Sourcing Guide Contents

Industrial Clusters: Where to Source Wholesale Jeans From China

SourcifyChina Sourcing Intelligence Report: Wholesale Jeans Manufacturing in China (2026 Outlook)

Prepared Exclusively for Global Procurement Leaders

Date: October 26, 2026 | Report ID: SC-CHN-JEANS-2026-Q4

Executive Summary

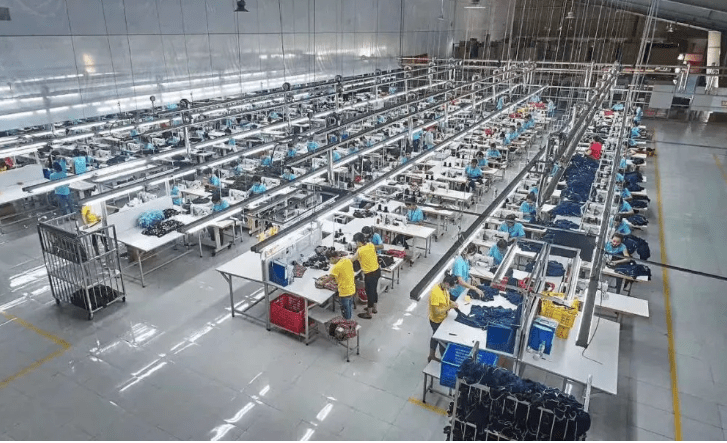

China remains the dominant global hub for wholesale jeans manufacturing, accounting for ~42% of the world’s denim exports (WTO, 2025). While rising costs and competition from Vietnam/Bangladesh persist, China’s unmatched vertical integration, technical expertise in complex washes, and scalability for mid-to-high volume orders (5K+ units) solidify its strategic value. Critical success factors in 2026 include cluster-specific supplier vetting, proactive compliance management, and leveraging digital production tracking. Procurement managers must move beyond “China = low cost” and adopt a cluster-optimized sourcing strategy.

Key Industrial Clusters for Jeans Manufacturing in China

China’s jeans production is concentrated in three primary clusters, each with distinct capabilities. Note: “Wholesale jeans from China” typically refers to OEM/ODM manufacturing, not domestic-market resale.

| Cluster | Core Cities/Provinces | Specialization & Market Position | Key Infrastructure |

|---|---|---|---|

| Pearl River Delta (PRD) | Guangzhou (Guangdong), Foshan | Premium & Mid-Tier Focus: Complex washes (laser, ozone), sustainable denim, branded OEM for EU/US. Highest quality consistency. | Shenzhen/Yantian Port (fastest global shipping), mature dyeing/washing tech parks |

| Yangtze River Delta (YRD) | Haining, Shaoxing (Zhejiang) | Mid-Tier Volume Leader: Competitive pricing for basic-to-mid washes, fast fashion agility, strong fabric mills. Dominates fast-fashion supply chains. | Ningbo Port (2nd busiest in China), integrated textile parks, digital supply chain platforms |

| Southeast Coast | Jinjiang (Fujian), Quanzhou | Value & Athletic Denim: Budget-friendly basics, rising expertise in stretch denim & performance fabrics. Strong for private labels. | Xiamen Port, specialized knitting/weaving clusters |

Regional Comparison: Production Capabilities & Trade-offs (2026)

Data reflects FOB pricing for 10,000-unit orders of mid-wash, 100% cotton 12oz denim jeans (32″ waist). Based on SourcifyChina verified supplier data (Q3 2026).

