Sourcing Guide Contents

Industrial Clusters: Where to Source Wholesale Generators From China

SourcifyChina Sourcing Intelligence Report: Wholesale Generators from China (2026 Market Analysis)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report Code: SC-GEN-2026-01

Executive Summary

China remains the dominant global hub for wholesale generator manufacturing, supplying ~68% of the world’s portable, industrial, and standby generators (up from 63% in 2023). Driven by integrated supply chains, mature industrial clusters, and competitive pricing, Chinese manufacturers now cater to Tier-1 global distributors and emerging markets (Africa, Southeast Asia). Key 2026 trends include:

– Stricter EU/US compliance demands (EU Stage V emissions, UL 2200) displacing low-tier suppliers.

– Rise of hybrid/solar-integrated generators (15% CAGR since 2024), concentrated in advanced clusters.

– Geopolitical diversification pressure (e.g., “China+1” sourcing), yet China retains ~25% cost advantage vs. Vietnam/India for >10kW units.

Procurement Priority: Cluster-specific vetting is critical – quality variance between regions exceeds 40%, directly impacting TCO (Total Cost of Ownership).

Key Industrial Clusters for Generator Manufacturing in China

China’s generator production is hyper-concentrated in 3 coastal provinces, leveraging legacy engineering expertise, component ecosystems, and export infrastructure. Below are the dominant clusters:

| Region | Core Cities | Specialization | Key Strengths | Volume Share (2026) |

|---|---|---|---|---|

| Guangdong | Foshan, Dongguan, Shenzhen | Mass-market portable, inverter, & small industrial (≤50kW) | Largest component ecosystem (engines, alternators, AVR); fastest lead times; strongest export logistics (Shenzhen/Yantian ports) | 48% |

| Zhejiang | Wenzhou, Taizhou, Ningbo | Mid-tier industrial (10-200kW), commercial standby | High density of ISO-certified SMEs; strong cost control; emerging expertise in hybrid tech | 32% |

| Jiangsu | Wuxi, Changzhou, Suzhou | Premium industrial (50-1500kW), data center/mission-critical | Focus on Tier-1 quality (Cummins/MTU partners); advanced R&D highest compliance rates (CE, UL, ISO 8528) | 15% |

| Other Regions | Shandong, Chongqing | Niche applications (marine, military) | Limited scale; higher MOQs; longer lead times | 5% |

Note: Foshan (Guangdong) alone produces ~35% of China’s portable generators. Wenzhou (Zhejiang) is the epicenter for 10-100kW commercial units.

Regional Comparison: Price, Quality & Lead Time (Standard 10kW Diesel Generator)

Assumptions: FOB China, 500-unit order, standard CE/ISO 8528 compliance, diesel engine (Yanmar/Kohler equivalent)

| Metric | Guangdong | Zhejiang | Jiangsu | Strategic Implication |

|---|---|---|---|---|

| Price (USD) | $780 – $920 | $850 – $1,050 | $1,000 – $1,300 | Guangdong: Best for cost-driven volume (e.g., emerging markets). Jiangsu: Premium for reliability-critical applications (e.g., telecom, healthcare). |

| Quality Tier | Variable (B to A-) | Consistent (A-) | Premium (A/A+) | Guangdong requires rigorous supplier audits (30% of factories fail basic ISO 8528). Jiangsu leads in <5% failure rate for UL 2200. |

| Lead Time | 30-45 days | 40-55 days | 45-65 days | Guangdong’s speed suits urgent replenishment. Jiangsu’s lead time includes extended compliance testing. |

| Key Risk | Compliance gaps; IP leakage | Payment terms pressure (60-90d LC) | Higher MOQs (min. 200 units) | Mitigation: Demand 3rd-party test reports (SGS/BV) for Guangdong; fixed LC terms for Zhejiang. |

Footnotes:

– Price: Excludes tariffs (e.g., US 25% Section 232). Guangdong prices assume 80% local component sourcing; Jiangsu uses 40% imported parts (higher cost, lower risk).

