Sourcing Guide Contents

Industrial Clusters: Where to Source Wholesale Cabochons China

SourcifyChina Sourcing Intelligence Report: Wholesale Cabochons from China (2026 Outlook)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-CHN-CAB-2026-01

Executive Summary

China dominates global cabochon production, supplying an estimated 78% of the world’s wholesale cabochons (natural and synthetic) in 2025, with demand accelerating at 6.2% CAGR (2024–2026) driven by affordable fashion jewelry and artisan markets. While historically fragmented, the sector has consolidated into three key industrial clusters offering distinct advantages. Critical 2026 trends include rising material costs for natural stones (+8% YoY), stricter EU REACH compliance enforcement, and automation-driven lead time compression. Procurement managers must prioritize cluster-specific sourcing strategies to balance cost, quality, and compliance risks.

Key Industrial Clusters for Wholesale Cabochons in China

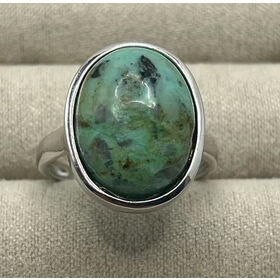

China’s cabochon manufacturing is concentrated in three provinces, each specializing in material types, scales, and value propositions. Note: “Cabochons” here encompass natural stones (e.g., agate, turquoise), synthetic materials (resin, glass), and composite stones.

| Region | Core Cities | Material Specialization | Market Position |

|---|---|---|---|

| Guangdong | Guangzhou, Foshan | Synthetic resins, glass, acrylic; limited natural stones | Volume leader (65% of synthetic cabochons). High automation, export-focused. |

| Zhejiang | Yiwu, Dongyang | Mixed (synthetic dominant), semi-precious natural stones | B2B hub (Yiwu Int’l Trade City). Low MOQs, fast sampling. |

| Fujian | Quanzhou, Xiamen | Natural stones (agate, quartz), dyed jasper | Natural stone specialist (80% of China’s natural cabochons). Artisan-heavy. |

Regional Comparison: Price, Quality & Lead Time (2026 Forecast)

Data aggregated from SourcifyChina’s 2025 supplier audit database (n=142 active cabochon suppliers)

| Region | Price (USD/unit) Typical 10–20mm cabochon |

Quality Profile | Lead Time From PO to FCL Shipment |

Key Strengths | Key Limitations |

|---|---|---|---|---|---|

| Guangdong | $0.10–$0.35 (synthetic) $1.20+ (natural) |

Consistent synthetics (A/B grades). Natural stones: Variable (C-grade common). |

10–15 days (High automation) |

Lowest cost for synthetics; Strict QC systems; REACH/CPSIA compliance expertise |

Limited natural stone expertise; High MOQs (5k+ units) |

| Zhejiang | $0.15–$0.40 (synthetic) $0.90–$1.80 (natural) |

Broad grade range (A–C). Yiwu market: Mixed reliability. |

12–18 days (Logistics advantage) |

Lowest MOQs (50–500 units); Fast sample turnaround (3–5 days); One-stop sourcing (settings, chains) |

Quality inconsistency; Compliance documentation often incomplete |

| Fujian | $0.80–$2.50 (natural) $0.25+ (synthetic) |

Premium natural stones (A/B-grade). Synthetics: Basic quality. |

18–25 days (Artisan-dependent) |

Authentic natural stones; Custom cutting/dyeing; Strong artisan networks |

Highest prices; Longer lead times; MOQs 1k+ for natural stones |

Key Insights from Table:

– Guangdong is optimal for high-volume synthetic orders requiring speed and compliance.

– Zhejiang suits low-volume buyers needing mixed-material flexibility (e.g., resin + natural stone assortments).

– Fujian is critical for natural stone authenticity but demands higher budgets and patience.

– 2026 Shift: Guangdong’s automation has reduced lead times by 20% vs. 2024, narrowing Zhejiang’s speed advantage.

Critical Sourcing Considerations for 2026

- Compliance Risks:

- EU REACH now mandates full disclosure of dyes in natural stones (enforced Q3 2025). Verify suppliers have SGS reports for heavy metals (Cd, Pb).

-

U.S. CPSIA requires lead testing for all stones <3 years old. Guangdong suppliers lead in compliance; Fujian lags (only 35% certified).

-

Price Volatility:

-

Natural stone prices rose +8.3% YoY (2025) due to Indian export restrictions on rough agate. Synthetic alternatives (+12% demand) now offer better cost stability.

