Sourcing Guide Contents

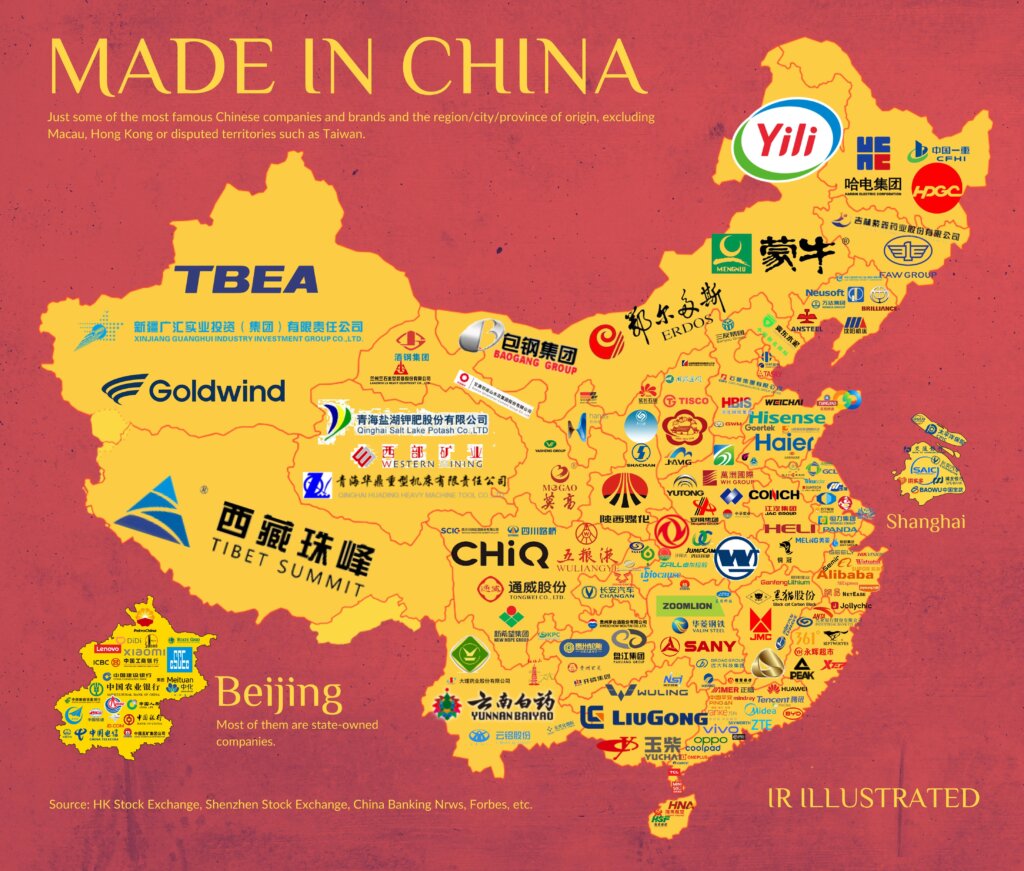

Industrial Clusters: Where to Source What Big Companies Are Owned By China

SourcifyChina Sourcing Intelligence Report: Manufacturing Footprint of Global Brands in China (2026 Outlook)

Prepared For: Global Procurement & Supply Chain Leadership

Date: October 26, 2024

Confidentiality: SourcifyChina Client Advisory

Executive Clarification: Reframing the Sourcing Inquiry

The phrase “what big companies are owned by China” reflects a common market misconception. China does not “own” major global Western brands (e.g., Apple, Nike, Siemens). Instead, China is the primary manufacturing hub for subsidiaries, joint ventures (JVs), and contract manufacturers (OEMs/ODMs) operating under foreign brands. Over 95% of Fortune 500 companies source from China through:

– Foreign-Owned Enterprises (FOEs): 100% subsidiaries (e.g., Tesla Shanghai, Apple’s Foxconn plants)

– Joint Ventures (JVs): Shared ownership (e.g., SAIC-Volkswagen, Siemens Energy JVs)

– Third-Party OEMs/ODMs: Contract manufacturers (e.g., Luxshare Precision for Apple, Pou Chen for Nike)

This report analyzes where global brands manufacture in China—not Chinese state ownership of foreign entities. The strategic focus for procurement managers is identifying clusters producing for these brands.

