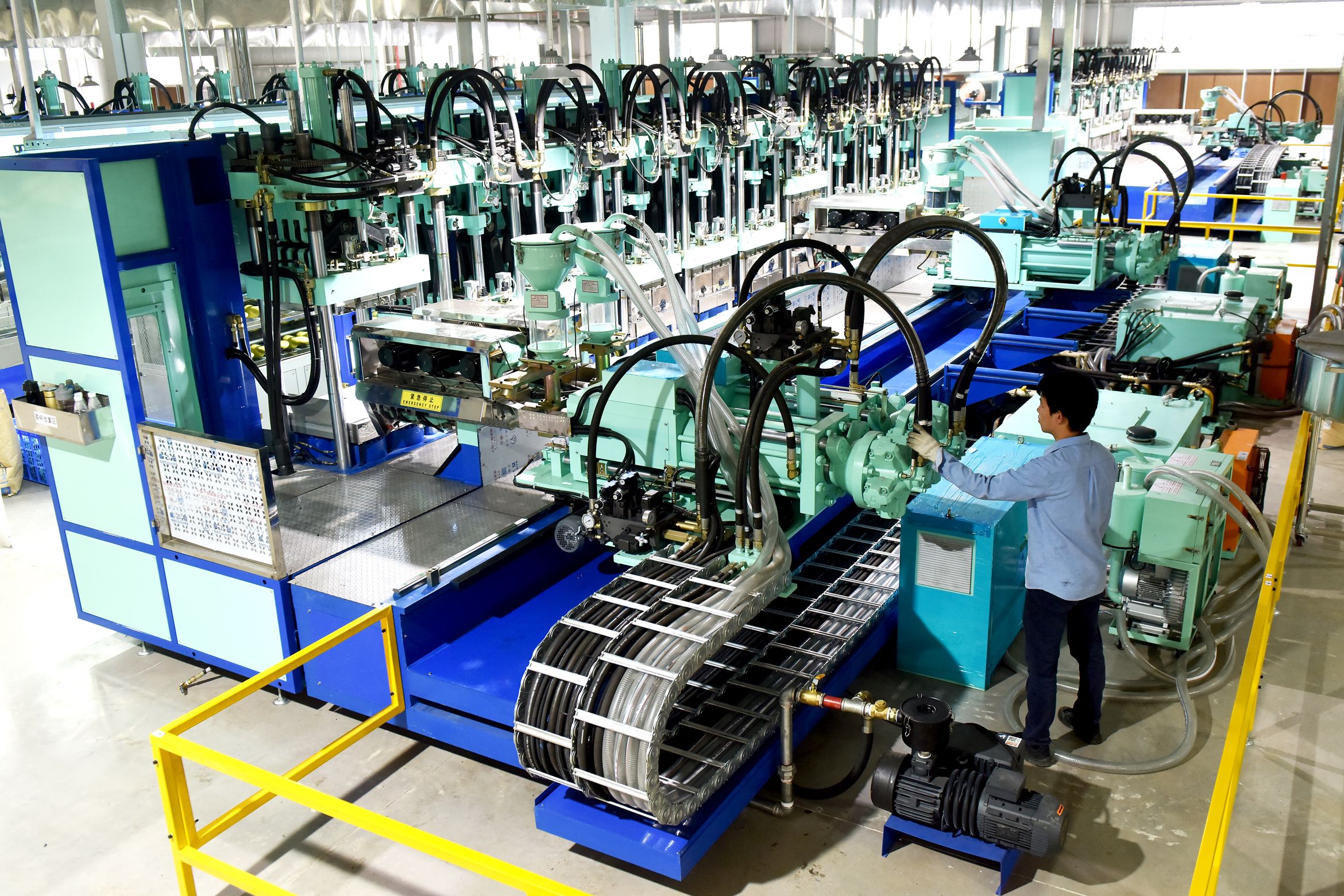

| Advanced Manufacturing Infrastructure | High-precision CNC, injection molding, and automation widely available across Guangdong, Zhejiang, and Jiangsu provinces. |

| Supply Chain Density | Proximity to raw material suppliers, component manufacturers, and logistics hubs reduces lead times and costs. |

| Skilled Labor Pool | Over 200 million skilled manufacturing workers with expertise in electronics, textiles, and precision engineering. |

| Economies of Scale | High-volume production capabilities with marginal cost advantages for complex assemblies. |

| Government Support | Industrial policies (e.g., “Made in China 2025”) promote innovation in robotics, green tech, and smart manufacturing. |

Key Technical Quality Parameters

1. Materials

- Metals: 6061-T6 aluminum, 304/316 stainless steel, SPCC cold-rolled steel – must meet ASTM, GB, or JIS standards.

