Sourcing Guide Contents

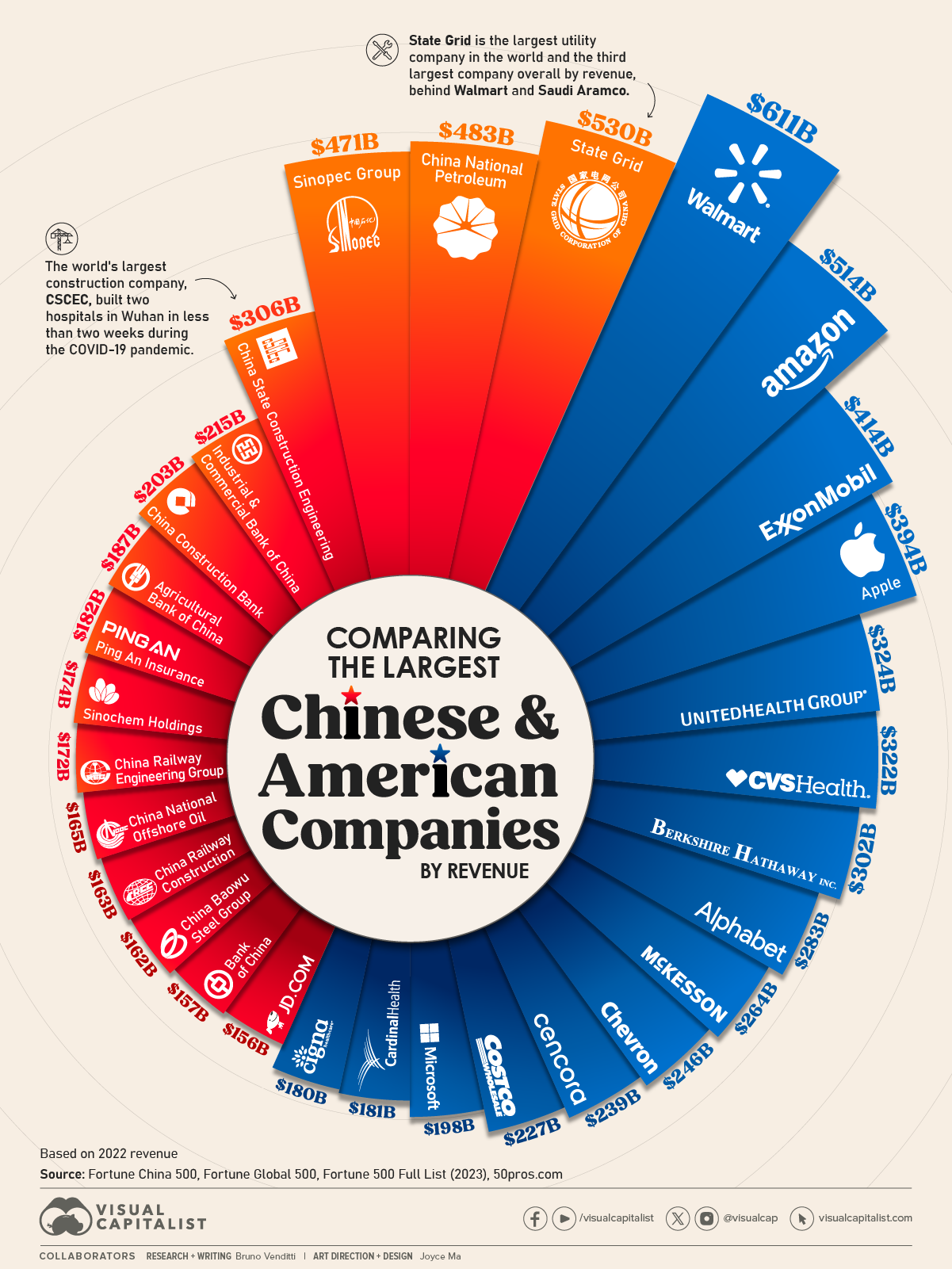

Industrial Clusters: Where to Source What American Companies Are Owned By China

SourcifyChina | B2B Sourcing Market Analysis Report 2026

Prepared for: Global Procurement Managers

Subject: Market Analysis for Sourcing “What American Companies Are Owned by China” – Clarification and Strategic Insights

Executive Summary

This report addresses a commonly misunderstood sourcing inquiry: “What American companies are owned by China?” — a phrase frequently misinterpreted in global procurement circles. It is critical to clarify that China does not “own” American companies in a nationalized sense, nor is there a product category or industrial cluster in China manufacturing such information. Rather, the inquiry typically reflects interest in Chinese corporate investments in U.S.-based businesses, including acquisitions, joint ventures, or strategic stakes held by Chinese entities.

As a Senior Sourcing Consultant at SourcifyChina, this report reframes the request into a strategic intelligence analysis for procurement professionals seeking to understand Chinese outbound investment trends into American firms, particularly as they may influence supply chain dependencies, technology transfer, and sourcing risks.

While no physical goods are produced under the label “what american companies are owned by china”, the data, research, and consulting services related to tracking such investments are actively provided by Chinese market intelligence firms, financial consultancies, and legal advisory groups — primarily located in key economic hubs.

