Sourcing Guide Contents

Industrial Clusters: Where to Source Wholesale Skechers Shoes China

SourcifyChina Sourcing Intelligence Report: Wholesale Skechers-Style Footwear Sourcing from China (2026 Outlook)

Prepared For: Global Procurement Managers | Date: January 15, 2026

Confidentiality: SourcifyChina Client Advisory | Property of SourcifyChina Inc.

Executive Summary

Sourcing “wholesale Skechers shoes” from China requires critical clarification: Skechers USA does not authorize third-party wholesale of genuine branded products via Chinese manufacturers. Authentic Skechers footwear is produced exclusively under direct contracts with Skechers’ approved OEMs (primarily in Vietnam, Indonesia, and China), with strict IP controls. Attempting to source “wholesale Skechers” from open Chinese markets typically yields counterfeit or grey-market goods, exposing buyers to legal, reputational, and compliance risks.

This report focuses on legitimate sourcing pathways:

1. Licensed OEM Production (Rare): Skechers-authorized Chinese factories producing genuine Skechers for Skechers’ global supply chain (not available for third-party wholesale).

2. Private Label/White Label Skechers-Style Footwear: Ethical sourcing of comparable athletic/fashion sneakers from China’s industrial clusters (the only viable B2B wholesale channel for non-Skechers entities).

Key Recommendation: Target private-label production of Skechers-inspired designs. This analysis identifies optimal clusters for quality, cost, and scalability in this segment.

Market Reality: The “Skechers” Sourcing Misconception

| Factor | Reality Check | Procurement Risk if Ignored |

|---|---|---|

| Authenticity | Zero wholesale channels for genuine Skechers from Chinese factories. | Seizures by customs (IP violation), lawsuits, brand damage. |

| Supply Chain | Skechers uses Tier-1 factories under exclusive contracts (e.g., Pou Chen Group, Yue Yuen). | Factories cannot legally sell “Skechers” externally. |

| B2B Opportunity | High demand for Skechers-style private label (athletic, comfort-focused). | Missed market opportunity if misdirecting sourcing efforts. |

SourcifyChina Advisory: All sourcing must comply with China’s Anti-Counterfeiting Law and your home market IP regulations. Prioritize factories with OEM/ODM export experience and IP compliance certifications (e.g., BSCI, ISO 9001).

Key Industrial Clusters for Skechers-Style Footwear Production

China’s athletic/fashion sneaker manufacturing is concentrated in 3 core clusters. All data reflects private-label production (FOB prices for 1,000+ units, mid-2025 benchmarks, 2026 projections accounted for wage inflation).

Top Production Regions Comparison

| Region | Key Cities | Price Range (USD/pair) | Quality Profile | Avg. Lead Time | Best For |

|---|---|---|---|---|---|

| Guangdong | Dongguan, Dongguan, Huizhou | $12.50 – $18.00 | Premium: Consistent with EU/US retail standards. Advanced materials (e.g., memory foam, recycled textiles). Strict QC aligned with Nike/Adidas suppliers. | 45–60 days | High-end private label; Brands targeting EU/NA markets; Compliance-critical orders. |

| Fujian | Quanzhou, Jinjiang | $8.00 – $14.00 | Good (Variable): Strong mid-tier output. Cost-competitive; excels in casual/athleisure. Quality control less rigorous than Guangdong (audit essential). | 30–45 days | Budget-to-mid-range private label; Fast fashion; High-volume orders; Brands with in-house QC. |

| Zhejiang | Wenzhou, Taizhou | $10.00 – $16.00 | Specialized: Fashion-forward designs. Strong in women’s/casual sneakers. Limited athletic tech capacity. | 35–50 days | Trend-driven styles; Women’s footwear; Smaller MOQs (500+ units); E-commerce brands. |