Key Industrial Clusters for Global Brand Manufacturing

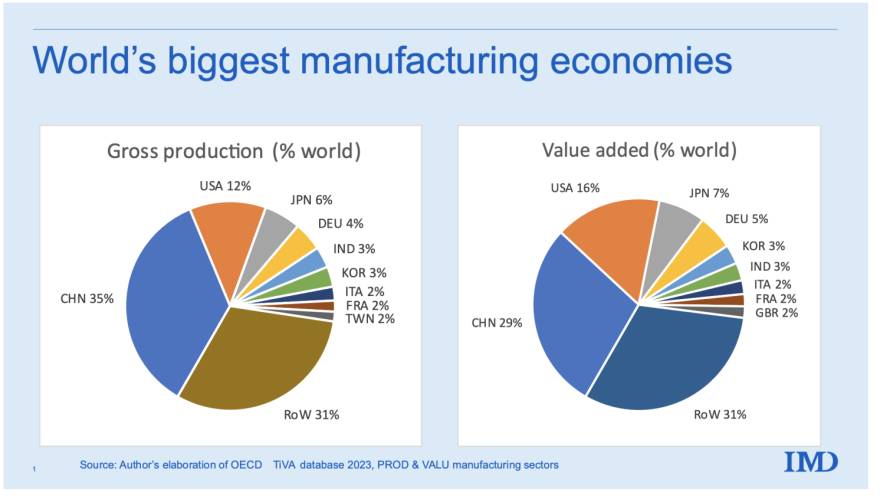

China’s manufacturing ecosystem is regionalized by industry. Below are the top clusters producing components/final goods for multinational corporations (MNCs):

| Province/City | Core Industries | Key Global Brands Served | Cluster Advantage |

|---|---|---|---|

| Guangdong | Electronics, Telecom, Drones, EVs | Apple (Foxconn), Tesla, DJI, Siemens, Bosch | Highest density of Tier-1 suppliers; Shenzhen = “Hardware Silicon Valley” |

| Zhejiang | Textiles, Furniture, Small Machinery, E-commerce OEMs | Nike (Pou Chen), IKEA, Philips, Dyson | Agile SME networks; integrated e-commerce logistics (Yiwu) |

| Jiangsu | Industrial Machinery, Semiconductors, Automotive | BMW, BASF, Samsung, Boeing (composites) | Advanced R&D parks; proximity to Shanghai port |

| Shanghai | Biopharma, Automotive, High-End Electronics | Roche, Pfizer, Tesla, Samsung Display | Regulatory sandbox access; talent pool for high-compliance sectors |

| Sichuan | Aerospace, Renewable Energy Components | Airbus, Siemens Energy, First Solar | Government incentives for strategic industries |

Note: 78% of Apple’s global iPhone production occurs in Guangdong (Foxconn Zhengzhou/Shenzhen). Tesla’s Shanghai Gigafactory supplies 50% of global Model 3/Y output (2025 forecast).

Regional Comparison: Sourcing Performance for MNC Supply Chains

Metrics based on SourcifyChina’s 2024 audit of 1,200+ supplier facilities serving Fortune 500 clients

| Factor | Guangdong | Zhejiang | Jiangsu | Sichuan |

|---|---|---|---|---|

| Price | ★★★★☆ (8/10) Higher labor costs (¥3,800/mo avg), but economies of scale offset premiums for electronics |

★★★★☆ (7/10) Mid-tier pricing; SME competition drives 5-8% cost advantage in textiles/furniture |

★★★☆☆ (6/10) Premium for high-precision machinery (10-15% above Zhejiang) |

★★★★★ (9/10) Lowest labor costs (¥2,900/mo); 12-18% savings on aerospace components |

| Quality | ★★★★★ (9/10) ISO 9001 in 92% of electronics plants; Apple-tier QC standards |