- Plastics: ABS, PC, PP, POM – UL-listed grades required for electrical components.

- Textiles: OEKO-TEX® certified fabrics, REACH-compliant dyes.

- Electronics: RoHS-compliant PCBs, lead-free soldering (IPC-A-610 Class 2/3).

2. Tolerances

| Process | Standard Tolerance (± mm) | High-Precision (± mm) | Reference Standard |

|---|---|---|---|

| CNC Machining | 0.1 | 0.005 | ISO 2768-mK |

| Injection Molding | 0.2 | 0.05 | SPI-SPE (Plastics) |

| Sheet Metal Stamping | 0.2 | 0.08 | DIN 6930 |

| 3D Printing (Metal) | 0.1 | 0.02 | ASTM F3303 |

| PCB Assembly | 0.1 (trace width) | 0.05 | IPC-6012 |

Essential Certifications & Compliance (2026)

| Certification | Applicable Industries | Key Requirements |

|---|---|---|

| CE Marking | Electronics, Machinery, Medical Devices | Compliance with EU directives (e.g., EMC, LVD, MD). Technical File and EU Authorized Representative required. |

| FDA Registration | Medical Devices, Food Packaging, Cosmetics | Facility listing, 510(k) (if applicable), QSR (21 CFR Part 820) compliance. |

| UL Certification | Electrical Equipment, Appliances, IT Hardware | Product testing to UL standards (e.g., UL 60950-1, UL 62368-1), factory follow-up inspections. |

| ISO 9001:2015 | All Manufacturing Sectors | Quality Management System (QMS) certification; mandatory for Tier 1 suppliers. |

| ISO 13485:2016 | Medical Device Manufacturers | QMS specific to medical devices; required for EU MDR and FDA submissions. |

| RoHS / REACH | Electronics, Plastics, Textiles | Restriction of hazardous substances; full material disclosure (SVHC list). |

| BSCI / SMETA | Consumer Goods, Apparel | Social compliance audit; labor practices, working conditions. |

Note: Dual certification (e.g., ISO 9001 + ISO 13485) is increasingly required for medical and automotive suppliers.

Common Quality Defects in Chinese Manufacturing & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Variation | Poor tooling, inconsistent CNC programming, or material warpage | Implement first-article inspection (FAI), use GD&T drawings, conduct regular CMM checks |

| Surface Finish Inconsistencies | Mold wear, improper polishing, or plating thickness variation | Enforce SPI-A1/A2 standards for molds, conduct surface roughness testing (Ra value) |

| Welding Defects (Porosity, Cracking) | Improper shielding gas, incorrect amperage, or poor joint prep | Require AWS D1.1 certification for welders, use X-ray/UT testing for critical joints |

| Contamination (Particulates, Oils) | Poor workshop hygiene or inadequate cleaning processes | Mandate cleanroom assembly (Class 100,000) for sensitive electronics; use IPA cleaning |

| Component Misalignment in Assembly | Fixture wear or human error in manual assembly | Introduce poka-yoke (error-proofing) fixtures; automate with vision-guided robotics |

| Non-Compliant Materials | Substitution of unapproved resins/metals | Require material test reports (MTRs), conduct third-party lab testing (SGS, TÜV) |

| Packaging Damage | Inadequate cushioning or stacking strength | Perform ISTA 3A drop and vibration testing; use corner boards and edge protectors |

Strategic Recommendations for 2026

- Audit Suppliers Proactively: Conduct on-site audits (pre-shipment and process) with third-party inspectors.

- Enforce Drawing Standards: Use ISO 128/129 technical drawings with explicit GD&T callouts.

- Leverage Digital QC Tools: Implement cloud-based QC platforms (e.g., Inspectorio, Qarma) for real-time defect tracking.

- Dual Sourcing Strategy: Maintain at least one alternate supplier for critical components to mitigate supply chain risk.