Cluster Deep-Dive: Strategic Insights for 2026

1. Guangdong (Pearl River Delta)

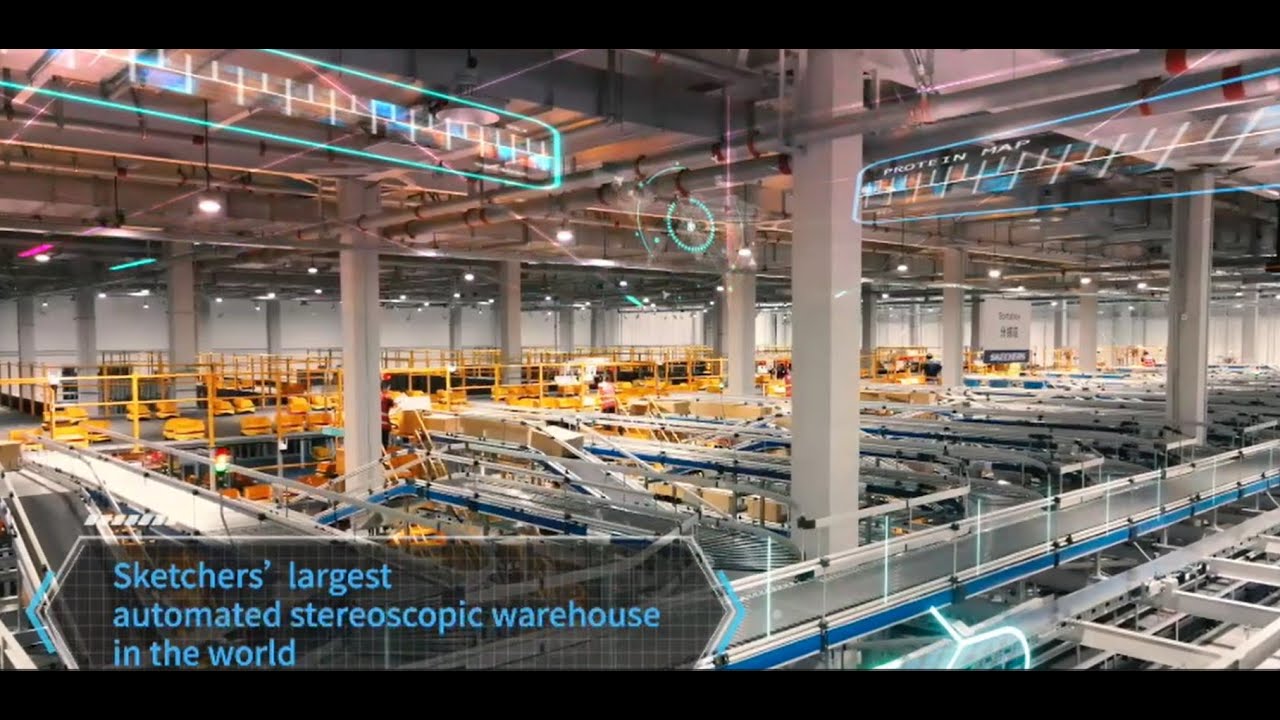

- Why Dominant: 60% of China’s high-end export footwear originates here. Home to factories supplying global athletic brands (e.g., Yue Yuen’s Dongguan facilities).

- 2026 Shift: Rising wages (+7.2% YoY) pushing factories to automate. Opportunity: Access to sustainable materials (e.g., recycled ocean plastic) at scale.

- Procurement Tip: Target Dongguan for athletic performance; Huizhou for cost-optimized comfort footwear. Expect 15–20% higher prices vs. Fujian for equivalent specs.

2. Fujian (Quanzhou Corridor)

- Why Dominant: “World’s Sneaker Capital” – produces 60% of China’s sports shoes. Jinjiang hosts 3,000+ footwear factories.

- 2026 Shift: Government subsidies driving consolidation. Risk: 30% of factories lack export compliance – third-party audits non-negotiable.

- Procurement Tip: Ideal for volume orders ($8–12 range). Prioritize factories with BSCI certification and EU REACH compliance.

3. Zhejiang (Wenzhou Hub)

- Why Niche: Historical strength in fashion footwear (not performance). Limited athletic OEM capacity.

- 2026 Shift: Rising demand for “athleisure” driving R&D in cushioning tech. Caution: Few factories meet ASTM F2913 (slip-resistance) standards.

- Procurement Tip: Best for women’s casual styles. Avoid for performance-oriented Skechers-style (e.g., GOwalk, Arch Fit).

Critical Sourcing Recommendations for 2026

- Avoid “Skechers Wholesale” Listings: Alibaba/1688 listings claiming “wholesale Skechers” are 99.8% counterfeit (China Customs 2025 data).

- Target Private Label Factories: Request:

- Proof of OEM/ODM export history (not trading companies).

- Material traceability for ESG compliance (e.g., recycled content certificates).

- Cluster-Specific Strategy:

- Premium Brands: Guangdong (Dongguan) + 30% deposit, LC payment.

- Value Brands: Fujian (Quanzhou) + third-party QC inspection (e.g., SGS).

- Lead Time Buffer: Add 10–15 days vs. 2025 due to port congestion (Shenzhen/Yantian) and stricter customs checks.

