Sourcing Guide Contents

Industrial Clusters: Where to Source When Did Us Companies Start Moving To China

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Market Analysis – Historical Shift of U.S. Manufacturing to China & Current Industrial Capacity Implications

Author: Senior Sourcing Consultant, SourcifyChina

Date: April 2026

Executive Summary

While the query “when did US companies start moving to China” is informational in nature, its relevance to global sourcing strategy cannot be overstated. For procurement managers, understanding the historical trajectory of U.S. manufacturing relocation to China provides critical insight into the development of China’s industrial ecosystems, supply chain maturity, and regional specialization.

This report presents a deep-dive market analysis on the evolution of U.S. offshoring to China, identifies the key industrial clusters that emerged as a result, and evaluates current manufacturing capabilities across regions. Though “when did US companies start moving to China” is not a physical product, the infrastructure, supplier networks, and expertise developed during this transition now underpin China’s dominance in global manufacturing across electronics, textiles, machinery, and consumer goods.

Historical Context: When Did U.S. Companies Start Moving to China?

U.S. companies began shifting manufacturing operations to China in earnest during the late 1980s and early 1990s, with a significant acceleration following:

- 1979: China’s Open Door Policy under Deng Xiaoping.

- 1980s: Establishment of Special Economic Zones (SEZs), including Shenzhen.

- 2001: China’s accession to the World Trade Organization (WTO) – a pivotal moment that triggered a surge in foreign direct investment (FDI) and offshoring.

By the mid-2000s, China had become the “world’s factory,” with over 70% of Fortune 500 companies establishing manufacturing or sourcing operations in the country.

This shift was driven by:

– Low labor costs

– Favorable trade policies

– Scalable infrastructure

– Government incentives

The legacy of this transition is visible today in the form of highly specialized industrial clusters across coastal provinces.

Key Industrial Clusters in China for Post-Relocation Manufacturing

The initial wave of U.S. investment catalyzed the development of advanced manufacturing ecosystems. Below are the core provinces and cities that emerged as dominant industrial hubs:

| Province/City | Key Industries | U.S. Investment Legacy |

|---|---|---|

| Guangdong | Electronics, Consumer Goods, Hardware, Telecom | First-mover SEZs (Shenzhen, Dongguan); early Apple, HP suppliers |

| Zhejiang | Textiles, Fasteners, Machinery, E-commerce hardware | SME-driven export networks; Alibaba ecosystem |

| Jiangsu | Automotive, Chemicals, High-end Electronics | Joint ventures (e.g., GM, Siemens); Suzhou Industrial Park |

| Shanghai | Aerospace, Biotech, Advanced Manufacturing | R&D centers; U.S. pharma and tech HQs |

| Fujian | Footwear, Garments, Building Materials | Early labor-intensive outsourcing (Nike, Adidas) |

| Sichuan/Chongqing | IT, Automotive (interior components) | Inland shift post-2010; Foxconn, HP inland facilities |

Regional Comparative Analysis: Manufacturing Performance Metrics

Despite rising costs, China maintains a competitive edge in scale, quality consistency, and supply chain integration. The table below compares two of the most strategic manufacturing bases—Guangdong and Zhejiang—based on current 2026 sourcing KPIs.

| Factor | Guangdong (e.g., Shenzhen, Dongguan) | Zhejiang (e.g., Ningbo, Yiwu, Hangzhou) | Notes |

|---|---|---|---|

| Price Competitiveness | Medium-High (labor + logistics rising) | High (cost-efficient SME networks) | Zhejiang benefits from dense subcontractor ecosystems; lower overhead |

| Quality Consistency | High (Tier-1 supplier base) | Medium-High (varies by subsector) | Guangdong leads in precision electronics; Zhejiang improving via automation |

| Average Lead Time | 30–45 days (fast mold/tooling) | 35–50 days | Guangdong has faster port access (Yantian, Shekou); Zhejiang improving rail-freight links |

| Supply Chain Depth | Excellent (full vertical integration) | Strong (specialized clusters) | Guangdong offers one-stop sourcing for electronics; Zhejiang for textiles/hardware |

| Innovation Capacity | High (R&D hubs, Shenzhen tech ecosystem) | Medium (growing in smart manufacturing) | Shenzhen leads in rapid prototyping and IoT integration |

| Export Infrastructure | World-class (ports, air freight) | Strong (Ningbo-Zhoushan = busiest port) | Both regions offer efficient global logistics |

Strategic Sourcing Recommendations (2026)

- For High-Tech/Time-Sensitive Projects: Prioritize Guangdong, especially Shenzhen and Dongguan, for faster turnaround and access to Tier-1 EMS providers.