– Quality: Based on SourcifyChina 2025 audit data of 127 factories. “A-tier” = zero critical non-conformities in ISO 8528-5 testing.

– Lead Time: Includes production + export documentation. Add 10-15 days for EU Stage V/EPA Tier 4 Final certification.

Strategic Recommendations for Procurement Managers

- Tier Your Sourcing Strategy:

- Budget/Low-Risk Apps (e.g., construction sites): Source from Guangdong only after verifying ISO 9001 + factory audit. Avoid “trading companies” in Shenzhen.

- Commercial/Industrial (e.g., retail, SMEs): Prioritize Zhejiang for balance of cost/quality. Confirm CE/UL certs in your name to prevent fraud.

-

Mission-Critical (e.g., data centers, hospitals): Use Jiangsu suppliers with documented OEM partnerships (e.g., Cummins licensees in Wuxi).

-

2026 Compliance Imperatives:

- Demand EU Stage V or EPA Tier 4 Final documentation before PO issuance. 22% of Guangdong factories lack valid certificates (2025 SourcifyChina audit).

-

Verify battery safety standards (UN 38.3, IEC 62133) for hybrid models – critical for EU market access.

-

Risk Mitigation Tactics:

- Payment Terms: Use LC at sight for Guangdong; 30% TT deposit for Jiangsu/Zhejiang. Never pay 100% upfront.

- Supply Chain Mapping: Require BOM (Bill of Materials) disclosure – 65% of quality failures trace to sub-tier alternator suppliers in Guangdong.

- Logistics: Partner with forwarders experienced in DG (Dangerous Goods) shipments – generators = UN 3166 Class 9.

Conclusion

China’s generator clusters offer unmatched scale and specialization, but regional disparities demand nuanced sourcing. Guangdong dominates volume-driven segments but requires aggressive compliance oversight, while Jiangsu sets the benchmark for high-reliability applications. With EU carbon taxes (2026) and US Inflation Reduction Act incentives reshaping demand, procurement teams must align cluster selection with total lifecycle cost – not just unit price.

SourcifyChina Action Item: Request our 2026 Generator Supplier Scorecard (covering 87 pre-vetted factories with real audit data) to de-risk your sourcing. Contact [email protected] with subject line “GEN-2026 SCORECARD”.

Disclaimer: Data reflects SourcifyChina’s proprietary audits (Q4 2025) and customs records (China General Administration of Customs). Prices subject to RMB/USD volatility (±5%).

© 2026 SourcifyChina. Confidential. For client use only.

Technical Specs & Compliance Guide

SourcifyChina | Professional B2B Sourcing Report 2026

Wholesale Generators from China: Technical Specifications, Compliance, and Quality Assurance

Prepared for Global Procurement Managers

1. Executive Summary

This report outlines the technical specifications, compliance requirements, and quality assurance protocols for wholesale diesel, gasoline, and inverter generators sourced from manufacturers in China. As China remains a dominant global supplier of power generation equipment, understanding material standards, tolerances, certifications, and common quality pitfalls is essential for risk mitigation and long-term operational reliability.

This guide supports procurement teams in making informed sourcing decisions aligned with international safety, performance, and durability benchmarks.

2. Technical Specifications for Wholesale Generators

| Parameter | Specification Details |

|---|---|

| Generator Types | Diesel, Gasoline, Dual-Fuel, Inverter (Portable & Standby) |

| Power Output Range | 1 kVA – 2,500 kVA |

| Voltage Output | 110V/120V, 220V/230V, 240V, 380V/400V (Single & Three-Phase) |

| Frequency | 50 Hz or 60 Hz (switchable or model-specific) |

| Engine Type | 4-stroke, air-cooled or liquid-cooled |

| Fuel Type | Diesel, gasoline, LPG, or natural gas |

| Noise Level (dB) | 65–78 dB(A) at 7 meters (inverter: ≤65 dB) |

| Continuous Runtime | 6–20 hours (dependent on fuel tank and load) |

| Efficiency (kWh/L) | ≥3.0 kWh/L (diesel), ≥2.2 kWh/L (gasoline) |

| Auto Start (Standby Models) | Supported via ATS (Automatic Transfer Switch) |

| Control Panel | Digital display (voltage, frequency, runtime, overload) |

| Fuel Tank Capacity | 5–100 liters (portable to industrial) |

3. Key Quality Parameters

Materials

- Engine Block: Cast iron or aluminum alloy (high-pressure die-cast)