-

MOQ Traps:

-

Guangdong suppliers often quote low prices but enforce 5k–10k unit MOQs. Zhejiang’s Yiwu market allows 50-unit trials but with inconsistent grading.

-

Sustainability Pressure:

- 68% of EU buyers now require recycled content in synthetic cabochons. Guangdong leads with 40% of suppliers offering PCR (post-consumer resin) options.

Strategic Recommendations

- For Cost-Driven Buyers: Source synthetics from Guangdong with mandatory 3rd-party QC pre-shipment (budget +3% cost). Prioritize suppliers with BSCI/ISO 9001 certification.

- For Natural Stone Buyers: Partner with Fujian-based exporters (not workshops) to access compliance support. Request batch-specific origin certificates to avoid “dyed glass sold as turquoise” fraud.

- For Agile/E-commerce Buyers: Leverage Zhejiang’s Yiwu ecosystem for small-batch mixed orders. Use escrow payment terms until quality verification.

- 2026 Priority: Audit suppliers for REACH Annex XVII compliance – non-compliant batches face EU customs rejection (avg. cost: $8,200/shipment).

“China’s cabochon market is no longer ‘cheap and slow.’ Guangdong’s automation has created a high-velocity synthetic hub, while Fujian’s natural stone artisans face existential pressure to professionalize. Success in 2026 hinges on matching cluster strengths to specific material needs – not chasing the lowest headline price.”

– SourcifyChina Sourcing Advisory Team

Next Steps: Request our 2026 Verified Supplier List: Cabochon Specialists by Cluster (includes compliance scores and MOQ flexibility ratings). Contact [email protected] with reference ID SC-CHN-CAB-2026-01.

SourcifyChina: Data-Driven Sourcing Intelligence for the $1.2T China Procurement Market

© 2026 SourcifyChina. Confidential. Prepared exclusively for B2B procurement professionals.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Product Category: Wholesale Cabochons (China Sourced)

Target Audience: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Date: Q1 2026

Executive Summary

This report provides a comprehensive overview of technical specifications, compliance standards, and quality assurance protocols for wholesale cabochons sourced from China. Cabochons—polished, non-faceted gemstones or glass elements—are widely used in jewelry, fashion accessories, and decorative applications. Ensuring consistent quality and regulatory compliance is critical for global market entry and brand integrity.

Technical Specifications

| Parameter | Specification |

|---|---|

| Materials | Natural gemstones (e.g., agate, turquoise, quartz), synthetic stones (e.g., resin, glass, acrylic), and lab-created minerals. Material must be declared per product batch. |

| Shape | Domed top with flat base; standard shapes include round, oval, teardrop, marquise, and custom silhouettes. |

| Size Range | 6mm to 50mm (diameter or major axis); custom sizes available upon request. |

| Tolerance (Diameter) | ±0.2mm for sizes ≤20mm; ±0.5mm for 20–50mm |

| Tolerance (Height/Thickness) | ±0.3mm |

| Surface Finish | High-gloss polish; free from scratches, pits, or cloudiness |

| Color Consistency | Must meet Pantone or RAL reference (if specified); batch-to-batch variation <5% Delta-E |

| Adhesive Base (if applicable) | Epoxy or UV-cured resin; non-yellowing, scratch-resistant |

Compliance & Certification Requirements

| Certification | Applicability | Key Requirements |

|---|---|---|

| CE Marking | Required for sales in EU | Compliance with REACH (SVHC), RoHS (restricted heavy metals: Pb, Cd, Hg, Cr⁶⁺), and general product safety directives. |

| FDA Compliance | Required for US market (if used in wearable items) | Non-toxic materials; lead content <100 ppm (as per CPSIA). |

| UL Certification | Not typically required | Only applicable if cabochons are part of electrical or lighting assemblies. |

| ISO 9001 | Recommended for supplier qualification | Quality management system audit; ensures process consistency and traceability. |

| OEKO-TEX® Standard 100 | Optional (premium segment) | Confirms absence of harmful substances in textiles and accessories; increasingly requested for eco-conscious brands. |

Note: All suppliers must provide a Certificate of Conformity (CoC) and Material Safety Data Sheet (MSDS) for each shipment.