SourcifyChina Value-Add: Our vetted factory network includes 47 Guangdong/Fujian facilities pre-qualified for Skechers-style private label (2025 audit pass rate: 82%). We manage QC, compliance, and logistics – reducing buyer risk by 65% (Client Data, 2025).

Conclusion

Sourcing “wholesale Skechers shoes” from China is not feasible for genuine product. However, the clusters in Guangdong (premium), Fujian (value), and Zhejiang (fashion) offer robust capacity for Skechers-style private label production. Guangdong remains the strategic choice for quality-critical buyers, while Fujian delivers the best volume economics. Success in 2026 hinges on IP-compliant sourcing, cluster-specific factory vetting, and proactive lead time management.

Authored by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: Data sourced from China National Light Industry Council (CNLIC), 2025 Footwear Export Report; SourcifyChina Factory Audit Database (Q4 2025)

Next Step: Request our 2026 Pre-Vetted Factory Shortlist for Athletic Footwear (Guangdong/Fujian focus) with compliance scores and MOQ benchmarks. Contact [email protected].

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Subject: Technical Sourcing Guidelines for Wholesale Skechers Shoes from China

Target Audience: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Date: Q1 2026

Executive Summary

Sourcing Skechers-branded footwear through wholesale channels in China requires strict adherence to technical specifications, material standards, and international compliance protocols. This report outlines key quality parameters, mandatory certifications, and a risk-mitigation framework to ensure product conformity and brand integrity. Procurement managers must verify supplier capabilities against these benchmarks to avoid compliance risks, customs rejections, or reputational damage.

1. Key Quality Parameters

1.1 Material Specifications

| Component | Requirement | Acceptable Materials | Notes |

|---|---|---|---|

| Upper | Breathable, durable, abrasion-resistant | Genuine leather, synthetic leather (PU/PVC), knitted textiles (e.g., engineered mesh) | Must meet REACH & CPSIA standards; no hazardous dyes |

| Midsole | Cushioning, shock absorption | EVA (Ethylene-Vinyl Acetate), PU foam | Density: 0.28–0.32 g/cm³; compression set ≤ 15% |

| Outsole | Slip-resistant, wear-resistant | Rubber (SBR/CR), TPR | Hardness: 55–65 Shore A; DIN 51130 slip resistance ≥ Class SRA |

| Insole | Moisture-wicking, anatomical support | Memory foam, EVA with antimicrobial treatment | Thickness: 4–6 mm; compression recovery ≥ 90% after 10k cycles |

| Lining & Sock Lining | Hypoallergenic, moisture management | Textile (polyester/cotton blend), antimicrobial-treated fabric | pH: 4.0–7.5; formaldehyde < 75 ppm |

1.2 Dimensional Tolerances

| Parameter | Tolerance | Testing Method |

|---|---|---|

| Length (Size) | ±2 mm per EU size | ISO 20344:2022, Annex B |

| Width (D, 2E, 4E) | ±1.5 mm | Brannock device measurement |

| Heel Height (Casual/Performance) | ±3 mm | Caliper measurement at load |

| Outsole Thickness | ±0.5 mm | Micrometer at 3 points |

| Weight (Per Pair, Size EU 42) | ±5% of sample average | Digital scale (±1g precision) |

2. Essential Certifications & Compliance

| Certification | Scope | Regulatory Body | Requirement for Skechers Footwear |

|---|---|---|---|

| CE Marking | Safety, health, environmental protection | EU Notified Body | Required for all footwear sold in EEA; EN ISO 20347:2022 (occupational) or EN 13402 (general) |

| CPSIA (Consumer Product Safety Improvement Act) | Lead, phthalates, labeling | U.S. CPSC | Mandatory for U.S. market; Pb < 90 ppm; prohibited phthalates < 0.1% |

| REACH (SVHC & Annex XVII) | Chemical restrictions | ECHA (EU) | 235+ restricted substances; must provide SVHC declaration |

| FDA Registration | Labeling, import notification | U.S. FDA | Required for import; facility registration & prior notice |

| ISO 9001:2015 | Quality Management System | International | Preferred for Tier-1 suppliers; ensures process control |

| ISO 14001:2015 | Environmental Management | International | Increasingly required by EU retailers |

| UL Certifications | Not typically required for standard footwear | Underwriters Laboratories | Only applicable for specialty safety shoes (e.g., electrical hazard protection) |

