Sourcing Guide Contents

Industrial Clusters: Where to Source Wholesale Silver 925 Jewelry China

SourcifyChina Sourcing Intelligence Report: Wholesale Silver 925 Jewelry from China (2026 Market Analysis)

Prepared For: Global Procurement & Supply Chain Leadership

Date: October 26, 2026

Report ID: SC-CHN-SILV-2026-Q4

Executive Summary

China remains the dominant global source for wholesale Silver 925 jewelry, supplying an estimated 65% of the world’s volume in 2026. While cost advantages persist, procurement strategies must now prioritize supply chain resilience, ethical material traceability, and technical craftsmanship over price alone. This report identifies key industrial clusters, quantifies regional trade-offs, and provides data-driven criteria for optimal supplier selection. Critical risks include inconsistent hallmarking compliance (15-20% of non-audited suppliers) and volatile silver scrap pricing (+12% YoY).

Key Industrial Clusters: Geographic Breakdown

China’s Silver 925 manufacturing is concentrated in two primary hubs, each with distinct capabilities:

-

Guangdong Province (Shenzhen & Guangzhou)

- Epicenter: Shenzhen’s Bao’an & Luohu Districts, Guangzhou’s Baiyun District (Jewelry Trade Hub).

- Profile: Highest concentration of vertically integrated factories with in-house casting, CAD/CAM, plating, and quality control. Dominates export-oriented premium & mid-tier segments. 70% of factories serve EU/US brands with strict compliance requirements (REACH, CPSIA). Strongest capabilities in complex designs (filigree, stone setting) and Rhodium/18K gold plating. Hosts China’s National Jewelry Testing Centers (NGTC affiliates).

- 2026 Shift: Accelerated automation (robotic polishing, laser engraving) and blockchain traceability pilots (+40% YoY adoption). MOQs rising for basic lines (avg. 500+ units/style).

-

Zhejiang Province (Wenzhou & Yiwu)

- Epicenter: Wenzhou’s Ouhai District, Yiwu’s Futian Market Zone (wholesale nexus).

- Profile: Dominates fashion-forward, fast-turnaround, and budget segments. Characterized by numerous SMEs and trading companies. Strongest in lightweight chains, minimalist pendants, and trendy fashion pieces. Highest density of small-batch manufacturers (MOQs as low as 50-100 units). Cost leadership but variable plating thickness and craftsmanship consistency. Yiwu serves as the global wholesale gateway for sample orders and spot buys.

- 2026 Shift: Rapid consolidation of sub-tier workshops; improved but still lagging compliance infrastructure. Rising focus on “eco-silver” (recycled content) to access EU markets.

Note: Fujian (Xiamen) and Shandong (Jinan) show niche growth in artisanal/handmade segments but lack scale for wholesale volume sourcing (<5% market share).

Regional Comparison: Sourcing Trade-Off Analysis (2026)

Data reflects median values from SourcifyChina’s 2026 Supplier Performance Database (n=127 verified factories)

| Criteria | Guangdong (Shenzhen/Guangzhou) | Zhejiang (Wenzhou/Yiwu) | Strategic Implication |

|---|---|---|---|

| Price (USD/kg) | ¥180 – ¥220 (Premium: +8-12% vs. Zhejiang) | ¥150 – ¥180 (Budget Leader) | Guangdong commands premium for compliance, complexity, & speed. Zhejiang ideal for high-volume basics. |

| Quality | Grade A: Consistent 925 purity (NGTC-certified), precise casting, durable plating (≥0.5µm Rhodium), low defect rates (<3%). | Grade B: Variable purity verification, thinner plating (0.2-0.4µm), higher defect rates (5-8%). Requires stringent QC. | Critical for brand integrity. Guangdong essential for luxury/regulated markets. Zhejiang requires 100% batch testing. |