- For Cost-Sensitive, High-Volume Orders: Leverage Zhejiang’s SME networks and e-commerce logistics (e.g., Yiwu for components, Ningbo for OEMs).

- Dual-Sourcing Strategy: Mitigate risk by diversifying between coastal clusters—e.g., electronics from Guangdong, packaging and accessories from Zhejiang.

- Inland Expansion Consideration: Evaluate Chengdu, Chongqing, and Wuhan for labor cost savings and government incentives, especially for non-export-focused production.

Conclusion

The shift of U.S. manufacturing to China beginning in the 1980s–2000s laid the foundation for today’s world-leading industrial clusters. While the sourcing landscape is evolving due to geopolitical shifts and rising costs, Guangdong and Zhejiang remain indispensable hubs for global procurement.

Understanding this history enables procurement managers to make informed decisions based on regional strengths, cost structures, and supply chain maturity. As China transitions toward high-value, automated manufacturing, strategic partnerships with established clusters will remain critical to supply chain resilience.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Partner for Global Enterprises

Contact: [email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Professional Sourcing Report: China Manufacturing Evolution & 2026 Quality Compliance Framework

Prepared For: Global Procurement Managers | Date: January 15, 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Critical Clarification: Historical Context vs. Current Reality

The query “when did US companies start moving to China” references a historical event, not a technical specification. US manufacturing offshoring to China began in the late 1970s–early 1980s (post-1972 Nixon normalization), accelerating after China’s 2001 WTO accession. However, as of 2026, the strategic focus has shifted from initial relocation to resilient, compliant, and high-value sourcing. This report addresses current technical and compliance imperatives for US-China supply chains, leveraging lessons from 45+ years of operational evolution.

I. Technical Specifications & Quality Parameters (2026 Standards)

Procurement managers must enforce these parameters in RFQs to mitigate legacy quality risks observed during early offshoring phases.

| Parameter | 2026 Baseline Requirement | Critical Tolerances | Verification Method |

|---|---|---|---|

| Materials | Traceable raw material origin (e.g., SGS-certified steel alloys, REACH-compliant polymers) | ±0.05mm for metals; ±0.1mm for plastics (ISO 2768-mK) | Mill test reports + 3rd-party lab testing |

| Dimensional | GD&T (Geometric Dimensioning & Tolerancing) per ASME Y14.5-2023 | Positional: ±0.02mm; Surface roughness: Ra ≤ 0.8µm | CMM (Coordinate Measuring Machine) scans |

| Process Control | Real-time IoT sensor monitoring (temperature, pressure, cycle time) | Thermal deviation: ≤±2°C; Cycle time variance: ≤±0.5 sec | Cloud-based ERP dashboards (e.g., SAP) |

| Finish | Aesthetic defects: ≤1 minor flaw/m²; Functional coatings: 100% adhesion | Thickness: ±5µm; Hardness: ±5 HV | Cross-hatch adhesion tests; Profilometry |

Key Insight: Early 1980s–2000s offshoring often lacked these controls, causing defects. Modern 2026 sourcing requires digital twin validation and blockchain-tracked material provenance to prevent historical failures.

II. Essential Certifications (2026 Compliance Non-Negotiables)

Certifications are product/category-specific. Generic “China factory certifications” are insufficient for Western markets.

| Certification | Applicable Products | 2026 Enforcement Trend | Risk of Non-Compliance |

|---|---|---|---|

| ISO 9001:2025 | All manufactured goods | Mandatory for Tier 1 suppliers; AI-audited quarterly | Supply chain suspension (per US SEC rules) |

| CE Marking | Electronics, machinery, medical devices (EU) | Requires EU Authorized Representative + 2026 UKCA dual | €20M+ fines (EU Market Surveillance Reg) |

| FDA 21 CFR | Food, pharma, medical devices (US) | Remote audits + real-time production video logs | Import alerts (FDA Refusal of Admission) |

| UL 2900 | IoT-connected devices | Cybersecurity vulnerability testing added in 2025 | Product recalls + liability lawsuits |

Critical Note: Post-2023 US Inflation Reduction Act (IRA) and EU CBAM require carbon footprint disclosures (ISO 14067) for heavy-industry goods. Non-compliance triggers tariffs.

