Introduction: Navigating the Global Market for Air Leather

Procurement and product teams are rethinking upholstery because buyers want a leather look without heat build‑up or animal inputs. Air leather (also marketed as leathaire) is a polyurethane (PU) micro‑perforated fabric that feels like leather while actively dissipating heat. It offers the aesthetic of leather with the comfort of breathable textiles.

The problem is clear: traditional PU, PVC, and full‑grain leathers trap heat and moisture, reducing comfort, increasing maintenance, and raising sustainability questions. Air leather’s woven, micro‑perforated structure is designed to solve that.

A quick comparison:

| Attribute | Air leather | Traditional PU/PVC leatherette | Real leather |

|————————–|————-|———————————|————–|

| Heat/odor control | High (micro‑perforated) | Low | Low |

| Look & hand | Leather‑like, soft | Varies; often firmer | Premium |

| Breathability | Built‑in via micro‑perfs | Limited/absent | Limited/absent |

| Petrochemical content | PU‑based | PU or PVC‑based | N/A |

| End‑of‑life | Textile recycling streams | Often landfill/waste-to‑energy | Complex (tanning) |

What this guide covers: material definition and manufacturing; performance vs. standard PU/PVC and real leather; durability and maintenance; compliance and sustainability across the USA and Europe; cost bands, supply, and lead times; testing and quality control; risk mitigations; and a practical decision checklist.

Illustrative Image (Source: Google Search)

Article Navigation

- Top 10 What Is Air Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is air leather

- Understanding what is air leather Types and Variations

- Key Industrial Applications of what is air leather

- 3 Common User Pain Points for ‘what is air leather’ & Their Solutions

- Strategic Material Selection Guide for what is air leather

- In-depth Look: Manufacturing Processes and Quality Assurance for what is air leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is air leather’

- Comprehensive Cost and Pricing Analysis for what is air leather Sourcing

- Alternatives Analysis: Comparing what is air leather With Other Solutions

- Essential Technical Properties and Trade Terminology for what is air leather

- Navigating Market Dynamics and Sourcing Trends in the what is air leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is air leather

- Strategic Sourcing Conclusion and Outlook for what is air leather

- Important Disclaimer & Terms of Use

Top 10 What Is Air Leather Manufacturers & Suppliers List

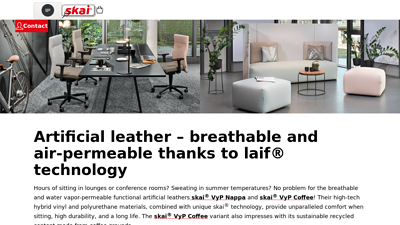

1. laif® technology | Breathable & air-permeable artificial leather – Skai

Domain: skai.com

Registered: 1998 (27 years)

Introduction: The functional skai® VyP synthetic leathers shine in practical use with outstanding properties such as breathability, water and air permeability and soft, ……

2. Aviation – Elmo Leather

Domain: elmoleather.com

Registered: 1998 (27 years)

Introduction: Elmolite is a cutting-edge technical leather tailored for aircraft seating. Weighing just 700 grams/m², it’s a high-performance, lightweight solution that ……

3. BOXMARK – Best in Leather Interior

Domain: boxmark.com

Registered: 1999 (26 years)

Introduction: BOXMARK is one of the world’s leading leather manufacturers and we guarantee your success. BOXMARK’s outstanding skills and know-how in development and ……

4. Sustainability – Garrett Leather

Domain: garrettleather.com

Registered: 1996 (29 years)

Introduction: Leather production is one of the oldest forms of recycling and at Garrett Leather, we work with tanneries that adhere to responsible manufacturing processes to ……

Illustrative Image (Source: Google Search)

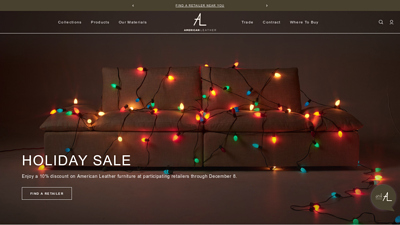

5. American Leather: Furniture Handcrafted in the US

Domain: americanleather.com

Registered: 1997 (28 years)

Introduction: Browse our selection of custom modern American made leather furniture for sale, including sleeper sofas, couches, sectionals, recliners & more….

6. Aero Leather Clothing | Handmade Leather Jackets

Domain: aeroleatherclothing.com

Registered: 1997 (28 years)

Introduction: Real leather jackets from world-famous UK manufacturers Aero Leather Clothing. Based in Scotland, we specialise in handmade leather jackets….

Understanding what is air leather Types and Variations

Understanding Air Leather: Types and Variations

Air leather is a synthetic upholstery material—typically polyurethane (PU) with micro-perforations—engineered to improve seating comfort through enhanced airflow. Unlike dense PU/PVC faux leathers, its perforated surface and often woven or knit backing provide breathability while maintaining a leather-like hand and appearance. For specification and procurement teams across furniture, hospitality, and contract seating, the material’s performance and cost position differ by structure and finish. Below are the principal types and their typical specifications, use cases, and trade-offs.

Type comparison

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| Micro‑perforated PU air leather | PU face with controlled micro‑perforations; thin coatings; breathable; smooth, leather‑like hand | Sofas, sectionals, armchairs, dining chairs; hospitality guestroom seating | Pros: Improved airflow and comfort; consistent surface; broad colorways. Cons: Perforations can collect dust/debris; delicate at edges; repairability limited compared to woven faces. |

| Woven‑face (knit/jacquard) air leather | Woven face engineered for leather‑like look; micro‑perforations through the yarn bundle; stronger seam/tensile performance | High‑traffic seating (contract/hospitality); family room sofas; sectional arm panels | Pros: Robust seam strength; better tear resistance; good breathability; easier to seam and repair. Cons: Thickness; heavier hand than smooth PU; potential yarn fraying at cuts if not finished. |

| Perforated PU over knit backer | Perforated PU surface bonded to polyester/rayon/acrylic knit; micro‑perforations help airflow; moderate stretch for curved frames | Office/guest seating with moderate curves; recliners; automotive‑style lounges | Pros: Balanced airflow and comfort; good cut/seam performance; flexible around complex frames. Cons: Requires careful bonding; long‑term edge adhesion must be tested; stretch variability can affect pattern alignment. |

| PU/PC (polycarbonate) hybrid blend | Blended PU/PC or hardcoat finish over micro‑perforated film; enhanced scuff resistance; firm hand | High‑use commercial seating (airports, cafés); education/academic chairs; public lounges | Pros: Superior scuff/scratch resistance; maintains airflow; durable finish. Cons: Slightly stiffer hand; higher cost; potential surface glare if finish is glossy. |

Micro-perforated PU Air Leather (PU face, perforated)

- Structure: Continuous PU film with factory‑driven micro‑perforations that create controlled airflow across the sitting surface.

- Comfort: Improved heat dissipation and moisture transfer versus non‑perforated PU, reducing the “sticky” feel in warm conditions.

- Feel and finish: Smooth, uniform leather‑like hand; broad color options; can be offered in matte or semi‑gloss finishes.

- Applications: Upholstered sofas, sectionals, armchairs, dining chairs; contract hospitality seating where comfort and consistent appearance are priorities.

- Considerations: Perforations can collect dust or debris—ensure cleanroom‑grade finish and specify easy‑clean maintenance guidelines. Edge finishing is critical to prevent fraying at seams and cut edges. Repair typically limited to patching rather than rewoven repair.

Woven-Face (Knit/Jacquard) Air Leather

- Structure: Woven substrate engineered to mimic leather texture and grain; yarn bundles include micro‑perforations to enable airflow while providing a durable face.

- Performance: Higher seam strength and tear resistance relative to smooth PU films; less prone to cracking under repeated flexion; breathable construction.

- Applications: High‑traffic commercial seating (contract/hospitality), family‑room sofas where durability is critical, and sectional arm panels subject to frequent handling.

- Considerations: Slightly heavier hand; ensure accurate cutting to reduce yarn fraying and apply appropriate edge finishes (fold, welt, or bonded edge). Yarn type and coating can affect wear resistance—evaluate abrasion and seam slippage per relevant test standards.

Perforated PU over Knit Backer

- Structure: Perforated PU surface bonded to a knit backing (often polyester/rayon/acrylic); combination balances surface aesthetics, airflow, and flexibility around complex frames.

- Comfort and fit: Micro‑perforations aid breathability; knit backing adds stretch for tighter curves and deeper tufting.

- Applications: Office/guest seating with moderate curves, recliners, automotive‑style lounge pieces where drape and frame compliance matter.

- Considerations: Seam and cut performance are generally good, but adhesion between PU and knit backer is critical; evaluate long‑term edge adhesion and peel strength. Stretch variability requires careful pattern alignment to avoid grain distortion.

PU/PC Hybrid or Hardcoat Finish Air Leather

- Structure: Polyurethane blended with polycarbonate or hardcoat finish over micro‑perforated base film; maintains breathability while improving surface resilience.

- Performance: Enhanced scuff and scratch resistance versus standard PU air leather; firmer hand and higher load‑bearing characteristics; better cleanability and stain resistance.

