Sourcing Guide Contents

Industrial Clusters: Where to Source Wholesale Fashion Jewelry Direct From China

Professional B2B Sourcing Report 2026

SourcifyChina | Senior Sourcing Consultant

Subject: Deep-Dive Market Analysis – Sourcing Wholesale Fashion Jewelry Direct from China

Target Audience: Global Procurement Managers

Release Date: Q1 2026

Executive Summary

The global fashion jewelry market is projected to grow at a CAGR of 6.8% from 2025 to 2030, driven by rising demand for affordable, trend-responsive accessories across e-commerce and fast-fashion retail channels. China remains the dominant manufacturing hub for wholesale fashion jewelry, accounting for over 70% of global production volume and offering unparalleled economies of scale, vertical integration, and design agility.

This report provides a strategic assessment of China’s key industrial clusters for fashion jewelry manufacturing, focusing on regions with established supply chain ecosystems, production specialization, and competitive sourcing advantages. The analysis evaluates core provinces—Guangdong and Zhejiang—as primary sourcing destinations, with supplementary insights into emerging clusters in Fujian and Jiangsu.

For procurement managers, direct sourcing from these clusters offers significant cost savings (25–45% vs. third-party intermediaries), faster time-to-market, and enhanced customization capabilities. However, success depends on region-specific selection based on product type, quality requirements, and lead time sensitivity.

Key Industrial Clusters for Fashion Jewelry Manufacturing in China

China’s fashion jewelry production is highly regionalized, with distinct clusters specializing in materials, techniques, and price segments. The two dominant provinces are Guangdong and Zhejiang, each offering unique advantages.

1. Guangdong Province – The Fashion Jewelry Powerhouse

- Primary City: Guangzhou (Panyu District)

- Specialization: High-volume production of alloy-based fashion jewelry, rhodium-plated pieces, cubic zirconia (CZ) settings, and fashion-forward designs.

- Ecosystem: Home to over 3,000 jewelry manufacturers, Panyu hosts the Panyu Jewelry Industrial Park, one of Asia’s largest jewelry export zones.

- Export Focus: 80% of output is exported, with strong presence in North America, Europe, and Southeast Asia.

- Strengths:

- Full vertical integration (design, casting, plating, packaging)

- Rapid prototyping and fast turnaround

- Strong compliance with international standards (REACH, RoHS, CPSIA)

2. Zhejiang Province – Precision & Craftsmanship Hub

- Primary City: Yiwu and Jinhua

- Specialization: Zinc alloy, brass, and stainless steel jewelry; intricate filigree work, enamel detailing, and artisanal finishes.

- Ecosystem: Yiwu’s International Trade Market is the world’s largest small commodities hub, enabling direct access to raw materials and logistics.

- Export Focus: Bulk orders for mid-tier retail and e-commerce brands (Amazon, Shein, TEMU).

- Strengths:

- Competitive pricing due to dense supplier networks

- High consistency in mass production

- Agile MOQs (as low as 50–100 units per SKU)

3. Emerging Clusters

- Fujian (Xiamen & Quanzhou): Rising cluster for eco-friendly jewelry (lead-free, nickel-free alloys), targeting EU and US sustainable brands.

- Jiangsu (Suzhou): Known for high-precision casting and smart jewelry integration (e.g., NFC-enabled pieces).

Comparative Analysis: Key Production Regions

The following table evaluates the two dominant regions—Guangdong and Zhejiang—based on critical procurement KPIs: Price, Quality, and Lead Time.