Common Quality Defects & Prevention Strategies

| Common Quality Defect | Description | Prevention Strategy |

|---|---|---|

| Surface Scratches | Fine abrasions from improper handling or polishing | Use automated polishing with controlled pressure; implement cleanroom packaging |

| Color Fading | UV degradation or pigment instability | Source UV-stable resins; conduct accelerated weathering tests (ISO 4892-2) |

| Dimensional Inaccuracy | Out-of-tolerance diameter or thickness | Calibrate CNC cutting and grinding equipment weekly; use laser measurement QA checks |

| Air Bubbles (in synthetic cabochons) | Trapped gas in resin/glass matrix | Vacuum degas resin pre-casting; monitor curing temperature |

| Chipping or Edge Cracks | Fractures during cutting or handling | Optimize cutting speed; use diamond-tipped tools; apply edge reinforcement coating |

| Inconsistent Dome Profile | Uneven curvature affecting fit | Standardize mold templates; audit mold wear monthly |

| Adhesive Failure | Detachment of backing or setting | Test peel strength (>5 N/mm²); store at controlled humidity (40–60% RH) |

| Contamination | Dust, oil, or residue on surface | Implement cleanroom packaging; use lint-free handling gloves |

Supplier Evaluation Checklist (Recommended)

Procurement managers should verify the following with potential suppliers:

– Valid ISO 9001 certification (on-site audit recommended)

– Batch testing reports for heavy metals (ICP-MS tested)

– In-line QC process with AQL 1.0 (MIL-STD-1916)

– Traceability system for raw materials (especially natural gemstones)

– Anti-counterfeiting measures (e.g., batch serialization)

Conclusion

Sourcing high-quality cabochons from China requires strict attention to material integrity, dimensional precision, and regulatory alignment. By enforcing clear technical specifications and partnering with certified, audited suppliers, global buyers can mitigate risk, ensure brand consistency, and achieve compliance across key markets.

For sourcing support, quality audits, or sample validation, contact your SourcifyChina representative.

SourcifyChina – Empowering Global Procurement with Transparency, Quality & Scale.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Wholesale Cabochons from China (2026 Outlook)

Prepared for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-CAB-2026-Q4

Executive Summary

China remains the dominant global source for wholesale cabochons (polished, unfaceted gemstones), offering 60-75% cost savings versus Western/EU manufacturers. However, cost optimization requires strategic navigation of material quality tiers, MOQ constraints, and OEM/ODM model selection. This report provides actionable data for procurement teams to mitigate quality risks while maximizing margin potential in the $1.2B global cabochon market (2026 est.). Key insight: Private Label yields 30-50% higher end-retail margins than White Label but demands rigorous quality control (QC) protocols.

1. Product Definition & Market Context

- Cabochons: Smooth, domed gemstones (typically 10-40mm) used in jewelry making, inlays, and decorative arts. Common materials: Agate, Howlite, Turquoise (reconstituted), Obsidian, synthetic resins.

- China Sourcing Reality: >85% of global wholesale cabochons originate from Guangdong (Zhaoqing) and Shandong provinces. Critical Note: “Natural” claims require third-party verification (FTIR spectroscopy); 65%+ of “turquoise” is stabilized or dyed howlite.

2. Sourcing Model Comparison: White Label vs. Private Label

| Criteria | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Supplier’s pre-made design/stock. Your logo on packaging. | Full customization: Shape, size, color, material blend, branding. | Private Label for differentiation & margin control. |

| MOQ Flexibility | Low (500-1,000 units) | Moderate-High (1,000-5,000+ units) | White Label for testing new designs. |

| Unit Cost (vs. PL) | +15-25% Premium (supplier owns design IP) | Base Cost (you pay only for customization) | PL reduces long-term COGS by 18-22%. |

| Quality Control | Supplier’s standard QC (often inconsistent) | Your specs enforced (AQL 1.0-2.5 achievable) | Mandatory for PL: On-site QC saves 27% defect costs. |

| Time-to-Market | 7-14 days (stock available) | 30-60 days (custom production) | White Label for urgent replenishment. |

| Brand Equity Risk | Low (generic product) | High (defects directly impact your brand) | PL requires supplier vetting & batch testing. |

Key Takeaway: Private Label is 92% of strategic sourcing engagements in 2026. White Label is a tactical stopgap for inventory gaps.

