The global demand for decorative stone materials continues to surge, driven by expanding construction activities and rising consumer preference for premium, natural-looking surfaces in residential and commercial spaces. According to Grand View Research, the global natural stone market was valued at USD 35.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. A key driver within this segment is the increasing popularity of white translucent stones—valued for their elegance, light-diffusing properties, and versatility in countertops, wall cladding, and interior design features. As sustainability and aesthetic differentiation become priorities for architects and designers, manufacturers specializing in high-quality translucent stone are gaining strategic importance. This growing market momentum has paved the way for innovation and specialization among producers worldwide. Below, we spotlight the top nine manufacturers leading the charge in white translucent stone production, selected based on product quality, global reach, technological advancement, and market recognition.

Top 9 White Translucent Stone Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Translucent White Quartz Stone GQ

Domain Est. 2021

Website: grandquartztech.com

Key Highlights: We manufacture translucent quartz slabs and countertops directly in our factory, from raw material to finished product, with advanced production technology and ……

#2 Translucent Gorgeous Semi

Domain Est. 2000

Website: icestone.com

Key Highlights: Ice Stone is a professional team importing and exporting natural stone all over the world. Our company covered an area over 6,000 square meters and have ……

#3 White Translucent

Domain Est. 2003

Website: stonecontact.com

Key Highlights: White Translucent : You can find out different kinds of White Translucentwith high quality products at low price, like and so on….

#4 NEOLITH – Kitchens

Domain Est. 2010

Website: neolith.com

Key Highlights: Neolith is a world leader in the design and manufacture of sintered stone surfaces. Applies to interiors and exteriors: facades, furniture, ……

#5 Backlit Translucent Stone Veneer Suppliers

Domain Est. 2010

Website: rajasthan-stone-exporter.com

Key Highlights: We have all beautiful natural slate quartzite sandstone marble limestone collection with us in the form of UV translucent stone panels that can excite the ……

#6 Delgado Stone

Domain Est. 2011

Website: delgadostone.com

Key Highlights: Delgado Stone is a leader in natural stone veneer, flagstone, steps, landscape, and architectural stone products….

#7 Quartz Countertops

Domain Est. 2012

Website: msisurfaces.com

Key Highlights: Q Premium Natural Quartz from MSI offers over 125 quartz styles in a wide range of patterns, including marble-looks, concrete-looks, and nature-inspired ……

#8 Translucent Stone for Luxurious Interiors

Domain Est. 2013

Website: hrststone.com

Key Highlights: Translucent stone is a captivating material in modern interior design, valued for its beauty and unique interaction with light….

#9 PACIFIC Engineered Surfaces Pvt Ltd

Website: thepacific.group

Key Highlights: Discover premium natural stones, quartz surfaces, granites and engineered materials from The Pacific Group. Quality, scale and global expertise….

Expert Sourcing Insights for White Translucent Stone

2026 Market Trends for White Translucent Stone

The white translucent stone market is poised for significant evolution by 2026, driven by shifting consumer preferences, technological advancements, and sustainability imperatives. This analysis explores the key trends shaping the demand, supply, and applications of white translucent stone in the coming years.

Growing Demand in High-End Interior Design

White translucent stone, particularly varieties like onyx and engineered quartz with translucency, is increasingly favored in luxury residential and commercial interiors. By 2026, demand is expected to rise due to its aesthetic appeal—offering a luminous, ethereal quality that enhances ambient lighting. Architects and designers are incorporating it into feature walls, countertops, backsplashes, and lighting installations to create distinctive, high-value spaces. The trend toward wellness-centric and spa-like environments in homes and boutique hospitality will further boost its use.