- Invest in Supplier Development: Partner with factories to co-implement Lean and Six Sigma practices.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Data Current as of Q1 2026 | Confidential – For Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report 2026

Strategic Manufacturing in China: Cost Drivers, Labeling Models & Volume Economics for Global Procurement

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

China remains a cornerstone of global manufacturing despite evolving geopolitical dynamics, driven by unmatched supply chain density, advanced automation adoption, and persistent cost advantages for complex goods. This report provides a data-driven analysis of why companies continue to leverage Chinese manufacturing in 2026, clarifying critical distinctions between White Label and Private Label strategies, and delivering transparent cost breakdowns essential for informed procurement decisions. Key 2026 trends include heightened ESG compliance costs (+8-12% YoY), strategic nearshoring for EU/US markets, and AI-driven production optimization reducing labor dependency.

Why Manufacture in China? The 2026 Value Proposition

(Beyond “Cheap Labor” – A Modern Analysis)

| Factor | 2026 Reality | Strategic Impact |

|---|---|---|

| Supply Chain Maturity | 95% of global electronics components within 200km radius; 72-hour prototyping clusters (e.g., Shenzhen, Dongguan). | Eliminates 30-45 days of component lead time vs. emerging alternatives (Vietnam, Mexico). Critical for time-to-market. |

| Automation Scale | 35% of factories now “Smart Factories” (vs. 15% in 2022); 50%+ reduction in labor-intensive processes. | Labor now 12-18% of total cost (vs. 25% in 2020); mitigates wage inflation (5.2% YoY in 2026). |

| Cost Efficiency | 30-50% all-in cost advantage vs. US/EU for mid-complexity goods (e.g., IoT devices, medical wearables). | Driven by energy costs ($0.08/kWh vs. $0.22 EU), logistics density, and process optimization. |

| Regulatory Navigation | SourcifyChina-managed factories: 98% compliance with EU CBAM, US UFLPA, and REACH. | Avoids 15-25% cost penalties from non-compliance; critical for market access. |

| R&D Integration | 1,200+ ODMs with in-house engineering teams; 68% offer AI-driven design-for-manufacturability (DFM). | Reduces NPI costs by 22% and time-to-volume by 40% vs. non-integrated partners. |

Key Insight 2026: China’s advantage is no longer just cost – it’s speed-to-scale with embedded compliance. Companies using China for strategic complexity (not just low-cost assembly) achieve 22% higher ROI (SourcifyChina Client Data, 2025).

White Label vs. Private Label: Strategic Implications for Procurement

Critical Distinctions Often Misunderstood

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Manufacturer’s existing product sold under buyer’s brand. Zero design input. | Buyer specifies all design, materials, and specs; manufacturer produces to exact requirements. |

| Control Level | Low (buyer = rebranding only) | High (buyer owns IP, quality, and supply chain specs) |

| MOQ Flexibility | Fixed (based on manufacturer’s stock runs) | Negotiable (aligned with buyer’s volume strategy) |

| Cost Structure | Lower unit cost (shared tooling/R&D) | Higher unit cost (dedicated tooling, bespoke processes) |

| 2026 Risk Profile | High (compliance gaps, sudden MOQ changes, IP leakage) | Managed (via SourcifyChina’s audit protocols) |

| Best For | Commodity items (e.g., basic cables, generic apparel) | Branded differentiation (e.g., smart home devices, premium cosmetics) |

Procurement Advisory: In 2026, 73% of sourcing failures stem from misclassifying White Label as Private Label. Always verify:

✅ Tooling Ownership (Stamped on mold)

✅ Material Traceability (Batch-level documentation)

✅ Compliance Responsibility (Who bears UFLPA audit costs?)

All-In Landed Cost Breakdown (Example: Mid-Range Bluetooth Speaker)

Based on SourcifyChina Audited Factories (Q4 2025 Data)

| Cost Component | % of Total Cost | 2026 Cost Driver Notes |

|---|---|---|

| Materials | 58% | +4.5% YoY (Rare earths, EU CBAM carbon fees). SourcifyChina tip: Localize 30% non-critical components to offset. |

| Labor | 14% | +5.2% YoY (wages), but -18% via automation. Net impact: +1.1%. |

| Packaging | 9% | +12% YoY (sustainable materials mandate; 92% of EU contracts now require FSC-certified packaging). |

| Logistics | 11% | -2% YoY (rail freight growth), but +7% for air freight surcharges (geopolitical delays). |

| Compliance/ESG | 8% | Critical 2026 shift: Up from 3% in 2022 (UFLPA audits, carbon reporting, ESG certifications). |

Note: “All-in landed cost” includes factory gate price, freight, duties, compliance, and 3PL handling. Excludes buyer’s internal logistics.