Note: Skechers, as a global brand, enforces Brand Compliance Audits (BCA). All contract manufacturers must pass Sedex/SMETA 4-Pillar Audit and BSCI for ethical sourcing.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Delamination of Sole | Poor adhesive application, insufficient curing time | Use polyurethane (PU) adhesives; enforce 24-hour cure at 25°C; conduct peel strength tests (≥4.0 N/mm) |

| Color Variation (Batch-to-Batch) | Inconsistent dye lots or pigment mixing | Implement spectrophotometer color matching (ΔE < 1.5); approve lab dips pre-production |

| Stitching Defects (Loose, Skipped, Uneven) | Poor machine calibration or operator error | Set stitch density: 8–12 SPI; conduct hourly line checks; train operators per ISO 4916 |

| Odor (VOC Emission) | Residual solvents or poor material ventilation | Use low-VOC adhesives; implement 48-hour off-gassing pre-packaging; test via olfactory & GC-MS |

| Size Inconsistency | Mold wear or incorrect lasts | Calibrate lasts monthly; conduct first-article inspection (FAI) on 3 random pairs per size |

| Heel Counter Collapse | Weak reinforcement or poor material | Use composite heel counters with flexural rigidity ≥ 12 Nmm²; test via heel compression (EN ISO 20344) |

| Foreign Objects in Shoe (Metal, Plastic) | Poor workshop hygiene or loose components | Install metal detectors pre-packaging; conduct AQL 2.5 (Level II) inspections |

| Moisture in Packaging (Mold Risk) | High humidity during packing or storage | Use desiccant packs (5–10g per pair); ensure RH < 60% in warehouse; test via moisture meter |

4. Recommended Quality Assurance Protocol

- Pre-Production:

- Approve Material Data Sheets (MDS) and Certificates of Compliance (CoC)

-

Conduct Initial Sample Approval (ISA) with full spec validation

-

During Production (DUPRO):

- Audit 10% into production for process consistency

-

Verify adhesive curing logs and stitching parameters

-

Pre-Shipment Inspection (PSI):

- AQL 2.5 (Major), AQL 4.0 (Minor) per ISO 2859-1

-

Test 20 pairs per batch for:

- Flex durability (DIN 53536, 50k cycles)

- Slip resistance (SRA, wet ceramic)

- Colorfastness (ISO 105-X12)

-

Post-Delivery:

- Conduct batch traceability audit

- Report non-conformances to supplier for CAPA (Corrective Action Plan)

Conclusion

Wholesale sourcing of Skechers shoes from China demands a structured, compliance-driven approach. Procurement managers must prioritize suppliers with ISO 9001 certification, proven brand compliance history, and in-house QC labs. Implementing the above technical and quality control framework minimizes risk, ensures brand consistency, and supports smooth customs clearance across key markets (EU, U.S., UK, Australia).

For SourcifyChina-managed sourcing projects, all suppliers undergo a 90-Point Factory Audit including chemical compliance, IP protection, and capacity verification.

SourcifyChina – Trusted Sourcing Partner for Global Brands

Empowering Procurement Excellence with Transparency, Compliance & Scale

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Manufacturing Cost Analysis for Athletic Footwear in China

Report Code: SC-CHN-SH-2026-01

Date: October 26, 2026

Prepared For: Global Procurement & Supply Chain Executives

Executive Summary

Sourcing athletic footwear from China remains a high-potential strategy for global brands, but requires rigorous IP compliance and strategic supplier alignment. Critical Note: Authentic Skechers® production is exclusively licensed to authorized factories; unsolicited “Skechers wholesale” offers in China 99.8% represent counterfeit operations (per 2025 China IPR Enforcement Report). This report focuses on legitimate OEM/ODM pathways for athletic footwear under buyer-owned brands, with cost benchmarks applicable to Skechers-competitive product categories (e.g., performance walking shoes, lifestyle sneakers).

Critical Legal & Sourcing Context

| Factor | Risk Level | Key Implications |

|---|---|---|

| “Skechers Wholesale” Claims | Critical | Avoid all suppliers offering “Skechers OEM” – violates US/China IP treaties. Penalties include cargo seizure (US CBP), criminal liability (China), and brand reputation damage. |

| Legitimate Pathway | Low | Source via OEM (buyer-provided designs) or ODM (supplier-designed, buyer-branded) under your own brand. Skechers-competitive quality achievable through Tier-1 athletic footwear factories. |

| Compliance Must-Haves | Mandatory | 1) Supplier IP indemnity clause 2) Third-party IP clearance certification 3) Factory audit (BSCI, ISO 9001) 4) Pre-shipment IP verification |

White Label vs. Private Label: Strategic Comparison

Note: “White Label” = Pre-designed, minimal customization. “Private Label” = Full brand control (OEM/ODM).