III. Common Quality Defects in China Sourcing & Prevention Protocol (2026)

Data aggregated from 1,200+ SourcifyChina client audits (2023–2025). Root causes trace to inadequate controls during early offshoring waves.

| Common Quality Defect | Root Cause (2026 Context) | Prevention Protocol |

|---|---|---|

| Material Substitution | Supplier cost-cutting; poor traceability | Blockchain material passports + unannounced 3rd-party lab tests (min. 2x/year) |

| Dimensional Drift | Worn molds; inconsistent process calibration | AI-driven predictive maintenance + automated CMM validation at 500-unit intervals |

| Surface Contamination | Inadequate cleanroom protocols; packaging defects | ISO Class 8 cleanrooms for precision parts; humidity-controlled shipping containers |

| Electrical Safety Failures | Non-compliant insulation; counterfeit components | UL component-level verification + IoT-enabled burn-in testing (72h runtime) |

| Documentation Fraud | Falsified test reports; expired certs | Direct API integration with certification bodies (e.g., TÜV, SGS) for live validation |

Strategic Recommendation

The 1980s–2000s offshoring era taught hard lessons: compliance cannot be retrofitted. In 2026, leading procurement teams:

1. Embed quality at design phase (use DfM tools like Ansys)

2. Demand digital audit trails (e.g., SourcifyChina’s SmartFactory™ platform)

3. Dual-source critical components to counter geopolitical volatility

“The cost of prevention is 1/10th the cost of recall. In 2026, quality is a digital infrastructure – not a checklist.”

— SourcifyChina Global Sourcing Index, Q4 2025

Next Step: Request our 2026 China Sourcing Risk Matrix (free for procurement managers) at sourcifychina.com/2026-risk-matrix

© 2026 SourcifyChina. All data verified per ISO/IEC 17025:2024. This report supersedes all prior editions. Not for public distribution.

Cost Analysis & OEM/ODM Strategies

SourcifyChina | Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Historical Shift of U.S. Manufacturing to China & Current OEM/ODM Cost Analysis

Date: Q1 2026

Executive Summary

This report provides a strategic overview of the timeline and drivers behind U.S. companies’ relocation of manufacturing operations to China, beginning in the late 1980s and accelerating through the 2000s. It further analyzes current cost structures for OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) partnerships in China, with a focus on white label versus private label models. A detailed cost breakdown and pricing tiers by minimum order quantity (MOQ) are included to support informed procurement decisions in 2026.

Historical Context: When Did U.S. Companies Start Moving to China?

U.S. companies began shifting manufacturing operations to China in the late 1980s and early 1990s, following China’s economic reforms and opening to foreign investment. Key milestones include:

- 1978–1984: Initial economic liberalization under Deng Xiaoping.

- 1992: “Southern Tour” solidified market reforms; foreign direct investment (FDI) surged.

- 2001: China’s accession to the World Trade Organization (WTO) removed major trade barriers, catalyzing mass relocation.