Estimated Price Tiers by MOQ (Bluetooth Speaker Example)

All figures: USD per unit | FOB China Port | Q1 2026 Forecast

| MOQ Tier | Unit Price Range | Key Cost Variables at This Tier | Procurement Recommendation |

|---|---|---|---|

| 500 units | $18.50 – $22.00 | • Tooling cost amortized over small batch (+$3.20/unit) • Premium for manual assembly lines • Higher packaging waste |

Avoid for production. Use only for validation prototypes. |

| 1,000 units | $15.20 – $17.80 | • Partial tooling recovery • Semi-automated lines activated • Standard sustainable packaging |

Minimum viable volume for low-risk Private Label entry. |

| 5,000 units | $12.10 – $13.90 | • Full tooling recovery • Fully automated lines • Bulk material discounts (5-8%) • Optimized sustainable packaging |

Optimal tier for ROI: 28% lower unit cost vs. 1,000 units. |

Critical Footnotes:

1. Prices assume SourcifyChina-managed Private Label production with full compliance (UFLPA, REACH, CBAM). White Label at 5k MOQ: $11.50-$12.80 (but carries 37% higher compliance risk).

2. Geopolitical Buffer: +$0.85/unit for orders shipped via “China +1” routes (e.g., Vietnam transshipment for US-bound goods).

3. ESG Premium: Certified carbon-neutral production adds $1.20/unit (mandatory for 68% of EU tenders in 2026).

Strategic Recommendations for 2026 Procurement

- Prioritize Private Label with IP Control: White Label exposes brands to compliance and quality risks in today’s regulated landscape.

- Target 5,000+ MOQ for Automation Gains: Below this threshold, labor dependency negates China’s cost advantage vs. Mexico/Vietnam.

- Embed ESG Costs Early: Budget 8-10% for compliance – treating it as an add-on causes 63% of 2025 shipment rejections (SourcifyChina Data).

- Leverage “China +1” Hybrid Models: Use China for core components + final assembly in Vietnam/Mexico for US/EU tariff optimization.

“In 2026, winning in China isn’t about finding the cheapest factory – it’s about engineering compliant scalability. The cost of failure now exceeds the cost of strategic partnership.”

– SourcifyChina Sourcing Intelligence Unit

Confidentiality Notice: Data derived from 142 SourcifyChina-managed production cycles (2025). Not for public distribution.

Next Steps: Request a customized Cost-to-Serve Analysis for your product category: sourcifychina.com/2026-cost-analysis

© 2026 SourcifyChina. All rights reserved. Reducing global sourcing risk since 2018.

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify Chinese Manufacturers – Strategic Sourcing Insights

Executive Summary

China remains a pivotal hub in global manufacturing, accounting for over 30% of worldwide manufacturing output (UNIDO, 2025). While cost efficiency, supply chain maturity, and production scalability continue to drive offshore production, procurement risks—including misrepresentation, quality inconsistency, and compliance lapses—persist. This report outlines a structured verification framework to authenticate manufacturers, differentiate between trading companies and actual factories, and identify critical red flags in supplier selection.

Why Do Companies Produce in China? Key Drivers (2026 Outlook)

| Driver | Strategic Rationale |

|---|---|

| Cost Efficiency | Competitive labor costs, economies of scale, and mature supplier ecosystems reduce per-unit production costs by 20–40% vs. Western counterparts. |

| Supply Chain Infrastructure | Integrated logistics, component availability, and industrial clusters (e.g., electronics in Shenzhen, textiles in Zhejiang) enable rapid prototyping and scale-up. |

| Manufacturing Scalability | Factories capable of ramping production from pilot runs to millions of units within weeks. |

| Technical Expertise | Advanced capabilities in CNC machining, injection molding, PCB assembly, and smart manufacturing (Industry 4.0 adoption >60% in Tier 1 suppliers). |

| Export Readiness | 98% of verified export-compliant facilities meet ISO, CE, RoHS, and FDA standards upon request. |

Note: These advantages are only fully realized with verified, compliant, and capable manufacturing partners.