- Applications: High‑use commercial seating (airports, cafés, education/academic chairs), public lounges, and hospitality common areas where durability and easy maintenance are essential.

- Considerations: Slightly stiffer hand may reduce drape; gloss levels can vary—specify matte or low‑gloss finishes to manage appearance under varied lighting. Expect higher cost than standard PU air leather; confirm supplier data on abrasion and colorfastness.

General Considerations Across Types

- Abrasion and seam performance: Specify against established standards (e.g., ANSI/BIFMA X5.1, EN 14727/16139 for contract seating). Note that woven and knit‑backed versions typically show superior seam strength and tear resistance compared to smooth PU films.

- Breathability and comfort: Micro‑perforations improve airflow; consider cushion design and fill materials (foam density, spring systems) to maximize comfort without compromising support.

- Cut and edge finishing: Choose edge treatments appropriate to the structure (fold, welt, bonded edge). Ensure clean cutting practices to prevent fraying or delamination.

- Cleaning and maintenance: Recommend water‑based cleaning agents and mild detergents; avoid harsh solvents (acetone, strong alkalines) that can attack PU surfaces. Establish protocols for perforations—use soft brushes or vacuums to remove debris.

- Environmental and regulatory: Air leather is fully synthetic PU; validate any claims around VOC emissions or Certifications with current supplier data (e.g., relevant testing and declarations). Consider fire‑retardant treatments or barrier layers where applicable to meet local codes in commercial environments.

Key Industrial Applications of what is air leather

Key Industrial Applications of What Is Air Leather

| Industry | Application | Why Air Leather Works | Example Use-Cases |

|---|---|---|---|

| Contract & Hospitality Furniture | Upholstered seating (sofas, chairs, booth seating, lounge pieces) | Comfort-first alternative with a leather-like hand, breathable micro-perforated surface reduces heat buildup. Vegan, easy to clean, and visually aligned with premium leather aesthetics without the maintenance of real leather. | Hotel lobbies, lounges, bars; restaurants; conference centers; boutique hotels |

| Residential Furniture | Consumer seating and casegoods (sofas, accent chairs, headboards) | Delivers a leather look and feel at a lower cost, with improved sitting comfort in warm climates or unconditioned spaces. Vegan appeal supports positioning in eco/vegan product lines. | Sofa programs, armchair collections, bedroom headboards for furniture brands |

| Office & Workplace Seating | Task, guest, and lounge seating | Breathability improves sitting comfort during long work sessions and across seasons. Cost control for large rollouts and easier replacement cycles. | Open-plan offices, co-working spaces, executive offices, visitor chairs |

| Healthcare (Non-Patient-Contact) | Waiting-room seating and visitor chairs | Leather-like appearance supports wayfinding and brand identity. Easier maintenance than genuine leather; animal-free for policy alignment. Ensure disinfectants are compatible; verify chemical resistance with the supplier. | Clinics, doctor offices, hospital lobbies, admin areas |

| Education & Libraries | Student/staff seating and lounge furniture | Enhances comfort in high-occupancy spaces with frequent turnover. Robust appearance for campus environments. | University lounges, library seating, student centers |

| Transportation Interiors (Buses, Trains, Marine, RVs) | Wall panels, headliners, bulkheads, partitions, and occasional seating | Lightweight compared with real leather; consistent look across large interior surfaces. Breathability improves perceived comfort in seating and near-touch panels. Verify UV/ moisture performance with supplier and perform field testing. | Bus and rail interior wraps, marine wheelhouse seating, RV lounge furniture |

| Public & Commercial Spaces | Airport terminals, malls, government buildings, hotels, restaurants | High-visibility, premium visual standard with better sitting comfort. Lower maintenance than real leather; vegan positioning. | Terminal lounges, mall seating, municipal waiting areas |

| Performance Venues & Leisure | Backstage and hospitality seating | Leather-like visual presence with improved comfort for extended events. | Concert hall lounges, VIP bars, green rooms |

What Is Air Leather, Practically?

– Breathable construction: Micro-perforations enable airflow, reducing heat buildup versus conventional PU/PVC leather and genuine leather.

– Leather-like hand and look: Woven base with a polyurethane (PU) surface delivers a premium appearance without the cost or upkeep of real leather.

– Vegan positioning: Compliant with animal-free product strategies and certifications that matter to certain B2B buyers.

– Design and spec-friendly: Consistent finish, color, and hand across large batches; easier to specify and replace than genuine leather.

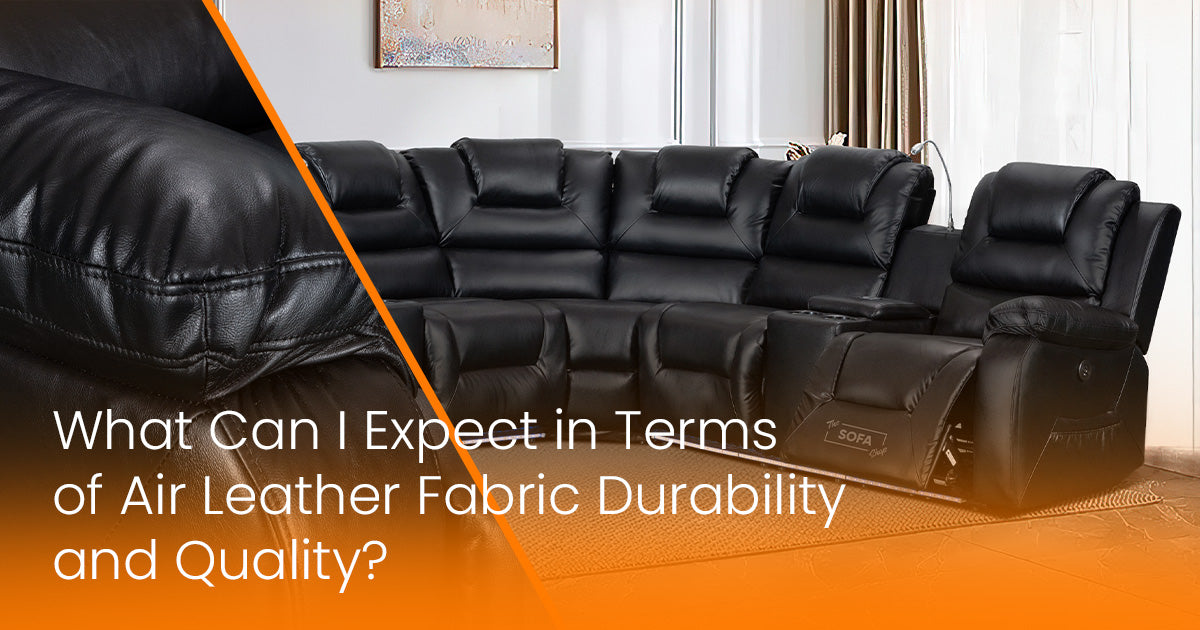

Illustrative Image (Source: Google Search)

3 Common User Pain Points for ‘what is air leather’ & Their Solutions

3 Common User Pain Points for “What Is Air Leather” & Their Solutions

1) Heat and stickiness in warm climates

- Scenario: Hospitality seating in humid regions; consumer furniture in warm seasons.

- Problem: Conventional faux leathers feel hot and clammy; they trap heat and moisture.

- Solution:

- Position air leather (aka leathaire) as a micro-perforated, breathable alternative to PU leather, vinyl, and bonded leather.

- Spec micro-perforation density and airflow where testing is available; publish care tips that emphasize “cool-to-touch” expectations and temperature guidance (e.g., avoid leaving in direct sun for extended periods).

- Provide sample testing kits for trade buyers to evaluate real-world comfort in showroom conditions.

- Impact: Higher perceived comfort and satisfaction; fewer returns related to heat discomfort.

- Implementation checklist:

- [ ] Update SKU and spec sheets with “air leather” attributes (polyurethane, woven feel, breathable).

- [ ] Add comfort messaging on product pages and hospitality sell sheets.

- [ ] Offer sample swatches and testing guides to B2B buyers.

2) Perception: “fake leather” vs. leather feel

- Scenario: Retail buyers, procurement teams, and end users debating leather feel versus ethical positioning.

- Problem: Stakeholders equate breathability with lower quality; confusion over whether air leather is leather.

- Solution:

- Frame air leather as a vegan, leather-like textile made of polyurethane with micro-perforations for airflow and a woven backing; emphasize its woven fabric hand-feel and leather-like aesthetics.

- Create comparative claims guidance for USA/EU:

- Avoid “genuine leather,” “real leather,” and “100% leather” language.

- Use “synthetic,” “leather-like,” “vegan,” “polyurethane air leather” (leathaire) descriptors.

- Where testing exists (e.g., breathability or temperature recovery), state verified results with date and method.

- Provide retail training and care cards highlighting the difference between air leather, PU leather, and real leather.

- Impact: Reduced claim-related compliance risk; clearer product education; improved buyer confidence.

- Implementation checklist:

- [ ] Publish claim-safe naming and labels (air leather/leathaire) with product families.

