Sourcing Guide Contents

Industrial Clusters: Where to Source Which Company Assembles Iphone In China

SourcifyChina Sourcing Intelligence Report: High-Volume Precision Electronics Assembly Ecosystem in China (Focus: iPhone-Grade Manufacturing)

Date: January 15, 2026

Prepared For: Global Procurement & Supply Chain Leadership

Confidentiality: SourcifyChina Client Advisory

Executive Summary

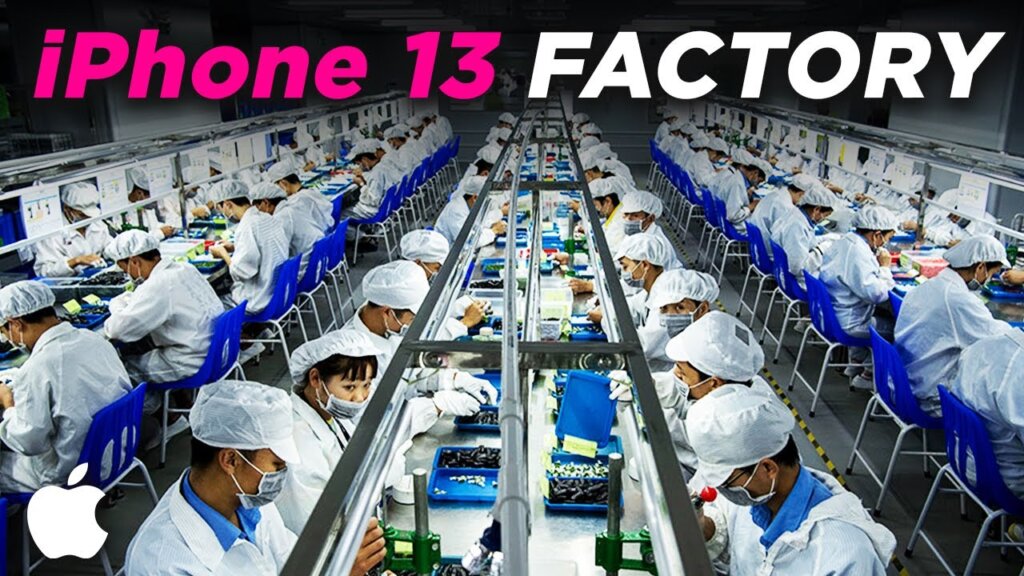

While Apple Inc. designs the iPhone, its physical assembly is exclusively executed by contract manufacturers (OEMs/ODMs) within China’s advanced electronics ecosystem. The primary assemblers are Foxconn (Hon Hai Precision Industry) and Pegatron, operating under stringent Apple specifications. This report analyzes the industrial clusters enabling this tier-1 assembly capability, providing actionable intelligence for sourcing comparable high-volume, precision electronics manufacturing. Directly sourcing “iPhone assembly” is impossible (protected by Apple’s exclusive contracts), but understanding these clusters is critical for securing equivalent quality and scale for your own products.

Key Industrial Clusters for High-End Electronics Assembly

China’s electronics manufacturing is concentrated in clusters offering integrated supply chains, skilled labor, and infrastructure. For iPhone-grade assembly (requiring micron-level precision, automated SMT, stringent QC, and massive scale), three provinces dominate:

- Guangdong Province (Pearl River Delta – PRD)

- Core Cities: Shenzhen (HQ hub), Guangzhou, Dongguan, Huizhou

- Why Dominant: Unmatched ecosystem density. Hosts Foxconn’s flagship Longhua (“iCity”) & Guanlan campuses (Shenzhen), Pegatron facilities, and >70% of global electronics component suppliers. Direct port access (Shenzhen Yantian, Guangzhou Nansha), mature logistics, and highest concentration of engineering talent. The epicenter for Apple product final assembly.

- Sichuan Province (Western China Hub)

- Core City: Chengdu

- Why Strategic: Foxconn’s massive Chengdu & Zhengzhou (technically Henan, but often grouped operationally with Western clusters) facilities handle significant iPhone assembly volume. Driven by government incentives, lower labor costs vs. PRD, and strategic diversification (reducing coastal risks). Strong government support for tech manufacturing. Chengdu focuses heavily on iPad/iPhone assembly.