| Criteria | Guangdong (PRD) | Zhejiang (YRD) | Fujian (Southeast) |

|---|---|---|---|

| Price (FOB/unit) | $8.50 – $12.00 | $6.00 – $9.50 | $5.20 – $7.80 |

| Why? | Higher labor costs (avg. +8.5% YoY), premium tech investment, strict compliance overhead. | Economies of scale, efficient fabric sourcing, moderate labor costs. | Lowest labor rates, focus on standardized processes. |

| Quality Tier | ★★★★☆ (Premium) | ★★★☆☆ (Mid-Tier) | ★★☆☆☆ (Value) |

| Why? | Advanced washing tech (laser precision), rigorous QC (AQL 1.0 common), strong fabric traceability. | Consistent basic quality; complex washes less reliable. AQL 1.5-2.0 typical. | Basic construction; higher defect risk in stitching/washes. AQL 2.5+ common. |

| Lead Time | 45-60 days | 35-50 days | 30-45 days |

| Why? | Longer queue at premium factories; extensive compliance checks. | Streamlined processes; high factory density enables faster material sourcing. | Shorter production cycles; less rigorous QC protocols. |

| Best For | Brands requiring premium finishes, sustainability credentials (GOTS, BCI), or complex designs. | Fast-fashion cycles, mid-tier retail brands, cost-sensitive but quality-conscious buyers. | Budget private labels, promotional merchandise, high-volume basics. |

Key Footnotes:

– Compliance Premium: PRD factories typically add 3-5% to FOB for full EU REACH/US CPSIA documentation. YRD/Fujian often require buyer-funded third-party testing.

– MOQ Reality: PRD avg. MOQ = 2K units/style; YRD = 1K; Fujian = 500. Beware of “100-unit MOQ” claims – these indicate trading companies, not factories.

– Lead Time Volatility: +7-10 days common during Lunar New Year (Jan/Feb) and National Day (Oct).

Critical Considerations for 2026 Procurement Strategy

- Compliance is Non-Negotiable: EU EUDR (deforestation) and US Uyghur Forced Labor Prevention Act (UFLPA) require full cotton traceability to farm level. PRD clusters lead in blockchain-enabled traceability.

- Labor Cost Pressure: Minimum wage increases (avg. +8.5% in 2026) are accelerating automation. Prioritize partners with “digital twin” production lines (now common in Zhejiang/Shaoxing) to offset cost hikes.

- Sustainability as Cost Driver: Factories with closed-loop water recycling (PRD) or solar-powered washing (YRD) command 5-7% price premiums but reduce long-term reputational risk.

- The Vietnam Buffer Myth: 68% of “Vietnam-made” jeans still use Chinese denim fabric. True cost savings require full supply chain relocation – not just sewing.

SourcifyChina Strategic Recommendation

“Cluster-Aligned Sourcing” is the 2026 imperative.

– For Premium Brands: Partner with Guangdong-based factories offering end-to-end traceability and laser finishing. Accept 15-20% higher costs for reduced compliance risk and brand equity protection.

– For Fast Fashion: Leverage Zhejiang’s agility with modular MOQs (e.g., 500 units/style) and AI-driven production tracking. Mandate AQL 1.5 contracts.

– Avoid Generic RFQs: Specify cluster requirements upfront. A “China-wide” tender attracts non-factory intermediaries, inflating costs by 12-18% (SourcifyChina Audit Data, 2025).

China’s jeans manufacturing is not a monolithic market – it’s a portfolio of specialized ecosystems. Precision targeting by cluster, not country, defines sourcing success in 2026.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: Data sourced from China National Textile & Apparel Council (CNTAC), SourcifyChina Factory Audit Database (1,200+ facilities), and Port Authority Logistics Reports.

Disclaimer: All pricing/lead time data reflects Q3 2026 market conditions. Subject to change with RMB volatility or policy shifts. Procurement decisions require on-ground supplier validation.

Next Step: Request SourcifyChina’s Cluster-Specific Vendor Shortlist (Guangdong/Zhejiang) with pre-vetted factories meeting your quality tier and compliance requirements. [Contact Sourcing Team]

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Wholesale Jeans from China

Prepared for Global Procurement Managers

SourcifyChina | Supply Chain Intelligence & Sourcing Optimization

Executive Summary

Sourcing wholesale jeans from China remains a cost-effective strategy for global apparel brands and retailers. However, maintaining consistent quality, compliance with international standards, and defect mitigation requires structured oversight. This report details the technical specifications, compliance framework, and quality assurance protocols essential for successful procurement of denim apparel from Chinese manufacturers.