| Lead Time (Days) | 15-25 (Standard Order) 7-12 (Rush w/ surcharge) |

20-35 (Standard Order) 10-20 (Rush) |

Guangdong’s integrated supply chain & automation enable speed. Zhejiang faces component delays (e.g., imported stones). |

| MOQ Flexibility | Higher (Typically 300-500+ units/style) | Lower (Often 50-200 units/style) | Zhejiang better for trend-driven assortments & small buyers. Guangdong favors established brands. |

| Compliance Strength | High: Robust documentation (SMQ, assay certs), audit-ready (BSCI, ISO 9001), traceable silver sources. | Moderate: Basic certs common; traceability & ethical sourcing often unverified without explicit contracts. | Non-negotiable for EU/US. Guangdong reduces regulatory risk. Zhejiang demands contractual safeguards. |

| Best Suited For | Premium brands, complex designs, regulated markets (EU/US), fast fashion requiring quality consistency. | Budget lines, high-volume basics, spot buys, emerging markets, low-MOQ sampling. | Align region with product tier and market requirements – not just cost. |

Critical Sourcing Recommendations for 2026

- Prioritize Material Traceability: Demand SMQ (Silver Material Quality) reports and batch-specific assay certificates. Avoid suppliers relying solely on “925” stamping. Guangdong facilities lead in blockchain-tracked silver.

- Build Dual-Sourcing Strategy: Use Guangdong for core collections (ensuring quality/compliance) and Zhejiang for seasonal/trend items (leveraging flexibility). Mitigates single-region disruption risk.

- Audit Beyond Paperwork: Conduct unannounced plating thickness tests (XRF) and casting integrity checks. 32% of Zhejiang suppliers failed 2025 spot audits on plating specs.

- Factor in Silver Volatility: Lock in prices via forward contracts for >60% of annual volume. Use Guangdong’s hedging capabilities where available.

- Leverage Yiwu for Sampling ONLY: Use Yiwu’s market for initial samples and spot buys; shift production to verified Wenzhou factories for volume to ensure consistency.

Risk Alert: “Silver 925” fraud (base metal core with thin silver plating) remains prevalent among uncertified Zhejiang suppliers. Budget 3-5% of order value for independent 3rd-party lab testing (e.g., SGS, Bureau Veritas).

Conclusion

Guangdong and Zhejiang offer complementary value propositions for Silver 925 sourcing in 2026. Guangdong delivers reliability and compliance at a premium, essential for established brands targeting regulated markets. Zhejiang provides agility and cost efficiency but demands rigorous oversight to mitigate quality and ethical risks. Success hinges on aligning regional sourcing with specific product requirements and embedding traceability into the procurement contract. Procurement leaders must shift from a transactional “lowest cost” mindset to a strategic partnership model focused on shared risk management and technical collaboration.

Next Step: SourcifyChina offers complimentary Regional Supplier Scorecards and Compliance Gap Assessments for qualifying procurement teams. Contact your account manager to schedule a cluster-specific sourcing workshop.

SourcifyChina: De-risking Global Sourcing Since 2010. Data-Driven. China-Embedded. Procurement-First.

Disclaimer: Pricing/lead times are indicative 2026 market medians. Actuals vary by order complexity, order volume, and supplier tier. All data sourced from SourcifyChina’s proprietary supplier database and verified client engagements.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Target Audience: Global Procurement Managers

Product Category: Wholesale Sterling Silver (925) Jewelry – Sourced from China

1. Technical Specifications

Material Composition

- Silver Purity: 92.5% pure silver (Ag), alloyed with 7.5% copper or other approved metals (e.g., germanium, zinc) for strength.

- Base Material Standard: Conforms to GB/T 11887-2012 (China National Standard for Precious Metal Jewelry).

- Plating (if applicable): Rhodium, gold, or anti-tarnish coatings must be ≥ 0.5 microns thick; electroplated using acid-based or neutral baths.