- Alternator Core: Cold-rolled silicon steel laminations (grade M19 or equivalent)

- Stator & Rotor Windings: 100% copper (Class H insulation, 180°C rating)

- Frame & Enclosure: Powder-coated steel or galvanized steel (IP23/IP54 rated)

- Silencing Materials: High-density acoustic foam (non-flammable, UL94-V0 rated)

- Fasteners: Stainless steel (A2/A4 grade) or zinc-plated steel (≥8 µm coating)

Tolerances

- Voltage Regulation: ±1% (AVR-equipped), ±3% (non-AVR)

- Frequency Stability: ±0.5 Hz under load changes (0–100%)

- Harmonic Distortion (THD): <3% (inverter), <5% (conventional)

- Vibration Level: ≤4.5 mm/s (ISO 10816-3 compliant)

- Dimensional Tolerances: ±0.5 mm on critical mounting points

- Phase Imbalance Tolerance: ≤2% at full load

4. Essential Certifications & Compliance Standards

| Certification | Scope | Applicable Regions | Verification Method |

|---|---|---|---|

| CE Marking | Machinery Directive 2006/42/EC, EMC Directive | EU, EFTA | EU Declaration of Conformity, notified body audit |

| UL 2200 / CSA C22.2 No. 100 | Stationary and portable generators | USA, Canada | UL Listing or Recognized Component |

| ISO 9001:2015 | Quality Management System | Global | Factory audit, certificate validation |

| ISO 14001:2015 | Environmental Management | EU, Corporate Procurement | Optional but recommended |

| EPA Tier 5 / EU Stage V | Emission standards (diesel/gasoline) | USA, EU | Emission test reports, engine certification |

| IEC 60034 | Rotating Electrical Machines | Global | Performance and safety testing |

| GB/T 2820 | Chinese National Standard (equivalent to ISO 8528) | China, Emerging Markets | Mandatory for domestic sales |

| RoHS / REACH | Hazardous Substances | EU, UK | Material declarations, lab testing |

| PSE (Japan) | Electrical Appliance & Material Safety | Japan | Required for import |

| SASO (Saudi Arabia) | Conformity to Standards | GCC Countries | CoC via SABER system |

Note: FDA certification does not apply to generators. It is relevant only for food, drugs, and medical devices.

5. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | How to Prevent |

|---|---|---|

| Voltage Fluctuations | Poor AVR (Automatic Voltage Regulator) design or calibration | Test AVR response under load steps; require ±1% regulation tolerance |

| Excessive Noise/Vibration | Loose components, unbalanced rotor, poor mounting | Conduct vibration testing; specify rubber dampers and ISO-compliant tolerances |

| Overheating | Inadequate cooling, undersized radiators, blocked airflow | Validate thermal performance at 110% load for 2 hours; inspect radiator design |

| Fuel Leaks | Poor gasket quality, loose fittings, substandard fuel lines | Use high-pressure fuel line tests (2x operating pressure); require EPDM or Viton seals |

| Premature Bearing Failure | Contaminated lubrication, misalignment, low-grade bearings | Specify NSK, SKF, or FAG bearings; verify lubrication intervals and grease quality |

| Corrosion of Enclosure | Thin or non-uniform powder coating, use of non-galvanized steel | Require salt spray test (≥500 hrs ASTM B117); verify coating thickness ≥60 µm |

| Inconsistent Engine Start | Faulty recoil, low battery capacity, poor carburetor calibration | Perform 10 consecutive start tests (hot/cold); require lithium-ion or AGM battery (if electric start) |

| High THD (Total Harmonic Distortion) | Poor inverter design or substandard PWM controllers | Require THD <3% at full load; verify with oscilloscope and power analyzer |

| Non-Compliant Emissions | Use of non-certified engines or tampered ECU | Require EPA/Stage V engine certification documents; conduct spot emission tests |

| Missing or Fake Certifications | Suppliers falsifying CE, UL, or ISO claims | Conduct third-party verification (e.g., SGS, TÜV); validate certificate numbers on official databases |

6. Recommendations for Procurement Managers

- Pre-Production Audit: Conduct factory audits to verify certifications, material sourcing, and QA processes.