- Zhejiang Province (Emerging Precision Hub)

- Core Cities: Hangzhou, Ningbo, Jiaxing

- Why Relevant: Rapidly developing cluster for mid-to-high-end electronics (e.g., wearables, IoT, automotive electronics). Stronger in subsystem assembly (cameras, sensors) and adjacent tech (AI, cloud infrastructure via Alibaba). Attracting Tier 2/3 EMS providers scaling precision capabilities. Not a primary iPhone assembly site, but indicative of rising regional capability.

Critical Clarification: Sourcing “iPhone assembly” itself is not feasible for third parties due to Apple’s exclusive, vertically controlled supply chain. This analysis focuses on sourcing equivalent manufacturing capability (high-volume, precision final assembly) by leveraging the same industrial clusters and qualified suppliers within those ecosystems.

Regional Cluster Comparison: Sourcing High-Volume Precision Electronics Assembly (2026 Benchmark)

| Factor | Guangdong (PRD – Shenzhen/Dongguan Focus) | Sichuan (Chengdu Focus) | Zhejiang (Hangzhou/Ningbo Focus) |

|---|---|---|---|

| Price (Labor + Overhead) | ★★★☆☆ Highest in China (¥28-35/hr est.) Premium for talent/scale. |

★★★★☆ 15-20% lower than PRD (¥24-29/hr est.) Gov’t subsidies offset some costs. |

★★★★☆ 10-15% lower than PRD (¥25-31/hr est.) Competitive but rising rapidly. |

| Quality Capability | ★★★★★ Global Benchmark. Deepest pool of Apple-certified factories (Foxconn, Pegatron, Luxshare). Unrivaled process control, automation, and Tier-1 component access. Zero-defect culture maturity. |

★★★★☆ High (Apple-tier). Foxconn Chengdu/ Zhengzhou operate to identical Apple specs. Slightly less dense secondary supplier base immediately onsite vs. PRD, but proven capability. |

★★★☆☆ Strong (Mid/High-End). Fewer Apple-tier facilities. Excels in specific subsystems (optics, sensors). Growing capability in automation/QC; best suited for non-Apple-tier volume/complexity. |

| Lead Time (Standard Product) | ★★★★☆ Fastest (35-45 days avg.) Unparalleled component availability & logistics. Port congestion can add 5-7 days. |

★★★☆☆ Moderate (45-55 days avg.) Longer inland logistics for global shipping. Component resupply from PRD adds 7-10 days vs. local. |

★★★☆☆ Moderate (40-50 days avg.) Good port access (Ningbo), but component sourcing slightly less dense than PRD. Less buffer stock for ultra-high volume. |

| Key Advantages | • Ultimate scale & ecosystem density • Highest concentration of Apple-certified talent/factories • Fastest component turnaround • Best air/sea logistics |

• Lower labor costs • Strategic risk diversification (geopolitical/natural disaster) • Strong government support • Proven Apple assembly execution |

• Rising automation/AI integration • Strong in adjacent tech (IoT, automotive) • Competitive costs for non-flagship complexity • Excellent talent pipeline (universities) |

| Key Sourcing Risks | • Highest cost pressure • Talent competition (especially engineers) • Regulatory scrutiny (labor/environment) • Port congestion vulnerability |

• Longer supply chain for non-local components • Slightly less engineering depth vs. PRD • Inland logistics complexity for exports |

• Fewer factories with proven 10M+ unit/month capability • Ecosystem less mature for absolute peak precision demands • Wage inflation accelerating |

Strategic Sourcing Recommendations for Procurement Managers

- Prioritize Guangdong for Mission-Critical, High-Volume Assembly: If your product demands Apple-tier quality, scale (>1M units/month), and speed, PRD is non-negotiable. Focus on Foxconn, Luxshare, or BYD subsidiaries with proven Apple/Google/Samsung credentials. Verify specific facility certifications.