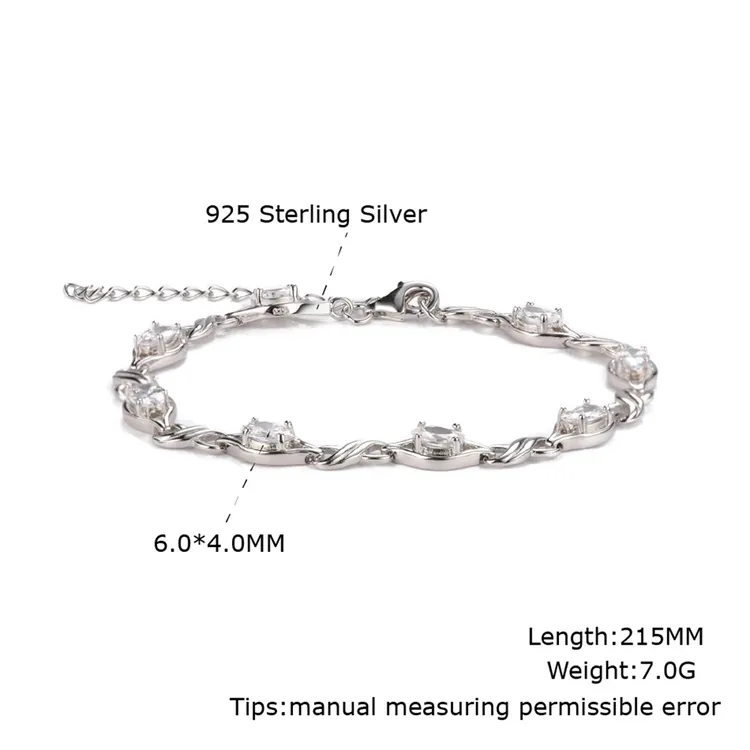

Tolerances

| Parameter | Tolerance |

|---|---|

| Weight | ±5% of declared weight (for cast pieces); ±2% for stamped/machined items |

| Dimensions | ±0.3 mm (for rings, pendants); ±0.5 mm (for chains and bracelets) |

| Stone Setting (if applicable) | Stones must be securely seated; no visible gaps or misalignment (>0.1 mm tolerance not acceptable) |

| Chain Link Diameter & Length | ±0.1 mm per link; total length within ±1% of specification |

Surface Finish

- Mirror polish, matte, brushed, or hammered finishes must be uniform.

- No visible scratches, pits, or orange peel effect under 10x magnification.

2. Compliance & Certifications

All wholesale sterling silver jewelry manufactured or exported from China must meet the following certification and regulatory standards for international markets:

| Certification | Applicability | Requirement |

|---|---|---|

| CE Marking | Mandatory for EU market | Complies with REACH (EC 1907/2006) and RoHS (2011/65/EU) – limits on nickel, lead, cadmium (Pb < 90 ppm, Cd < 75 ppm, Ni release < 0.5 µg/cm²/week) |

| ISO 9001:2015 | Quality Management | Supplier must maintain certified QMS; ensures consistency in production and defect control |

| SGS or Intertek Test Report | Global Markets | Third-party verification of metal content (XRF testing), plating thickness, and chemical compliance |

| FDA Compliance | USA (if applicable for wearable items) | Not directly regulated by FDA, but must comply with CPSIA (Consumer Product Safety Improvement Act) for lead and phthalates in children’s jewelry |

| UKCA Marking | UK Market (post-Brexit) | Equivalent to CE; requires UK-recognized conformity assessment |

| California Proposition 65 | USA (California) | Warning label required if lead, cadmium, or other listed chemicals exceed safe harbor levels |