- [ ] Train sales on compliant messaging for EU/US.

- [ ] Roll out care guides distinguishing air leather from traditional faux leather.

3) Maintenance and cleaning uncertainty

- Scenario: Commercial hospitality, contract seating, and e-commerce buyers seeking longevity and easy care.

- Problem: Lack of clarity leads to miscleaning (e.g., harsh solvents, aggressive rubbing), which can degrade finish or aesthetics.

- Solution:

- Provide clear, repeatable care instructions suited to polyurethane:

- Routine maintenance: dust or vacuum with soft brush; wipe with a microfiber cloth.

- Spot cleaning: use a 1:1 water-to-mild soap solution or 50:50 water-to-isopropyl alcohol for stubborn marks; dab (don’t rub), then dry with clean cloth.

- Avoid: bleach, ammonia, solvent-based cleaners, industrial degreasers, and abrasive pads.

- Temperature guidance: avoid prolonged direct sun and high heat exposure to prevent softening or stickiness.

- Offer optional performance treatments (e.g., stain-guard) where appropriate; document results from independent tests when available.

- Impact: Longer aesthetic life; fewer cleaning-related claims; easier maintenance for facilities teams.

- Implementation checklist:

- [ ] Add on-product care labels and downloadable care sheets.

- [ ] List approved cleaners and methods in spec documentation.

- [ ] Include maintenance frequency recommendations by use-case (residential vs. contract).

Notes and boundaries

– Product definition: Air leather is a synthetic polyurethane textile with micro-perforations that allow airflow and a woven backing; marketed as leathaire in some channels.

– Claims: In the USA/EU, do not imply it is leather; rely on “leather-like,” “vegan,” and “synthetic” descriptors. Back up breathability, comfort, and stain-performance claims with verifiable test methods and dates.

– Sustainability: If LCA or recycled content data exist, provide them transparently. Otherwise avoid sustainability claims about “breathability = eco” until validated.

Use this guide to align positioning, care, and compliance so buyers understand air leather’s benefits and how to deploy it effectively across hospitality and residential programs.

Strategic Material Selection Guide for what is air leather

Strategic Material Selection Guide: What is air leather (and when should you choose it)?

What is air leather? How is it made, what makes it different, and under what product or market conditions should it be considered over conventional options? The following guide distills decision-critical attributes from available information and clarifies where data is incomplete for USA and European buyers.

What is air leather?

- Air leather is a man-made alternative to real leather characterized by micro-perforations that allow airflow, which improves sitting comfort by reducing heat and moisture buildup compared with traditional leather surfaces.

- It is marketed interchangeably as “leathaire,” and it is constructed as a woven fabric with a leather-like feel.

- It is positioned as a vegan alternative to real leather, emphasizing comfort in warm or sedentary-use contexts.

How is it made?

- Composition: polyurethane derived from petroleum, making it a synthetic product.

- Manufacturing: micro-perforations create an open weave that facilitates air exchange; the surface texture mimics leather.

Comfort profile and key trade-offs

- Comfort: micro-perforation-driven breathability is its defining advantage, specifically reducing the warm, “sticky” sensation common on non-breathable leather surfaces.

- Feel: leather-like touch with a woven fabric backing, delivering aesthetic similarity with a softer tactile experience than many monolithic faux-leather sheets.

- Breathability vs moisture: Breathability supports thermal comfort; however, water resistance and cleaning implications are not specified, which requires product-level validation for hospitality, healthcare, or family-use scenarios.

- Wear/aging and repair: longevity, abrasion, and repairability data are not provided; buyers should plan pilot testing before scaling.

Selection logic: when is air leather the right choice?

- Choose when:

- Breathability and seated comfort are top priorities in warm climates, urban living, or commercial lounges where people sit for extended periods.

- Brand or category strategy calls for a vegan leather alternative with a leather-like look and feel but with demonstrably better thermal comfort.

- Defer or evaluate further when:

- Moisture management, cleanability, or wipe-down performance are critical and not explicitly documented.

- Durability KPIs (e.g., Martindale abrasion, tensile strength, UV resistance) and maintenance protocols must be known for compliance or warranty (e.g., hospitality, contract, or family-grade furniture).

- Sustainability claims are required (certifications, recycled content, end-of-life pathways); additional supplier documentation is needed.

Implementation guidance (procurement and product teams)

- Confirm technical performance in the target environment:

- Sit tests in warm conditions; measure thermal comfort, perceived stickiness, and humidity recovery vs control materials (genuine leather, PU/PVC faux leather, and textile upholstery).

- Request supplier data:

- Composition specifics, including backing fabric and finish systems.

- Breathability metrics (e.g., air permeability, MVTR) and durability testing results.

- Cleanability and care instructions; confirm compatibility with commercial cleaning agents in applicable markets.

- Pilot before scale:

- Run controlled A/B trials in key markets (e.g., urban apartments, warm climates, hospitality lounges) to validate comfort claims and monitor initial wear patterns.

- Labeling and documentation:

- Ensure vegan and material composition claims align with market regulations and retailer standards; prepare specification sheets for sales and service teams.

Comparison matrix: air leather vs conventional options (for USA/Europe)

The table below organizes the decision-relevant attributes where data is available; gaps are noted for targeted follow-up with suppliers.

Illustrative Image (Source: Google Search)

| Attribute | Air Leather | Genuine Leather | PU/PVC Faux Leather | Textile Upholstery |

|---|---|---|---|---|

| Composition | Synthetic; polyurethane; woven fabric with micro-perforations | Natural animal hide | Synthetic polymers (PU or PVC) | Woven or knitted textile fibers |

| Breathability | High (micro-perforations allow airflow) | Low to moderate; can feel warm | Low; typically non-breathable | Varies by fabric; often higher than leather/faux |

| Feel/Hand | Leather-like; soft; woven backing | Luxurious; unique patina | Plastic-like; varies by topcoat | Soft to structured depending on fiber |

| Comfort in heat | Designed to be cooler and less sticky | Can become hot and sticky | Often warm and sticky | Comfort depends on fiber; typically breathable |

| Vegan | Yes | No | Yes | Yes |

| Key performance data (durability, maintenance, sustainability) | Not provided in source | Not provided in source | Not provided in source | Not provided in source |

How does the micro-perforated woven structure influence seating comfort across climates?

Given that air leather is specifically engineered for airflow, it tends to perform better than non-breathable leather and faux leather in warm or sedentary-use contexts; however, cleaning and maintenance regimes, moisture management, and long-term wear must be validated for the intended market and use case.

What should USA/European B2B buyers verify before committing?

- Confirm breathability results and thermal-comfort data in realistic settings.

- Obtain durability and cleanability testing aligned to the target segment (residential contract, hospitality, healthcare, family use).

- Ensure regulatory and claims compliance for vegan and material disclosures in both USA and EU markets.

In-depth Look: Manufacturing Processes and Quality Assurance for what is air leather

In-depth Look: Manufacturing Processes and Quality Assurance for Air Leather

What it is: Air leather (also marketed as leathaire) is a micro-perforated polyurethane (PU)–coated woven fabric designed to feel and look like leather while allowing airflow through the surface. Its core value proposition is comfort—less heat buildup and a cooler touch—making it particularly suitable for seating and other upholstery applications where breathability matters.

How it’s made and how you keep it reliable: B2B buyers in the USA and Europe should evaluate air leather through the lens of four production blocks—Prep, Forming, Assembly, and Quality Control (QC)—and ensure claims (e.g., “breathable,” “PU,” “micro-perforated”) map to recognized standards.

Manufacturing Steps Overview

A disciplined flow-through from material selection to QC minimizes variability and protects performance over time.

Illustrative Image (Source: Google Search)

- Prep: Raw material selection and formulation

- Substrate: Woven polyester or nylon (balanced construction, ~180–350 gsm) chosen for stability, stretch control, and tear resistance; consistent yarn denier and thread count support uniform film adhesion.

- PU formulation: Thermoplastic PU resin (TPU) or solvent-based PU, tailored by crosslink density and plasticizers to balance hand-feel, abrasion resistance, and cold performance; antimicrobial and flame-retardant additives integrated when required by contract.

- Pigments/Dyes: Masterbatches with UV stabilizers ensure color fastness and reduced fading on exposure.

-

Why it matters: Small formulation changes (e.g., lower plasticizer load) can dramatically alter flexibility and surface crack resistance at low temperatures; this affects seat durability and user perception of “luxury.”

-

Forming: Film creation and micro-perforation

- PU film: Cast on release paper (solvent route) or extruded via T-die (for solvent-free), calibrated to target thickness (often 0.6–1.2 mm for upholstery).

- Embossing: Grain pattern applied to replicate leather’s tactile cues; careful release and back-roll temperature control prevents fish-eye defects.

- Micro-perforation: Controlled hole pattern—pin or laser—typically with hole diameters of ~0.1–0.3 mm and area-percentage around 2–5% (example: ~1 mm pitch across the surface). Calibration ensures consistent air permeability while resisting fluid ingress.

-

Simple example: Imagine placing a fine-mesh screen over a warm surface. Even small holes allow heat to dissipate; too many or too large, and the surface becomes weak. For air leather, micro-perforation is the tuned screen.