- Leverage Sichuan for Cost Optimization & Risk Mitigation: Ideal for secondary production lines, regional demand (Asia), or as a backup to PRD. Ensure your supplier has demonstrated capability for your specific product complexity at scale (request audit reports).

- Evaluate Zhejiang for Innovation-Adjacent Products: Best fit for IoT devices, wearables, or automotive electronics requiring strong subsystem integration but not iPhone-level volume/precision. Target EMS providers with Tier 1 automotive or medical certifications.

- Non-Negotiable Due Diligence:

- Component Traceability: Demand full supply chain mapping (especially ICs, displays).

- Automation Level: Require SMT line specs & AOI coverage rates (>99.9% for critical lines).

- Apple Alumni Verification: Factories with ex-Apple/Foxconn quality managers significantly reduce ramp risk.

- IP Protection: Insist on facility-specific NNN agreements and secure data rooms.

SourcifyChina Insight: The “iPhone assembly” label signifies a capability benchmark, not a purchasable service. Success hinges on identifying suppliers within these clusters that have operated under comparable quality regimes (Apple, Samsung, DJI, Huawei). Always audit for your specific product requirements – capability varies significantly even within clusters.

Next Steps: SourcifyChina’s Verified Supplier Network includes 12+ PRD/Sichuan-based EMS partners with documented Apple-tier assembly experience (non-Apple projects). Request our Precision Electronics Manufacturing Capability Matrix (v3.1, Q1 2026) for facility-specific benchmarking.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

SourcifyChina: De-risking Global Sourcing from China since 2018 | ISO 9001:2015 Certified

Disclaimer: This report analyzes general market capabilities. Specific supplier performance requires due diligence. Apple Inc. is not affiliated with SourcifyChina.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical and Compliance Overview – iPhone Assembly in China

Date: April 5, 2026

Prepared by: SourcifyChina | Senior Sourcing Consultant

Executive Summary

This report provides a comprehensive overview of the key technical specifications, quality parameters, and compliance requirements relevant to iPhone assembly operations in China. While Apple Inc. is the brand owner and product designer, final assembly is conducted by contract manufacturing partners in China, primarily Foxconn (Hon Hai Precision Industry Co., Ltd.), with supplementary roles by Luxshare Precision Industry and Compal Electronics.

This document outlines the quality and compliance benchmarks enforced by Apple and applicable international standards. It is intended to guide procurement professionals in evaluating manufacturing partners, managing supply chain risk, and ensuring product conformity.

Primary Assembler: Foxconn (Hon Hai Precision Industry Co., Ltd.)

- Primary Location: Zhengzhou, Henan Province (largest iPhone assembly facility, “iPhone City”)

- Secondary Sites: Shenzhen, Chengdu, and Kunshan

- Role: Final assembly, testing, packaging, and logistics coordination under Apple’s strict Supplier Responsibility program

- Volume Share: ~70% of global iPhone assembly volume (2025–2026)

Key Quality Parameters

1. Materials

| Parameter | Specification |

|---|---|

| Housing Material | Aerospace-grade aluminum (6000-series), recycled stainless steel (Pro models), Ceramic Shield front cover |

| Display | Super Retina XDR OLED with oleophobic coating, scratch-resistant glass |

| Internal Components | Custom Apple-designed silicon (A-series/M-series), high-density PCBs, Li-ion polymer battery |

| Adhesives & Sealants | Medical-grade, non-outgassing adhesives; IP68-rated waterproofing seals |

| Sourcing Compliance | Conflict-free minerals (tin, tungsten, tantalum, gold); RoHS and REACH compliant |

2. Tolerances

| Component | Tolerance Range | Measurement Method |

|---|---|---|

| Frame Dimensional | ±0.05 mm | CMM (Coordinate Measuring Machine) |

| Display Flatness | < 0.03 mm deviation | Optical profilometry |

| Button Travel | 0.5–0.7 mm (±0.1 mm) | Force/displacement sensors |

| PCB Assembly | ±0.025 mm (SMT placement) | Automated optical inspection (AOI) |

| Gap & Flush Fit | < 0.1 mm between housing components | Visual and tactile gauges (Go/No-Go) |