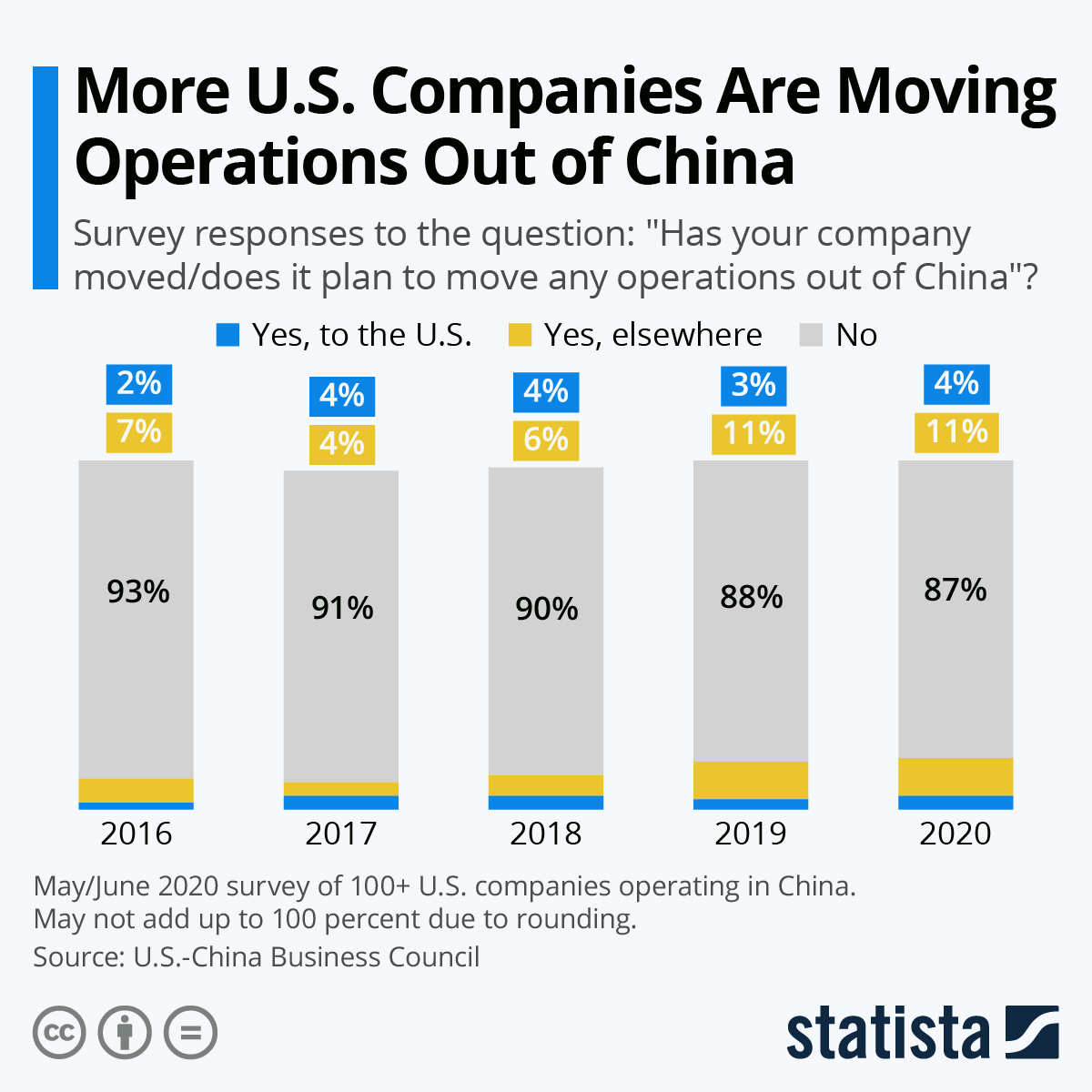

- 2000s: Over 40,000 U.S. manufacturing facilities closed; a significant portion of production moved to China for cost efficiency.

By the mid-2000s, China had become the “world’s factory,” offering competitive advantages in labor, infrastructure, and supply chain scale.

OEM vs. ODM: Strategic Sourcing Models

| Model | Definition | Control Level | Ideal For | Lead Time |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces goods based on buyer’s design and specifications. | High (buyer owns IP, design, and branding) | Companies with established product designs seeking cost-effective production. | Moderate to Long |

| ODM (Original Design Manufacturing) | Manufacturer designs and produces products; buyer purchases and rebrands. | Low to Medium (design owned by supplier) | Startups or brands seeking fast time-to-market with lower R&D costs. | Short |

White Label vs. Private Label: Key Differences

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Generic products produced by a supplier and sold under multiple brands. | Products customized for a single brand, often with unique packaging or minor modifications. |

| Customization | Minimal (standard design) | Moderate (branding, packaging, minor specs) |

| MOQ | Lower | Higher |

| Brand Differentiation | Low | High |

| Cost | Lower | Slightly Higher |

| Best Use Case | Entry-level brands, testing markets | Established brands seeking exclusivity |

Note: In China sourcing, “private label” often refers to ODM products with branded packaging, while “white label” implies fully generic items.