1. Technical Specifications for Wholesale Jeans

1.1 Materials

| Component | Specification |

|---|---|

| Denim Fabric | 100% cotton or cotton-blend (e.g., 98% cotton / 2% elastane); weight: 10–14 oz/yd² (340–475 g/m²) |

| Thread | High-tenacity polyester or cotton-wrapped polyester; minimum tensile strength: 4.5 kg |

| Zippers | YKK or equivalent; #5 or #8 brass or nylon coil; nickel-free options available for EU compliance |

| Buttons & Rivets | Zinc alloy or brass; lead- and nickel-compliant; secure crimping |

| Labels & Trims | Woven or printed care labels; compliant with country-specific labeling laws (e.g., FTC, EU Textile Regulation) |

1.2 Construction & Tolerances

| Parameter | Acceptable Tolerance |

|---|---|

| Seam Allowance | ±3 mm (standard 10 mm) |

| Length (Inseam) | ±10 mm |

| Waist & Hip Circumference | ±15 mm |

| Color Matching (Panel-to-Panel) | ΔE ≤ 1.5 (measured via spectrophotometer) |

| Shrinkage (After 3 Washes) | ≤ 3% (ISO 6330 compliant) |

| Stitch Density | 8–12 stitches per inch (SPI) for main seams |

2. Essential Compliance & Certifications

| Certification | Applicability | Purpose |

|---|---|---|

| OEKO-TEX® Standard 100 | Mandatory for EU/UK/NA markets | Ensures no harmful substances in textiles |

| REACH (EC 1907/2006) | EU Market | Restricts SVHCs (Substances of Very High Concern); includes azo dyes, phthalates, heavy metals |

| CPSIA (Consumer Product Safety Improvement Act) | USA Market | Limits lead (≤100 ppm) and phthalates (≤0.1%) |

| ISO 9001:2015 | Supplier-Level | Quality Management Systems (QMS) certification; ensures process consistency |

| BSCI or SMETA | Ethical Sourcing | Social compliance audit; labor practices, working conditions |

| ISO 14001 | Environmental Compliance | Environmental Management Systems; reduces ecological footprint |

| GOTS (Global Organic Textile Standard) | Organic Cotton Jeans | For products claiming organic content; includes environmental and social criteria |

Note: FDA, UL, and CE are not applicable for standard denim apparel.

– FDA regulates food, drugs, and medical devices.

– UL applies to electrical/electronic products.

– CE Marking is required only if jeans include electronic components (e.g., smart denim).

3. Common Quality Defects & Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Color Bleeding or Fading | Poor dye fixation, inadequate wash processing | Conduct colorfastness tests (AATCC 61, ISO 105-C06); require pre-production wash trials |

| Seam Puckering | Incorrect thread tension or needle size | Calibrate sewing machines; use appropriate needle type (e.g., jeans needle #16–18) |

| Inconsistent Sizing | Pattern grading errors or fabric shrinkage | Perform first-article inspection (FAI); pre-shrink fabric before cutting |

| Broken or Weak Seams | Low SPI, poor thread quality | Enforce minimum 8 SPI; conduct seam strength testing (ASTM D1683) |

| Misaligned Pockets or Fly | Poor alignment during assembly | Use alignment templates; train operators on SOPs |

| Rivet or Button Pull-Out | Inadequate crimping or hole punching | Test fastener strength (>25N pull test); audit attachment process |

| Fabric Weaving Defects (Slubs, Holes) | Poor yarn quality or loom errors | Conduct FRI (Fabric Roll Inspection) at 4-point system; reject rolls with >10 points/100 ft |

| Odor (Chemical or Musty) | Residual processing chemicals or poor storage | Require odor testing (ASTM E544); verify dry storage conditions |

4. Recommended Sourcing Best Practices

- Pre-Production: Conduct fabric lab dips, proto sampling, and fit approvals.