-

Assembly: Laminate to substrate and finish

- Adhesive coating: PU or polyurethane–urea adhesives, applied in a controlled wet film thickness, allow strong yet flexible bond lines without stiffening the composite.

- Lamination: PU film laminated to woven substrate using calender rolls; dwell time, temperature, and pressure tuned to prevent edge curl and delamination.

- Topcoat/finish: Optional thin topcoat (silicone or PU) improves scuff resistance and surface cleanability.

-

Why it matters: Proper lamination ensures the micro-perforated film remains intact across high-strain zones like seat cushions and armrests; overheat or under-cure can cause holes to tear or seal closed.

-

QC: Testing, documentation, and traceability

- AQL sampling: Statistical sampling (often AQL 2.5 for defects) validates lot acceptance; defects such as pinholes, uneven grain, or surface adhesion are screened at source.

- Measurement systems: Breathability (air permeability), tensile/tear, abrasion, color fastness, and cold-crack checks confirm the promise of air leather in real use conditions.

- Simple example: A QA lab might run a breathability test by pulling air through a 50 cm² area at a defined pressure. If the rate is outside the approved range, it flags the batch for correction.

Quality Standards and Test Benchmarks (ISO and allied)

Air leather’s distinctiveness rests on breathability and durability. Map claims to specific tests and thresholds; avoid vague language.

| Attribute | Test Method (ISO/ASTM) | Typical Target Range | Purpose/Notes |

|---|---|---|---|

| Air permeability (breathability) | ISO 9237 | ~20–120 L/m²/s at 200 Pa | Demonstrates airflow through micro-perforations; balance with abrasion/water resistance. |

| Tensile strength | ISO 13934-2 | ≥150 N (warp/weft) | Ensures fabric can withstand stress during use and assembly. |

| Tear resistance | ISO 13937-2 | ≥20 N | Prevents tear propagation in seams and high-strain areas. |

| Abrasion (Martindale) | ISO 12947-2 | ≥25,000 cycles | Confirms surface durability for seating; align等级 with intended use. |

| Color fastness to rubbing (dry/wet) | ISO 105-X12 | ≥4 (dry), ≥3 (wet) | Validates color stability when touched or cleaned. |

| Cold crack (film cracking at low temp) | ISO 7619-1 (contact) or ASTM D2136 (similar) | No cracks at -10°C (example) | Critical for seats in colder climates or transport. |

| VOC/HCHO/emissions | ISO 16000-series | Pass for applicable limits | Supports indoor-air quality claims in USA/EU. |

| Fungal resistance | ISO 846 (A/B) | No significant growth | Applicable in humid geographies; supports durability. |

| Seam strength | ISO 13936-2 | ≥120 N seam strength | Prevents seam failures during upholstery assembly. |

| Dimensional stability | ISO 5077 | ≤3% change | Keeps upholstery taut and prevents sagging. |

Note: The exact targets depend on the product specification and the intended application. Always confirm project-specific performance criteria before bulk production.

Illustrative Image (Source: Google Search)

Production Controls and Defect Prevention

- Process discipline:

- Line speed vs. cure balance: Under-cure can cause surface tack; over-cure risks closed micro-perforations and brittle film.

- Environmental control: Humidity and temperature in lamination impact adhesive bonding; keep rooms at stable conditions (e.g., 50–60% RH, 20–25°C).

- Pin/laser tuning: Monitor perforation rate and hole size; periodic audit via air permeability tests prevents airflow drift.

- Common defects:

- Pinholes/oversized perforations (lead to weak spots and excessive airflow), adhesion failure (delamination under stress), uneven grain (visible and tactile defects), and surface hardening (cold crack in low-temp handling).

- Traceability:

- Lot tracking from resin and substrate to finished roll; retain test certificates to streamline claims and customer audits.

Sourcing and Compliance Guidance (USA/EU)

- Label accuracy: Claim alignment with actual material (e.g., “PU film on woven substrate; micro-perforated for breathability”).

- Regional standards: In the USA, consider ASTM methods alongside ISO; in the EU, ISO predominates, but customer-specific protocols often apply. Ensure REACh (EU) and Proposition 65 (USA) compliance where required.

- Communication clarity: Avoid broad “leather” terminology unless the specification clearly allows it; keep marketing claims specific to breathability and PU construction.

Quick Takeaways for B2B Buyers

- Confirm airflow: Ask for ISO 9237 results and pin diameter/pitch data. Higher is not always better—balance airflow with durability.

- Check film integrity: Verify tensile/tear and cold crack to prevent seating failures in colder markets.

- Demand traceability: Include AQL inspection and retained test certificates in your purchase terms.

- Think “summer seat comfort”: A breathable seat cushion with micro-perforations feels cooler to the touch compared to traditional faux leather; make that difference measurable with the test plan above.

Relatable example: Picture two armchairs—one with air leather, one without micro-perforation. On a warm day, your clients feel less heat buildup on the air leather chair after 30 minutes, because air moves through the surface. To sustain that experience across markets, your supplier must keep perforation consistency tight and film durability high. That’s what robust manufacturing and ISO-based QC deliver.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is air leather’

Practical Sourcing Guide: A Step-by-Step Checklist for Air Leather

Ready to find a breathable, PU-based leather alternative for your next product line? Start with the following checklist to clarify requirements, evaluate suppliers in the USA and Europe, and ensure performance and compliance from concept to order.

1) Clarify product and business requirements

Do your specifications cover use-case, performance, certification, and sourcing terms?

Table: Sourcing requirements to confirm

| Requirement | What to confirm | Notes |

|---|---|---|

| End use and product category | Furniture (upholstery), apparel, accessories, interiors | Air leather is marketed for comfort seating due to breathability |

| Definition alignment | Breathable PU-based, micro-perforated, leathaire branding (if applicable) | Confirms it is the same “air leather” as referenced |

| Material performance | Breathability, feel/softness, abrasion resistance, tear strength, seam slippage | Breathability is the key differentiator; quantify minimums for durability |

| Finishing options | Color range, topcoat (matte/gloss), embossing, backings (woven/knit/foam), thicknesses | Validate colorfastness to rub tests and lightfastness |

| Regulatory/compliance | RoHS, REACH SVHC, Prop 65 (CA), VOC emissions, FR (if applicable) | Confirm region-specific requirements (USA/EU) |

| Manufacturing readiness | MOQ, lead times, capacity, sampling, rework/returns policy | Aim for multi-color/colorway sampling before bulk |

| Logistics and Incoterms | Packaging, roll width and length, freight terms, traceability | Include roll labeling and lot traceability |

| Commercials | Unit price tiers, tooling charges (if any), payment terms, warranty | Confirm price ladders by volume bands |

| Sustainability | Recyclability claims, supplier environmental program, PCR option | Verify any recycled content claims with test data |

2) Define the technical specification (RFP-ready)

Are your specs measurable and testable?

- Material identity: PU-based leather alternative; breathable via micro-perforations; marketed as leathaire.

- Tactile: Leather-like hand; comfort for seating due to airflow.

- Performance targets:

- Breathability/micro-perforations: method to be agreed (e.g., air permeability test).

- Durability: abrasion (Martindale), tear (N), seam slippage (N).

- Optics: lightfastness and colorfastness (rub, sweat).

- Dimensional stability, shrinkage, and curling.

- VOC/odor limits (if applicable).

- Finishing: color/finish options, backing type and thickness.

- Batch consistency: per-lot QA and tolerance windows.

- Documentation: TDS, MSDS, CoC, compliance certificates.

3) Supplier discovery and qualification (USA/EU)

Do you have a short list aligned to air leather’s defining features?

Table: Supplier evaluation criteria

| Criteria | What to ask | Why it matters |

|---|---|---|

| Experience with “air leather”/leathaire | Do you make breathable, micro-perforated PU leather alternatives? | Ensures the product matches the reference definition |

| Product range | Colors, finishes, backings, emboss patterns | Avoids excessive custom tooling lead times |

| Performance support | Can you provide test data for breathability and durability? | Validates claims with independent data |

| Compliance | RoHS, REACH SVHC, Prop 65, VOC emissions | Confirms regional regulatory alignment |

| MOQ and flexibility | Minimum order sizes by color/pattern | Reduces inventory risk and improves agility |

| Lead times | Typical sampling, pre-production, bulk | Aligns to product development timeline |

| Logistics | Delivery options across USA/EU, Incoterms | Optimizes landed cost and reliability |

| Quality system | ISO 9001/14001, process controls, lot traceability | Supports consistent quality and traceability |

| Pricing structure | Volume bands, adders for special finishes | Enables total cost of ownership modeling |

4) Sampling and proof-of-concept

Are samples validated against performance and finish expectations?

Illustrative Image (Source: Google Search)

- Request 3–5 colorways in two thicknesses/backings; request A/B specimens with micro-perforations.

- Perform tests: breathability/micro-perforation integrity; abrasion; tear; seam strength; colorfastness to rub and light; VOC/odor if required.

- Conduct user trials: tactile comfort, heat dissipation on seating surfaces, visual consistency across roll.