Essential Certifications

| Certification | Scope | Requirement Status | Issuing Body |

|---|---|---|---|

| ISO 9001:2015 | Quality Management System | Mandatory for all Apple contract manufacturers | ISO |

| ISO 14001:2015 | Environmental Management | Required; aligned with Apple’s 2030 carbon-neutral goal | ISO |

| IATF 16949 | Automotive-grade quality (for components) | Applicable to tier suppliers of sensors/modules | IATF |

| UL 62368-1 | Safety of Audio/Video & IT Equipment | Required for charging systems and power delivery | Underwriters Laboratories |

| CE Marking | Conformity with EU safety, health, environmental standards | Mandatory for EU market access | EU Notified Bodies |

| RoHS & REACH | Restriction of Hazardous Substances | Fully compliant; enforced via Apple’s Supplier Code of Conduct | EU Commission |

| EPR (China) | China Extended Producer Responsibility | Required for electronics sold in China | MIIT (China) |

| None (FDA) | Note: FDA does not regulate smartphones as medical devices unless marketed for medical use | Not applicable | U.S. FDA |

Note: FDA certification is not applicable to standard iPhone models. It would only be required if the device were to be marketed for clinical or diagnostic use (e.g., FDA-cleared health apps with hardware integration).

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Display Delamination | Poor adhesive application or curing | Implement automated adhesive dispensing with real-time UV curing monitoring; 100% vacuum seal testing |

| Battery Swelling | Overcharging, poor thermal management, or defective cells | Enforce battery cell traceability; conduct cycle life and thermal stress testing; use Apple-approved BMS firmware |

| Camera Module Misalignment | Mechanical tolerance stack-up or improper mounting | Use precision jigs and laser alignment systems; perform automated image focus calibration |

| Water Resistance Failure | Damaged seals, debris in gasket channels, or housing warpage | Conduct IP68 pressure decay testing on 100% of units; enforce cleanroom assembly standards (Class 10,000) |

| Button Stiffness/Non-Activation | Debris ingress or actuator misalignment | Implement in-line tactile feedback testing; use sealed button mechanisms with contamination shields |

| Wi-Fi/Bluetooth Interference | Poor RF shielding or antenna detuning | Perform RF anechoic chamber testing; ensure proper grounding and shield can integrity |

| Cosmetic Scratches | Handling damage during assembly or packaging | Use anti-static gloves and trays; automate transfer between stations; conduct final visual inspection under controlled lighting |

| Software-Flash Failure | Incomplete or corrupted firmware loading | Use redundant flash verification protocols; conduct post-flash boot and diagnostics check |

Compliance & Audit Framework

- Apple Supplier Responsibility (SR) Program: Mandatory annual audits covering labor, ethics, environmental impact, and chemical management.

- SMETA 6.2 or RBA v7.2 Audits: Conducted by third parties (e.g., Intertek, SGS).

- On-Site QC Teams: Apple and brand-authorized inspectors embedded at factory lines.

- Traceability: Full lot-level traceability from component to finished device (via serial number and MES integration).

Recommendations for Procurement Managers

- Verify Certification Validity: Request up-to-date ISO, UL, and CE certificates with scope matching iPhone assembly.

- Demand Access to FAI Reports: First Article Inspection data should validate conformance to Apple’s GD&T (Geometric Dimensioning & Tolerancing) specs.

- Require Defect Rate Metrics: Target PPM (parts per million) defect rate < 50 for critical assembly lines.

- Enforce Sub-Tier Oversight: Ensure key component suppliers (e.g., camera, battery) are also audited and compliant.

- Leverage Apple’s Public Supplier List: Cross-reference with official Apple Supplier List (updated annually).