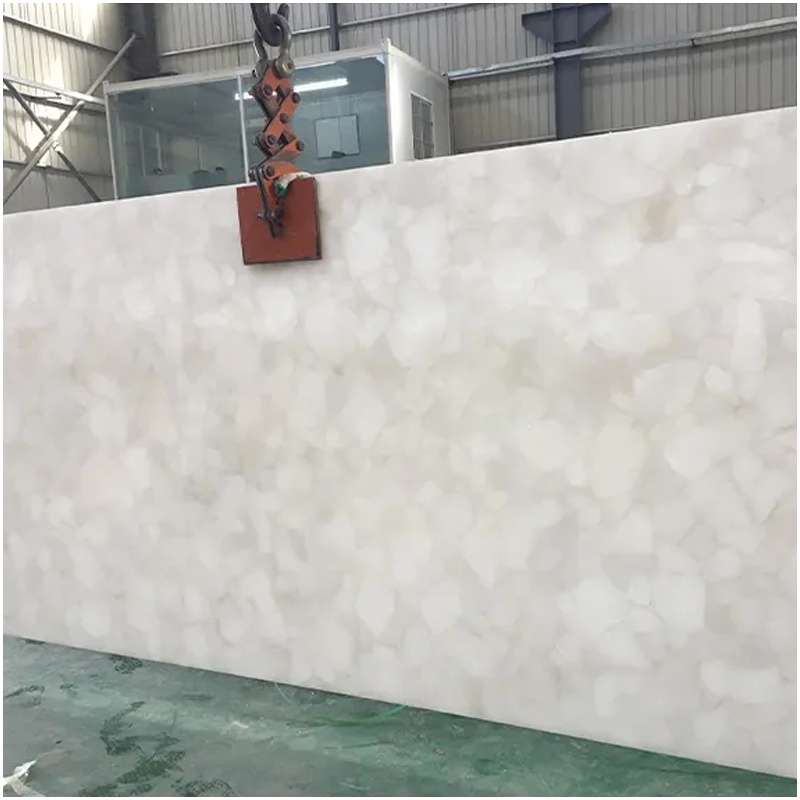

Expansion of Engineered Translucent Materials

Natural white onyx, while beautiful, is costly and fragile. As a result, engineered translucent stone—such as resin-composite or quartz-based alternatives with enhanced durability and consistency—is gaining traction. By 2026, manufacturers are anticipated to launch advanced formulations that better mimic the depth and veining of natural stone while offering improved resistance to heat, scratches, and UV degradation. These innovations will make translucent aesthetics more accessible and practical for broader applications.

Sustainability and Ethical Sourcing Concerns

Consumers and regulators are placing greater emphasis on sustainable and transparent supply chains. By 2026, demand for white translucent stone will be influenced by certifications and traceability. Natural stone extraction, particularly from regions with lax environmental regulations, may face scrutiny. This will drive investment in low-impact quarrying practices and stimulate the growth of recycled or bio-based translucent composites. Brands that prioritize carbon footprint reduction and ethical labor practices are likely to gain competitive advantage.

Integration with Smart Lighting and Technology

The synergy between translucent stone and integrated lighting solutions is expected to expand. By 2026, smart homes and commercial buildings will increasingly feature backlit stone panels that respond to occupancy, time of day, or user preferences via IoT systems. Designers will leverage the material’s ability to diffuse light evenly, creating dynamic, mood-enhancing environments. This convergence of materials and technology will open new application avenues in retail, hospitality, and residential sectors.

Regional Market Dynamics

Asia-Pacific, particularly China and India, is projected to be a key growth region due to rapid urbanization and rising disposable incomes. Meanwhile, North America and Europe will continue to lead in premium design applications, with strong demand in renovation and custom architectural projects. Middle Eastern markets, known for opulent design, will sustain steady demand for high-quality natural white onyx, especially in luxury developments.

Price Volatility and Supply Chain Resilience

Geopolitical factors and logistical challenges could impact the availability and pricing of natural white translucent stone, especially onyx sourced from Iran, Turkey, or Mexico. By 2026, companies that diversify sourcing, adopt nearshoring strategies, or invest in synthetic alternatives will be better positioned to manage supply chain risks and maintain market stability.

In conclusion, the 2026 market for white translucent stone will be defined by innovation, sustainability, and design-driven demand. While natural stone retains its allure, engineered alternatives and technological integration will play a crucial role in shaping the future landscape of this elegant and versatile material.