- Approve pilot colors and thicknesses; document any rework to finish or backing.

5) Commercialization and contracts

Do commercial terms lock in quality and cost?

Table: Commercial clauses checklist

| Clause | What to include | Rationale |

|---|---|---|

| Specification and finish schedule | Performance targets, colors, backing, thickness, tolerances | Prevents disputes over quality |

| QA and inspection | AQL levels, per-lot testing, acceptance criteria | Ensures uniform lot quality |

| Packaging and labeling | Roll width/length, lot IDs, roll sequencing | Improves traceability and production planning |

| Lead times and capacity | Sampling, pre-production, bulk schedule; capacity guarantees | Reduces scheduling risk |

| Payment and pricing | Volume price tiers, price protection period, payment terms | Stabilizes cost structure |

| Compliance and documentation | RoHS/REACH/Prop 65/VOC certificates; TDS/MSDS | Confirms regulatory alignment |

| Warranties and returns | Quality guarantees, defect handling, rework/returns policy | Reduces risk on performance issues |

6) Pilot run and scale-up

Will the first production lot validate process controls?

- Pilot produce 2–3 colors across one backing; verify breathability and performance consistency.

- Track yield, roll-to-roll uniformity, and any edge conditions (curling, seam slippage).

- Lock in process and finalize approval; plan for replenishment and safety stock.

7) Risk management and contingency

What happens if supply or quality shifts?

- Dual-source critical colors; keep equivalent finishes on standby.

- Monitor commodity/PU pricing; establish price escalation caps and volume incentives.

- Maintain regulatory monitoring (REACH updates, Prop 65 changes); update compliance documentation periodically.

8) KPIs for ongoing sourcing success

Are you tracking the right metrics?

- Quality defect PPM; breaching of performance tolerances; lot rejection rate.

- Lead time adherence; schedule adherence to pilot and bulk orders.

- Cost per roll/yard vs. budget; price variance by volume band.

- Supplier responsiveness; QA resolution time; documentation completeness.

Ready to move forward? If you share your end-use, target performance, and volumes, I can tailor the RFP spec, supplier shortlist, and KPI targets to your USA/EU operations.

Comprehensive Cost and Pricing Analysis for what is air leather Sourcing

Comprehensive Cost and Pricing Analysis for Air Leather Sourcing

Executive summary

– Price range (as-sold): $1.90–$3.20 per linear yard (FOB Asia), $3.50–$5.80 per yard (CIF USA/EU, net of duty and freight).

– Primary cost drivers: PU topcoat chemistry (DMF-free, waterborne), backing fabric spec, perforation density, thickness, colorway complexity, and finishing/lamination methods.

– Logistics and duties: Air leather is typically classified under PU textile fabrics (HS 5903), with 8% MFN duty in the USA and 8% duty in the EU; logistics vary materially by incoterms, lane, and mode.

– Savings levers: Reduce micro-perforation density and pattern complexity; standardize widths (≥140 cm) and roll lengths (50–60 m); bundle colors; source from a fabric mill with integrated coating/lamination; negotiate lead times for better yields.

Cost breakdown (typical B2B ranges; FOB vs. CIF)

| Item | Unit | Typical range | Notes |

|---|---|---|---|

| Fabric price (FOB Asia) | $/m² | $2.10–$3.50 | Varies with thickness (0.6–1.2 mm), PU chemistry, backing, and finish |

| Logistics (FOB Asia → USA/EU) | $/m² | $0.25–$1.10 | Sea ≈ $0.25–$0.50; air ≈ $0.70–$1.10; depends on lane, volume, and season |

| Duty (HS 5903) | % of CIF value | 8% | Applies in both USA and EU under MFN; local freight additional |

| Freight handling and delivery | $/m² | $0.05–$0.20 | Handling, last-mile; varies by port and warehouse location |

| Net landed cost (CIF USA/EU) | $/m² | $3.50–$5.80 | Fabric + logistics + duty + handling (excludes VAT) |

Typical total cost composition by cost bucket (FOB Asia)

| Bucket | Contribution (share) | Primary levers |

|---|---|---|

| Materials | 58–66% | PU chemistry, backing fabric, coating weight, perforation density |

| Labor | 7–11% | Lamination, embossing/perforation, QC; automation reduces unit labor |

| Utilities/Overhead | 8–12% | Energy, water, depreciation; coaters with scale have lower rates |

| Logistics/Incoterms | 18–24% | Mode, lane, packaging density; switching from air to sea halves logistics cost |

Price tiers by specification (FOB Asia)

| Grade | Thickness | Perforation density | Backside | Typical base price ($/m²) |

|---|---|---|---|---|

| Economy | 0.6–0.7 mm | Medium | Knit/polyester | $2.10–$2.60 |

| Standard | 0.8–0.9 mm | Medium | Knit/polyester | $2.60–$3.10 |

| Premium | 1.0–1.2 mm | Medium–High | Knit/jacquard | $3.10–$3.50 |

Major price multipliers

– Premium finishes: 10–25% (satin, high-grain emboss, anti-static, soft-touch topcoats).

– Micro-perforation density: +3–10% for dense patterns; plain micro-perforation ≈ +1–3%.

– Waterborne/DMF-free chemistries: +5–8% vs solvent-based.

– Embossing patterns and two-tone effects: +4–12% (tooling and setup).

– Certified chemistries and test coverage: +1–4% (REACH/SVHC screening, Prop 65, OEKO-TEX/RCS/BDS).

– Special widths: <130 cm widths may price higher or be unavailable; ≥140 cm standard widths reduce cost per use.

Material cost structure (what drives it)

– PU topcoat and layers: DMF-free, waterborne coatings typically cost 5–8% more than solvent-based.

– Backing fabric: Polyester knit or jacquard; heavier/power-stretch backings increase cost.

– Adhesives: Lamination strength vs flame-retardant (FR) additives add cost; FR versions often 5–10% higher.

– Finish and coatings: Anti-slip, anti-static, or high-grain embossing layers increase material and setup.

– Colorways: Bulk colors reduce changeover; specialized pigments and deep shades add 1–3%.

Illustrative Image (Source: Google Search)

Labor and manufacturing cost drivers

– Lamination and coating line speed: High-throughput lines lower per-square-meter labor; off-peak capacity offers discounts.

– Perforation and embossing: Laser/perforation tools and setups add fixed costs; standard patterns are cheaper.

– Finishing and trimming: Seam alignment and roll quality control influence rework and waste.

– Sampling and changeovers: New colors and patterns incur MOQs and setup; bundling reduces per-unit setup cost.

Logistics and incoterms (USA and EU)

– Duty: HS 5903 (PU-coated/laminated textiles) at 8% MFN duty in both USA and EU; additional local freight and handling apply.

– Incoterms: FOB vs CIF vs DDP shifts duty, freight, and risk to seller; DDP reduces buyer hassle but hides cost.

– Modes:

– Sea freight (LCL): $0.25–$0.50/m² lane-dependent; lead time 25–40 days.

– Air freight: $0.70–$1.10/m²; lead time 3–7 days; high volatility.

– Packaging: Rolls in sleeves + pallets; aim for 25–30 rolls per pallet; optimize cube to reduce per-square-meter freight.

– Testing and compliance: Buyers in EU should plan REACH/SVHC screening, OEKO-TEX for dyed articles, and VOC guidance; USA buyers typically follow Prop 65 labeling; plan $150–$350 per bill of lading for testing where required.

Risk, lead times, and MOQs

– MOQs: Standard colors 300–600 m; custom colors 800–1,500 m; custom perforation or embossing 1,000+ m.

– Lead times:

– Standard color: 10–15 days production + 3–5 days QC/roll prep + transit.

– Custom color: 20–25 days + transit.

– Custom perforation/emboss: 25–35 days + transit.

– Capacity: Fabric mills with integrated coating/lamination reduce lead times and cost.

Tips to save cost

– Simplify perforation: Use standard micro-hole patterns over bespoke dense matrices; saves 3–10%.

– Avoid solvent-based with DMF-free claims if not contractually required; waterborne is greener but costs more.

– Standardize widths to ≥140 cm and rolls to 50–60 m; minimizes waste on upholstery cutting and lowers per-yard price.

– Bundle colorways: Request ≤5 bulk colors per order to minimize setups; negotiate lower pricing on aggregated volumes.

– Move to bulk orders: Break-even typically ≥3,000 m per SKU; aggregate seasonal demand for better per-unit pricing.

– Shift to sea freight for routine replenishment; hold safety stock to avoid premium airfreight.

– Select mills with integrated coating/lamination; fewer handoffs reduce overhead and lead times.

– Consolidate shipments: Combine fabric and trims to improve container utilization; target ≥90% cube fill.

Illustrative Image (Source: Google Search)

How breather vs non-breather compares

– Air leather’s key differentiator is micro-perforation and/or woven backing that improves airflow; standard faux leather (PU) often lacks this.

– Pricing uplift vs non-breather: +2–8% depending on perforation density and pattern tooling; most buyers accept this for seating comfort and heat mitigation claims.