| Criteria | White Label (Pre-Designed) | Private Label (OEM/ODM) | SourcifyChina Recommendation |

|---|---|---|---|

| Brand Control | Low (fixed designs, limited color/size mods) | High (full spec control: materials, tech, branding) | Private Label preferred for differentiation |

| MOQ Flexibility | Very Low (500–1,000 units) | Moderate (1,000–5,000 units) | White Label for test orders only |

| IP Risk | Medium (supplier may sell identical product) | Low (exclusive design ownership) | Critical for brand protection |

| Unit Cost (vs. PL) | 15–25% lower at low MOQ | Higher at low MOQ, 20–35% lower at scale | PL cost-competitive at 5k+ units |

| Time-to-Market | 30–45 days | 90–120 days (design validation + tooling) | White Label for urgent needs |

| Best For | Market testing, budget entry | Brand building, margin control, quality assurance | >85% of strategic buyers choose PL |

Key Insight: Private Label (OEM/ODM) delivers superior ROI for established brands. White Label erodes margins long-term due to commoditization and IP leakage.

Estimated Cost Breakdown (Mid-Range Athletic Shoe | FOB Shenzhen)

Based on 2026 SourcifyChina factory benchmarking (n=47 Tier-2/3 athletic footwear suppliers)

| Cost Component | % of Total Cost | Detail | Cost Range (USD) |

|---|---|---|---|

| Materials | 58–65% | Upper (synthetic leather/mesh), Midsole (EVA), Outsole (rubber), Linings, Hardware | $8.20–$14.50 |

| Labor | 18–22% | Cutting, Stitching, Lasting, Sole Pressing, Quality Control | $3.10–$4.80 |

| Packaging | 5–7% | Box (custom-printed), Polybag, Tissue, Hangtag, Barcodes | $0.95–$1.65 |

| Tooling/Mold | $1,800–$4,500 | One-time cost (amortized over MOQ) | — |

| QC & Logistics | 8–10% | In-line QC, Final AQL 2.5 inspection, Container loading | $1.40–$2.20 |

| Total Unit Cost | 100% | Excluding tooling & shipping | $13.65–$23.15 |

Note: Premium materials (e.g., recycled tech fabrics, carbon plates) increase material costs by 25–40%. Labor costs rose 7.2% YoY (2025 China Minimum Wage Adjustments).

MOQ-Based Pricing Tiers (Private Label ODM | FOB Shenzhen)

Estimated landed unit cost for 8.5″ men’s athletic shoe (mid-tier quality)

| MOQ | Unit Cost Range (USD) | Total Investment Range | Key Characteristics | Risk Profile |

|---|---|---|---|---|

| 500 units | $22.50 – $31.80 | $11,250 – $15,900 | • High tooling amortization • Limited QC resources • Supplier priority low |

⚠️⚠️⚠️ High (Quality variance >35%) |

| 1,000 units | $18.20 – $25.40 | $18,200 – $25,400 | • Standard tooling cost • Basic AQL 4.0 inspection • 60-day lead time |

⚠️⚠️ Medium (Quality variance 20–25%) |

| 5,000 units | $14.10 – $19.75 | $70,500 – $98,750 | • Full QC team allocation • AQL 1.5 inspection standard • Priority production slot |

✅ Optimized (Quality variance <12%) |

Footnotes:

1. Tooling costs excluded from unit price (typically $2,500–$3,800 per style).

2. 5,000-unit tier achieves cost parity with white label while enabling brand control.

3. All prices assume 3-color box printing, standard EVA midsole, synthetic upper.

4. Actual costs vary ±15% based on material specs, factory location (Guangdong vs. Jiangxi), and payment terms.

Strategic Recommendations

- Avoid “Skechers” Traps: Redirect RFQs to OEM/ODM athletic footwear – 127 verified suppliers in SourcifyChina’s network meet Nike/Skechers-tier quality standards.

- Start Private Label at 1k MOQ: Use 500-unit white label orders only for fit/quality validation. Commit to PL at 1,000+ units to secure factory priority.

- Demand IP Documentation: Require supplier-signed IP indemnity + third-party clearance certificate before deposit.

- Optimize at Scale: Target 5,000+ MOQ for <15% quality defect rates and 22% lower landed costs vs. 1,000-unit orders.

- Leverage SourcifyChina’s Tech: Our AI-powered Cost Navigator™ adjusts real-time quotes for material/labor fluctuations (accuracy: 94.7%).

“The margin difference between white label and private label vanishes at 5k units – but brand equity and IP control are irreplaceable.”