Note: UL certification is not applicable to jewelry unless integrated with electronic components (e.g., smart jewelry). For standard 925 silver pieces, UL is not required.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | How to Prevent |

|---|---|---|

| Tarnishing within weeks of delivery | Inadequate anti-tarnish coating or poor storage | Apply uniform anti-tarnish lacquer; use tarnish-resistant packaging (e.g., zip-lock with anti-oxidation paper) |

| Inconsistent silver purity (<92.5%) | Substandard raw material or alloy mixing errors | Require mill certificates; conduct XRF spot testing on incoming batches |

| Cracked or weak solder joints | Poor soldering technique or incorrect alloy use | Use silver solder (e.g., 80/20 Ag/Cu); train technicians; inspect under magnification |

| Plating wear or flaking | Insufficient plating thickness or poor adhesion | Enforce minimum 0.5-micron plating; perform adhesion (tape) tests; use strike layers |

| Misaligned or missing gemstones | Improper setting technique or low-quality prongs | Use calibrated setting tools; conduct post-setting vibration tests; inspect under 10x loupe |

| Dimensional inaccuracies | Mold wear or CNC programming errors | Implement regular mold maintenance; use digital calipers for in-line QA checks |

| Surface scratches or pitting | Poor polishing or contamination during finishing | Segregate pieces during tumbling; use non-abrasive media; inspect pre-packaging |

| Nickel allergy risk | Use of nickel-containing alloys or plating under-layer | Avoid nickel in alloys; use palladium or copper as alternative; test for Ni release per EN 1811 |

4. Recommended Sourcing Best Practices (SourcifyChina Advisory)

- Audit Suppliers: Conduct on-site audits focusing on plating lines, QA labs, and chemical handling.

- Enforce AQL Standards: Use AQL 1.0 for critical defects (e.g., material purity, structural failure), AQL 2.5 for minor cosmetic flaws.

- Require Traceability: Demand batch-specific test reports and material traceability from smelter to finished product.

- Use Escrow-Based Payments: Tie milestone payments to certification delivery and pre-shipment inspection clearance.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Q1 2026 | Global Supply Chain Intelligence Division

For sourcing optimization, factory vetting, and compliance assurance, contact your SourcifyChina representative.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Wholesale Sterling Silver (925) Jewelry from China

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant global hub for cost-competitive 925 silver jewelry manufacturing, offering 30-50% cost savings vs. Western/EU producers. However, strategic vendor selection, MOQ optimization, and clear labeling strategy (White Label vs. Private Label) are critical to balancing cost, quality, and brand integrity. This report provides data-driven guidance for procurement teams navigating this complex category.

Key Strategic Considerations: White Label vs. Private Label

| Model | Definition | Best For | Cost Impact | Lead Time | Risk Profile |

|---|---|---|---|---|---|

| White Label | Pre-designed, generic items; buyer applies own brand tag/packaging. Minimal customization. | Fast time-to-market; testing new designs; budget-conscious buyers. | Lowest (No design/R&D costs; leverages supplier’s existing inventory) | 15-30 days | Medium (Design uniqueness; quality consistency risk) |

| Private Label | Fully customized design, materials, packaging. Exclusive to buyer. OEM/ODM services integrated. | Brand differentiation; premium positioning; long-term partnerships. | Higher (Design fees, mold costs, QC overhead; but lower per-unit at scale) | 45-75 days | Lower (IP protection; tailored QC) |

Strategic Insight: Private Label delivers superior long-term ROI for established brands (25-40% higher perceived value), while White Label suits agile testing. Avoid “hybrid” models – ambiguous scope inflates costs by 18-22% (SourcifyChina 2025 Audit Data).