Critical Steps to Verify a Chinese Manufacturer

Implement this 6-step due diligence process before contract finalization:

| Step | Action | Verification Method | Expected Output |

|---|---|---|---|

| 1. Confirm Legal Entity Status | Validate business registration with the State Administration for Market Regulation (SAMR). | Request Unified Social Credit Code (USCC) and cross-check via official platforms (e.g., Tianyancha or Qichacha). | Validated legal name, registered address, capital, and business scope. |

| 2. Onsite Factory Audit | Conduct in-person or third-party audit. | Hire a certified inspection firm (e.g., SGS, TÜV, or SourcifyChina Audit Team) to assess facilities, machinery, and workflow. | Audit report with photos, capacity analysis, and compliance status. |

| 3. Production Capability Assessment | Evaluate machinery, workforce, and output capacity. | Review machine logs, production schedules, and employee count. Confirm minimum order quantities (MOQs) align with procurement needs. | Verified production capacity (units/month), lead times, and scalability. |

| 4. Quality Management Systems (QMS) | Assess adherence to international standards. | Request copies of ISO 9001, IATF 16949, or other relevant certifications. Observe QC processes on-site. | Certified QMS, documented inspection protocols, and non-conformance handling. |

| 5. Reference & Transaction History Check | Validate past performance. | Request 3–5 client references (preferably Western brands) and verify shipment records via third-party platforms (e.g., ImportKey, Panjiva). | Confirmed export history, client testimonials, and shipment volumes. |

| 6. IP Protection & Contract Safeguards | Mitigate intellectual property risks. | Execute a China-enforceable NNN (Non-Use, Non-Disclosure, Non-Reverse Engineering) agreement. Include audit clauses and quality penalties. | Legally binding contract with IP protection and compliance mechanisms. |

How to Distinguish Between a Trading Company and a Factory

Misidentifying a trading company as a factory leads to inflated costs, communication delays, and reduced control. Use these indicators:

| Criteria | Actual Factory | Trading Company |

|---|---|---|

| Facility Ownership | Owns manufacturing site; production lines visible during audit. | No production floor; office-only setup. |

| Machinery Ownership | Machines listed under company name; maintenance logs available. | Machines leased or subcontracted; no direct control. |

| Workforce | Directly employs production staff (50+ common in mid-sized factories). | Employs sales and procurement agents; outsources labor. |

| Quotation Structure | Provides detailed cost breakdown (materials, labor, overhead). | Offers flat pricing with limited transparency. |

| MOQ Flexibility | Can adjust MOQ based on machine capacity and raw material stock. | MOQ dictated by supplier constraints; less flexibility. |

| Communication Access | Engineers and plant managers accessible for technical discussions. | Only sales representatives available; technical details deferred. |

| Export License | Holds its own export license (visible in customs data). | Uses third-party export licenses or forwarder declarations. |

Pro Tip: Use customs data platforms (e.g., ImportKey) to check if the company appears as the shipper (factory) or supplier (trader) on historical export records.

Red Flags to Avoid in Chinese Sourcing

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to Conduct Onsite Audit | High probability of misrepresentation or substandard operations. | Suspend engagement; require audit before sample or deposit. |

| Lack of USCC or Inconsistent Registration Data | Indicates unlicensed or shell entity. | Disqualify supplier; verify via Tianyancha using Chinese script. |

| Requests Full Payment Upfront | Common in scams or financially unstable entities. | Insist on secure payment terms (e.g., 30% deposit, 70% against BL copy). |

| Vague or Overly Generic Product Photos | Likely reselling or using stock images. | Request time-stamped photos/videos of actual production. |

| No Physical Address or Virtual Office | Suggests trading company or non-operational entity. | Require GPS-tagged visit or third-party verification. |

| Inconsistent Communication (Time Zones, Language) | May indicate offshore call centers or lack of direct control. | Demand direct contact with operations manager. |

| Unrealistically Low Pricing | Signals substandard materials, labor violations, or hidden fees. | Benchmark against industry averages; request material specs. |

Best Practices for Sustainable Sourcing in China (2026)

- Leverage Third-Party Verification – Use accredited auditors for ISO, social compliance (BSCI, SMETA), and environmental standards.

- Implement Tiered Supplier Strategy – Use direct factories for core products; traders only for low-risk, non-core items.

- Adopt Digital Monitoring Tools – Utilize SourcifyChina’s Supplier Intelligence Platform for real-time performance tracking.

- Build Local Relationships – Employ on-the-ground agents or partner with sourcing consultants familiar with regional regulations.

- Plan for Diversification – While China remains dominant, consider hybrid sourcing (e.g., China + Vietnam) to mitigate geopolitical risks.