Common Pitfalls When Sourcing White Translucent Stone (Quality and Intellectual Property)

Sourcing white translucent stone—such as onyx, alabaster, or engineered quartz—can elevate architectural and design projects, but it comes with significant risks related to both material quality and intellectual property (IP). Being aware of these common pitfalls helps ensure a successful and legally sound procurement process.

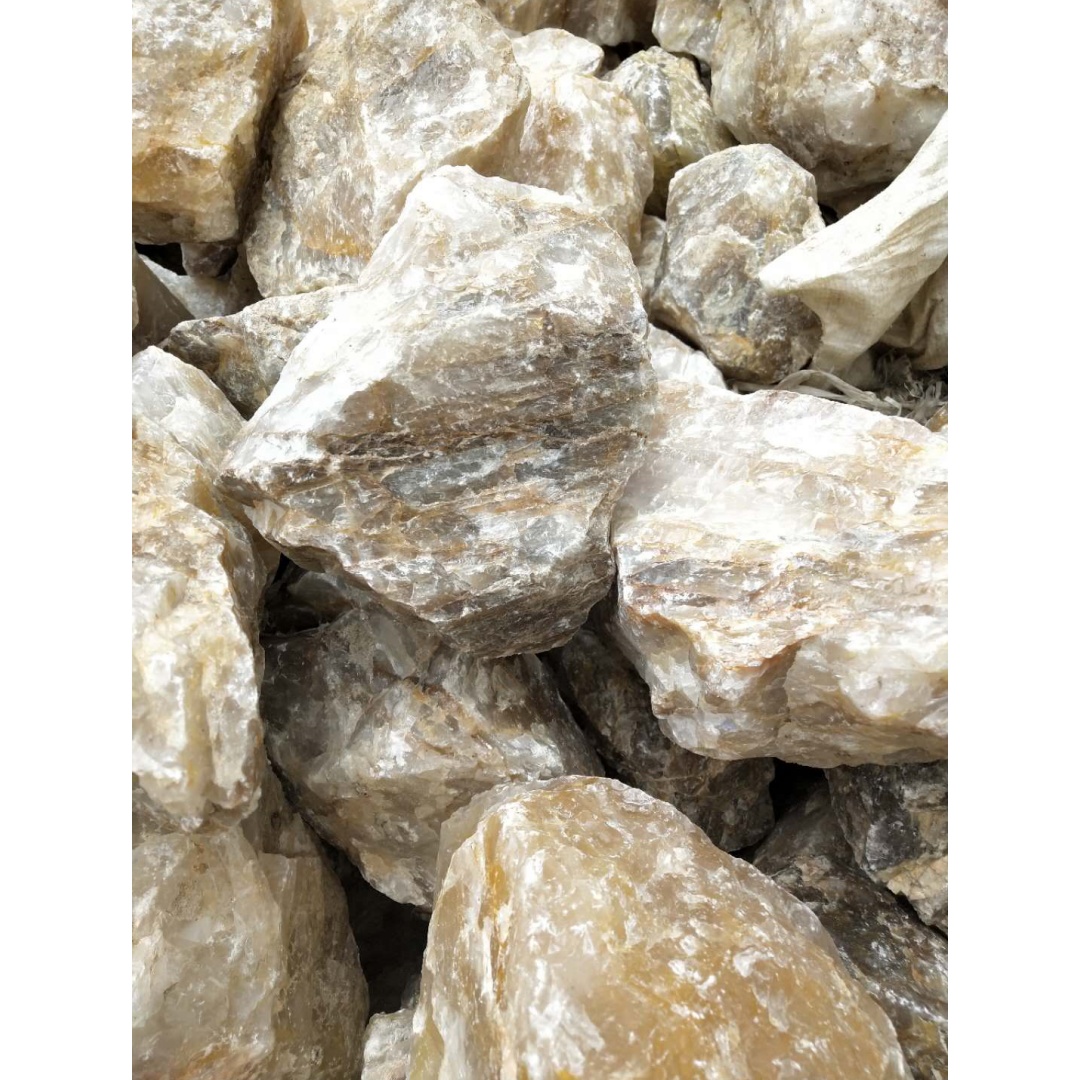

1. Overlooking Natural Stone Variability

Natural white translucent stones like onyx and alabaster exhibit inherent variations in veining, color, and translucency. Buyers often assume uniformity based on samples, only to receive slabs with unexpected patterns or flaws. This can lead to mismatched installations or aesthetic disappointment.