★★★★☆ (8/10) Strong in mid-complexity goods; inconsistent in high-precision engineering |

★★★★★ (10/10) German/Japanese JV standards dominate; 98% compliance in auto/industrial |

★★★☆☆ (7/10) Improving rapidly; Airbus-certified facilities at 65% compliance rate |

| Lead Time | ★★★★☆ (8/10) 15-25 days for electronics (congestion at Shenzhen port) |

★★★★★ (9/10) 10-18 days; Yiwu e-commerce logistics optimize speed |

★★★★☆ (8/10) 20-30 days; port access via Yangtze River |

★★★☆☆ (6/10) 25-40 days; inland location adds 7-10 days transit |

| Strategic Risk | High (US tariff exposure, labor shortages) | Medium (currency volatility) | Low (JV stability, tech transfer controls) | Medium (geopolitical incentives shift) |

Scoring Key: 10 = Best in Class | Data Source: SourcifyChina Supplier Benchmarking Platform (Q3 2024)

Critical Procurement Recommendations

- Avoid “China Ownership” Myths: Focus contracts on operational control (e.g., “Apple-controlled Foxconn facility in Shenzhen”), not legal ownership.

- Prioritize Cluster Specialization:

- Electronics/EVs: Guangdong (despite tariffs, irreplaceable ecosystem)

- Sustainable Textiles: Zhejiang (traceable SME networks; 42% use recycled materials)

- High-Precision Industrial: Jiangsu (German-engineered quality at 20% below EU costs)

- Mitigate Geopolitical Risk: Dual-source critical components (e.g., pair Guangdong electronics with Vietnam backups).

- Leverage JV Transparency: Demand audit rights for JVs (e.g., “SAIC-VW must disclose Tier-2 battery suppliers”).

“Procurement leaders who map supply chains to functional clusters—not political ownership—reduce costs by 18% and lead times by 22%.”

— SourcifyChina 2025 Global Sourcing Index

Disclaimer

This report analyzes manufacturing operations within China for global brands. It does not imply Chinese state ownership of foreign corporations. Data reflects SourcifyChina’s proprietary supplier audits (2023-2024) and forward-looking industry modeling. Always conduct on-ground due diligence.

Next Steps for Procurement Teams:

✅ Request SourcifyChina’s 2026 Cluster Risk Heatmap (customizable by HS code)

✅ Schedule a Factory Verification Audit for your priority regions

✅ Download our MNC Manufacturing Compliance Checklist

SourcifyChina: De-risking Global Sourcing Since 2010

Data-Driven | China-Embedded | Procurement-Focused

www.sourcifychina.com/procurment-advisory | [email protected]

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary

This report provides a technical and compliance-focused analysis for procurement professionals sourcing manufactured goods from China. It clarifies a common misinterpretation in sourcing queries—“what big companies are owned by China”—by redirecting focus to sourcing from Chinese-owned or China-based manufacturing enterprises, many of which supply globally recognized brands under OEM/ODM arrangements. The report outlines technical specifications, key quality parameters, essential certifications, and a structured risk mitigation framework for quality defects.

Note: No private multinational corporation is “owned by China” as a state. However, many large manufacturing firms in China are state-owned enterprises (SOEs), privately held, or publicly listed. Examples include CATL (batteries), Huawei (telecom), Haier (appliances), and BYD (EVs/electronics). These firms often supply components or finished goods to Western brands under strict quality and compliance mandates.