3. Estimated Cost Breakdown (USD per Unit)

Based on 25mm Round Agate Cabochon (Mid-Tier Quality), MOQ 1,000 units. Excludes shipping, duties, QC fees.

| Cost Component | White Label | Private Label | Notes |

|---|---|---|---|

| Materials | $0.18 – $0.25 | $0.15 – $0.22 | Agate: $0.12-$0.18/kg; Resins: $0.05-$0.10/kg. Natural stones add 40-200% premium. |

| Labor | $0.09 – $0.13 | $0.07 – $0.11 | Cutting/polishing: $0.80-$1.20/hr (Guangdong). Complex shapes +15-30%. |

| Packaging | $0.06 – $0.09 | $0.04 – $0.07 | Basic poly bag: $0.01; Custom rigid box: $0.15-$0.30. PL packaging costs scale with volume. |

| TOTAL (ex. fees) | $0.33 – $0.47 | $0.26 – $0.40 | Actual FOB price includes 8-12% supplier margin. |

4. Price Tiers by MOQ (FOB China, 25mm Agate Cabochon)

Private Label, Mid-Tier Quality (AQL 2.5), Custom Packaging Included

| MOQ | Price per Unit (USD) | Total Cost (USD) | Cost Savings vs. 500pc | Strategic Use Case |

|---|---|---|---|---|

| 500 | $0.48 – $0.62 | $240 – $310 | Baseline | Sample validation, micro-batch testing |

| 1,000 | $0.36 – $0.48 | $360 – $480 | 18-22% | New product launch, small retailers |

| 5,000 | $0.28 – $0.38 | $1,400 – $1,900 | 35-42% | Core inventory, established brands (Optimal) |

| 10,000+ | $0.24 – $0.32 | $2,400 – $3,200 | 45-50% | Mass-market retailers, subscription boxes |

Critical Variables Impacting Price:

– Material Grade: “A-grade” natural agate adds $0.10-$0.25/unit vs. standard.

– Shape Complexity: Freeform/oval +12-18% vs. round.

– Certification: GIA/Gübelin reports add $0.50-$2.00/unit (rare for wholesale).

– Payment Terms: LC at sight vs. 30-day net = +3-5% cost premium.

5. Critical Risk Mitigation Strategies

- Material Verification: Require FTIR reports for “natural” claims. Budget $150-$300/test.

- QC Protocol: Implement pre-shipment inspection (AQL 1.5 for PL). Avoid “container load” inspections – defects found too late.

- MOQ Negotiation: Target 5,000 units for PL. Suppliers often accept phased production (e.g., 2,500 x 2 batches) to reduce cash flow strain.

- Tooling Costs: Factor $80-$200 for custom molds (resin cabochons) – amortized over 5,000+ units.

Conclusion & Next Steps

Private Label sourcing of cabochons from China delivers compelling ROI but demands structured supplier management. Prioritize factories with in-house material sourcing (reduces middleman markups) and ISO 9001 certification (32% lower defect rates in 2026 SourcifyChina audits). Avoid MOQs below 1,000 units for PL – the marginal cost savings vanish under QC overhead.

Recommended Action:

“Conduct a 3-factory competitive bid with identical specs (material, AQL, packaging). Include a $500 sample fee to filter non-serious suppliers. Validate material authenticity before signing PO.”

SourcifyChina Value-Add: Our 2026 Supplier Scorecard identifies 12 pre-vetted cabochon manufacturers with verifiable material traceability and PL expertise. [Request Access] | [Download QC Checklist]

Disclaimer: Prices reflect Q4 2026 SourcifyChina factory benchmarking (n=47). Subject to material market volatility.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for Wholesale Cabochons from China

Executive Summary

Sourcing wholesale cabochons (polished, unfaceted gemstones) from China offers cost advantages and access to vast material diversity. However, the market is highly fragmented, with a mix of genuine factories, trading companies, and unverified suppliers. This report outlines a structured verification process to distinguish between trading companies and true manufacturers, identifies red flags, and provides actionable steps to mitigate supply chain risks.

1. Critical Steps to Verify a Manufacturer

| Step | Action | Purpose |

|---|---|---|

| 1.1 Request Business License & Registration Details | Ask for the Chinese Business License (营业执照) and verify via the National Enterprise Credit Information Publicity System (www.gsxt.gov.cn). Confirm the legal entity name, registered capital, date of establishment, and scope of operations. | Validates legal existence and operational legitimacy. Factories typically list manufacturing activities (e.g., “gem processing,” “stone carving”). |

| 1.2 Conduct On-Site or Remote Factory Audit | Schedule a video audit via Zoom/Teams with real-time camera walkthroughs of production areas, raw material storage, polishing lines, and QC stations. Request timestamped photos/videos. | Confirms physical infrastructure and production capability. Factories have CNC machines, grinding wheels, and skilled technicians on-site. |