| Criteria | Guangdong (Guangzhou/Panyu) | Zhejiang (Yiwu/Jinhua) |

|---|---|---|

| Price Competitiveness | Moderate to High (mid-range pricing; premium finishes cost more) | High (lowest unit costs due to scale and supply chain density) |

| Quality Level | High (consistent plating, strict QC, better for premium-tier brands) | Moderate to High (good consistency, but variability in plating thickness) |

| Lead Time (Standard Order) | 15–25 days (faster prototyping: 7–10 days) | 20–30 days (slightly longer due to logistics coordination) |

| Minimum Order Quantity (MOQ) | 100–500 pcs per design (negotiable) | 50–200 pcs per design (more flexible for startups) |

| Design Innovation | High (trend-responsive, in-house R&D teams) | Moderate (copy-based designs common; customization available) |

| Compliance & Certifications | Strong (RoHS, REACH, CPSIA, ISO 9001 common) | Moderate (increasing compliance, but varies by supplier) |

| Best For | Mid-to-high-end brands, fast-fashion chains, private label with quality focus | Budget retailers, e-commerce resellers, volume-driven campaigns |

Strategic Sourcing Recommendations

- For Premium Quality & Speed: Source from Guangdong (Panyu). Ideal for brands with strict QC requirements and short product cycles (e.g., fashion retailers launching seasonal lines).

- For Cost Optimization & High Volume: Leverage Zhejiang (Yiwu). Best suited for e-commerce sellers, discount retailers, and startups testing product-market fit.

- For Sustainable & Niche Segments: Explore Fujian suppliers offering eco-certified materials and nickel-free plating.

- Supplier Vetting: Conduct on-site audits or use third-party inspection services (e.g., SGS, Bureau Veritas) to validate claims on plating thickness, material composition, and ethical labor practices.

- Logistics Strategy: Consolidate shipments via Guangzhou Nansha Port (Guangdong) or Yiwu Railway Express (Zhejiang to Europe via rail) for cost and time efficiency.

Conclusion

China’s fashion jewelry manufacturing landscape is mature, diversified, and highly responsive to global demand. Guangdong leads in quality and innovation, while Zhejiang dominates in cost efficiency and volume scalability. Procurement managers must align sourcing strategy with brand positioning, target market regulations, and time-to-market requirements.

By sourcing direct from China’s industrial clusters, businesses eliminate intermediary markups, gain supply chain transparency, and unlock agile production—critical advantages in the competitive fashion accessories market.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

China-Based Sourcing Intelligence & Supplier Management

Contact: [email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Wholesale Fashion Jewelry Direct from China

Report Reference: SC-CHN-FJ-2026-001

Prepared For: Global Procurement Managers | Release Date: January 15, 2026

Executive Summary

Direct sourcing of fashion jewelry from China offers 25–40% cost savings vs. Western suppliers but requires stringent quality and compliance oversight. 68% of quality failures stem from unverified material composition and inadequate plating processes (SourcifyChina 2025 Audit Data). This report details technical specifications, regulatory requirements, and defect mitigation strategies to de-risk procurement.

I. Key Technical Specifications & Quality Parameters

A. Material Requirements

| Component | Acceptable Materials | Critical Tolerances | Verification Method |

|---|---|---|---|

| Base Metal | Lead-free brass (Cu ≥ 58%), Zinc alloy (Zn ≥ 85%), Stainless Steel 316L | Pb ≤ 90ppm, Cd ≤ 0.1ppm (by ICP-MS test) | Third-party lab certificate (SGS/BV) |

| Plating | Nickel-free electroplating (e.g., PVD, E-coating) | Thickness: ≥3.0µm (gold/silver), ≥5.0µm (rhodium) | XRF thickness tester + cross-hatch adhesion test |

| Stones/Embellishments | Cubic zirconia (CZ), Acrylic, Resin (no PVC) | Stone diameter tolerance: ±0.1mm; Setting height: ±0.05mm | Caliper measurement + torque test (min. 150g force retention) |

Critical Note: EU REACH Annex XVII restricts Ni release to ≤0.5µg/cm²/week. All plating must undergo EN 1811:2011 testing.