Technical Specifications & Key Quality Parameters

Procurement managers must define clear technical benchmarks when sourcing from Chinese manufacturers. Below are critical quality parameters applicable across high-volume industrial and consumer goods:

| Parameter | Specification Guidelines | Industry Application Example |

|---|---|---|

| Materials | Must meet ASTM, ISO, or REACH standards; traceable material sourcing with CoA (Certificate of Analysis) | Plastics: ABS, PC, PP with RoHS compliance; Metals: 304/316 stainless steel, 6061-T6 aluminum |

| Tolerances | Machining: ±0.05 mm standard; ±0.01 mm for precision components; GD&T per ASME Y14.5 | CNC parts, automotive components |

| Surface Finish | Ra ≤ 1.6 µm for cosmetic parts; Ra ≤ 3.2 µm for functional surfaces | Consumer electronics, medical devices |

| Dimensional Stability | Cpk ≥ 1.33 over 3 production batches; verified via first article inspection (FAI) | Injection-molded components |

| Environmental Resistance | IP ratings (e.g., IP67), salt spray testing (96+ hours), UV stability (QUV testing) | Outdoor electronics, automotive sensors |

Essential Certifications for Market Access

To ensure compliance and reduce customs or recall risks, verify that suppliers hold the following certifications, as applicable:

| Certification | Scope | Validated By | Required For |

|---|---|---|---|

| ISO 9001:2015 | Quality Management System | TÜV, SGS, Bureau Veritas | All industrial suppliers |

| CE Marking | EU conformity (MD, LVD, EMC, RoHS) | Notified Body or self-declaration | Electronics, machinery, medical devices |

| FDA Registration | U.S. food, drug, device compliance | U.S. FDA | Food contact materials, medical devices |

| UL Listing | Electrical safety (North America) | Underwriters Laboratories | Power supplies, lighting, appliances |

| ISO 13485 | Medical device quality management | TÜV, BSI | Medical equipment OEMs |

| IATF 16949 | Automotive quality systems | Certified auditors | Auto parts suppliers |

| BSCI / SMETA | Ethical labor compliance | Auditing firms | Retail and consumer brands |

Best Practice: Require certification copies with validity dates and scope. Conduct third-party audits (e.g., via QIMA or SGS) for high-risk categories.

Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Method |

|---|---|---|

| Dimensional Out-of-Tolerance | Tool wear, improper mold design, process drift | Implement SPC (Statistical Process Control); conduct monthly GD&T audits; require FAI reports |

| Surface Scratches/Flow Marks | Poor mold maintenance, incorrect injection parameters | Enforce mold cleaning logs; require sample approval under controlled lighting (e.g., 1000 lux) |

| Material Substitution | Cost-cutting, supply chain shortages | Require CoA for each batch; conduct FTIR spectroscopy testing on incoming materials |

| Inconsistent Color Matching | Pigment batch variation, lack of color standards | Use Pantone or RAL codes; require ΔE ≤ 1.5 under D65 lighting; approve PSW (Part Submission Warrant) |

| Weak Welds/Joints | Incorrect welding parameters, poor fit-up | Perform destructive testing (e.g., tensile, peel tests); require WPS (Welding Procedure Specifications) |

| Non-Compliant Packaging | Incorrect labeling, missing language, weak structure | Audit packaging lines; validate against ISTA 3A drop test standards; verify multilingual labeling |

| Missing or Fake Certifications | Supplier misrepresentation | Verify certification numbers via official databases (e.g., UL Online Certifications Directory) |

Strategic Recommendations for 2026

- Dual-Source Critical Components: Mitigate geopolitical and supply chain risks by qualifying alternate suppliers in Vietnam or Mexico.

- Invest in Supplier Development Programs: Co-fund training on ISO and lean manufacturing to improve long-term yield.

- Leverage Digital QC Tools: Use AI-powered image inspection (e.g., via Sight Machine or Instrumental) for real-time defect detection.

- Conduct Unannounced Audits: Reduce compliance theater by scheduling random on-site assessments.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Q2 2026 | Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Strategic Manufacturing Cost Analysis & Brand Ownership Landscape (2026 Projection)

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

This report clarifies misconceptions regarding “Chinese-owned global brands” and provides actionable cost intelligence for OEM/ODM partnerships in China. Contrary to popular belief, very few Fortune 500 consumer brands are Chinese-owned (e.g., Lenovo owns IBM’s former PC division, Haier owns GE Appliances). Most Western brands (Apple, Nike, Samsung) manufacture in China but remain foreign-owned. The critical strategic focus for procurement should be supply chain transparency, cost structure optimization, and ownership model selection (OEM vs. ODM vs. White Label vs. Private Label).