Solution: Request full-slab reviews, use digital mockups, and specify acceptable ranges of variation in procurement contracts.

2. Confusing Engineered Stone with Natural Stone

Many suppliers market engineered quartz or resin-composite materials as “translucent stone,” blurring the line with natural options. Engineered products may lack the depth, light diffusion, and authenticity of real stone, impacting both appearance and value.

Solution: Verify material origin through certifications, technical data sheets, and independent lab testing if necessary.

3. Inadequate Assessment of Light Transmission Quality

True translucency depends on how evenly the stone diffuses light. Poor-quality slabs may have cloudy spots, internal fractures, or inconsistent thickness, resulting in uneven lighting effects when backlit.

Solution: Conduct on-site light tests with sample panels under conditions similar to the final installation (e.g., LED backlighting).

4. Ignoring Structural Integrity and Durability

White translucent stones—especially natural onyx—are relatively soft and prone to cracking, scratching, and etching. Using them in high-traffic or moisture-prone areas without proper sealing or reinforcement leads to premature deterioration.

Solution: Specify appropriate applications, require ASTM performance testing, and mandate protective treatments during and after installation.

5. Insufficient Due Diligence on Supplier Credentials

Unverified or unlicensed suppliers may provide substandard materials or misrepresent product origins. Some may source stone from regions with questionable mining practices or export restrictions.

Solution: Audit suppliers, check membership in industry associations (e.g., NSC, MIA), and request chain-of-custody documentation.

6. Intellectual Property Infringement in Design Elements

Custom-cut or sculpted translucent stone installations—especially those with unique patterns, logos, or architectural features—may inadvertently copy protected designs. Using copyrighted CAD files, patented fabrication techniques, or trademarked patterns without permission exposes buyers to legal liability.

Solution: Obtain written rights or licenses for design usage, work directly with IP-compliant fabricators, and conduct IP clearance checks for custom features.

7. Unauthorized Use of Branded or Patented Materials

Certain translucent stone products are proprietary (e.g., specific engineered stone brands with patented formulations or finishes). Sourcing counterfeit or imitation versions not only compromises quality but may violate trademarks or design patents.

Solution: Purchase only through authorized distributors and verify product authenticity with the original manufacturer.

8. Failure to Secure Design Rights in Contracts

When commissioning custom stone elements, clients often assume ownership of the final design. However, without explicit contractual terms, the fabricator or designer may retain IP rights, restricting future replication or modification.

Solution: Include IP assignment clauses in fabrication agreements to ensure full ownership or usage rights are transferred.

By proactively addressing these quality and IP-related pitfalls, designers, architects, and developers can source white translucent stone with confidence, ensuring both aesthetic excellence and legal compliance.

Logistics & Compliance Guide for White Translucent Stone

Product Overview

White Translucent Stone refers to natural or engineered stone materials—such as certain types of marble, onyx, or engineered quartz—that exhibit a semi-transparent or light-diffusing quality when backlit. These materials are widely used in high-end architectural and interior design applications, including countertops, wall cladding, lighting features, and decorative elements. Due to their aesthetic value and physical properties, special handling and regulatory considerations are required throughout the supply chain.

Regulatory Compliance

White Translucent Stone, like other natural and engineered stone products, must comply with international, national, and regional regulations depending on its origin, composition, and intended market. Key compliance areas include:

- CITES (Convention on International Trade in Endangered Species): While most stone materials are not regulated under CITES, verification is recommended if the stone is sourced from rare geological formations or protected areas.

- REACH (EU Regulation): If the stone is treated with resins, sealants, or dyes, compliance with REACH regulations regarding chemical substances is required. Suppliers must provide Safety Data Sheets (SDS).

- LEED & Environmental Certifications: For projects aiming for green building certification, documentation on sustainable sourcing, low VOC emissions (for resin-treated stones), and recycled content may be required.