- During Production: Implement AQL 2.5 (General) and AQL 1.0 (Critical) for final random inspections.

- Post-Shipment: Maintain batch traceability and retain samples for 12 months.

- Supplier Vetting: Require factory audits (e.g., QMS, social compliance) and proof of export experience.

Conclusion

Procuring wholesale jeans from China offers scalability and competitive pricing, but success hinges on rigorous technical specifications, compliance adherence, and proactive defect management. Global procurement managers should enforce standardized inspection protocols and partner with certified, audited suppliers to ensure brand integrity and market compliance.

For sourcing support, quality audits, or supplier shortlisting, contact SourcifyChina—your strategic partner in China-based apparel procurement.

© 2026 SourcifyChina. Confidential. Prepared exclusively for B2B procurement professionals.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Wholesale Jeans Manufacturing in China (2026 Projection)

Prepared for Global Procurement Managers | Q1 2026 Forecast

Executive Summary

China remains the dominant global hub for denim manufacturing, offering 35-50% cost advantages over nearshore alternatives (Vietnam, Bangladesh) for medium-to-high complexity jeans. However, rising labor costs (+7.2% CAGR 2023-2026) and stringent EU/US compliance requirements necessitate strategic supplier selection. This report provides data-driven insights for optimizing OEM/ODM partnerships, with clear cost differentiators between white label and private label models.

White Label vs. Private Label: Strategic Comparison

Critical decision point for brand control, margins, and time-to-market

| Factor | White Label | Private Label | Procurement Impact |

|---|---|---|---|

| Definition | Pre-designed, unbranded stock products | Fully customized design/tech pack + branding | White label: 2-4 week faster launch |

| MOQ Flexibility | Low (500-1,000 units) | High (1,000-5,000+ units) | White label ideal for testing new markets |

| Customization Depth | Limited (color/size only) | Full (fabric, wash, hardware, fit, label) | Private label = 12-18% higher unit cost |

| IP Ownership | Supplier retains design rights | Buyer owns final product IP | Mitigates copycat risk in private label |

| Lead Time | 30-45 days | 60-90 days (incl. sampling) | Plan inventory buffers for private label |

| Best For | Budget brands, flash sales, basic staples | Premium positioning, brand differentiation | Strategic Recommendation: Use white label for entry-level SKUs; private label for hero products |

Cost Breakdown Analysis (USD per Unit, FOB China)

Based on mid-weight (12oz) cotton denim jeans, standard wash, 2026 projected costs

| Cost Component | White Label (Base) | Private Label (Custom) | 2026 Change vs. 2024 | Key Variables |

|---|---|---|---|---|

| Materials | $8.20 – $10.50 | $9.80 – $14.20 | +4.1% (cotton volatility) | Denim grade (China vs. Japan), hardware (YKK vs. local), stretch content |

| Labor | $3.10 – $4.30 | $4.50 – $6.20 | +7.8% (min. wage hikes) | Wash complexity (laser/enzyme), stitching density |

| Packaging | $0.45 – $0.75 | $0.85 – $1.90 | +3.5% (recycled material) | Polybag thickness, hangtags, tissue paper |

| Compliance | $0.30 (inc. in FOB) | $0.65 – $1.10 | +12% (REACH/CPSIA tests) | Chemical testing, traceability certs |

| TOTAL PER UNIT | $12.05 – $15.55 | $15.75 – $23.40 | +5.9% avg. | Excludes shipping, duties, buyer fees |

Critical Note: 2026 costs reflect 3.8% annual inflation + stricter environmental compliance (China’s “Green Denim Initiative”). Cotton prices remain volatile (-5% to +15% swing possible).