Validation and testing checklist

– Verify base cloth weight and PU thickness by production batch.

– Request REACH/SVHC compliance, OEKO-TEX Standard 100 or equivalent for dyed products, and Prop 65 reports for USA markets.

– Confirm flame-retardant (TB 117, EN 1021-1/-2) as required; FR versions typically add 5–10% cost.

– Validate perforation patterns and topcoat hardness to maintain tactile feel and durability.

Key takeaways

– Expect air leather at $2.10–$3.50/m² FOB Asia; net landed $3.50–$5.80/m² in USA/EU excluding VAT.

– The best cost-performance balance uses waterborne PU at 0.8–0.9 mm with standard micro-perforation and 140 cm width; plan MOQs of 300–600 m and 2–3 weeks lead time.

– Optimize sourcing by simplifying perforation patterns, standardizing widths, bundling colors, and shifting replenishment to sea freight with safety stock.

Alternatives Analysis: Comparing what is air leather With Other Solutions

Alternatives Analysis: Comparing Air Leather with Other Solutions

For commercial furnishing in the USA and Europe, two common alternatives to air leather are genuine leather and PU leather. Air leather is a PU-based woven fabric with micro‑perforations that allows airflow. The core value proposition is coolness, comfort, and a leather‑like touch without the stickiness of traditional faux leather or genuine leather on hot days. Below is a concise comparison and interpretation for B2B buyers.

Illustrative Image (Source: Google Search)

Comparative Table

| Criterion | Air Leather (PU‑based woven, micro‑perforated) | Genuine Leather | PU Leather (Standard) |

|---|---|---|---|

| Breathability & Temperature Comfort | High: micro‑perforations promote airflow; designed for “cool sit” | Moderate: can feel warm in heat; generally not perforated | Lower: typically heat‑retentive and prone to stickiness in warm conditions |

| Smell (Volatile Emissions) | Low: synthetic PU; ventilated weave helps reduce odor buildup | Low to moderate: leather tanning/finishing odors can linger initially | Low to moderate: can release odors depending on formulation |

| Cleaning & Maintenance | Straightforward: wipeable; ventilating weave aids evaporation | Requires conditioning/periodical treatments to prevent cracking | Wipeable; may hydrolyze with heat/humidity if low grade |

| Price Tier | Mid | High | Lower to mid (wide variability by quality) |

| Brand/Perception | Vegan, modern; leather‑like feel | Premium, heritage, natural | Vegan, functional; lower‑cost alternative |

| Sustainability & End‑of‑Life | PET‑compatible options exist; recyclability varies by stack; no animal inputs | Natural material; tanning impacts vary by process | Synthetic; end‑of‑life often landfill/incineration; recyclability limited |

| Typical Use Cases | Seating where heat comfort matters; premium‑feeling vegan range | High‑end contract/commercial projects; luxury segments | Budget or mid‑range projects where cost control is critical |

| Compliance Highlights | VOC and formaldehyde regulations apply in the US/EU; confirm material specs | Leather production regulated (e.g., REACH in EU for chrome use) | VOC and chemical controls apply; formulation‑specific |

| Procurement Notes | Confirm breathability stack, coating, perforations, and warranty | Verify hide quality, finish, and care regimen | Verify grade, base fabric, and moisture resistance warranty |

Analysis

- Choose air leather when temperature comfort and a vegan, leather‑like feel are priorities. Its micro‑perforations materially reduce heat buildup and stickiness versus standard PU leather and traditional genuine leather in warm conditions. ✅🔥

- Choose genuine leather when brand signal and premium durability are decisive. It delivers prestige and heritage but requires care and can feel warmer in heat. Be explicit about care, maintenance, and potential tanning standards. 🧭🛡️

- Choose standard PU leather when cost and ease of cleaning dominate. Manage expectations on breathability and potential hydrolysis over time by specifying grades and testing. 💰🧽

- In humid or high‑traffic environments, validate breathability and warranties through material tests. Ensure the air leather stack (coating, backer, perforations) is documented for compliance with US/EU VOC/formaldehyde limits.

Bottom line: Air leather solves the heat problem that keeps buyers from choosing PU faux leather, at a price premium over basic PU and a potential value premium over genuine leather when comfort is a decisive criterion. 😊

Essential Technical Properties and Trade Terminology for what is air leather

Essential Technical Properties and Trade Terminology for Air Leather

Overview of key points

– Composition and construction: Air leather is a synthetic alternative—typically polyurethane (PU) coated onto a woven or knit textile—engineered for breathability via micro-perforations; marketed as “leathaire.”

– Breathability and comfort: Micro-perforations enable air and moisture vapor transmission, reducing heat buildup and sweating versus conventional PU/PVC leather alternatives.

– Performance metrics: Key technical properties include abrasion resistance (Martindale), tear and tensile strength, dimensional stability, hand-feel, and lightfastness; values vary by product line and should be verified with suppliers.

– Certifications and compliance: Commonly REACH-compliant; other relevant certifications vary (OEKO-TEX, VOC/low-emission furniture standards) and must be confirmed for specific grades.

– Durability and maintenance: Suitable for indoor furniture (e.g., sofas, chairs) with cleaning via water-based methods; avoid strong solvents; specific care and abrasion warranties are SKU-dependent.

– Moisture and waterproofing: Breathability trades off with full waterproofing; surface hydrostatic pressure or WP ratings are product-specific and must be tested.

– Lead times and supply: Production lead times typically 4–8 weeks for custom orders; MOQs, dye lots, and dye-to-match vary by mill and coating line; stock vs. custom availability depends on mill capacity.

– Trade terms and risk: MOQ, OEM/ODM, private label, repeat orders and reorder windows, sampling timelines, and acceptance criteria (AQL, dimensional tolerances) should be defined in the commercial order.

– Applications and sustainability: Furniture upholstery, automotive interiors (seat/back/side trims), small leather goods; environmental claims differ across suppliers—request LCA, recycled content, and solvent policies.

– Procurement and QC: Validate performance via standardized tests, confirm certifications, align care labels, and document all technical specifications in spec sheets and contracts.

Composition and Construction

- Material base: PU resin applied to a woven or knit textile backing to emulate leather hand and appearance.

- Surface features: Micro-perforations (typically visible patterns) to enable air flow and moisture vapor transmission.

- Terminology alignment: Trade names include “air leather” and “leathaire”; not standardized as a material class in ISO/IEC standards; often traded as “breathable PU leather alternative” or “micro-perforated PU.”

Technical Properties (benchmarks to validate with suppliers)

- Thickness: Commonly 0.7–1.5 mm (trimmed; tolerances vary).

- Abrasion resistance: 50,000–150,000 Martindale cycles (product line dependent).

- Tensile strength and tear strength: Typically comparable to quality PU laminates; exact N/50 mm and N values should be confirmed in spec sheets.

- Dimensional stability: Tested via change-in-dimensions after accelerated aging/humidity cycles; ensure supplier data at 23°C/50% RH and 40°C/90% RH.

- Breathability/MVTR: Measured in g/m²/24h; micro-perforation patterns materially affect MVTR; confirm tested methods and results for SKU.

- Lightfastness: Minimum 4 (blue scale) is commonly used for indoor applications; validate per ISO 105-B02.

- Pilling resistance: Class 4/5 recommended for upholstery; test via ISO 12945-2 if applicable to the surface.

- Colorfastness to rubbing: Dry ISO 105-X12 ≥4; wet ≥3; confirm per SKU for upholstery use.

- Chemical and cleaning: Water-based cleaning recommended; avoid strong solvents; request chemical resistance lists for cleaning agents.

- Moisture handling: Breathability reduces heat and sweat; this typically limits full waterproofing; hydrostatic head (ISO 811) is SKU-specific.

Standards, Testing, and Compliance

- ISO/ASTM methods commonly referenced: Martindale (abrasion), ISO 3377 (tear), ISO 1421 (tensile), ISO 105-B02 (lightfastness), ISO 105-X12 (rubbing/crocking), ISO 12945-2 (pilling), ISO 811 (hydrostatic head).

- Flammability requirements: Region-dependent (e.g., TB 117-2013 for furniture components in California; equivalent EU national standards such as EN 1021 in furniture applications); consult upholstered assembly standards.

- Chemical compliance: REACH registration is typical; additional certifications (OEKO-TEX Standard 100, GREENGUARD/UL VOC emissions) are line-specific and should be requested.

- Sustainability: Recycled content, solvent usage policies, and LCA documentation vary; require product-specific environmental statements and compliance.

Performance Comparison: Air Leather vs Conventional PU/PVC Faux Leather

| Property | Air leather (micro-perforated PU) | Conventional PU (no micro-perforations) | PVC leather (leatherette) |

|---|---|---|---|

| Breathability/MVTR | Higher due to perforations | Lower | Lower |

| Comfort in warm conditions | Improved airflow, cooler touch | Warm, can feel tacky | Warm, less breathable |

| Abrasion performance | Similar (line-dependent) | Similar | Similar/varies |

| Lightfastness | Product-specific | Product-specific | Product-specific |

| Moisture handling | Better moisture vapor escape; not fully waterproof | Limited | Limited |

| Care | Water-based cleaning; avoid strong solvents | Water-based cleaning; avoid strong solvents | Water-based cleaning; avoid strong solvents |

| Sustainability claims | Vary by supplier (REACH baseline; optional certifications) | Vary | Vary |

| Applications | Furniture upholstery, interior auto trim | Furniture upholstery, interior auto trim | Cost-sensitive furniture upholstery |

Note: Numerical MVTR, hydrostatic head, and abrasion ratings should be taken from supplier test reports; they vary across product lines.