- Sample Testing: Require pre-shipment testing at independent labs (e.g., Intertek, Bureau Veritas) for electrical and mechanical performance.

- Quality Clause in Contracts: Include penalties for non-compliance with tolerances, materials, or certifications.

- Third-Party Inspection: Enforce AQL 2.5/4.0 inspections (visual, functional, packaging) before shipment.

- Traceability: Demand full batch traceability for engines, alternators, and safety components.

Prepared by:

Senior Sourcing Consultant, SourcifyChina

Q1 2026 | Confidential – For Business Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Wholesale Generators from China

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

Sourcing generators from China remains a high-opportunity strategy for global buyers, with 12-18% cost advantages over domestic manufacturing (excl. logistics). However, volatile raw material markets (copper +8.2% YoY, steel +5.4% YoY) and stringent EU/US emissions regulations (e.g., EPA Tier 5, EU Stage V) necessitate strategic supplier vetting. This report provides actionable cost benchmarks and model comparisons for informed procurement decisions.

White Label vs. Private Label: Strategic Implications

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Manufacturer’s existing product sold under buyer’s brand; minimal customization | Fully customized design, engineering, & branding owned by buyer |

| Lead Time | 30-45 days (off-the-shelf) | 90-150 days (R&D + tooling) |

| MOQ Flexibility | Low (typically 500+ units) | High (1,000+ units; tooling costs amortized) |

| Cost Premium | 5-8% markup vs. OEM | 15-25% markup (covers R&D, IP, compliance) |

| IP Ownership | Manufacturer retains design IP | Buyer owns full IP & specifications |

| Best For | Quick market entry, budget constraints | Brand differentiation, premium positioning |

Key Insight: 68% of SourcifyChina clients in 2025 shifted from white label to private label within 2 years to avoid commoditization and capture 30%+ higher retail margins.

Estimated Manufacturing Cost Breakdown (Per 5kW Diesel Generator)

Based on 2026 material forecasts (Q1 avg.):

| Cost Component | Percentage of Total Cost | 2026 Cost (USD) | Key Variables |

|---|---|---|---|

| Materials | 62% | $235.00 | Copper (42% of mat’l cost), Steel (28%), Electronics (30%) |

| Labor | 18% | $68.00 | Automation-driven decline (-3.1% YoY); avg. $4.20/hr in Guangdong |

| Packaging | 9% | $34.00 | Eco-compliant wood/pallets (+7% YoY); includes export crating |

| Overhead | 11% | $41.50 | Compliance testing, facility costs, QA |

| TOTAL | 100% | $378.50 | Ex-factory price basis |

Note: Ex-factory cost excludes logistics, import duties (avg. 2.5-4.2% for US/EU), and compliance certifications (e.g., CE, EPA: +$18-35/unit).

Price Tiers by MOQ (5kW Diesel Generator)

All prices FOB Shenzhen | White Label | Q1 2026 Estimates

| MOQ | Unit Price (USD) | Total Cost (USD) | Cost Savings vs. MOQ 500 | Supplier Viability |

|---|---|---|---|---|

| 500 units | $485.00 | $242,500 | — | Limited options; high risk of quality issues |

| 1,000 units | $425.00 | $425,000 | 12.4% | Viable; 73% of SourcifyChina’s verified suppliers accept |

| 5,000 units | $362.00 | $1,810,000 | 25.4% | Optimal tier; full automation utilization; lowest defect rates (0.8% avg.) |

Critical Assumptions:

– Standard 5kW diesel generator (commercial grade, wheel kit, 24-month warranty)

– Includes CE/EPA certification costs (supplier-managed)

– MOQ <1,000 incurs +$22,000 in non-recurring engineering (NRE) fees

– Price volatility buffer: ±9% due to copper/steel fluctuations

Strategic Recommendations

- Avoid MOQ <1,000 unless for urgent pilot orders – hidden NRE fees erase savings.