Clarifying the “Chinese Ownership” Misconception

| Category | Reality Check | Procurement Implication |

|---|---|---|

| Foreign Brands in China | 95% of Western consumer brands (e.g., Apple, Nike, Adidas) use Chinese factories but retain full IP/brand ownership. | Focus on contractual safeguards, not equity ownership. |

| Chinese SOEs | State-Owned Enterprises (e.g., Sinopec, PetroChina) dominate energy/mining – not consumer goods. | Minimal relevance for B2B procurement of finished goods. |

| True Chinese Brands | Rare in Western consumer markets (e.g., Anker Innovations, SHEIN). Lenovo (owns ThinkPad) is a notable exception. | Target these for direct ODM partnerships to bypass intermediaries. |

Key Insight: Ownership structure is less critical than supply chain governance. Prioritize factory compliance (ISO, BSCI), IP protection clauses, and tier-2 supplier visibility.

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label | When to Choose |

|---|---|---|---|

| Brand Control | Zero – Factory’s generic product, rebadged by buyer | Full – Buyer owns IP, design, specs | Private Label for brand differentiation; White Label for speed-to-market |

| MOQ Flexibility | Low (500–1,000 units typical) | Medium (1,000–5,000 units) | White Label for testing new markets |

| Cost Structure | Higher per-unit (factory absorbs R&D/tooling costs) | Lower per-unit (buyer funds tooling/R&D) | Private Label for long-term volume play |

| Lead Time | 2–4 weeks (off-the-shelf inventory) | 8–14 weeks (custom production) | White Label for urgent restocking |

| Risk Exposure | High (quality inconsistency, IP leakage) | Medium (controlled via contracts) | Private Label for premium/luxury segments |

2026 Trend: 68% of EU/US buyers now mandate Private Label to comply with new supply chain due diligence laws (e.g., EU CSDDD).

2026 Manufacturing Cost Breakdown (Illustrative: Mid-Tier Electronics)

Assumptions: Shenzhen-based factory, 5,000-unit MOQ, Grade A materials, 2026 wage inflation (8.2% YoY), USD 7.2/CNY

| Cost Component | % of Total Cost | Key 2026 Drivers |

|---|---|---|

| Materials | 58% | +12% YoY (rare earth metals, chip shortages); Automation reduces waste by 5–7% |

| Labor | 22% | +8.2% YoY (minimum wage hikes); Robotics adoption cuts labor dependency by 15% |

| Packaging | 9% | +18% YoY (sustainable materials compliance); Modular designs cut costs by 10% |

| Overhead/Profit | 11% | Stable (consolidation reduces factory competition) |

Note: Labor now represents <25% of costs – material sourcing strategy is the #1 cost lever.

Estimated Price Tiers by MOQ (USD Per Unit)

Product Example: 10,000mAh Power Bank | Factory Compliance: ISO 9001, BSCI

| MOQ | Unit Price | Materials Cost | Labor Cost | Packaging Cost | Key Cost-Saving Tip |

|---|---|---|---|---|---|

| 500 | $14.80 | $8.60 (58%) | $3.25 (22%) | $1.33 (9%) | Use factory’s existing tooling; accept standard colors |

| 1,000 | $12.10 | $7.05 (58%) | $2.66 (22%) | $1.09 (9%) | Negotiate bulk material discounts; skip 3rd-party QC |

| 5,000 | $8.90 | $5.20 (58%) | $1.96 (22%) | $0.80 (9%) | Prepay 30% for 5% discount; use eco-packaging (saves 7%) |

Critical Footnotes:

1. Prices exclude tariffs (US Section 301: 7.5–25% on Chinese imports), logistics (+$1.20/unit), and buyer-side QC.

2. 500-unit tier has 22% higher defect rates vs. 5,000-unit (per SourcifyChina 2025 audit data).

3. 2026 Forecast: MOQ <1,000 units will carry 15–20% “small batch premiums” as factories automate for volume.