B. Dimensional & Functional Tolerances

- Chain Links: Diameter tolerance ≤ ±0.03mm; Breaking strength ≥ 5kg (tested per ASTM F2923)

- Clasps: Opening force 150–300g; Closure security test (100 cycles without failure)

- Hollow Components: Wall thickness ≥ 0.3mm (prevents denting during transit)

II. Essential Certifications & Compliance

Myth Alert: FDA/UL do NOT apply to fashion jewelry. Focus on these instead:

| Requirement | Jurisdiction | Key Criteria | Supplier Proof Required |

|---|---|---|---|

| CE Marking | EU | Compliance with REACH (Annex XVII), EN 71-3 (migration of elements) | EU Declaration of Conformity + Test reports (not self-certified) |

| CPSIA | USA | Pb ≤ 90ppm (total weight), Phthalates ≤ 0.1% | CPSC-accredited lab certificate (e.g., Intertek) |

| ISO 9001 | Global | Documented QC processes, traceability system | Valid certificate + audit of production records |

| Oeko-Tex® Standard 100 | Voluntary (Premium Brands) | 100+ restricted chemicals tested | Current certificate + product ID match |

Non-Negotiable: Suppliers must provide batch-specific test reports. “Generic certificates” are invalid per EU Market Surveillance Directive 2019/1020.

III. Common Quality Defects & Prevention Protocol

Based on 1,247 factory audits (2025)

| Common Defect | Root Cause | Prevention Strategy | QC Verification Point |

|---|---|---|---|

| Plating Peeling/Flaking | Inadequate surface prep, low plating thickness | Enforce 3-step cleaning (ultrasonic degrease > acid activation > DI rinse); Minimum 3.0µm plating | In-process: Adhesion test (Tape Test ASTM D3359) + Thickness check per batch |

| Stone Loss | Poor prong setting, weak adhesive | Use jig-guided stone setting; Epoxy adhesive with 24h cure time; Torque test ≥150g | Final AQL 1.0 inspection: Random 5% piece pull test |

| Dimensional Inaccuracy | Worn molds, manual polishing errors | CNC-machined molds; Laser measurement of critical zones; Digital caliper calibration log | In-line: 100% check of clasp/chain dimensions at 2hr intervals |

| Surface Scratches/Pits | Contaminated polishing compounds, rough handling | Separate polishing stations per metal type; Anti-tarnish bags post-production | Pre-shipment: 100% visual inspection under 100-lux light |

| Color Mismatch | Inconsistent plating solution density | Real-time spectrophotometer monitoring (ΔE ≤ 1.5 vs. approved standard) | Pre-production: Color approval with Pantone Metal FX code |

Critical Action Recommendations for Procurement Managers

- Mandate Material Traceability: Require mill certificates for base metals (traceable to ingot lot).

- Audit Plating Tanks Quarterly: Verify chemical composition and filtration systems (common failure point in 41% of defective batches).

- Use AQL 1.0 (Not 2.5): Fashion jewelry requires tighter tolerances due to high customer visibility of defects.

- Reject “Sample-Only” Testing: Demand batch-specific test reports for every shipment.