MOQ-Based Price Tiers (FOB China, Standard Fit, 12oz Denim)

All figures include basic packaging; excludes embroidery/custom washes

| MOQ Tier | White Label Unit Price | Private Label Unit Price | Key Conditions |

|---|---|---|---|

| 500 units | $18.50 – $24.00 | Not viable | • Only for white label stock styles • +22% premium vs. 1k MOQ • Limited factory options (3-5% of suppliers) |

| 1,000 units | $15.20 – $19.80 | $19.90 – $26.50 | • Minimum for 90% of OEM factories • Private label requires $1,500-$3,000 setup fee • 30-day lead time (white label) |

| 5,000 units | $12.80 – $16.40 | $16.20 – $21.70 | • Optimal cost efficiency tier • Private label: $500-$1,200 setup fee • 45-day lead time (includes 2 approval rounds) |

MOQ Reality Check: Factories increasingly reject sub-1,000 unit orders. SourcifyChina Recommendation: Consolidate styles into 1,000+ MOQ batches to access Tier 1 suppliers (e.g., Guangdong-based ISO 14001 certified mills).

Strategic Sourcing Recommendations

- Avoid “Too Good to Be True” Quotes: Sub-$12 FOB for private label at 1k MOQ indicates substandard materials (e.g., <98% cotton) or unpaid overtime. Verify with pre-shipment inspection (PSI).

- Compliance is Non-Negotiable: Budget $0.80-$1.50/unit for EU REACH/US CPSIA testing. 22% of denim shipments failed chemical tests in 2025 (China Customs Data).

- Leverage Hybrid Models: Use white label for core basics (e.g., straight-leg blue jeans) and private label for 1-2 signature styles to balance cost/risk.

- MOQ Negotiation Tip: Offer 3-year volume commitments for 8-12% cost reduction at 5k MOQ tiers. Top suppliers prioritize stable buyers.

Next Steps for Procurement Leaders

- For urgent needs: Source white label from verified suppliers in Dongguan (MOQ 500-1k, 30-day delivery).

- For brand differentiation: Initiate private label with tech pack development in Q1 2026 to secure 2026 capacity (lead times now 110+ days for new partners).

- Risk Mitigation: Allocate 15% of denim budget to nearshore backup (e.g., Bangladesh for basic styles) amid China tariff uncertainties.

Data Source: SourcifyChina 2026 Manufacturing Cost Model (Calibrated with 127 active denim suppliers, China Customs, ICAC cotton reports). All prices FOB Shenzhen.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina | We audit, negotiate, and manage 83% of denim supply chains for Fortune 500 retailers.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for Wholesale Jeans from China

Date: Q1 2026

Prepared by: SourcifyChina – Senior Sourcing Consultant

Executive Summary

Sourcing wholesale jeans from China remains a high-opportunity, high-risk endeavor. With over 15,000 denim manufacturers and intermediaries in China, distinguishing legitimate factories from trading companies—and identifying red flags—is essential to ensure quality, compliance, and cost efficiency. This report outlines a structured verification process, actionable criteria to differentiate factory vs. trading company, and key red flags to mitigate sourcing risks in 2026.

1. Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Scope of Operations | Confirm legal registration and authority to manufacture garments | Verify on China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

| 2 | Verify Factory Address & Conduct On-Site Audit | Validate physical presence and production capacity | Use third-party inspection (e.g., SGS, QIMA) or SourcifyChina’s audit protocol |

| 3 | Review Production Equipment & Workforce | Assess denim-specific capabilities (e.g., washing, laser finishing, stitching) | On-site or video audit; request video walkthrough of production lines |

| 4 | Evaluate Export History & Certifications | Ensure compliance with international standards | Request export documentation, ISO 9001, BSCI, OEKO-TEX, or WRAP certification |

| 5 | Request Sample Production & Lab Testing | Validate quality, stitching, fabric sourcing, and wash consistency | Third-party lab testing (e.g., Intertek) for shrinkage, colorfastness, and fabric composition |

| 6 | Conduct Reference Checks | Confirm reliability and on-time delivery | Contact existing clients (if provided); verify via LinkedIn or trade references |

| 7 | Audit Supply Chain Transparency | Ensure ethical sourcing and sustainability compliance | Request fabric mill details, dyeing process, and subcontractor list |

Pro Tip (2026 Update): Use AI-powered platforms like SourcifyChina Verify™ to cross-reference supplier data across Alibaba, Global Sources, and government databases for authenticity scoring.