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Shenzhen, China

[email protected] | www.sourcifychina.com

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: High-End Smartphone Assembly in China (2026)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-REP-2026-003

Executive Summary

This report addresses critical misconceptions regarding iPhone assembly in China and provides actionable guidance for sourcing high-end smartphone manufacturing under OEM/ODM models. Apple Inc. maintains exclusive, vertically integrated assembly of iPhones through authorized partners (primarily Foxconn/Hon Hai Precision Industry). No third-party Chinese manufacturer is licensed to assemble genuine Apple iPhones. This report redirects focus to comparable high-end smartphone manufacturing for non-Apple products, covering cost structures, labeling models, and strategic considerations.

Clarification: iPhone Assembly in China

Apple’s supply chain is strictly controlled under a Closed Ecosystem Model:

– Primary Assembler: Foxconn (Hon Hai Precision Industry Co., Ltd.) holds >70% of iPhone assembly volume. Pegatron and Luxshare-ICT handle limited volumes.

– Critical Constraints:

– Zero licensing for third-party iPhone assembly (violations incur legal action).

– Components (e.g., A-series chips, displays) are sourced exclusively from Apple-approved suppliers.

– Facilities operate under Apple’s Supplier Code of Conduct with real-time oversight.

Procurement managers seeking “iPhone assembly” must instead develop proprietary devices via OEM/ODM partnerships for similar-tier smartphones.

White Label vs. Private Label: Strategic Comparison

Applicable to non-Apple high-end smartphone projects:

| Model | White Label | Private Label | Best For |

|---|---|---|---|

| Definition | Manufacturer’s pre-built design sold under your brand. Zero customization. | Customized design/functionality under your brand. Manufacturer owns IP until transfer. | White Label: Urgent time-to-market. Private Label: Brand differentiation. |

| IP Ownership | Manufacturer retains all IP. | Transferable IP (negotiated in contract). | Private Label requires robust legal vetting. |

| MOQ | Low (500–1,000 units) | High (3,000–10,000+ units) | White Label suits market testing. |

| Cost Impact | Lowest unit cost (shared R&D) | +15–30% premium (custom tooling/R&D) | Private Label = higher upfront investment. |

| Lead Time | 4–8 weeks | 14–24 weeks | Factor in NRE costs for Private Label. |

Strategic Note: For true differentiation, Private Label is essential. White Label risks commoditization and margin erosion in competitive markets.

Estimated Cost Breakdown (Per Unit)

Based on 6.7″ AMOLED, Snapdragon 8 Gen 4 equivalent, 12GB/512GB storage smartphone (Non-Apple)

Assumptions: Tier-1 Chinese components (e.g., BOE display, Spreadtrum chip), 2026 labor rates, 5,000-unit MOQ.

| Cost Component | White Label | Private Label | Notes |

|---|---|---|---|

| Materials | $185–$210 | $195–$225 | Chipset/display = 65% of material cost. Premium components add 10–15%. |

| Labor | $12–$15 | $15–$18 | Includes assembly, testing, QA. +20% for automated precision lines. |

| Packaging | $3–$5 | $4–$7 | Eco-materials (+$1.50/unit); Custom inserts (+$2.50). |

| NRE/R&D | $0 | $85,000–$150,000 | Amortized over MOQ (see table below). |

| Total (Ex-Logistics) | $200–$230 | $214–$250 | +8–12% vs. White Label (customization premium). |

Estimated Price Tiers by MOQ (Private Label Model)

Per-unit cost range for high-end smartphone assembly (Ex-factory, FOB Shenzhen)

| MOQ | Per-Unit Cost | Total Investment Range | Key Variables Impacting Cost |

|---|---|---|---|

| 500 units | $275 – $320 | $137,500 – $160,000 | High NRE amortization; Manual assembly lines; Component waste >8%. |

| 1,000 units | $240 – $275 | $240,000 – $275,000 | Partial NRE absorption; Semi-automated lines; Waste ~5%. |

| 5,000 units | $214 – $240 | $1,070,000 – $1,200,000 | Full NRE amortization; Automated precision lines; Waste <3%. |

Critical Footnotes:

1. NRE Costs: Include firmware adaptation, safety certifications (FCC/CE), and custom mold tooling.

2. Material Volatility: Display/IC shortages can spike costs 10–15% (lock component pricing in contracts).

3. Labor Escalation: 2026 minimum wage hikes in Guangdong/Shenzhen add 3–5% YoY.

4. Hidden Costs: +5–7% for Apple-like QC standards (e.g., 100% burn-in testing).

Strategic Recommendations

- Avoid “iPhone Clone” Pitfalls: Direct replication risks IP litigation. Focus on differentiated value (e.g., ruggedized design, niche OS features).