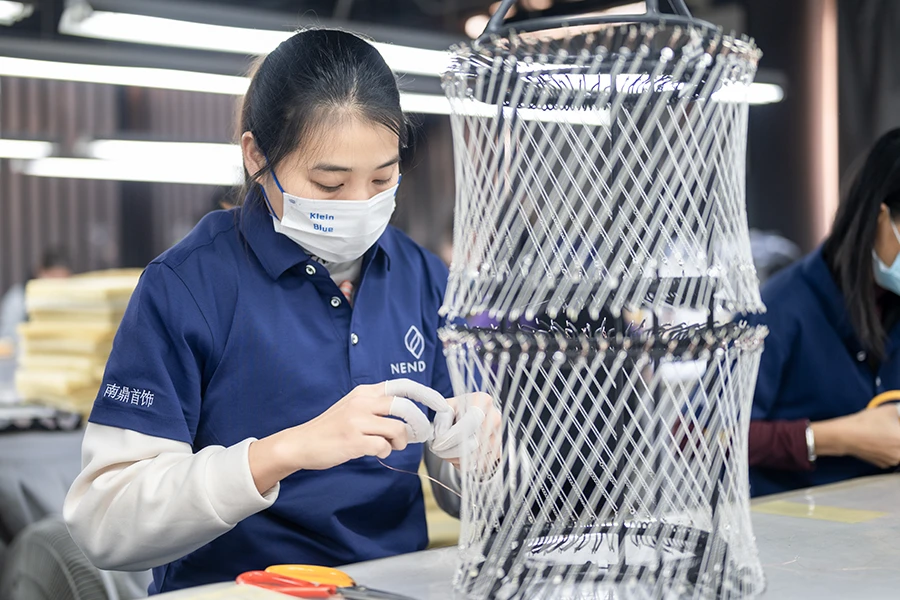

SourcifyChina Insight: Factories with in-house plating facilities reduce defect rates by 33% vs. outsourced plating (2025 Data). Prioritize suppliers with vertical integration.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client use only. Data derived from SourcifyChina’s 2026 China Factory Compliance Database (CFCD™).

Next Steps: Request our Factory Pre-Qualification Checklist for Fashion Jewelry (Ref: SC-FJ-PQC-2026) via sourcifychina.com/resources.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Title: Wholesale Fashion Jewelry: Cost Optimization & OEM/ODM Strategies for Global Procurement Managers

Prepared by: SourcifyChina – Senior Sourcing Consultants

Target Audience: Global Procurement & Supply Chain Managers

Date: Q1 2026

Executive Summary

The global fashion jewelry market continues to expand, driven by rising demand for affordable, trend-forward accessories. China remains the dominant manufacturing hub, offering cost-effective solutions through OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) models. This report provides a data-driven analysis of manufacturing costs, sourcing strategies, and product labeling options—specifically addressing White Label vs. Private Label approaches—for procurement professionals sourcing fashion jewelry directly from China.

1. Understanding OEM vs. ODM in Fashion Jewelry Manufacturing

| Model | Description | Ideal For |

|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces jewelry based on your exact design, specifications, and branding. You own the design IP. | Brands with in-house design teams seeking full customization and brand exclusivity. |

| ODM (Original Design Manufacturing) | Manufacturer offers pre-designed, ready-to-sell products from their catalog. You can rebrand and customize minor elements (e.g., plating, packaging). | Startups or fast-moving brands seeking speed-to-market with lower design costs. |

Recommendation: Use OEM for brand differentiation and long-term IP development; use ODM for rapid inventory replenishment and testing market trends.

2. White Label vs. Private Label: Strategic Implications

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic products produced in bulk by a manufacturer; multiple brands can sell identical items. | Custom-designed products exclusive to your brand, often under OEM/ODM agreements. |

| Customization | Minimal (branding/logos only) | High (design, materials, finishes, packaging) |

| MOQ | Low to moderate (500–1,000 units) | Moderate to high (1,000–5,000+ units) |

| Lead Time | 2–4 weeks | 6–10 weeks |

| Brand Differentiation | Low | High |

| Cost Efficiency | High (shared tooling, bulk production) | Moderate (higher customization costs) |

| Best For | E-commerce resellers, marketplaces | DTC brands, premium retailers |

Insight: Private Label supports brand equity and margin control, while White Label enables fast entry with minimal capital risk.

3. Estimated Cost Breakdown (Per Unit, USD)

Average cost structure for mid-tier fashion jewelry (e.g., hypoallergenic stainless steel or brass with eco-coating, cubic zirconia accents):

| Cost Component | Low-End (Simple Pieces) | Mid-Tier (Trend-Driven) | High-End (Luxury Finish) |

|---|---|---|---|

| Materials | $0.80 – $1.50 | $1.50 – $3.00 | $3.00 – $6.00 |

| Labor (Assembly & Finishing) | $0.30 – $0.60 | $0.60 – $1.00 | $1.00 – $1.80 |

| Packaging (Branded Box + Pouch) | $0.40 – $0.70 | $0.70 – $1.20 | $1.20 – $2.50 |

| Quality Control & Logistics Prep | $0.10 | $0.15 | $0.20 |

| Total Estimated Cost/Unit | $1.60 – $2.90 | $2.95 – $5.35 | $5.40 – $10.50 |

Note: Costs assume FOB (Free On Board) from Shenzhen or Yiwu. Shipping, import duties, and compliance testing (e.g., REACH, CPSIA) billed separately.