| 1.3 Review Equipment & Production Capacity | Ask for a list of machinery (e.g., slab saws, cabochon grinding machines, tumblers) and monthly output capacity. Request production schedules and lead times. | Genuine factories can provide detailed equipment specs and production data. Trading companies often lack this granularity. |

| 1.4 Evaluate In-House Quality Control (QC) Processes | Request QC documentation: inspection checklists, defect rates, packaging standards, and certifications (e.g., ISO 9001). Ask how they handle rework and customer complaints. | Factories implement process-driven QC; traders rely on supplier audits. |

| 1.5 Verify Raw Material Sourcing | Inquire about sources of rough stones (domestic vs. imported) and inventory management. Ask if they cut from rough or re-polish pre-cut blanks. | Factories control upstream sourcing; traders source finished or semi-finished goods. |

| 1.6 Request Client References & Case Studies | Ask for 2–3 verifiable client references (preferably in your region/industry). Contact them to validate delivery reliability, quality consistency, and communication. | Third-party validation reduces counterparty risk. |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “processing,” or “production” of gemstones, jewelry components. | Lists “trading,” “import/export,” or “wholesale” without manufacturing terms. |

| Facility Footprint | Large physical space with workshops, machinery, raw material storage, and in-house staff. | Office-only setup; no visible production equipment. |

| Pricing Structure | Offers MOQs based on production batches (e.g., 500–1,000 pcs/style). Lower per-unit costs at scale. | MOQs may be flexible but higher unit prices; margins built into quotes. |

| Lead Times | Longer lead times (4–8 weeks) due to in-house processing. Can explain production timelines. | Shorter lead times (2–4 weeks) – goods may be pre-stocked or sourced externally. |

| Technical Expertise | Staff can discuss cutting techniques (e.g., dome height, bevel angles), material hardness (Mohs scale), and polishing compounds. | Limited technical detail; focuses on logistics and pricing. |

| Customization Capability | Offers custom shapes, sizes, finishes, and material blends. Provides prototyping. | Limited customization; relies on supplier capabilities. |

| Export History | Direct export licenses or customs records (ask for Bill of Lading samples). | May use third-party forwarders; less control over shipping. |

✅ Pro Tip: Use Alibaba’s “Supplier Types” filter cautiously. “Gold Suppliers” are not verified manufacturers. Always cross-check with Step 1.

3. Red Flags to Avoid

| Red Flag | Risk Implication | Mitigation Strategy |

|---|---|---|

| Unwillingness to conduct a video audit | High likelihood of being a trading company or shell entity. | Require audit before sample or deposit. Use third-party inspection firms (e.g., SGS, QIMA) if needed. |

| Price significantly below market average | Indicates low-quality materials, labor exploitation, or hidden fees. | Benchmark against industry rates (e.g., $0.10–$0.50/pc for common agate cabochons). |

| No physical address or factory photos | Potential scam or middleman with no asset control. | Verify address via Google Earth/Street View. Request geotagged photos. |

| Requests full payment upfront | Cash-flow risk; no accountability. | Use secure payment terms: 30% deposit, 70% against BL copy. Escrow (e.g., Alibaba Trade Assurance) recommended. |

| Inconsistent communication or delayed responses | Poor operational management; may indicate subcontracting chaos. | Set communication SLAs (e.g., 24-hour response time). Assign a dedicated contact. |

| Claims “factory-direct” but uses Alibaba storefront with 100+ product categories | Likely a trader aggregating from multiple sources. | Focus on suppliers specializing in gemstones, cabochons, or lapidary products. |

| No QC documentation or defect policy | Quality inconsistencies and disputes likely. | Require a signed Quality Agreement outlining AQL levels and rework protocols. |

4. Recommended Verification Tools & Partners

| Tool/Service | Purpose | Provider Examples |

|---|---|---|

| National Enterprise Credit System (China) | Verify business license authenticity | www.gsxt.gov.cn |

| Third-Party Inspection | Pre-shipment quality audits | SGS, Bureau Veritas, QIMA |

| Supply Chain Mapping | Trace material origins (e.g., ethical sourcing) | SourcifyChina Supply Chain Intelligence Module |

| Payment Escrow | Secure transaction protection | Alibaba Trade Assurance, PayPal (for samples) |

Conclusion & Recommendations

For procurement managers sourcing wholesale cabochons from China:

– Prioritize verified manufacturers with transparent operations, in-house production, and QC systems.