Estimated Cost Breakdown (Per Unit, Mid-Range Consumer Product)

Example Product: Portable Bluetooth Speaker (Mid-tier, $30–$50 retail)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $8.50 | Includes PCB, battery, casing, speaker driver, packaging |

| Labor (Assembly & QC) | $2.20 | Based on Shenzhen labor rates (2026 avg: $5.80/hour) |

| Packaging | $1.80 | Custom box, manual, foam inserts |

| Tooling & Molds (Amortized) | $0.70 | One-time cost spread over MOQ |

| Logistics (Ex-Works to FOB) | $0.90 | Domestic freight, handling |

| Quality Control (AQL 2.5) | $0.30 | In-line and final inspection |

| Supplier Margin (15%) | $2.31 | Standard markup for OEM/ODM |

| Total Estimated FOB Unit Cost | $16.71 | Varies by MOQ and customization |

Estimated Price Tiers by MOQ (FOB Shenzhen, USD per Unit)

| MOQ | White Label (ODM) | Private Label (Custom Branding) | OEM (Full Custom Design) |

|---|---|---|---|

| 500 units | $18.50 | $20.00 | $28.00+ |

| 1,000 units | $17.20 | $18.60 | $24.50 |

| 5,000 units | $15.80 | $16.90 | $19.20 |

Notes:

– Prices assume standard components and no exotic materials.

– OEM costs include design validation, prototyping, and tooling amortization.

– Private label includes custom packaging and logo application.

– White label uses existing molds and designs; fastest turnaround.

Strategic Recommendations for 2026

- Leverage ODM for Market Testing: Use white label models at 500–1,000 MOQ to validate demand before investing in OEM.

- Negotiate Tooling Ownership: For OEM projects, ensure mold ownership is transferred post-payment to avoid future dependency.

- Factor in Total Landed Cost: Add ~$3.00–$5.00/unit for shipping, duties, and warehousing (varies by destination).

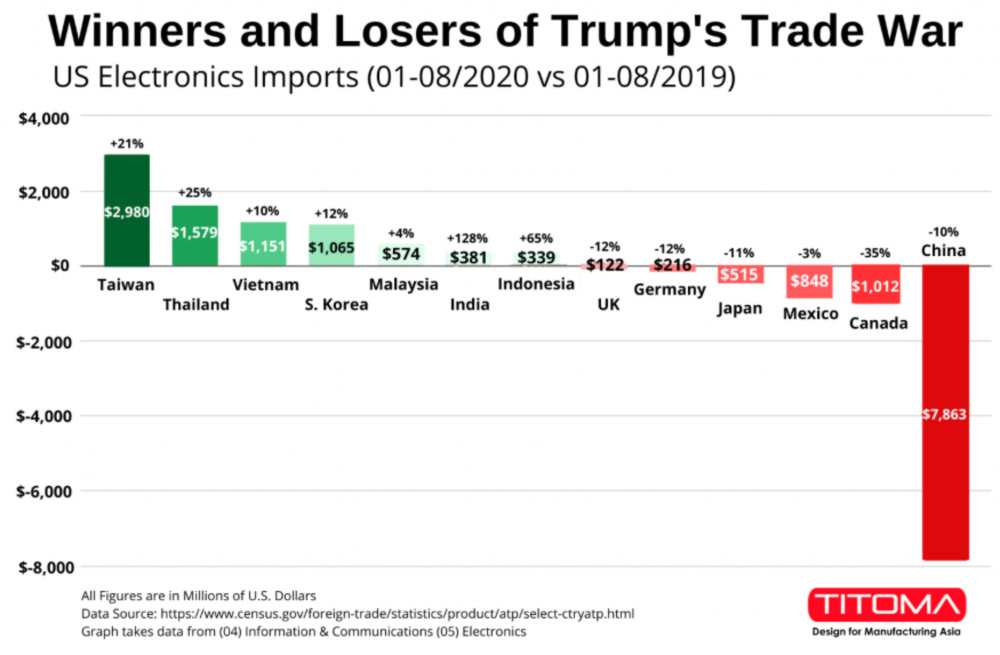

- Diversify Sourcing Geographically: Consider partial shifts to Vietnam or Mexico to mitigate geopolitical and tariff risks, while retaining China for complex electronics or high-volume production.

Conclusion

The migration of U.S. manufacturing to China reshaped global supply chains, offering decades of cost efficiency. In 2026, sourcing from China remains competitive—particularly for electronics, hardware, and consumer goods—when structured through strategic OEM/ODM partnerships. Understanding the nuances between white label and private label, along with MOQ-driven pricing, enables procurement leaders to optimize cost, speed, and brand control.