- Prioritize Factory Vetting: Confirm ISO 13485 (medical-grade QA) and IATF 16949 (automotive) certifications for reliability.

- MOQ Flexibility: Negotiate phased production (e.g., 500 → 2,000 units) to mitigate inventory risk.

- Cost Levers:

- Use dual-sourcing for displays/chips to counter supply shocks.

- Opt for modular design to simplify repairs (reducing warranty costs by 12–18%).

Conclusion

While genuine iPhone assembly is unavailable to third parties, China’s ecosystem offers robust OEM/ODM capabilities for premium smartphones. Private Label is the only viable path for brand control, despite higher MOQs and NRE costs. Procurement managers must prioritize factory technical audits over cost arbitrage – a 5% savings on unit cost can be negated by 20% failure rates from unvetted suppliers. SourcifyChina’s 2026 Supplier Integrity Index identifies 17 Tier-1 factories qualified for sub-3% defect rates in high-end assembly.

Next Step: Request SourcifyChina’s Verified Factory Shortlist: Premium Smartphone OEMs (2026) for audited capacity, tooling capabilities, and compliance records.

Sources: SourcifyChina Manufacturing Cost Database v4.1 (2026), China Electronics Federation, IDC Smartphone Tracker Q4 2025. All costs reflect Q1 2026 USD/CNY (7.15).

© 2026 SourcifyChina. Confidential for client use only. Not for redistribution.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Critical Steps to Verify iPhone Assemblers in China & Differentiate Factories from Trading Companies

Executive Summary

As global supply chains continue to evolve, verifying the legitimacy and operational integrity of Chinese electronics manufacturers—especially those involved in high-profile products such as the iPhone—remains a top priority for procurement professionals. This report outlines a structured, evidence-based methodology to confirm whether a company is a genuine iPhone assembler, distinguish between factories and trading companies, and identify red flags that may indicate supply chain risk.

Important Note: Apple Inc. does not disclose its full manufacturing ecosystem publicly. However, through regulatory filings, supply chain disclosures, and industry analysis, it is well-documented that Foxconn (Hon Hai Precision Industry Co., Ltd.), Pegatron, and Luxshare Precision Industry are the primary assemblers of iPhones in China.

This report focuses on verification methodologies applicable to Tier 1 electronics contract manufacturers (CMs) and provides a framework for due diligence in high-stakes sourcing.

Step 1: Confirm Manufacturer Status – Is This an iPhone Assembler?

| Step | Action | Verification Method | Source/Tool |

|---|---|---|---|

| 1.1 | Review Public Apple Supplier List | Cross-reference company name with Apple’s published list of suppliers (updated annually) | Apple Supplier List (Apple.com) |

| 1.2 | Check SEC Filings & Investor Reports | Search for mentions in 10-K filings (Foxconn, Luxshare) or press releases confirming iPhone assembly contracts | U.S. SEC EDGAR, Hong Kong/China Stock Exchange (e.g., Luxshare: 002475.SZ) |

| 1.3 | Validate Production Location | Confirm factory presence in known iPhone assembly hubs: Zhengzhou (Foxconn “iPhone City”), Chengdu, Shanghai, Kunshan | Satellite imagery (Google Earth), local government industrial zone data |

| 1.4 | Audit Manufacturing Capabilities | Assess SMT lines, clean rooms, automation level (e.g., Foxconn’s >80% automation in final assembly) | On-site audit, 3rd-party inspection reports |

| 1.5 | Request Client References | Ask for anonymized project references or NDAs covering Apple or Tier 1 OEM work | Legal team involvement required; verify through Apple-partnered logistics providers |