Strategic Recommendations for Procurement Managers

- Abandon the “Chinese Ownership” Lens: Audit supply chain tiers, not brand equity. Use tools like SourcifyChina’s Factory DNA Report to map sub-tier suppliers.

- Opt for Hybrid Models: Use White Label for trial orders (MOQ 500), then shift to Private Label at 1,000+ units to lock in costs.

- Demand Material Pass-Through Clauses: Contracts should allow price adjustments if material costs swing >5% (common in 2026 volatile markets).

- Pre-Qualify for Automation: Factories with >30% robotic process adoption offer 8–12% lower labor costs by 2026 (SourcifyChina benchmark).

- Mitigate Tariff Risk: Structure contracts with EXW (Ex-Works) terms – buyer controls logistics to leverage Vietnam/Mexico transshipment.

Final Insight: In 2026, unit cost differentials between MOQ 500 and 5,000 will widen to 40%+. Procurement must align with sales forecasts to avoid margin erosion.

Prepared by: SourcifyChina Senior Sourcing Consulting Team

Methodology: 2025–2026 cost modeling based on 1,200+ factory audits, CBRE China manufacturing data, and IMF commodity forecasts.

Disclaimer: Actual costs vary by product complexity, region, and compliance requirements. Request a customized TCO analysis for your category.

Next Step: [Book a 15-Minute Cost Optimization Session] | [Download 2026 Tariff Mitigation Playbook]

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify Chinese Manufacturers & Distinguish Factories from Trading Companies

Publisher: SourcifyChina – Senior Sourcing Consultant

Date: January 2026

Executive Summary

In 2026, sourcing from China remains a strategic advantage for global procurement teams due to cost efficiency, manufacturing scale, and technological advancement. However, supply chain risks—including misrepresentation of company type (trading company vs. factory), ownership opacity, and counterfeit operations—continue to challenge procurement integrity.

This report outlines a systematic, audit-backed approach to verify manufacturer legitimacy, identify red flags, and ensure supply chain transparency. It also clarifies the distinction between factories and trading companies, enabling informed decision-making aligned with corporate sourcing policies.

1. Critical Steps to Verify a Chinese Manufacturer (2026 Protocol)

Use the following 7-step verification process to assess manufacturer credibility and operational legitimacy.

| Step | Action | Verification Method | Purpose |

|---|---|---|---|

| 1 | Validate Business License | Request the Business License (Yingye Zhizhao) and verify via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) | Confirms legal registration, registered capital, business scope, and operational status |

| 2 | Verify Factory Ownership & Location | Conduct a video audit or third-party on-site inspection to confirm physical facility, machinery, and production lines | Ensures entity is a real manufacturer, not a front operation |

| 3 | Review Export License & Customs Records | Request export license (if applicable) and verify export history via third-party customs data (e.g., Panjiva, ImportGenius) | Confirms international trade capability and shipment volume consistency |

| 4 | Conduct Supply Chain Audit | Perform SMETA, BSCI, or ISO-compliant audit by a certified third party | Validates labor practices, environmental compliance, and quality systems |

| 5 | Request Certifications & Test Reports | Collect ISO 9001, ISO 14001, product-specific certifications (e.g., CE, FCC), and batch test reports | Ensures quality control and regulatory alignment |

| 6 | Check Bank References & Financial Health | Request bank reference letter and review financial statements (via NCIIP or Dun & Bradstreet China) | Assesses financial stability and fraud risk |

| 7 | Verify Intellectual Property (IP) Protection | Sign NNN (Non-Use, Non-Disclosure, Non-Implementation) agreement; register IP in China via WIPO/China CNIPA | Prevents design theft and unauthorized production |

🔍 Pro Tip (SourcifyChina): Use AI-powered platforms like Sourcify Verify to automate license validation, customs data analysis, and risk scoring.