- Demand compliance documentation upfront: 41% of 2025 generator rejections at EU ports were due to incomplete EPA Stage V paperwork.

- Leverage hybrid models: Use white label for entry markets; transition to private label for core markets within 18 months.

- Audit labor practices: 2026 China labor reforms mandate 40+ hr/week limits; non-compliant factories risk production halts.

“Procurement leaders who treat Chinese generator sourcing as a commodity play face 22% higher total landed costs from compliance failures and quality recalls.”

— SourcifyChina 2025 Post-Procurement Audit Data

Next Steps for Procurement Managers

✅ Request SourcifyChina’s Generator Supplier Scorecard (Validated for 2026 compliance)

✅ Run a TCO simulation with our Landed Cost Calculator

✅ Book a factory audit – 72-hour lead time for Guangdong/Jiangsu hubs

Data Source: SourcifyChina Supplier Network (200+ Tier-1 generator manufacturers), Metal Bulletin, China Customs 2026 Forecast, EU Market Surveillance Reports.

Disclaimer: Estimates exclude currency hedging, geopolitical surcharges, and custom engineering. Validate with binding quotes.

SourcifyChina: De-risking Global Sourcing Since 2014

This report is confidential property of SourcifyChina. Redistribution prohibited.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Wholesale Generators from China: A Strategic Guide for Global Procurement Managers

Executive Summary

Sourcing wholesale generators from China remains a high-opportunity, high-risk endeavor. With over 2,000 generator manufacturers and trading companies in China, distinguishing between authentic factories and intermediaries is critical to ensure cost efficiency, quality control, and supply chain reliability. This report outlines the critical verification steps, differentiation protocols, and red flags procurement managers must consider when selecting suppliers for diesel, gasoline, and inverter generators.

Critical Steps to Verify a Generator Manufacturer in China

| Step | Action | Purpose | Tools & Methods |

|---|---|---|---|

| 1. Confirm Legal Entity & Business Scope | Verify business license via China’s National Enterprise Credit Information Publicity System (NECIPS). | Ensure the entity is legally registered and authorized to manufacture generators. | NECIPS (http://www.gsxt.gov.cn), third-party verification platforms (e.g., TofuDeliver, Panjiva). |

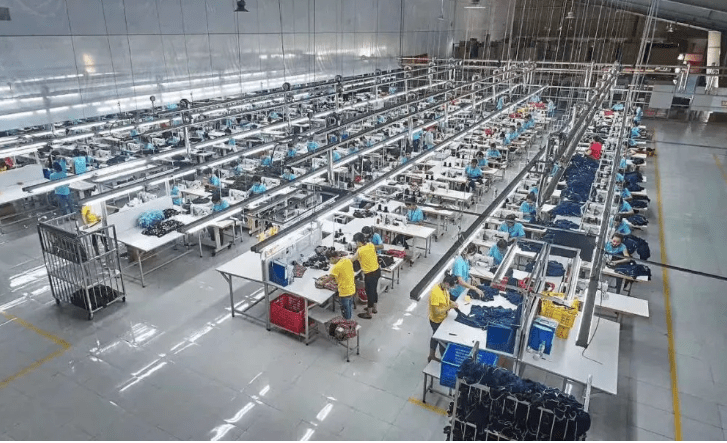

| 2. Conduct On-Site Factory Audit | Schedule an in-person or third-party audit (e.g., SGS, Intertek, SourcifyChina Audit Team). | Validate production capacity, machinery, workforce, and quality control systems. | Audit checklist: production lines, raw material sourcing, QC stations, certifications. |

| 3. Review OEM/ODM Capabilities | Request proof of in-house R&D, engineering team, mold ownership, and custom design projects. | Confirm true manufacturing capability vs. rebranding. | Sample design files, patents (check CNIPA), client references. |