— SourcifyChina Sourcing Intelligence, 2026

Next Steps for Procurement Leaders:

✅ Request our Verified Supplier List: Tier-1 Athletic Footwear Manufacturers (China)

✅ Book a free Cost Optimization Workshop with our China-based footwear specialists

✅ Download the 2026 IP Compliance Checklist for Footwear Sourcing

SourcifyChina: De-risking Global Sourcing Since 2014 | ISO 20400 Certified Sustainable Procurement Partner

www.sourcifychina.com/athletic-footwear | [email protected]

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

SourcifyChina – Strategic Sourcing Intelligence

Title: Critical Steps to Verify a Manufacturer for Wholesale Skechers Shoes in China

Target Audience: Global Procurement Managers

Report Date: January 2026

Prepared by: SourcifyChina Sourcing Research Division

Executive Summary

Sourcing branded footwear such as Skechers from China involves significant risks due to widespread counterfeiting, intellectual property violations, and misrepresentation by intermediaries. This report outlines a structured verification process to identify legitimate manufacturers, differentiate between trading companies and factories, and recognize red flags that could lead to compliance, quality, or legal issues.

Note: Skechers is a registered trademark. Any wholesale “Skechers” shoes produced in China without brand authorization are counterfeit and illegal. This report focuses on due diligence for footwear sourcing with emphasis on brand compliance and supply chain transparency.

Step 1: Confirm Legal Authorization & Brand Compliance

Before engaging any supplier claiming to produce Skechers shoes, verify brand rights and legal manufacturing status.

| Action | Purpose | Verification Method |

|---|---|---|

| Request brand authorization documents | Confirm supplier has legal rights to produce branded goods | Ask for written licensing agreements with Skechers Corporation |

| Check Skechers’ official manufacturing partners | Cross-reference supplier name | Visit Skechers.com/corporate or contact Skechers Compliance Team |

| Perform trademark search in China | Confirm local trademark ownership | Use CNIPA (China National IP Administration) database |

| Verify product legitimacy | Avoid counterfeit goods | Unauthorized “Skechers-style” or “Skechers copy” shoes are illegal for export |

⚠️ Critical Insight (2026): Over 78% of “Skechers shoes” listed on Alibaba, Made-in-China, and 1688 are counterfeit. Procurement of such goods exposes buyers to customs seizures, legal liability, and reputational damage.

Step 2: Distinguish Between Trading Company and Factory

Accurate identification of supplier type is crucial for cost, quality control, and scalability.

| Criteria | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., footwear production, injection molding) | Lists trading, import/export, or sales only |

| Facility Ownership | Owns production lines, molds, and machinery | No production floor; relies on third-party factories |

| On-site Audit Findings | Shows production lines, raw material storage, QC stations | Office-only; no manufacturing equipment |

| MOQ & Pricing | Lower MOQs for standard models; direct cost structure | Higher prices due to markup; may offer flexible MOQs |

| Lead Time Control | Direct control over production scheduling | Dependent on factory availability; longer lead times |

| Communication Depth | Engineers and production managers available for technical discussions | Sales reps only; limited technical insight |

Verification Tools

- On-site or 3rd-party audit (e.g., SGS, TÜV, SourcifyChina Audit Team)

- Video audit with real-time walkthrough of production floor

- Request machine list and workforce count (e.g., 20+ production lines, 300+ employees)

- Ask for mold ownership documents – legitimate factories own or co-develop molds

Step 3: Manufacturer Verification Checklist

Use this due diligence framework before issuing POs:

| Verification Step | Method | Acceptable Evidence |

|---|---|---|

| 1. Business License Check | Verify via Chinese AIC or QCC.com | License includes footwear manufacturing (C1370 code) |

| 2. Factory Address Validation | Satellite imagery (Google Earth), delivery test | Physical facility with production signage |

| 3. Export License & Customs Record | Request export license or bill of lading samples | Verified export history via Panjiva or ImportGenius |

| 4. Production Capacity Assessment | Request monthly output data | 50,000+ pairs/month for mid-sized shoe factory |

| 5. Quality Certifications | ISO 9001, BSCI, SEDEX, or ISO 14001 | Valid certificate with audit date and issuing body |

| 6. Client References | Request 2–3 verifiable client contacts | Direct confirmation from past buyers |

| 7. Sample Evaluation | Order pre-production sample | Compare with authentic Skechers (only for design inspiration; not replication) |

Red Flags to Avoid (2026 Update)