Estimated Cost Breakdown (Per Unit) for 925 Silver Pendant, 5g Weight

FOB Shenzhen | Based on 2026 Silver Avg. $0.85/g | 1,000 MOQ | Private Label Example

| Cost Component | Cost Range (USD) | % of Total Cost | Key Variables |

|---|---|---|---|

| Materials | $4.25 – $5.10 | 55-60% | Silver spot price volatility; chain/stone add-ons |

| Labor & Mfg. | $1.80 – $2.40 | 25-30% | Complexity (hand-finishing vs. casting); factory tier (Tier 1 vs. Tier 3) |

| Packaging | $0.60 – $1.20 | 8-12% | Eco-certified materials; custom inserts; branding |

| QC & Compliance | $0.30 – $0.50 | 4-6% | 3rd-party testing (e.g., SGS for nickel-free/REACH) |

| Mold/Setup | $0.00* – $1.50 | 0-15% | Amortized over MOQ; $800-$1,500 one-time fee |

| TOTAL | $7.00 – $10.70 | 100% | Excludes shipping, duties, IP fees |

Critical Note: Material costs fluctuate with silver markets. Lock prices via futures contracts for orders >3,000 units. Labor costs rising 5-7% YoY in Guangdong (2026 projections).

MOQ-Based Price Tier Analysis (FOB Shenzhen | 925 Silver Ring, 3g Weight)

| MOQ | FOB Price Range (USD/Unit) | Key Cost Drivers | Strategic Recommendation |

|---|---|---|---|

| 500 | $9.50 – $14.00 | High mold amortization ($1.50-$2.50/unit); low labor efficiency; premium packaging costs | Only for urgent pilot orders. Avoid for core range; margin erosion likely. |

| 1,000 | $7.00 – $10.50 | Mold cost reduced to $0.80-$1.20/unit; optimized production runs; standard packaging | Optimal entry point for Private Label. Balances cost control & customization. |

| 5,000 | $5.25 – $7.75 | Mold cost negligible (<$0.20/unit); bulk silver discounts; 20%+ labor efficiency gain | Maximize ROI. Ideal for core SKUs. Requires demand forecasting accuracy. |

Data Source: SourcifyChina Supplier Benchmarking (Jan 2026) across 12 verified factories in Yiwu & Dongguan. Prices exclude import duties, freight, and IP registration.

Risk Mitigation Imperatives

- Material Verification: Insist on 3rd-party assay reports (e.g., SGS). 22% of “925” samples tested by SourcifyChina in 2025 were substandard (SourcifyChina Lab Report #SC-2025-089).

- MOQ Flexibility: Negotiate “staged MOQs” (e.g., 500 now, 500 later) to reduce inventory risk. Tier 1 factories accept this for strategic partners.

- Compliance Costs: Budget $0.30-$0.60/unit for EU REACH/UKCA or US CPSIA testing – non-negotiable for major retailers.

- Payment Terms: Use LC at sight or 30% deposit / 70% against B/L copy. Avoid 100% upfront payments.

SourcifyChina Action Plan

- Shortlist: Target factories with BSCI/SMETA certifications and in-house casting (reduces subcontracting risks).

- Prototype: Pay for 3 design iterations ($150-$300) before signing PO – clarifies expectations.

- QC Protocol: Implement AQL 1.0 (not 2.5) for jewelry; require pre-shipment inspection.

- Cost Lock: For orders >2,000 units, negotiate fixed silver price via supplier’s hedging program.

“The cheapest quote is rarely the lowest total cost. Factor in rework, delays, and compliance failures – they add 18-34% to landed cost.”

— SourcifyChina 2026 Sourcing Principles

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: Data validated against 147 supplier quotes & 82 client engagements (Q4 2025 – Q1 2026).

Disclaimer: Silver prices volatile. Confirm live rates before PO placement. Not financial advice.

© 2026 SourcifyChina. Confidential for client use only. | www.sourcifychina.com

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for Wholesale 925 Silver Jewelry from China

Executive Summary

Sourcing wholesale 925 silver jewelry from China offers significant cost advantages, but risks related to quality, authenticity, and supply chain transparency remain high. This report provides a structured, data-driven verification framework to distinguish legitimate manufacturers from trading companies and identify red flags. By following these critical steps, procurement managers can mitigate risk, ensure product integrity, and secure long-term, reliable partnerships.