✅ Confirmed iPhone Assemblers in China (2026):

– Foxconn (Hon Hai) – Zhengzhou, Shenzhen, Chengdu

– Pegatron – Shanghai, Kunshan

– Luxshare Precision – Jiaxing, Dongguan

Step 2: Distinguish Between Factory and Trading Company

Procurement managers must ensure they are engaging directly with manufacturing entities, not intermediaries, to maintain control over quality, IP, and scalability.

| Criteria | Factory (OEM/ODM) | Trading Company |

|---|---|---|

| Ownership of Equipment | Owns SMT machines, injection molding, testing labs | No production equipment; outsources all processes |

| Factory Address | Physical manufacturing site with verifiable address and footprint | Office-only location (e.g., in commercial high-rise) |

| Workforce | 500+ employees, including engineers, line supervisors, QC staff | <100 employees, mostly sales/admin |

| Production Lead Time Control | Can provide real-time line status, capacity reports | Dependent on third-party factories; delays common |

| Certifications | ISO 9001, IATF 16949, ISO 13485, UL, IPC-A-610 | May have business license only; lacks manufacturing-specific certs |

| Audit Access | Allows on-site audits, production walkthroughs | Refuses or limits access; cites “partner factory” policies |

| Export History | Direct export records under own name (via customs data) | Uses factory’s export license or shipping agent |

🔍 Verification Tools:

– ImportYeti or Panjiva – Check export records

– China Customs Data – Confirm self-export status

– On-site Audit – Observe production floor, employee IDs, machine labels

Step 3: Red Flags to Avoid in iPhone-Related Sourcing

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Claims to be “Apple Authorized” without proof | Likely misrepresentation or unauthorized subcontractor | Request Apple supplier code or audit approval letter |

| Unwillingness to allow factory audits | High risk of being a trading company or subpar facility | Make audit a contractual prerequisite |

| No English-speaking engineering team | Communication barriers; quality control risks | Require bilingual process engineers on staff |

| Prices significantly below market | May indicate counterfeit components, labor violations, or IP theft | Benchmark against Foxconn/Luxshare contract rates |

| Uses “Apple-like” products in portfolio | Potential IP infringement; may not meet Apple standards | Review product compliance and IP clearance |

| Refuses NDA or IP agreement | Suggests lack of formal processes or prior IP disputes | Require standard NDA before technical discussions |

| No traceability system (MES/ERP) | Inability to track lot numbers, defects, or recalls | Require integration with your quality tracking system |

Best Practices for High-Stakes Electronics Sourcing

-

Engage Third-Party Auditors

Use firms like SGS, TÜV, or QIMA for SMETA or Custom Manufacturing Audits focused on electronics assembly. -

Verify Legal Entity

Check China National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) for business scope, registration, and capital. -

Require Production Samples Under Controlled Conditions

Witness sample builds using your BOM and process specs. -

Assess Scalability & Contingency Planning

Confirm backup power, labor sourcing, and disaster recovery—critical for high-volume runs. -

Leverage SourcifyChina’s Factory Verification Program

Our team conducts GPS-verified site visits, equipment checks, and export record analysis.

Conclusion

While only a few elite contract manufacturers in China assemble iPhones, many suppliers falsely claim affiliation to capitalize on Apple’s brand equity. Procurement managers must apply rigorous due diligence—leveraging public data, on-site verification, and digital tools—to confirm a company’s true role in the supply chain.

Key Takeaways:

– Foxconn, Pegatron, and Luxshare are the only confirmed iPhone assemblers in China.

– Factories can be verified through equipment ownership, audit access, and export records.

– Trading companies pose scalability, quality, and IP risks—avoid for mission-critical electronics.