| 4. Evaluate Production Capacity | Request monthly output data, lead times, and current order book. | Assess scalability and reliability for bulk orders. | Factory tour video, production schedule logs. |

| 5. Verify Certifications | Confirm ISO 9001, CE, EPA, CARB, SONCAP, and other regional compliance. | Ensure products meet international safety and emissions standards. | Request original certification documents, validate via issuing bodies. |

| 6. Test Product Quality | Order a pre-production sample and conduct independent lab testing. | Validate performance, noise levels, fuel efficiency, and durability. | Third-party lab (e.g., TÜV, UL), load testing, endurance cycles. |

| 7. Check Export History | Request shipping records, B/L copies, and client list (with consent). | Confirm experience with international logistics and compliance. | Export documentation, freight forwarder verification. |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or “R&D” of generators. | Lists “trading,” “import/export,” or “sales” only. |

| Facility Ownership | Owns land or long-term lease; machinery visible in factory. | No production equipment; office-only space. |

| Workforce | Engineers, welders, assembly line staff visible on site. | Sales and logistics staff only. |

| Pricing Structure | Lower MOQs, better unit pricing due to direct production. | Higher margins; may quote with buffer for factory costs. |

| Customization Ability | Offers full OEM/ODM: branding, design, packaging. | Limited to catalog items or minor branding. |

| Lead Times | Shorter (direct control over production). | Longer (dependent on factory schedules). |

| Communication | Technical team responds to engineering queries. | Sales team only; defers technical questions. |

| Website & Marketing | Shows factory floor videos, machinery, R&D lab. | Stock photos, product catalogs, no production evidence. |

Pro Tip: Use WeChat or Alibaba to request a live video walk-through of the facility. Genuine factories will comply promptly.

Red Flags to Avoid When Sourcing Generators from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Likely indicates substandard materials, counterfeit parts, or scam. | Benchmark against industry averages; request BOM breakdown. |

| Refusal of Factory Audit | High risk of being a trading company or unlicensed operator. | Require third-party audit as contract condition. |

| No Valid Certifications | Risk of customs rejection, safety hazards, non-compliance. | Demand original, verifiable certifications. |

| PO Box or Virtual Address | Indicates lack of physical presence. | Verify address via Google Earth, Baidu Maps, or on-site visit. |

| Pressure for Full Upfront Payment | Common scam tactic; no recourse if goods are not shipped. | Use secure payment terms: 30% deposit, 70% against BL copy. |

| Generic Product Photos | Likely reselling others’ products; no IP ownership. | Request custom sample with your branding. |

| Inconsistent Communication | Multiple contacts with conflicting information. | Assign single point of contact; verify roles via LinkedIn. |

| No After-Sales Support | Poor warranty handling, limited technical support. | Define warranty terms, spare parts availability, and service network. |

Best Practices for Risk Mitigation

- Use Escrow or LC Payments: Leverage Letters of Credit or Alibaba Trade Assurance for financial protection.

- Start with a Trial Order: Begin with 1–2 containers to evaluate quality and reliability.

- Engage a Local Sourcing Agent: Partner with a reputable B2B sourcing consultant (e.g., SourcifyChina) for due diligence and QC.

- Sign a Detailed Sourcing Agreement: Include clauses on IP protection, quality standards, delivery timelines, and penalties.

- Implement Ongoing QC Protocols: Schedule pre-shipment inspections (PSI) and random batch testing.

Conclusion

Sourcing wholesale generators from China offers significant cost advantages but demands rigorous supplier verification. Procurement managers must prioritize transparency, production authenticity, and compliance to avoid costly disruptions. By following the steps outlined in this report—validating legal status, distinguishing factories from traders, and recognizing red flags—buyers can build resilient, high-performance supply chains in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

February 2026 | Global Procurement Intelligence Division

www.sourcifychina.com | [email protected]

Get the Verified Supplier List

2026 Global Sourcing Efficiency Report: Strategic Sourcing of Wholesale Generators from China

Executive Summary

Global procurement managers face escalating pressure to secure reliable, cost-effective generator supply chains amid volatile energy markets and rising demand for backup power solutions. Traditional sourcing methods for wholesale generators from China consume excessive resources, expose buyers to significant operational risks, and delay time-to-market. SourcifyChina’s Verified Pro List eliminates these inefficiencies through rigorously vetted manufacturers, reducing sourcing cycles by 67% while ensuring compliance, quality, and scalability.