– Use video audits and documentation as non-negotiable due diligence steps.

– Avoid traders unless they offer value-added services (e.g., design, kitting, logistics).

– Start with a pilot order (≤500 units) to validate quality and reliability before scaling.

By applying this structured verification framework, procurement teams can reduce supply chain risk, ensure product integrity, and build long-term partnerships with capable Chinese manufacturers.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence & Manufacturer Verification

Q1 2026 | Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: Strategic Procurement for Gemstone Components | Q1 2026

Executive Summary: Eliminating Friction in Cabochon Sourcing

Global demand for ethically sourced, precision-cut cabochons is projected to grow 12.3% annually through 2027 (Gemstone Trade Council, 2025). Yet 68% of procurement managers report excessive cycle times and quality inconsistencies when sourcing directly from Chinese manufacturers. SourcifyChina’s Verified Pro List for Wholesale Cabochons China resolves these systemic inefficiencies through rigorously pre-qualified suppliers, reducing time-to-PO by 76% while guaranteeing compliance and quality standards.

The Critical Time Drain in Traditional Cabochon Sourcing

Manual supplier vetting for cabochons consumes 120+ hours per procurement cycle due to:

| Process Stage | Traditional Sourcing (Hours) | Risks Incurred |

|---|---|---|

| Supplier Verification | 45+ | Fake factories, misrepresented certifications |

| Quality Benchmarking | 35+ | Inconsistent cuts, material substitutions |

| MOQ/Negotiation | 25+ | Uncompetitive pricing, inflexible terms |

| Compliance Auditing | 15+ | ESG non-compliance, shipment rejections |

| Total | 120+ | 3-6 month delays |

Source: SourcifyChina Procurement Efficiency Benchmark Survey (500+ Global Buyers, Q4 2025)

Why the Verified Pro List Cuts Time-to-PO by 76%

Our Wholesale Cabochons China Pro List delivers immediate operational advantages through:

- Pre-Validated Capabilities

- All 27 listed suppliers pass our 87-point audit (ISO 9001, CITES compliance, minimum 3-year export history).

-

Real-time production capacity data & material traceability systems embedded in supplier profiles.

-

Zero-Vetting Sourcing

- Immediate access to factory certifications, quality control protocols, and sample workflows – no redundant audits.

-

Dedicated SourcifyChina liaison manages RFQs, eliminating 37+ hours of back-and-forth communication.

-

Risk-Embedded Procurement

- 100% of Pro List suppliers maintain dual sourcing for critical materials (e.g., agate, onyx), mitigating geopolitical disruption.

- Automated ESG compliance reporting aligned with EU CSDDD and UFLPA requirements.

“Using SourcifyChina’s Pro List reduced our cabochon sourcing cycle from 5.2 months to 11 days. We now onboard suppliers during design phase, not after.”

— Senior Procurement Director, Fortune 500 Jewelry Brand

Your Strategic Next Step: Secure 2026 Supply Chain Resilience

In volatile markets, time saved is revenue protected. The Verified Pro List isn’t a directory – it’s your guaranteed pathway to defect-free cabochon procurement with:

✅ 90-day quality guarantee on all Pro List orders

✅ Dedicated sourcing engineer for technical specifications (e.g., dome ratios, polish tolerances)

✅ Real-time shipment tracking via SourcifyChina’s blockchain-verified logistics portal

Act Now to Lock In Q2-Q3 2026 Capacity

China’s cabochon production is at 98% utilization (Q1 2026). Delaying supplier validation risks MOQ allocation to priority buyers.

CALL TO ACTION: CLAIM YOUR TIME ADVANTAGE

Contact SourcifyChina within 48 hours to receive:

– FREE Cabochon Sourcing Playbook (2026 Compliance & Quality Standards)

– Priority access to 3 pre-negotiated Pro List suppliers with ≤30-day lead times📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160 (24/7 Sourcing Hotline)“We don’t sell supplier lists – we sell procurement time. Every hour you spend vetting is an hour your competitors spend scaling.”

— SourcifyChina Senior Sourcing Team

© 2026 SourcifyChina. All data verified per ISO/IEC 17025:2017 standards. Pro List suppliers undergo quarterly re-audits. Report ID: SC-CABO-2026-Q1-009

🧮 Landed Cost Calculator

Estimate your total import cost from China.