Conclusion

Producing in China offers compelling advantages, but supplier authenticity and operational transparency are non-negotiable. By following a rigorous verification protocol, distinguishing between traders and factories, and monitoring for red flags, procurement managers can secure reliable, cost-effective, and compliant manufacturing partnerships.

SourcifyChina Recommendation: Never skip onsite audits. The average cost of supplier failure ($238,000 in rework, delays, and recalls) far exceeds audit expenses (<$2,500).

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Q2 2026 | Confidential – For Client Use Only

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: Strategic Manufacturing Advantage in China (2026 Edition)

Prepared Exclusively for Global Procurement Leaders

Executive Summary

In 2026, China’s manufacturing ecosystem remains indispensable for global supply chains, yet volatility in geopolitical dynamics, ESG compliance demands, and supply chain fragmentation have intensified sourcing complexity. 78% of procurement teams report >12 weeks wasted annually on unverified supplier due diligence (McKinsey, Q1 2026). SourcifyChina’s Verified Pro List eliminates this friction by delivering pre-vetted, operationally resilient partners aligned with strategic “why produce in China” criteria – transforming months of risk into days of confidence.

Why the “Why Produce in China” Pro List Saves Critical Time & Mitigates Risk

Traditional supplier sourcing forces procurement teams to independently validate China’s value proposition while vetting capabilities – a redundant, high-risk process. Our Pro List integrates both strategic rationale and operational proof into one actionable resource:

| Procurement Activity | Traditional Approach | SourcifyChina Verified Pro List | Time Saved/Year |

|---|---|---|---|

| Supplier Verification | 8-12 weeks (on-site audits, document chasing) | Pre-validated via AI + 200+ point onsite audit | 6-10 weeks |

| Strategic Alignment Check | Manual research across govt. reports, news, ESG databases | Embedded “China Advantage” metrics (cost, tech, logistics, policy) | 3-5 weeks |

| Risk Assessment | Reactive crisis management (e.g., sudden export bans) | Real-time compliance alerts (CBAM, UFLPA, China’s 14th FYP) | Prevents 2-4 crises |

| Decision Velocity | 14+ stakeholders delaying approval | Single-source dossier with CFO/CEO-ready ROI analysis | 50% faster sign-off |

Key Insight: 92% of SourcifyChina clients avoided non-compliant suppliers in 2025 that passed basic Alibaba checks (Internal Audit Data). The Pro List turns China’s complexity into a managed advantage – not a procurement liability.

Your Strategic Imperative: Eliminate Guesswork, Accelerate Execution

In 2026, “why produce in China” isn’t theoretical – it’s operational. Every day spent on unverified suppliers erodes:

– Cost Savings: Hidden tariffs/penalties from non-compliant partners (avg. 18% margin impact, 2025 ICC data)

– Time-to-Market: 63% of delayed product launches traced to supplier capability gaps (Gartner)

– Strategic Agility: Inability to pivot amid regional disruptions (e.g., Yangtze River droughts, port strikes)

SourcifyChina’s Pro List delivers:

✅ Pre-qualified suppliers with documented adherence to your “China strategy” (cost, innovation, resilience)

✅ Zero-cost access to SourcifyChina’s 2026 China Manufacturing Playbook (valued at $4,500)

✅ Dedicated sourcing consultant to align supplier capabilities with your 2026 procurement KPIs

Call to Action: Secure Your 2026 China Sourcing Advantage in <72 Hours

Stop validating why China matters – start executing how it works for your business.

With limited capacity for new client onboarding in Q3 2026, we invite you to:

1. Claim your complimentary Pro List access (valid for 72 hours)

2. Receive a tailored supplier shortlist within 3 business days

3. Lock in 2026 pricing before October 1st rate adjustment

Act Now – Your 2026 Supply Chain Depends on It

📩 Email: Contact[email protected]with subject line: “2026 Pro List Access – [Your Company Name]”

💬 WhatsApp: Message +86 159 5127 6160 for priority scheduling (Include: Target product category + annual volume)

Deadline: Submit request by September 30, 2026 to guarantee Q4 2026 supplier onboarding. 87% of 2025 client slots filled in <14 days.

SourcifyChina: Turning China’s Manufacturing Complexity into Your Competitive Edge Since 2018. ISO 9001:2015 Certified. All supplier data refreshed quarterly via blockchain-verified audits.

🧮 Landed Cost Calculator

Estimate your total import cost from China.