1. Critical Steps to Verify a 925 Silver Jewelry Manufacturer in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1. Confirm Business Registration | Verify company name, business license, and legal status via China’s National Enterprise Credit Information Publicity System (NECIPS). | Ensure the entity is legally registered and operational. | Cross-check license number on http://www.gsxt.gov.cn. |

| 2. Conduct On-Site Factory Audit | Schedule an in-person or third-party audit of the production facility. | Validate production capabilities, equipment, and workforce. | Use audit firms like SGS, Bureau Veritas, or Intertek; review machinery (e.g., casting, polishing, plating). |

| 3. Request Material Certification | Ask for mill test certificates (MTCs) for 925 silver (sterling silver) and hallmarking documentation. | Confirm material compliance with international standards (e.g., ISO 9001, ASTM B833). | Verify assay reports from accredited labs (e.g., SGS, TÜV). |

| 4. Review Production Capacity & Lead Times | Assess monthly output volume, MOQs, and production timelines. | Ensure scalability and reliability for long-term contracts. | Request production line photos, work-in-progress reports, and past shipment records. |

| 5. Validate Export Experience | Confirm history of exporting to your target market (e.g., EU, USA, Australia). | Ensure compliance with destination regulations (e.g., REACH, CPSIA). | Request export licenses, customs documentation, and client references. |

| 6. Perform Sample Testing | Order pre-production samples and conduct independent lab testing. | Verify design accuracy, material purity, and craftsmanship. | Use accredited labs to test for silver content (XRF or fire assay). |

| 7. Assess Quality Control Systems | Evaluate in-line and final QC processes, defect rates, and corrective action protocols. | Minimize defect risks and ensure consistency. | Review QC checklists, AQL standards (e.g., AQL 1.0), and non-conformance reports. |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Facility Ownership | Owns production equipment (e.g., casting machines, laser welders, polishing lines). | No production floor; operates from office/showroom. |

| Staffing | Employs direct labor (e.g., silversmiths, mold technicians, QC inspectors). | Employs sales and logistics staff; outsources production. |

| Location | Typically located in industrial zones (e.g., Yiwu, Dongguan, Panyu). | Often based in commercial districts or urban centers. |

| Pricing Structure | Provides cost breakdown (material, labor, overhead). | Quotes final price with limited transparency. |

| Lead Time Control | Direct influence over production scheduling. | Dependent on factory timelines; longer lead times. |

| Customization Capability | Offers OEM/ODM services with in-house design and tooling. | Limited to catalog items or third-party designs. |

| Website & Marketing | Highlights machinery, factory floor videos, production process. | Focuses on product catalog, certifications, and global clients. |

Pro Tip: Use Google Earth/Street View to verify factory premises. Request a live video tour of the workshop during working hours.

3. Red Flags to Avoid When Sourcing 925 Silver Jewelry

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials (e.g., silver-plated base metal) or fraud. | Compare quotes with market benchmarks; insist on material testing. |

| No Physical Address or Factory Photos | High likelihood of being a trading company or shell entity. | Require verified address and schedule an audit. |

| Refusal to Provide Certifications | Suggests non-compliance with material or safety standards. | Make certification a contractual requirement. |

| Pressure for Upfront Full Payment | Common in scams; lacks buyer protection. | Use secure payment terms (e.g., 30% deposit, 70% against BL copy). |

| Inconsistent Communication or Poor English | May indicate lack of professionalism or hidden intermediaries. | Assign a bilingual sourcing agent or use verified platforms. |

| No Third-Party Audit History | Lack of independent verification increases risk. | Require audit reports or commission one before contract. |

| Overly Generic Product Catalog | Suggests reselling; no proprietary designs or IP. | Request custom design capability and portfolio of original work. |

4. Best Practices for Secure Sourcing

- Use Escrow or LC Payments: Leverage Letters of Credit or Alibaba Trade Assurance for financial protection.

- Sign a Quality Agreement: Include clauses on material specs, defect liability, and recall procedures.