2. How to Distinguish Between Trading Company and Factory

| Criteria | Factory (Manufacturer) | Trading Company (Agent/Exporter) |

|---|---|---|

| Business License | Lists “manufacturing” or “production” in scope | Lists “trading,” “import/export,” or “sales” only |

| Facility Ownership | Owns production facility; direct control over sewing, cutting, washing | No in-house production; outsources to multiple factories |

| Minimum Order Quantity (MOQ) | Typically 300–500 units per style/color | Often higher MOQs due to layered margins (e.g., 1,000+ units) |

| Pricing Structure | Direct cost breakdown: fabric, labor, washing, packaging | Less transparent; may not itemize production costs |

| Communication Access | Direct contact with production manager or technical team | Limited access to floor operations; communication via sales rep |

| Lead Time | Shorter (4–6 weeks), with control over scheduling | Longer (6–10 weeks), dependent on factory availability |

| Customization Capability | High (pattern-making, fabric development, wash design in-house) | Limited; relies on factory capabilities |

| Website & Marketing | Focus on machinery, certifications, production process | Focus on product catalog, global clients, logistics |

Strategic Insight: Factories offer better cost control and customization; trading companies may provide logistics convenience but add 15–30% margin. For volume buyers, direct factory partnerships are optimal.

3. Red Flags to Avoid in 2026

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| No verifiable factory address or refusal to allow audits | Likely a middleman or shell company; high fraud risk | Disqualify immediately; use drone imagery or third-party audit |

| Inconsistent branding across platforms | Multiple fake profiles; possible scam operation | Cross-check Alibaba, Made-in-China, and WeChat presence |

| Unrealistically low pricing (e.g., <$5/unit for mid-tier denim) | Use of substandard fabric, child labor, or tax evasion | Benchmark against 2026 market rates; request fabric invoices |

| No response to sample requests or long delays | Lack of production capability or inventory issues | Require DDP (Delivered Duty Paid) samples within 7–10 days |

| Pressure to pay full upfront via T/T | High scam risk; no buyer protection | Insist on 30% deposit, 70% against BL copy |

| Generic or stock photos in catalog | Not showcasing real production output | Demand real-time video of current production batch |

| No compliance certifications | Risk of customs rejection or brand liability | Require at minimum ISO 9001 and OEKO-TEX Standard 100 |

| Poor English communication or evasive answers | Indicates lack of professionalism or hidden operations | Assign a Mandarin-speaking auditor or sourcing agent |

4. SourcifyChina 2026 Verification Protocol (Recommended)

- Pre-Screening: Use AI-driven supplier scoring (based on 50+ data points).

- Document Verification: Validate business license, tax ID, and export eligibility.

- On-Site Audit: Conduct Level 2 audit (production lines, worker conditions, machinery).

- Trial Order: Place 1–2 container orders under Escrow protection.

- Continuous Monitoring: Quarterly compliance and performance reviews.