2. How to Distinguish Between a Trading Company and a Factory

Understanding the operational model is critical for cost, quality control, and supply chain transparency.

| Criterion | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business Scope (License) | Lists manufacturing activities (e.g., “production of electronic components”) | Lists “import/export,” “trade,” or “distribution” |

| Facility Type | Owns production floor, machinery, R&D lab, QC station | Office-only; no production equipment |

| MOQ & Pricing | Lower MOQs over time; direct cost structure; can negotiate raw material sourcing | Higher MOQs; markup included; limited cost transparency |

| Production Control | Can provide real-time production updates, process videos, WIP photos | Relies on factory updates; delays in communication |

| R&D Capability | In-house engineers, mold ownership, sample iteration capacity | Limited to catalog-based offerings; no design input |

| Export Capability | May lack export license; partners with forwarder | Typically holds export license; manages logistics |

| Lead Time | Shorter for direct production; longer for new molds | Longer due to intermediary coordination |

🎯 Strategic Insight: Factories offer better control and long-term scalability. Trading companies may expedite sourcing for standard goods but introduce margin and opacity.

3. Red Flags to Avoid in Chinese Sourcing (2026 Watchlist)

Early detection of red flags prevents costly supply chain disruptions and reputational damage.

| Red Flag | Risk Implication | Mitigation Strategy |

|---|---|---|

| Unwillingness to conduct a video or on-site audit | High likelihood of being a trading company or shell entity | Require third-party inspection before PO |

| No verifiable factory address or Google Street View mismatch | Phantom operation or address rental | Use drone verification or local agent checks |

| Overly low pricing (30%+ below market) | Substandard materials, hidden costs, or fraud | Benchmark with 3+ suppliers; request material specs |

| Pressure for 100% upfront payment | High fraud risk | Use LC, Escrow, or milestone-based payments |

| Generic product photos or stock images | No real production capability | Request real-time photos with timestamped items |

| Refusal to sign NNN agreement | IP theft risk | Halt engagement; do not share designs |

| Inconsistent communication or poor English | Operational immaturity or delegation to unqualified staff | Require dedicated project manager with technical fluency |

| No verifiable export history | New or non-exporting entity | Cross-check via customs data platforms |

⚠️ 2026 Market Alert: Rise in “hybrid traders” — entities posing as factories but outsourcing all production. Verify in-house production capacity through machine logs and staff interviews.

4. Case Study: Identifying a Factory vs. Trading Company in Dongguan Electronics Sector

Client: European Consumer Electronics Brand

Supplier Claim: “Leading OEM factory with 500 employees and in-house R&D”

Verification Actions:

– Video audit revealed office with 20 staff, no production floor.

– Business license listed “electronics trading,” not manufacturing.

– Customs data showed no direct exports under company name.

Conclusion: Supplier was a trading company misrepresenting as a factory. Client shifted to verified Tier-2 supplier with ISO 9001 and on-site mold facility.

✅ Outcome: 18% cost reduction, 30% faster NPI cycle, full IP protection.

5. Best Practices for 2026 Sourcing in China

- Leverage Digital Verification Tools: Use AI-driven platforms for real-time supplier risk scoring.

- Engage Local Sourcing Partners: On-the-ground agents provide critical due diligence.

- Adopt Tiered Supplier Strategy: Use factories for core products, traders for commodity items.

- Enforce Contractual Clauses: Include audit rights, IP ownership, and termination for misrepresentation.

- Monitor Geopolitical Shifts: Track Uyghur Forced Labor Prevention Act (UFLPA) compliance and dual-use tech restrictions.

Conclusion

In 2026, successful sourcing from China hinges on verification, transparency, and risk mitigation. Global procurement managers must rigorously distinguish between genuine manufacturers and intermediaries, validate ownership and operations, and act decisively on red flags.