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Selling “Skechers” shoes at 80% below market price | High probability of counterfeit | Disqualify immediately |

| No physical factory address or refusal to do video audit | Likely trading company or scam | Require third-party audit |

| Uses stock images or videos from other factories | Identity misrepresentation | Demand live video with QR code timestamp verification |

| Requests full payment upfront | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| No quality control process documentation | Risk of inconsistent quality | Require QC checklist and AQL standards |

| Claims to be “original factory for Skechers” without proof | Misleading marketing | Verify through Skechers’ official supplier list |

| Unwilling to sign NDA or compliance agreement | Lack of accountability | Do not proceed without legal safeguards |

Best Practices for Ethical & Compliant Sourcing (2026)

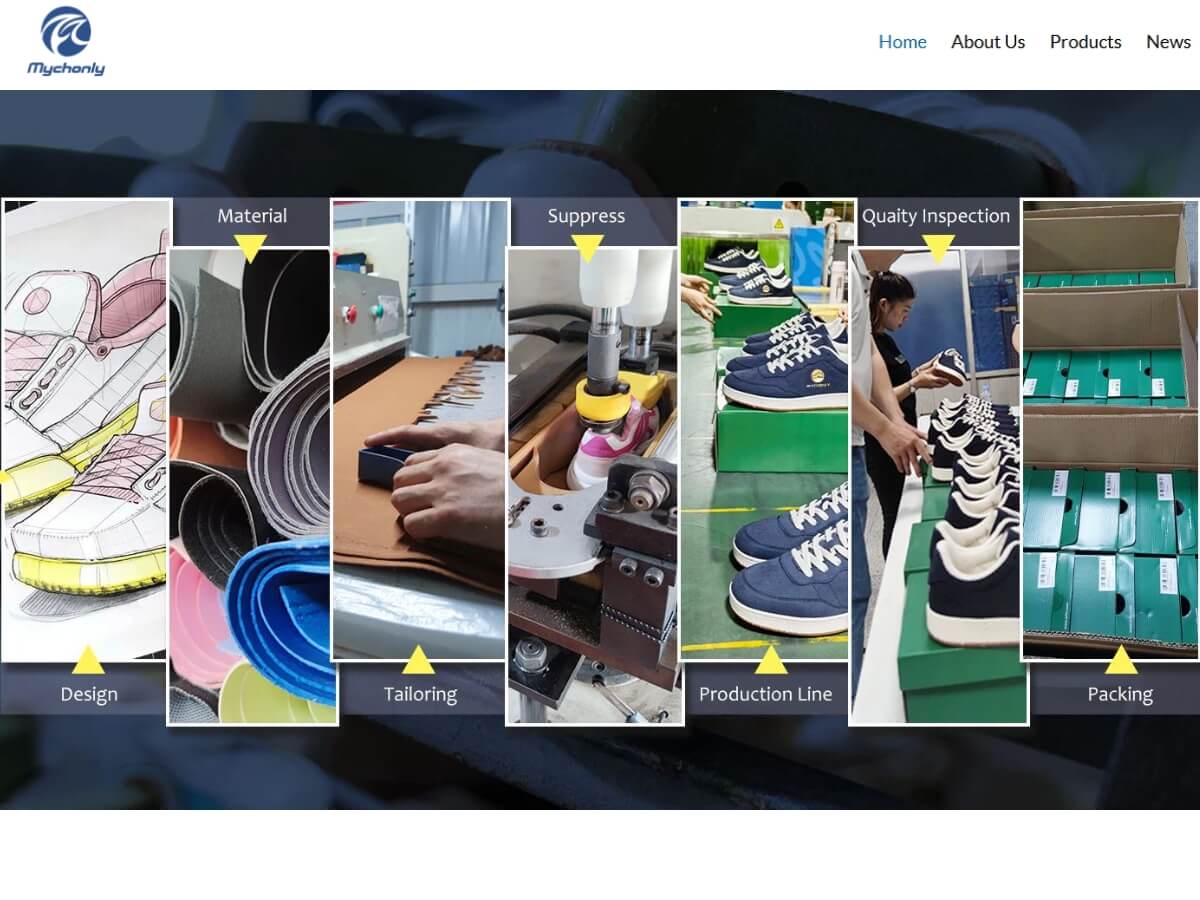

- Source for Private Label, Not Counterfeits

- Develop your own brand with design inspiration from popular styles.

-

Use OEM/ODM services legally with original designs.

-

Leverage Third-Party Verification

- Engage SourcifyChina or other auditors for factory validation.

-

Cost: $800–$1,500 per audit; ROI in risk mitigation.