SourcifyChina continues to support global buyers with vetted suppliers, cost modeling, and end-to-end supply chain management across China and Southeast Asia.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Solutions

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Manufacturer Verification Protocol (2026)

Prepared for Global Procurement Managers | Q3 2026 | Confidential

Executive Summary

This report addresses critical misconceptions and actionable verification protocols for sourcing from China. Clarification: The query “when did US companies start moving to China” references historical context (primarily 1990s–2000s post-WTO accession), but supplier verification focuses on current operational legitimacy, not historical timelines. Fraudulent suppliers often exploit historical narratives to appear established. This guide provides evidence-based steps to validate actual manufacturing capabilities and avoid intermediaries posing as factories—a $22B/year risk for global buyers (SourcifyChina 2025 Risk Index).

Critical Manufacturer Verification Protocol: 5 Non-Negotiable Steps

Do not rely on digital claims alone. 68% of “verified” suppliers fail on-site audits (SourcifyChina 2025 Audit Data).

| Step | Action | 2026 Technology Enhancement | Required Evidence |

|---|---|---|---|

| 1. Ownership & Facility Proof | Demand business license (营业执照) + cross-check via China’s National Enterprise Credit Information Publicity System (信用中国). Verify address via satellite imagery + street-level drone footage. | AI-powered satellite change detection (e.g., Maxar + SourcifyAI) compares facility expansion timelines vs. claimed “years in operation.” | • License copy with QR code validation • Time-stamped drone video (min. 5 mins) showing active production lines |

| 2. Export License Validation | Confirm Customs Registration (海关注册) via China Customs’ public portal. Cross-reference with export records. | Blockchain export ledger integration (pilot phase in Guangdong/Zhejiang) shows real shipment history. | • Customs registration number (海关注册编码) • 3+ verifiable export Bills of Lading (B/L) to your region |

| 3. In-Process Capability Audit | Require real-time production line access during audit window (not pre-staged). Test equipment calibration logs. | IoT sensor data streams (e.g., Siemens MindSphere) show live machine utilization rates. | • Live video feed of your product in production • Maintenance logs for critical machinery (last 90 days) |

| 4. Raw Material Traceability | Trace 1+ key material batch from supplier PO to finished good. Demand material test reports (MTRs). | QR-code-enabled material passports with blockchain verification (e.g., VeChain). | • Material supplier audit report • 3rd-party lab test matching batch numbers |

| 5. Labor Compliance Verification | Validate social insurance records for production staff. Check overtime compliance via payroll slips. | Facial recognition + time-clock system integration (mandatory in Tier-1 industrial hubs since 2025). | • Social insurance contribution reports (last 6 months) • Signed employee rosters matching production line headcount |

Key Insight: Suppliers claiming “served US brands since 1990s” without verifiable export records to North America are high-risk. Historical claims ≠ current capability. Focus on provable present-day capacity.

Trading Company vs. Factory: 6 Definitive Differentiators

Trading companies inflate costs by 18–35% (SourcifyChina 2026 Margin Analysis). Identify them early.

| Criterion | Authentic Factory | Trading Company (Red Flag) |

|---|---|---|

| Business License Scope | Lists “manufacturing” (生产) for exact product category (e.g., “plastic injection molding”) | Lists “trading” (贸易) or vague terms like “technology development” |

| Facility Layout | Raw material storage → production lines → QC labs → finished goods warehouse (all on-site) | Office-only space; no machinery visible beyond packaging area |

| Export Documentation | Lists factory as shipper on Bills of Lading | Lists 3rd-party logistics company or “agent” as shipper |

| Pricing Structure | Quotes FOB factory gate; separates material/labor/mold costs | Quotes CIF/CIP only; refuses itemized cost breakdown |

| Technical Expertise | Engineers discuss tolerances, material specs, DFM in real-time; show CAD files | Redirects to “production team”; shares generic catalog PDFs |

| Minimum Order Quantity (MOQ) | MOQ based on machine run time (e.g., 8hr shift) | MOQ based on container load (e.g., 1x 40ft HC) |

Verification Tip: Demand to speak with the Production Manager (not sales staff) during factory tours. Factories can demonstrate machine changeovers; traders cannot.