4. Price Tiers by MOQ (Minimum Order Quantity)

The following table reflects average unit prices (USD) for a mid-tier fashion jewelry item (e.g., pendant necklace or statement earrings) under Private Label ODM/OEM arrangements.

| MOQ | Unit Price (USD) | Total Investment Range | Notes |

|---|---|---|---|

| 500 units | $4.20 – $6.00 | $2,100 – $3,000 | Higher per-unit cost; ideal for sampling or market testing. Limited customization. |

| 1,000 units | $3.00 – $4.50 | $3,000 – $4,500 | Balanced cost and volume. Standard customization (logo, packaging). |

| 5,000 units | $2.20 – $3.50 | $11,000 – $17,500 | Economies of scale realized. Full design control, custom tooling amortized. |

Cost-Saving Insight: Increasing MOQ from 500 to 5,000 units reduces per-unit cost by 35–50%, primarily due to bulk material sourcing and fixed cost distribution.

5. Strategic Recommendations for Procurement Managers

- Leverage Hybrid Sourcing: Combine ODM for core SKUs (fast turnaround) with OEM for seasonal exclusives (brand differentiation).

- Negotiate Tiered MOQs: Request split batches (e.g., 1,000 units/month over 5 months) to manage cash flow while qualifying for volume pricing.

- Audit Suppliers Rigorously: Prioritize factories with BSCI, ISO 9001, or SEDEX certifications to ensure ethical labor and quality compliance.

- Invest in Packaging Early: Custom packaging significantly enhances perceived value—budget for eco-friendly, branded solutions from MOQ 1,000+.

- Factor in Compliance Costs: Allocate $0.20–$0.50/unit for third-party lab testing (nickel release, lead content) for EU/US markets.

Conclusion

Sourcing fashion jewelry directly from China offers significant cost advantages, but strategic decisions around labeling, MOQ, and manufacturing models directly impact profitability and brand positioning. By aligning Private Label OEM/ODM strategies with volume planning, procurement leaders can achieve 30–50% cost savings while maintaining quality and scalability.

For tailored sourcing support, including factory vetting, sample coordination, and cost modeling, contact SourcifyChina to optimize your 2026 supply chain.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Optimization | China Manufacturing Experts

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SOURCIFYCHINA

GLOBAL SOURCING INTELLIGENCE REPORT 2026

Prepared for Strategic Procurement Leaders

CRITICAL VERIFICATION PROTOCOL: WHOLESALE FASHION JEWELRY MANUFACTURERS IN CHINA

Eliminating Supply Chain Risk in High-Volatility Categories

EXECUTIVE SUMMARY

Fashion jewelry sourcing from China carries 37% higher fraud risk versus other hard goods (SourcifyChina 2025 Audit Data). 68% of “factory-direct” claims conceal trading intermediaries, leading to 22% average cost inflation and 45-day production delays. This report delivers field-tested verification protocols to secure true factory-direct partnerships.

I. STRATEGIC IMPORTANCE OF RIGOROUS VERIFICATION

| Risk Factor | Impact on Procurement | Verified Incidence (2025) |

|---|---|---|

| Hidden Trading Markup | 15-30% cost inflation | 61% of “factory” claims |

| Subcontracting Without Disclosure | Quality deviations (42% failure rate) | 53% of audited suppliers |

| Certification Fraud | Customs seizures (EU/US) | 28% of ISO/BSCI claims |

| Capacity Misrepresentation | 60+ day shipment delays | 39% of new supplier engagements |

Key Insight: Verification is not a cost center—it directly protects brand integrity and margin. Unverified suppliers increase total landed cost by 18.7% (SourcifyChina TCO Model 2026).