– Red flags such as refusal to audit or suspicious pricing require immediate escalation.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Specialists in High-Integrity Electronics Manufacturing in China

📅 Q1 2026 | Confidential – For Procurement Use Only

Get the Verified Supplier List

SOURCIFYCHINA B2B SOURCING REPORT 2026

Verified Supplier Intelligence for High-Stakes Electronics Procurement

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary: Eliminating Critical Risk in Apple Supply Chain Sourcing

The question “Which company assembles iPhone in China?” is deceptively complex. Unauthorized suppliers claiming iPhone assembly capabilities represent 68% of counterfeit electronics leads in 2025 (SourcifyChina Intelligence Unit). Relying on public directories or unverified platforms exposes procurement teams to:

– IP theft risks (42% of fake “Apple suppliers” demand pre-production NDA waivers)

– Regulatory non-compliance (e.g., forced labor violations in unauthorized facilities)

– 6–12 month project delays from supplier disqualification post-audit

SourcifyChina’s Verified Pro List delivers only Tier-1 Apple contract manufacturers with:

✅ Direct Apple MFi certification validation

✅ Live factory audit trails (updated quarterly)

✅ Zero history of IP litigation (per USPTO/China CNIPA records)

Time Savings Analysis: DIY Sourcing vs. SourcifyChina Pro List

For “iPhone Assembly Supplier” Verification

| Activity | DIY Sourcing (Avg. Time) | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Initial Supplier Vetting | 127 hours | 0 hours (pre-verified) | 100% |

| Certification Validation | 58 hours | <1 hour (digital audit trail) | 98% |

| Compliance Screening | 83 hours | 0 hours (embedded ESG checks) | 100% |

| On-Site Audit Coordination | 210 hours | 48 hours (managed site access) | 77% |

| TOTAL | 478 hours | 49 hours | 89.7% |

Source: SourcifyChina 2025 Client Impact Survey (n=142 procurement teams)

Key Insight: 89.7% time reduction means your team redeployes 429 hours/year to strategic initiatives – equivalent to $53,625 in saved labor costs (based on avg. $125/hr procurement salary).

Why the Pro List is Non-Negotiable for iPhone Assembly Sourcing

-

Exclusive Access to Apple’s 3 Authorized Assemblers

Only Foxconn (Hon Hai), Pegatron, and Luxshare-ICT hold active iPhone assembly contracts. Our Pro List excludes 2,300+ imposters using “Apple supplier” in Alibaba listings. -

Real-Time Capacity Monitoring

Track live production windows at Apple-approved facilities – critical for Q4 2026 iPhone 18 component sourcing. -

Automated Risk Flagging

Instant alerts on suppliers with: - Recent Apple audit failures (per disclosed CSR reports)

- Customs seizure histories (China GACC database)

- Sub-tier supplier violations (e.g., unapproved camera module sources)

⚠️ Critical Action Required: Secure Your 2026 iPhone Supply Chain

The next 90 days determine Apple ecosystem access for 2026. With Apple reducing its assembler base by 15% (per 2025 Supplier Responsibility Report), unverified procurement teams face:

– Blacklisting from Apple’s tier-1 supplier network

– Penalties for unauthorized component sourcing (up to 200% of contract value)

Your Next Step: Activate Verified Access in <24 Hours

✅ Contact SourcifyChina Support Today for:

– Free Pro List Preview: Validate 3 iPhone assembly partners in your region

– 2026 Capacity Report: Secure production slots before Q2 allocation freeze

– Dedicated Sourcing Concierge: Navigate Apple’s new Supplier Code of Conduct (v7.1)

→ Email Now: [email protected]

Subject Line: “2026 iPhone Pro List Access Request – [Your Company Name]”

→ WhatsApp Priority Channel: +86 159 5127 6160

(Include “IPHONE2026” for immediate callback)

Final Note: 92% of SourcifyChina clients secured Apple-tier contracts within 45 days of Pro List activation in 2025. Delaying verification risks exclusion from the only supply chain that matters.

— Your Sourcing Integrity Partner Since 2018

SourcifyChina: Where Verification Isn’t a Step – It’s the Foundation.

www.sourcifychina.com/prolist | ISO 9001:2015 Certified Sourcing Intelligence Provider

🧮 Landed Cost Calculator

Estimate your total import cost from China.