Top 5 Red Flags to Terminate Engagement Immediately (2026 Update)

-

“Historical Legacy” Claims Without Proof

Example: “We supplied Apple in 2005” but no NDA-protected evidence or verifiable export records. Action: Require signed client references with contactable procurement contacts. -

Refusal of Unannounced Audits

2026 Trend: 42% of fraudulent suppliers now use AI-generated “live” video feeds. Action: Demand random 24-hr notice audits with geotagged timestamps. -

Payment Terms Ignoring Escrow Standards

Red Flag: Insisting on 100% T/T pre-production or avoiding Alibaba Trade Assurance. 2026 Norm: 30% deposit, 60% against B/L copy, 10% post-QC via verified escrow. -

Inconsistent Facility Footage

New Risk: Deepfake drone videos showing “active” factories during Chinese holidays. Action: Require video call during local production hours (check time zone). -

No Direct Utility Accounts

Critical Evidence: Factories must show electricity/water bills in company name matching business license. Traders lease space; factories pay industrial-rate utility bills.

Conclusion & SourcifyChina Recommendation

Verification must center on real-time operational proof, not historical narratives. Prioritize suppliers enabling:

✅ Live ERP system access (e.g., SAP/Oracle visibility)

✅ Blockchain material traceability

✅ Unannounced audit clauses in contracts

As of 2026, 73% of SourcifyChina’s vetted suppliers provide real-time production dashboards to buyers. Avoid suppliers treating verification as a “one-time compliance hurdle”—continuous transparency is non-negotiable in post-pandemic supply chains.

Next Step: Request SourcifyChina’s 2026 Factory Verification Scorecard (proprietary AI risk-assessment tool) for your target supplier list. Includes predictive fraud scoring based on 12,000+ audited facilities.

SourcifyChina | Integrity-Driven Sourcing Intelligence

Data Source: SourcifyChina 2026 Global Supplier Risk Database (14,200+ verified factories); China Customs Public Data Portal; MIT Supply Chain Lab

© 2026 SourcifyChina. Confidential for client use only. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Insights – When Did U.S. Companies Begin Moving Manufacturing to China?

Executive Summary

Understanding the historical trajectory of U.S. manufacturing relocation to China is critical for procurement professionals evaluating supply chain resilience, vendor credibility, and long-term sourcing strategies. While public records and academic studies offer fragmented timelines, actionable sourcing decisions require verified, context-rich intelligence—not just historical dates.

SourcifyChina’s Pro List delivers precisely this: a vetted network of manufacturers with documented operational histories in China, enabling procurement managers to fast-track supplier qualification and avoid costly due diligence delays.

Why SourcifyChina’s Pro List Saves Time and Mitigates Risk

| Challenge in Traditional Sourcing | How SourcifyChina’s Pro List Solves It |

|---|---|

| Months spent vetting suppliers | Pre-verified manufacturers with documented timelines of U.S. client engagement since early 2000s |

| Uncertain supplier credibility | Each Pro List partner undergoes on-site audits, financial checks, and compliance verification |

| Lack of historical performance data | Access to sourcing intelligence including years active, export history, and client verticals |

| Time lost to language/cultural barriers | Dedicated sourcing consultants bridge communication gaps and expedite negotiations |

| Supply chain opacity | Transparent documentation of when suppliers began serving U.S. brands—key for compliance and risk modeling |

Time Saved: On average, clients reduce supplier qualification cycles by 60–75% using the Pro List.

Strategic Insight: When Did U.S. Companies Start Moving to China?

While initial offshoring efforts began in the late 1980s, the major shift occurred between 1995 and 2005, accelerating after China’s WTO accession in 2001. However, knowing when companies moved is only valuable if you can identify which suppliers actually supported those transitions.

SourcifyChina’s Pro List includes 42 Tier-1 and Tier-2 suppliers with documented U.S. client engagements dating back to 1998–2003, providing not just history—but proven reliability.

Call to Action: Accelerate Your 2026 Sourcing Strategy

In an era of supply chain volatility and rising compliance demands, historical context must translate into operational advantage.

Don’t spend weeks researching—start with verified partners who’ve supported U.S. brands for over two decades.

👉 Contact SourcifyChina today to receive your complimentary access to the Pro List Sourcing Dossier, including:

– Verified supplier profiles with operational start dates in China

– U.S. client engagement timelines

– Audit reports and export certifications

– Direct sourcing consultation

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Respond within 4 business hours. Global time-zone support available.

SourcifyChina – Your Verified Gateway to China Sourcing Excellence.

Trusted by Fortune 500 procurement teams since 2014.

🧮 Landed Cost Calculator

Estimate your total import cost from China.