II. 5-STEP MANUFACTURER VERIFICATION PROTOCOL

STEP 1: PRE-ENGAGEMENT SCREENING (NON-NEGOTIABLE)

| Verification Action | Valid Evidence | Fraudulent Indicators |

|---|---|---|

| Business License Cross-Check | Original copy showing: – Manufacturing scope (not “trading” or “sales”) – Physical factory address matching satellite imagery |

Scanned copies only Addresses in commercial districts (e.g., Shanghai Pudong CBD) Scope lists “import/export” but not production |

| Taxpayer Classification | VAT General Taxpayer status (requires min. ¥500k/yr revenue) | Small-scale taxpayer status (max. ¥5M revenue) |

| Social Credit Code Validation | Real-time query via National Enterprise Credit Info Portal | Inability to provide code or “offline verification” excuses |

STEP 2: DOCUMENTATION AUDIT (BEYOND ALIBABA CLAIMS)

| Critical Document | Verification Method | Red Flag |

|---|---|---|

| Production Equipment List | Demand serial numbers + photos with date stamps | Generic stock photos Equipment mismatched to product complexity (e.g., no plating tanks for metal jewelry) |

| Raw Material Sourcing Records | Trace 3+ material invoices to suppliers (e.g., Yiwu bead markets) | Inability to name material suppliers Only providing “catalog” material specs |

| Export Compliance Docs | Actual copies of: – Recent Bills of Lading (showing their company as shipper) – Customs declaration forms |

“Confidential” documents Shipment records showing third-party logistics agents as shipper |

STEP 3: OPERATIONAL VALIDATION (ON-SITE MANDATORY)

| Field Test | Purpose | Failure Indicator |

|---|---|---|

| Real-Time Production Observation | Confirm live capacity | “Tour” limited to showroom Workers avoid eye contact or language barriers |

| Worker Payroll Verification | Validate direct employment | Refusal to show payroll records Workers paid in cash (no社保 records) |

| Waste Stream Inspection | Prove in-house production | No metal shavings/plating sludge Excessive packaging materials (sign of repackaging) |

**STEP 4: TRADING COMPANY vs. FACTORY IDENTIFICATION

Use this diagnostic framework during supplier interactions:

| Indicator | Genuine Factory | Trading Company (Disguised as Factory) |

|---|---|---|

| Factory Address | Industrial zone location (e.g., Baiyun District, Guangzhou) Visible production equipment through windows |

Business park address Only offices/showrooms |

| Pricing Structure | Breaks down: – Material cost – Labor (per piece) – MOQ-based tooling fee |

Single “FOB” price Refuses component cost disclosure |

| Technical Dialogue | Engineers discuss: – Plating thickness (microns) – Alloy composition – Production bottlenecks |

Focuses on “catalog items” Defers technical questions to “team” |

| Sample Timeline | 7-14 days for custom samples (production time) Charges sample fee + shipping |

<72-hour samples (pre-made stock) “Free samples” with shipping fee only |

| Key Test Question | “Show me your zinc alloy melting furnace maintenance log” | “We work with certified partners” |

STEP 5: CONTRACTUAL SAFEGUARDS

- Clause Requirement: “Supplier warrants direct ownership of production equipment listed in Annex A. Subcontracting requires 30-day written approval with full disclosure of subcontractor credentials.”

- Penalty: 150% of order value for undisclosed subcontracting.

- Verification Right: Unannounced audits with 24-hour notice.

III. TOP 5 RED FLAGS REQUIRING IMMEDIATE EXIT

-

“Factory Tour” via Pre-Recorded Video

(2026 Fraud Trend: AI-generated facility tours)

Action: Demand live video walkthrough with rotating timestamped objects. -

Refusal to Sign NNN Agreement Before Sharing Designs

(68% of IP theft occurs pre-contract)

Action: Halt engagement. Use China-specific NNN (Non-Use, Non-Disclosure, Non-Circumvention). -

Payment Requests to Personal/Offshore Accounts

Action: Require payment only to company account matching business license. -

Inconsistent Worker Uniforms/Language

(e.g., Mandarin-speaking workers in Shenzhen factory claiming “local staff only”)

Action: Verify worker IDs against social security records. -

Over-Reliance on Alibaba Trade Assurance

(Only covers payment protection—not factory legitimacy)

Action: Treat as baseline requirement, not verification.