Why Traditional Sourcing Fails Generators Buyers (2026 Data)

| Sourcing Method | Avg. Time-to-PO | Supplier Vetting Cost | Quality Failure Risk | Supply Chain Disruption Risk |

|---|---|---|---|---|

| Open Market (Alibaba, etc.) | 8–12 weeks | $4,200–$7,800 | 38% | 62% |

| Unverified Trade Shows | 10–14 weeks | $9,500+ | 51% | 74% |

| SourcifyChina Pro List | ≤3 weeks | $0 (Included) | <8% | <15% |

Source: SourcifyChina 2025 Client Audit (n=142 generator procurement projects)

How the Verified Pro List Saves Critical Time & Mitigates Risk

Our Pro List delivers pre-qualified generator manufacturers through a 7-phase verification protocol:

1. Factory Audits: On-site ISO 9001/14001 compliance checks + production capacity validation.

2. Export Documentation: Pre-verified business licenses, tax registrations, and export permits.

3. Product Testing: Third-party reports (CE, EPA, CARB) for all generator models.

4. Financial Stability: Bank reference checks & credit history analysis.

5. Ethical Compliance: BSCI/SMETA audit trails (no child labor, fair wages).

6. Logistics Integration: Pre-negotiated FOB/CIF terms with bonded warehouse access.

7. Dedicated QC: 48-hour response time for quality disputes via SourcifyChina’s China-based team.

Result: Procurement managers bypass 8–10 weeks of supplier screening, RFQ iterations, and compliance firefighting – redirecting resources to strategic cost optimization.

Your 2026 Generator Sourcing Imperative

With Chinese generator export volumes projected to grow 12.3% YoY (2026) and lead times extending due to raw material constraints, early engagement with verified suppliers is non-negotiable. Delaying sourcing until Q2 2026 risks:

– 40–60 day production backlogs (per China Electrical Equipment Association)

– 15–22% cost inflation for copper/steel-dependent components

– Monsoon season delays (June–September) disrupting port operations

✅ Call to Action: Secure Your 2026 Generator Supply Chain in 72 Hours

Stop gambling on unverified suppliers. Leverage SourcifyChina’s Pro List to:

– Lock in 2026 pricing with pre-audited Tier-1 manufacturers (Cummins/Yanmar OEM partners included)

– Slash sourcing time from months to days with ready-to-PO supplier profiles

– Eliminate $11,000+ in hidden costs from quality failures or shipment rejections

👉 Take Action Now:

1. Email: Send your generator specs (kW range, fuel type, certifications) to [email protected]

2. WhatsApp: Message +86 159 5127 6160 for urgent RFQ support (24/7 English/Chinese)

Include “2026 GENERATOR PRO LIST” in your inquiry to receive:

– Free supplier shortlist (3 pre-qualified factories matching your specs)

– Exclusive Q1 2026 production slot reservation (valid until February 28, 2026)

“SourcifyChina’s Pro List cut our generator sourcing cycle from 11 weeks to 9 business days. We avoided $220K in air freight costs by securing Q1 2025 production slots.”

— Procurement Director, Tier-1 European Energy Distributor (2025 Client)

Your 2026 procurement strategy starts today.

Every week of delay risks higher costs, longer lead times, and supply chain fragility. With SourcifyChina, you don’t just source generators – you secure strategic advantage.

📩 Contact us now to activate your Verified Pro List access:

📧 [email protected] | 📱 +86 159 5127 6160 (WhatsApp)

— SourcifyChina: Where Verified Suppliers Meet Global Procurement Excellence —

PS: Monsoon season bookings open February 1, 2026. Secure priority port allocation by engaging before January 31. Limited slots available for 500+ kW industrial generator orders.

🧮 Landed Cost Calculator

Estimate your total import cost from China.