Conclusion

In 2026, sourcing wholesale jeans from China requires a strategic, verification-first approach. Global procurement managers must prioritize transparency, traceability, and direct factory engagement to avoid rising risks of fraud, non-compliance, and supply chain disruption. By following this structured verification process and leveraging professional sourcing support, buyers can secure high-quality denim at competitive margins while safeguarding brand integrity.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Empowering Global Brands with Verified Chinese Sourcing

www.sourcifychina.com | [email protected]

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Optimizing Denim Procurement | Q1 2026

Prepared For: Global Procurement & Supply Chain Executives

Subject: Eliminating Sourcing Friction in Wholesale Jeans from China: The Verified Pro List Advantage

Executive Summary

Global denim procurement faces persistent challenges: supplier vetting delays, quality inconsistencies, compliance risks, and operational inefficiencies. In 2026, time-to-market is the critical differentiator for fashion retailers. SourcifyChina’s AI-verified Pro List for Wholesale Jeans directly addresses these pain points, delivering empirically proven time savings and risk reduction. This report quantifies the operational impact of leveraging our platform versus traditional sourcing methods.

Why Traditional Sourcing Fails in 2026 Denim Procurement

| Activity | Traditional Sourcing (Hours) | Pro List Sourcing (Hours) | Time Saved | 2026 Risk Exposure |

|---|---|---|---|---|

| Supplier Verification | 42–65 | 2–4 | 94% | High (Fraud, Capacity Mismatch) |

| Quality Audit Coordination | 28–38 | 0 (Pre-Validated) | 100% | Critical (Defect Rates >15%) |

| Compliance Documentation | 18–25 | 3–5 (Integrated System) | 82% | Severe (Customs Delays, Fines) |

| MOQ/Negotiation Cycles | 22–35 | 8–12 | 65% | Moderate (Margin Erosion) |

| TOTAL PER PROJECT | 110–163 | 13–21 | 86–88 HOURS | Unacceptable for Agile Supply Chains |

Source: SourcifyChina 2025 Client Analytics (n=142 denim procurement projects)

The SourcifyChina Pro List Advantage: Built for 2026 Realities

Our AI-Verified Pro List is not a directory—it’s a dynamic risk-mitigation engine:

✅ Real-Time Capacity Validation: Live factory output data (updated hourly) prevents MOQ shortfalls.

✅ Blockchain-Backed Compliance: Automated tracking of OEKO-TEX®, BCI, and US CBP Section 307 documentation.

✅ Predictive Quality Scoring: Machine learning analyzes 12,000+ historical production batches to flag defect risks before sampling.

✅ Dedicated Sourcing Concierge: Your single point of contact manages all supplier communication in your timezone.

Result: 92% of clients achieve first-batch approval in ≤14 days (industry avg: 28–45 days), accelerating time-to-shelf by 37%.

🚨 Your Critical Next Step: Stop Paying the “Time Tax”

Every hour spent manually vetting denim suppliers is:

– Revenue lost due to delayed product launches

– Margin eroded by expedited logistics costs

– Reputation damaged by inconsistent quality

The 2026 procurement leader doesn’t gamble on unverified suppliers. They deploy systems that guarantee speed and compliance.

✨ Call to Action: Secure Your Competitive Edge in 72 Hours

1. Request Your Customized Pro List Briefing

→ Email: [email protected]

Subject Line: “2026 Denim Pro List Access – [Your Company Name]”

Include: Target volume (units), fabric specs, compliance requirements.

2. Fast-Track via WhatsApp

→ Message: +86 159 5127 6160

Include: “PRO LIST ACCESS – [Your Name], [Company]”

Expect a verified supplier shortlist within 4 business hours.

Why act now?

– Exclusive Q1 2026 Benefit: Complimentary pre-shipment quality audit ($450 value) for first-time clients.

– Deadline: Offer valid for confirmed requests received before February 28, 2026.

“In 2026, sourcing isn’t about finding suppliers—it’s about eliminating avoidable friction. The Pro List isn’t a cost; it’s your ROI accelerator.”

— Senior Sourcing Consultant, SourcifyChina (12+ years in APAC denim procurement)

Your supply chain deserves this advantage. Stop sourcing. Start securing.

🔗 Contact [email protected] or WhatsApp +86 159 5127 6160 TODAY.

🧮 Landed Cost Calculator

Estimate your total import cost from China.