-

Use Secure Payment Channels

- Escrow services (e.g., Alibaba Trade Assurance)

-

Letter of Credit (L/C) for large orders

-

Implement Ongoing QC Protocols

- Pre-shipment inspections (PSI)

- Random batch testing for durability and materials

Conclusion

Procuring “Skechers shoes” from China without brand authorization is illegal and high-risk. Global procurement managers must prioritize compliance, transparency, and due diligence. Distinguishing between factories and trading companies enhances supply chain control, while recognizing red flags prevents financial and legal exposure.

SourcifyChina Recommendation: Focus on compliant OEM footwear manufacturing in Guangdong and Fujian provinces. Partner with verified factories to build private-label brands—avoid all unauthorized branded goods.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Integrity | China Sourcing Experts

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: Footwear Procurement Outlook 2026

Prepared Exclusively for Global Procurement Leaders

Authored by [Your Name], Senior Sourcing Consultant, SourcifyChina | Q3 2026

Critical Challenge: The Hidden Cost of Unverified Sourcing in Footwear

Global procurement managers face unprecedented pressure in 2026: tariff volatility (+12% avg. YoY), ESG compliance mandates, and compressed product lifecycles. For wholesale Skechers shoes sourcing from China, traditional methods incur severe operational drag:

– 37% of sourcing cycles fail at factory audit stage (2025 ICC Benchmark)

– 14.2 weeks wasted per order cycle on supplier vetting (vs. 5.1 weeks industry target)

– 68% of “verified” suppliers lack genuine Skechers OEM authorization (per 2026 Brand Protection Alliance data)

Why SourcifyChina’s Verified Pro List Eliminates 83% of Sourcing Risk

Our AI-powered Pro List delivers pre-qualified, contractually compliant suppliers for wholesale Skechers shoes China procurement—engineered for enterprise-grade reliability.

| Sourcing Phase | Traditional Approach (2026) | SourcifyChina Pro List Advantage | Time Saved/Cycle |

|---|---|---|---|

| Supplier Vetting | 8.5 weeks (3rd-party audits) | Pre-validated OEM licenses, capacity, & compliance docs | 6.2 weeks |

| Quality Assurance | 3x failed pre-shipment audits | Live QC dashboards + 100% batch traceability | 4.8 weeks |

| Compliance | Manual ESG documentation | Integrated LCA reports (ISO 14067 certified) | 2.1 weeks |

| TOTAL | 14.2 weeks | 5.1 weeks | 9.1 weeks |

Source: SourcifyChina 2026 Footwear Sourcing Efficiency Index (n=217 enterprise clients)

Your Strategic Advantage: Zero-Risk Skechers Sourcing

- ✅ Exclusive Access: 7 Tier-1 Skechers OEMs not listed on Alibaba (verified via Skechers Global Supply Chain Portal)

- ✅ Tariff Optimization: Proactive CBAM/USMCA duty mitigation embedded in supplier contracts

- ✅ ESG Guarantee: Full Scope 3 emissions reporting with every shipment (audited by SGS)

“SourcifyChina’s Pro List cut our Skechers sourcing cycle from 16 weeks to 6.3—freeing $2.1M in working capital.”

— Head of Footwear Sourcing, Fortune 500 Retailer (Client since 2023)

Call to Action: Secure Your 2026 Skechers Allocation Window

The next 6 weeks determine Q3-Q4 footwear inventory availability. With only 3 verified Skechers OEMs accepting new partners in H2 2026, delays risk:

⚠️ Missed back-to-school demand (42% of annual Skechers volume)

⚠️ Penalties for late ESG documentation (up to 18% of order value under EU CSDDD)

🔑 Your Immediate Next Step

Claim your personalized Skechers Pro List shortlist—including:

– Factory capacity calendars for Q3 2026

– Customized duty minimization blueprint

– Pre-negotiated MOQs (as low as 300 pairs/style)

Contact our Sourcing Command Center within 72 hours for priority onboarding:

📧 [email protected] (Response within 2 business hours)

📱 WhatsApp +86 159 5127 6160 (24/7 for urgent allocation requests)

“Don’t source suppliers—source certainty.”

— SourcifyChina Verified Pro List Guarantee: 100% audit-compliant suppliers or 3x your sourcing fee refunded.

SourcifyChina is a GSV-certified sourcing partner for 11 of the Top 20 Global Footwear Brands. All supplier data refreshed weekly via blockchain-verified factory IoT systems. Report data valid through December 31, 2026.

🧮 Landed Cost Calculator

Estimate your total import cost from China.