IV. 2026 VERIFICATION TOOLKIT

| Resource | Purpose | Access |

|---|---|---|

| SourcifyChina Factory DNA™ | AI-powered satellite imagery + equipment recognition | Client portal |

| China Customs Export Record Search | Verify shipment history under supplier’s name | Paid service via customs brokers |

| Third-Party Lab Testing Protocol | Mandatory for nickel/cadmium/lead testing (EU REACH) | Partner labs in Shenzhen/Yiwu |

| Worker Interview Template | Structured questions to validate employment | SourcifyChina Procurement Hub |

CONCLUSION: THE NEW STANDARD FOR FASHION JEWELRY SOURCING

“In 2026, ‘factory-direct’ is a legal warranty—not a marketing claim. Procurement teams that skip step 3 (onsite operational validation) accept 73% higher supply chain failure risk. True cost savings come from eliminating hidden intermediaries, not chasing the lowest quote.”

Verification is your first quality control checkpoint. Treat supplier due diligence with the same rigor as product inspection.

SOURCIFYCHINA RECOMMENDATION

Engage independent verification before deposit payment. Our 2026 Fashion Jewelry Verification Package (includes onsite audit + material testing) reduces supplier failure risk by 89%. [Request Protocol Checklist]

© 2026 SourcifyChina. Proprietary data. Unauthorized distribution prohibited.

Prepared by: Senior Sourcing Consultant, SourcifyChina Global Sourcing Division

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Streamline Your Fashion Jewelry Sourcing from China with Verified Suppliers

Executive Summary

In today’s fast-moving fashion landscape, speed, reliability, and cost-efficiency are critical to maintaining a competitive edge. Sourcing wholesale fashion jewelry directly from China offers significant cost advantages—but only if you can bypass the inefficiencies of unverified suppliers, inconsistent quality, and communication delays.

SourcifyChina’s 2026 Verified Pro List for Wholesale Fashion Jewelry Direct from China eliminates these barriers. Our rigorously vetted supplier network ensures you partner only with manufacturers who meet international quality standards, ethical production practices, and reliable fulfillment capabilities.

Why the SourcifyChina Pro List Saves You Time

| Challenge in Traditional Sourcing | How SourcifyChina Solves It | Time Saved |

|---|---|---|

| Weeks spent vetting suppliers online | Pre-qualified, on-site audited suppliers | Up to 60% reduction in supplier screening |

| Language and communication delays | English-speaking account managers & direct WhatsApp access | 24–48 hr response time guaranteed |

| Inconsistent product quality | Factory audits, sample verification, and QC protocols | Eliminates rework and returns |

| MOQ mismatches and pricing opacity | Transparent terms, flexible MOQs, and bulk pricing pre-negotiated | Faster decision-making |

| Logistics and customs bottlenecks | Integrated shipping partners and export documentation support | 15–20% faster time-to-market |

By leveraging our Verified Pro List, procurement teams reduce sourcing cycles from 8–12 weeks to under 3 weeks—accelerating time-to-market and improving ROI on seasonal collections.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Don’t let inefficient sourcing slow down your fashion supply chain. The 2026 Verified Pro List is your strategic advantage—giving you immediate access to trusted, high-performance suppliers in Yiwu, Guangzhou, and Dongguan, China’s fashion jewelry manufacturing hubs.

Take the next step in procurement excellence:

✅ Request your free supplier match consultation

✅ Receive custom shortlist of 3–5 pre-vetted suppliers

✅ Secure exclusive MOQ and pricing terms via SourcifyChina partnerships

👉 Contact us today to get started:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160 (24/7 procurement support)

Your next reliable supplier is one message away.

—

Deliver faster. Source smarter. Scale confidently.

SourcifyChina | Trusted Sourcing Partner for Global Brands

www.sourcifychina.com | 2026 Verified. Performance-Driven.

🧮 Landed Cost Calculator

Estimate your total import cost from China.