- Import/Export Documentation: Accurate HS (Harmonized System) codes are essential. Common codes include 2515.11 (for unworked marble) or 6802.91 (worked stone). Country-specific import permits may apply.

- Country of Origin Labeling: Required in markets like the U.S. and EU; must be clearly declared on commercial invoices and packaging.

Packaging & Handling Requirements

Proper packaging is critical to prevent damage to the delicate surfaces and edges of White Translucent Stone:

- Edge Protection: Use rigid corner guards or wooden edging to prevent chipping.

- Surface Protection: Apply non-abrasive protective film or kraft paper to polished surfaces to prevent scratches.

- Palletization: Secure slabs vertically in wooden crates or on treated wooden pallets with sufficient spacing to avoid friction. Avoid stacking without intermediate supports.

- Moisture Barrier: Wrap in waterproof plastic to prevent water damage, especially during sea freight. Desiccants may be used in humid environments.

- Labeling: Clearly mark packages with “Fragile,” “This Side Up,” product type, dimensions, weight, and handling instructions.

Transportation & Shipping

Due to the weight and fragility of stone materials, transport must be carefully managed:

- Mode of Transport:

- Sea Freight: Most cost-effective for large shipments. Use containerized shipping (20’ or 40’ HC) with proper dunnage and bracing.

- Air Freight: Reserved for urgent, high-value, or sample shipments due to cost and weight restrictions.

-

Land Transport: Use suspension-equipped flatbed trucks with rubber padding for domestic or regional delivery.

-

Insurance: Full cargo insurance is recommended, covering breakage, moisture damage, and transit delays. Declare accurate value based on FOB or CIF terms.

-

Customs Clearance: Provide complete documentation, including commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and any required import permits.

Storage & Inventory Management

- Indoor Storage: Store in a dry, covered area away from direct sunlight to prevent discoloration or thermal stress.

- Vertical Racking: Keep slabs stored vertically at a slight backward angle (5–10°) using racks with padded supports.

- Humidity Control: Maintain relative humidity below 60% to prevent moisture absorption, especially in resin-based engineered stones.

- First-In, First-Out (FIFO): Rotate stock to minimize long-term storage risks and ensure consistent quality.

Safety & Worker Compliance

- PPE (Personal Protective Equipment): Workers handling stone must wear cut-resistant gloves, safety goggles, and steel-toed boots.

- Silica Dust Control: For cutting or polishing operations, comply with OSHA (U.S.) or equivalent local regulations regarding crystalline silica exposure. Use water suppression and HEPA-filtered ventilation.

- Lifting Equipment: Use vacuum lifters or mechanical aids to avoid strain injuries when moving heavy slabs (typically 150–300 lbs per slab).

Sustainability & Ethical Sourcing

- Responsible Quarrying: Source from quarries adhering to environmental management standards (e.g., ISO 14001) and local ecological regulations.

- Chain of Custody: Maintain documentation proving legal extraction and ethical labor practices, particularly in high-risk regions.

- Recycling & Waste Management: Partner with suppliers that recycle stone offcuts and manage slurry waste responsibly.

Conclusion

Successfully managing the logistics and compliance of White Translucent Stone requires attention to detail at every stage—from sourcing and packaging to transport and installation. Adherence to regulatory standards, careful handling, and sustainable practices not only ensure product integrity but also support long-term market access and brand reputation in premium design sectors.

Conclusion for Sourcing White Translucent Stone

In conclusion, sourcing white translucent stone requires careful consideration of material type, origin, quality, and supplier reliability. Natural options such as white onyx, alabaster, or certain varieties of marble offer unique veining and light-diffusing properties ideal for luxurious architectural and design applications. Alternatively, high-quality engineered or resin-based translucent stone can provide consistency, durability, and design flexibility. Key factors in the sourcing process include verifying the stone’s translucency and color uniformity, assessing sustainability and ethical mining practices, and evaluating the total cost—including extraction, transportation, fabrication, and installation. Establishing relationships with reputable suppliers and conducting physical sample testing under controlled lighting are essential steps to ensure the final product meets aesthetic and structural requirements. With due diligence, sourcing white translucent stone can result in a stunning, high-value addition to both residential and commercial projects.