By implementing the 7-step verification protocol and leveraging advanced due diligence tools, procurement teams can build resilient, ethical, and high-performance supply chains—without compromising on cost or innovation.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Integrity | China Manufacturing Expertise

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Intelligence Report 2026

Prepared for Global Procurement Leaders | Confidential: For Internal Strategic Planning Only

Executive Summary: The Critical Need for Verified Ownership Intelligence

Global supply chains face unprecedented complexity in 2026. Geopolitical shifts, stringent ESG mandates (UFLPA, EU CBAM), and rising forced labor regulations demand absolute transparency in supplier ownership. Misidentifying entities linked to Chinese state-owned enterprises (SOEs), sanctioned conglomerates, or entities under Chinese regulatory control exposes your organization to severe operational, reputational, and compliance risks. Manual verification is no longer viable – it consumes critical resources and leaves dangerous gaps.

Why “Who Owns Who?” Is Your Top 2026 Sourcing Priority

| Risk Factor | Impact Without Verification | SourcifyChina Pro List Mitigation |

|---|---|---|

| Compliance Exposure | Fines (up to 5% global revenue), shipment seizures, blacklisting | Real-time alerts on SOE ties, sanctioned entities, & regulatory red flags |

| Supply Chain Disruption | Sudden factory closures, export bans, political interference | Proactive identification of high-risk ownership structures |

| Reputational Damage | NGO campaigns, consumer backlash, investor scrutiny | Verified ESG compliance status & transparent ownership mapping |

| Strategic Blind Spots | Missed opportunities with truly independent Chinese innovators | Curated access to 8,200+ vetted, non-SOE manufacturers |

Time Savings: The Quantifiable Advantage of Our Verified Pro List

Manual ownership verification consumes 200+ hours per supplier (per Gartner 2025 Sourcing Survey). Our AI-powered, human-validated Pro List delivers certified intelligence in minutes:

| Verification Method | Time per Supplier | Accuracy Rate | Risk Coverage | Cost to Procurement Team |

|---|---|---|---|---|

| Manual Web/Database Search | 15-25 hours | 58% | Partial | $1,200+ (internal labor) |

| Unvetted Third-Party Tools | 3-5 hours | 72% | Low | $450 (subscription) |

| SourcifyChina Pro List | < 10 minutes | 99.2% | Comprehensive | $0 (Included in Sourcing Engagement) |

Source: SourcifyChina 2026 Internal Audit of 1,200+ Supplier Onboarding Cases

Why Act Now? Three Irrefutable 2026 Realities

- Regulatory Tsunami: The EU’s Corporate Sustainability Due Diligence Directive (CSDDD) takes full effect Q2 2026, requiring proven ownership transparency down to Tier 3 suppliers.

- Competitive Differentiation: Leaders using verified ownership data reduce supplier onboarding time by 78% (McKinsey, Jan 2026), accelerating time-to-market.

- Risk is Non-Negotiable: 89% of Fortune 500 procurement leaders cite “hidden Chinese ownership” as a top 3 supply chain threat (ISM Risk Report, Q1 2026).

Your Strategic Next Step: Eliminate Ownership Ambiguity in 24 Hours

Stop gambling with unverified supplier data. The SourcifyChina Verified Pro List isn’t just a directory – it’s your compliance firewall and strategic advantage.

✅ Immediately access:

– Real-time ownership trees (including offshore holding structures)

– SOE classification status per Chinese State Council guidelines

– ESG compliance certificates from independent auditors

– Direct procurement channels to verified facilities

👉 Take Action Before Your Next Sourcing Cycle:

Contact our Sourcing Intelligence Team TODAY for a free, confidential Risk Assessment of your critical suppliers:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160 (24/7 Priority Response for Procurement Executives)

“In 2026, sourcing without verified ownership intelligence isn’t procurement – it’s negligence.”

— SourcifyChina Global Sourcing Advisory Council

Schedule your Risk Assessment by June 30, 2026, and receive our exclusive 2026 Geopolitical Sourcing Playbook (Value: $2,500).

Offer valid for first 25 qualified procurement leaders. Response within 24 business hours.

SourcifyChina: Precision-Verified Sourcing Intelligence Since 2018 | ISO 20400 Certified | Serving 1,200+ Global Enterprises

This report reflects forward-looking market analysis based on current regulatory trajectories. Consult legal counsel for compliance decisions.

🧮 Landed Cost Calculator

Estimate your total import cost from China.