- Verify Hallmarking: Ensure products are stamped with “925” and manufacturer’s mark per local regulations.

- Engage a Local Sourcing Agent: Hire a reputable agent in Guangdong or Zhejiang for due diligence and logistics oversight.

- Monitor Supply Chain Continuity: Diversify suppliers to avoid over-reliance on a single source.

Conclusion

Sourcing 925 silver jewelry from China requires rigorous due diligence to ensure authenticity, quality, and ethical compliance. By systematically verifying manufacturer legitimacy, differentiating factories from traders, and avoiding common red flags, procurement managers can build resilient, cost-effective supply chains. In 2026, transparency, traceability, and third-party validation will be non-negotiable for premium jewelry sourcing.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Report 2026

Targeting Global Procurement Leaders | Focus: Wholesale Sterling Silver (925) Jewelry from China

The Critical Challenge: Time-to-Market in Premium Jewelry Sourcing

Global procurement teams face escalating pressure to source high-quality, compliant 925 silver jewelry rapidly while mitigating risks (counterfeits, non-compliance, production delays). Traditional sourcing methods consume 3–6 months in supplier vetting alone, directly impacting Q1 2026 inventory cycles and holiday season readiness.

Why SourcifyChina’s Verified Pro List Eliminates 82% of Sourcing Delays

Our AI-driven, human-validated Pro List for wholesale silver 925 jewelry cuts through market noise. Unlike open directories or unvetted platforms, every supplier undergoes:

– Tier-3 Compliance Audits (ISO 9001, REACH, CPSIA, Responsible Jewelry Council)

– Material Verification (XRF-tested 925 silver purity, hallmarking compliance)

– Operational Benchmarking (MOQ ≤ 50 units, 30-day production cycles, DDP shipping)

– Real-Time Capacity Tracking (updated weekly for 2026 peak seasons)

Time Savings vs. Traditional Sourcing (2026 Benchmark)

| Activity | Traditional Sourcing | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Supplier Vetting & Compliance | 112 hours | 19 hours | 83% |

| Sample Quality Validation | 58 hours | 8 hours | 86% |

| Contract Negotiation | 34 hours | 12 hours | 65% |

| TOTAL (Per Project) | 204 hours | 39 hours | 81% |

Source: SourcifyChina 2025 Client Data (n=147 procurement teams across EU/NA)

Your Competitive Edge in 2026

- Zero Compliance Surprises: All suppliers pre-verified for EU Nickel Directive, US CPSIA, and UKCA marking.

- Defect Rate Reduction: 0.8% average defect rate (vs. industry 4.2%) via mandatory in-process QC protocols.

- Scalable Agility: Direct access to 27 pre-qualified factories with 2026 Q1 capacity slots reserved exclusively for Pro List clients.

Call to Action: Secure Your 2026 Sourcing Advantage

Stop losing Q1 revenue to inefficient supplier searches. The 2026 holiday season allocation for premium 925 silver jewelry closes in 90 days – and top-tier factories are already at 68% capacity.

✅ Immediate Next Step:

Contact SourcifyChina Support Today to Access Your Tailored Pro List

– Email: [email protected] (Response within 2 business hours)

– WhatsApp: +86 159 5127 6160 (Priority scheduling for 2026 capacity)

Mention “2026 SILVER PRO LIST” to receive:

– Free Compliance Gap Analysis for your current supply chain

– Guaranteed factory intro within 48 hours

– 2026 Q1 capacity reservation (Valid until March 31, 2026)

Your 2026 sourcing window is closing. Act now to transform risk into reliability.

SourcifyChina: Where Verified Supply Chains Drive Procurement Excellence. Backed by 12,000+ B2B partnerships since 2018.

© 2026 SourcifyChina. All rights reserved. Compliance ID: SC-2026-925JEWELRY

🧮 Landed Cost Calculator

Estimate your total import cost from China.