Applications

- Furniture: Sofas, sectionals, armchairs, accent chairs, headboards.

- Automotive interiors: Seat facings, back panels, side trims, door cards (confirm automotive specs if required).

- Small leather goods: Limited use cases requiring leather-like hand with breathability (check line suitability).

Environmental and VOC Considerations

- Emissions: Indoor air quality standards (e.g., GREENGUARD/UL) vary by grade; request test results for the specific SKU.

- Solvent use: Manufacturing lines may vary (water-based vs solvent-based systems); obtain chemical disclosure and policy.

- End-of-life: Disposal pathways depend on coating/backing composition; consult local regulations.

Care and Maintenance

- Cleaning: Use water-based cleaners; test in inconspicuous areas; avoid bleach and strong solvents.

- Storage: Avoid high heat and direct sunlight; maintain humidity and temperature stability to preserve dimensional stability.

Trade Terminology and Commercial Terms

| Term | Definition | Why it matters |

|---|---|---|

| MOQ (Minimum Order Quantity) | Smallest order volume a supplier will accept | Impacts cost, production scheduling, and inventory planning |

| Lead time | Production time from PO to shipment | Aligns with launch timelines and inventory replenishment |

| Sample approval | Pre-production sample confirmation | Reduces risk of mismatch in hand, color, and performance |

| Color matching/dye-to-match | Matching to a standard or batch | Ensures consistency across SKUs and replenishment orders |

| AQL (Acceptable Quality Level) | Statistical sampling plan for inspections | Establishes acceptable defect rates for production lots |

| OEM/ODM | Original equipment manufacturing/design | Enables customization vs. buying existing lines |

| Private label | Branding on standard or custom SKUs | Differentiates product without in-house manufacturing |

| Repeat orders/reorder window | Order cycles and availability windows | Predicts replenishment and reduces stockouts |

| Dimensional tolerance | Allowed variance in thickness, width, roll length | Critical for fit during upholstery and cutting |

| Roll length | Meters per roll | Influences yield and cutting optimization |

| Width | Roll width in cm/inch | Determines cutting layouts and seam strategies |

| Care label instructions | End-user maintenance guidance | Reduces warranty claims and improves user experience |

Supplier Evaluation and Sourcing Checklist

- Technical pack: Request thickness, weight, backing type, perforation pattern, MVTR, Martindale, tensile/tear, lightfastness, pilling, and dimensional stability data.

- Compliance: Confirm REACH status and obtain applicable certifications (OEKO-TEX, VOC emissions).

- Performance testing: Audit third-party test certificates or conduct in-house verification.

- Environmental documentation: Solvent usage policy, recycling content, and any available LCA summaries.

- Commercial terms: MOQ, lead time, AQL, payment terms, and warranty coverage aligned to use case.

- Color and dye lot control: Confirm dye lots, color-matching criteria, and repeat order color drift limits.

Sample and Development Process

- Sampling: Request material swatches and lab dips; expect 1–2 weeks for standard samples; longer for custom colorways.

- Pilot runs: For OEM/ODM, align on coating chemistry, perforation designs, and hand-feel targets before bulk production.

- Approval gates: Require sign-off on sample hand, color, and technical performance; incorporate AQL inspection upon first production batch.

Warranty and Risk Considerations

- Abrasion coverage: Warranties are SKU-specific (e.g., “X years on abrasion”); confirm test standards and exclusions.

- Lightfastness: Fade claims depend on exposure conditions; ensure care labels reflect realistic use environments.

- Staining and chemical resistance: Define acceptable cleaning agents and exclusions; document warranty exclusions for misuse.

Summary

Air leather is a breathable, synthetic PU-based alternative featuring micro-perforations that enable airflow and moisture vapor transmission, delivering superior comfort in warm conditions compared with conventional PU and PVC faux leathers. Its performance hinges on validated technical properties—abrasion, tensile/tear strength, dimensional stability, lightfastness, and MVTR—alongside compliance (REACH, optional certifications) and clear trade terms (MOQ, lead times, AQL, OEM/ODM). Effective sourcing requires comprehensive spec sheets, test reports, and care labeling to align durability, compliance, and user experience for furniture and select automotive interior applications.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics and Sourcing Trends in the what is air leather Sector

Navigating Market Dynamics and Sourcing Trends in the Air Leather Sector

Air leather—also marketed as leathaire—refers to breathable, micro-perforated polyurethane (PU) or microfiber composites that mimic leather while allowing air and moisture vapor to pass through the surface. The defining trait is its woven structure and micro-ventilation, which improves seating comfort compared with traditional PU or PVC “faux” leathers. For B2B buyers in the USA and Europe, this segment sits at the intersection of furniture, hospitality, contract interiors, and automotive interiors, with rising demand for breathable upholstery that balances durability, comfort, and price.

Market Dynamics

- Demand drivers

- Comfort-first procurement: End-users penalize heat buildup and stickiness in seating; air leather’s perceived coolness and air-permeability lower complaints in warm climates and dense installations.

- Vegan and “animal-friendly” positioning: While marketing narratives differ by market, air leather provides a synthetic alternative with a leather-like hand.

-

Interior designers shifting to breathable looks: Micro-perforated surfaces signal premium design intent and tactile differentiation without full leather cost.

-

Geography and use cases

- USA: Sofas, recliners, sectional and modular lounge programs, hospitality guestroom seating; growing adoption in healthcare waiting areas due to cleanability.

- Europe: High-traffic contract seating in offices, education, and hospitality; Scandinavian and UK designers favor breathable faux leathers for summer comfort and cost control.

-

Automotive: Seat side bolsters and inserts seeking airflow while meeting abrasion standards.

Illustrative Image (Source: Google Search)

-

Supply chain and resilience

- Chemistry-driven: Core materials are PU resin, solventborne or waterborne coatings, and often a microfiber nonwoven base. Chemistry controls tack, drape, hand, and breathability.

- China as the dominant manufacturing hub: Most capacity and innovation in breathable composites resides in coastal provinces; India and Vietnam have growing lines for value-tier products.

-

Lead times: Typical 60–90 days for standard colors in small to mid volumes; custom micro-perforation or embossing and long freight lanes can extend to 120+ days.

-

Cost and pricing dynamics

- Price index vs materials: Typically below full-grain leather and above basic PU; premium air leather competes with corrected grain leather and some premium PU.

-

Freight sensitivity: Micro-perforated fabrics add bulk; ocean freight volatility and container capacity influence landed cost predictability.

Illustrative Image (Source: Google Search)

-

Compliance and labeling

- Chemical management is central: EU REACH and California Prop 65 drive formulation disclosure, with increasing avoidance of certain plasticizers, solvents, and flame-retardant additives.

- Certifications vary: GREENGUARD/GREENGUARD Gold, OEKO-TEX Standard 100 (for textiles), and ISO 3795 (flame spread) are commonly requested in specification packages.

- Labeling: “Vegan leather” claims are common but carry risk; document material composition (PU, microfiber, backing) and verify against brand legal and marketing standards.

Sourcing Trends

- Manufacturing approaches

- Spunlaced nonwovens + breathable PU: Microfiber “leather” sheets with controlled micro-perforations; best hand-feel and abrasion performance, typically highest cost.

- Woven substrates + PU topcoat: Micro-perforations in the top coat; cost-efficient and widely available for furniture.

-

Air-mesh/3D knit + PU lamination: Breathability and cooling via open-mesh structures; very breathable with a different visual/aesthetic.

-

Innovation vectors

- Nano-perforation and controlled micro-porosity: Improve hand softness while maintaining airflow; reduces cracking versus thick coatings.

- Low-VOC chemistry and waterborne systems: Faster regulatory compliance and better odor performance in sealed environments.

- Coatings that resist scratching and UV discoloration: Critical for contract applications and hospitality turnover.

-

Bio-based polyurethane: Early-stage offerings with partial content (e.g., sugar-based polyols) and better CO₂ footprints; still niche with premium pricing.

Illustrative Image (Source: Google Search)

-

Quality and procurement focus

- Breathability metrics: Air permeability (L/m²/s) and Moisture Vapor Transmission Rate (MVTR, g/m²/24h) are frequently included in specifications.

- Durability: Martindale abrasion (Wyzenbeek in the USA) thresholds vary by contract tier; focus on seam slippage and tack points, not just surface wear.

- Hand and drape: The “leather-like” hand is often the selling point; sample testing against real leather and standard PU is recommended to validate tactile performance.

- Thermal comfort: Seat cooling is a user-perceived benefit; consider site climate and use intensity when selecting perforation density and pattern.

Sustainability and Circularity

- Environmental profile

- Petrochemical origin and end-of-life: PU-based air leather is not biodegradable and presents recyclability challenges; avoid biodegradable claims unless validated via formal LCA.

-

LCA signals: Waterborne systems and recycled content reduce emissions and VOC exposure; bio-based PU improves cradle-to-gate impact but carries higher cost and supply variability.

-

Circularity and responsible sourcing

- Recycled microfiber content: Increasing availability for value and mid tiers; verify source traceability and content percentage.

- Repairability and longevity: Choose abrasion-optimized grades to extend replacement cycles; microfiber-based products typically outperform standard PU in long-term durability.

- Take-back or recycling programs: Rare in this category; monitor pilot programs by Chinese compounders and specialty mills.

Procurement Benchmarks: Alternatives and Attributes

| Alternative/Type | Feel/Hand | Breathability | Durability (relative) | Price Index (relative) | Sustainability Angle | Best Applications |

|---|---|---|---|---|---|---|

| Microfiber leather + breathable PU (air leather) | Premium leather-like | High (micro-perforation) | High | High | Low-VOC options; recycled content possible | Contract seating, recliners, hospitality |

| Woven PU topcoats with micro-perforation | Good | Moderate to high | Good | Mid | Waterborne systems increasingly available | Price-sensitive sofas, lounges |

| Air-mesh/3D knit + PU lamination | Lightweight | Very high | Moderate | Low to mid | Lower material weight; lower VOC options | Summer/seasonal seating, warm climates |

| Bio-based PU (partial content) | Variable | Variable | Variable | Premium | Lower cradle-to-gate emissions; limited supply | Experimental or premium niche programs |

| Traditional PU/PVC faux leather | Good | Low | Good | Low to mid | Lower footprint vs PVC; no biodegradability | Budget upholstery where breathability is secondary |

Buyer Checklist (USA/EU)

- Confirm intended use and climate: Higher perforation density for warm climates and long seated durations.

- Request technical data: Air permeability, MVTR, Martindale/Wyzenbeek, seam slippage, VOC/REACH and Prop 65 statements, ISO 3795 for flame spread.

- Request odor and tactile samples: Validate “leather-like” claims against real leather and standard PU; confirm tack points and stretch behavior.

- Chemistry and labeling compliance: Use standardized Supplier Substance Declarations (e.g., ZDHC MRSL) and review marketing claims for “vegan leather.”

- Logistics and lead times: Factor 60–90+ day lead times; secure inventory buffers and consider alternative perforation patterns for supply flexibility.

In short, air leather is moving from niche to mainstream where breathability, tactile performance, and moderate durability intersect. Sourcing success in 2025 hinges on chemistry selection (especially waterborne, low-VOC systems), supplier transparency on REACH/Prop 65, and performance validation through rigorous lab and wear testing.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of what is air leather

Air Leather FAQs for B2B Buyers

1) What is air leather?

A breathable, man‑made alternative to leather made from polyurethane (PU). It features a woven base and a surface with micro‑perforations that allow airflow, giving it a leather‑like feel without sweating like traditional leather or dense faux leather. Also marketed as “leathaire.” Vegan if formulated without animal‑based inputs.

2) How is it manufactured?

- Base: Woven fabric substrate (e.g., polyester knit) providing dimensional stability and hand.

- Surface: PU film/finish with micro‑perforations and a leather‑like grain.

- Process: The PU is applied and finished on the woven backing; perforations are created to enable breathability.

- Source note: Made from petroleum‑derived PU; fully synthetic.

3) What are the key performance attributes?

| Attribute | What to expect | Trade‑off to consider |

|---|---|---|

| Breathability | Air flow via micro‑perforations | Lower moisture barrier than non‑perforated PU |

| Feel/hand | Leather‑like softness and texture | Varies by supplier/finish |

| Durability | Contract‑grade options available | Abrasion/stitch tear depend on backing/finish |

| Appearance | Smooth grain with tonal variation options | Grain pattern uniformity varies |

| Maintenance | Wipe‑clean with mild agents | Avoid high pH or solvent cleaners |

| Odor | Low odor when new | Off‑gas can vary; request MSDS and verify |

| Environmental note | PU derived from petroleum | Post‑consumer recycling challenges; check take‑back programs |

4) Which applications is it suited for?

- Seating: contract sofas, lounge chairs, ottomans, headboards; ideal where temperature comfort matters (hospitality, corporate lounges, education, retail).

- Accessories: decorative panels, wall elements, accent furniture components.

- Limit use: heavy‑wear outdoor, wet zones, or applications requiring strong moisture barriers unless a protective topcoat is specified.

5) How does air leather perform compared to leather, PU leather, and fabric?

| Material | Comfort | Breathability | Maintenance | Cost/Availability | Best use cases |

|---|---|---|---|---|---|

| Real leather | Warm, premium | Moderate (wears open) | Conditioning required | Higher | High‑end office, luxury hospitality |

| PU (non‑perforated) | Soft | Low‑moderate | Easy | Lower | Budget seating, accessories |

| Air leather | Cool, comfortable | Higher due to micro‑perforations | Easy | Moderate | Contract/comfort seating |

| Fabric | Varies | Often good | Varies (stain guard helps) | Moderate‑low | Long‑term durability; heavy‑use seating |

6) Is air leather vegan and compliant for the USA/EU?

- Vegan: Yes, if made only with synthetic materials and no animal‑based finishes. Confirm with suppliers.

- Compliance (request certificates as applicable):

- REACH (EU): SVHC disclosure for PAHs, plasticizers, and colorants; ask for REACH/SVHC statements and relevant test reports.

- Prop 65 (US-CA): Confirm compliance and request Prop 65 statements where needed.

- VOC/off‑gassing: Ask for MSDS/SDS and VOC test data; request room temperature and storage stability specifications.

- Fire safety: Check FR compliance for the intended market/standard; verify FR treatments used are compliant (e.g., no restricted flame retardants if applicable).

7) What are the care and cleaning recommendations?

- Routine: Vacuum or dry brush; wipe with mild soap solution and soft cloth; rinse with water; air dry fully.

- Stains: Blot, don’t rub. Use gentle, water‑based cleaners; avoid solvents, harsh chemicals, and high‑pH products.

- Maintenance: Periodically reapply compatible leather/PU protector per supplier guidance if recommended.

- Colorfastness: Check wet/dry rub results; use mild detergents; test in an inconspicuous area first.

8) What should I verify with suppliers before purchase?

| Item | What to request/verify |

|---|---|

| Composition/spec | Full stack: woven backing type, PU system, finish/topcoat, thickness, weight |

| Breathability data | Perforation pattern and airflow/permeability metrics (e.g., ASTM D737, ISO 7233) |

| Durability | Martindale/abrasion, tear/stitch tear, stretch set, colorfastness (wet/dry rub) |

| Compliance | REACH/SVHC statement, Prop 65 where applicable, VOC off‑gassing data, MSDS/SDS |

| FR | Relevant FR certification/test results for market (e.g., EN 1021, NFPA 260, TB117‑2013, CAL 117) |

| Warranty/returns | Minimum acceptable specs, warranty length, acceptance criteria |

| Sustainability | Take‑back/recycling options; packaging sustainability; low‑VOC manufacturing |

| MOQ/lead times | Standard sizes, custom colors/grains, production schedule, logistics |

Strategic Sourcing Conclusion and Outlook for what is air leather

Strategic Sourcing Conclusion and Outlook

Air leather delivers a clear, defensible edge: breathable comfort at leather-like appearance and touch. Its micro-perforated polyurethane construction reduces heat buildup, making it a superior alternative to conventional PU or genuine leather for high-contact seating. In B2B terms, it pairs differentiated product experience with stable, synthetic supply.

Breathability comparison (typical, verify with suppliers):

| Material | Breathability | Feel | Durability | Cost Range | Typical MOQ | Sustainability/Regulatory Considerations | Typical Use Cases |

|——————–|—————|————————–|————|———————-|————-|————————————————————|—————————————-|

| Air leather | High | Leather-like, cooler sit | Good | Mid | Moderate | PU-based; ensure VOC/fire-retardant compliance (US/EU) | Contract/commercial seating, residential |

| Genuine leather | Low | Premium, warms over time | High | High | Large hides | Complex hides variability; tanning effluent regulations | Premium sofas, case goods |

| PU/Faux leather | Low–Medium | Plastic hand, warmer | Good | Low–Mid | Moderate | PU; check plasticizer/halogen FR restrictions | Budget seating, wall panels |

| Textiles | High | Soft, breathable | Variable | Wide | Moderate | FR treatments must meet BS 5852 (EU), TB 117 (US) | Upholstery across segments |

Sourcing outlook (USA/EU):

– Differentiate through comfort; communicate the “no sweat” claim with testing data (air permeability, thermal contact temperature).

– Source mid-tier brands for stable quality and lead times; Asia offers lowest cost, EU/US offer proximity and tighter compliance ecosystems.

– Negotiate MOQs, colorbank consistency, seam slippage/friction specs, and abrasion performance; request batch-to-batch color control.