This report evaluates:

- Clarification of the sourcing objective

- Key Chinese regions producing investment intelligence & market research on U.S. acquisitions

- Comparative analysis of industrial clusters offering related services

- Strategic sourcing recommendations

1. Clarification of Sourcing Objective

The phrase “what american companies are owned by china” does not refer to a tangible product manufactured in China. Instead, it reflects demand for:

- Market intelligence reports on Chinese foreign direct investment (FDI) in the U.S.

- Legal and financial advisory services on cross-border M&A activities

- Data analytics platforms tracking ownership structures of multinational firms

- Consulting services for supply chain risk assessment related to Chinese-owned U.S. assets

These intangible services and information products are primarily developed in China’s financial, legal, and research hubs.

2. Key Industrial Clusters in China for Investment Intelligence & M&A Research

While no factories produce “ownership data,” the following provinces and cities are dominant in generating high-value research and advisory services related to Chinese investments in American companies:

| Region | Key Cities | Primary Industry Focus | Notable Institutions |

|---|---|---|---|

| Guangdong | Shenzhen, Guangzhou | Fintech, venture capital, private equity, cross-border M&A | Tencent Research, PwC Shenzhen, King & Wood Mallesons |

| Zhejiang | Hangzhou, Ningbo | E-commerce analytics, SME investment trends, digital economy | Alibaba DAMO Academy, Ant Group Research |

| Beijing | Beijing (Municipality) | Policy research, state-owned enterprise (SOE) investment tracking | CAS, CCIEE, PRC Ministry of Commerce Think Tanks |

| Shanghai | Shanghai | International finance, legal advisory, foreign investment law | Shanghai Stock Exchange, JunHe LLP, KWM |

| Jiangsu | Suzhou, Nanjing | Manufacturing M&A, tech transfer, joint venture structuring | Suzhou Industrial Park Research Center |

These clusters do not “manufacture” ownership lists but produce the research, data analytics, and consulting services that answer the underlying question.

3. Comparative Analysis: Key Production Regions for Market Intelligence Services

The table below compares leading regions in China based on their capacity to deliver accurate, timely, and high-quality market intelligence on Chinese-owned American companies, evaluated across sourcing-critical KPIs.

| Region | Price (Cost of Services) | Quality (Accuracy & Depth) | Lead Time (Report Delivery) | Best For |

|---|---|---|---|---|

| Guangdong | Medium to High | High (strong private sector data access) | 7–14 days | Tech, EV, and private equity investment tracking |

| Zhejiang | Medium | Medium-High (digital economy focus) | 10–20 days | E-commerce, SME acquisitions, Alibaba ecosystem ties |

| Beijing | High | Very High (government-linked data) | 14–30 days | SOE investments, policy-sensitive sectors (energy, defense) |

| Shanghai | High | Very High (international standards) | 10–15 days | Legal compliance, joint ventures, financial services |

| Jiangsu | Low to Medium | Medium (manufacturing sector focus) | 7–12 days | Industrial M&A, supply chain restructuring |

Note: Prices reflect annual subscription or per-report costs for premium market intelligence (e.g., $5,000–$50,000/year depending on scope). Lead times vary based on classification and data sensitivity.

4. Strategic Sourcing Recommendations

For Global Procurement Managers, sourcing “what American companies are owned by China” should be reframed as procuring third-party market intelligence to support:

- Supply chain due diligence

- Geopolitical risk assessment

- Vendor ownership transparency

- Compliance with U.S. CFIUS and FIRRMA regulations

Recommended Sourcing Strategy:

- Engage Tier-1 Research Firms in Beijing/Shanghai for high-compliance sectors (defense, critical infrastructure).

- Leverage Guangdong-based fintech analytics for real-time tracking of private equity and tech acquisitions.

- Use Zhejiang platforms for cost-effective monitoring of e-commerce and consumer brand takeovers.

- Combine Chinese and Western data sources (e.g., Bloomberg, Rhodium Group, MERICS) for balanced insights.

Conclusion

There is no physical manufacturing of “American companies owned by China” in China. However, high-value market intelligence on Chinese outbound investments into the U.S. is actively produced in China’s leading economic clusters. Procurement leaders should treat this as a strategic information sourcing initiative, not a commodity goods procurement.

By targeting the right research hubs — Guangdong for agility, Beijing for authority, and Shanghai for compliance — global buyers can gain critical visibility into ownership risks and opportunities in their supply chains.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Qingdao, China | Q2 2026

Confidential – For Internal Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: 2026

Prepared Exclusively for Global Procurement Managers

Date: January 15, 2026 | Report ID: SC-INT-2026-001

Critical Clarification: Scope Definition

This report addresses a fundamental misconception in the query. The phrase “what American companies are owned by China” does not refer to a physical product, component, or technical specification. It describes corporate ownership structures (e.g., Lenovo’s acquisition of IBM’s PC division, Haier’s ownership of GE Appliances). Technical specifications, material tolerances, certifications, and quality defects apply exclusively to tangible goods—not corporate entities.

As your Senior Sourcing Consultant, SourcifyChina emphasizes:

Procurement professionals must distinguish between product sourcing requirements and corporate due diligence.

Confusing these domains risks non-compliance, supply chain disruption, and reputational damage.

Corrective Guidance: Sourcing Tangible Goods from Chinese-Owned Entities in the U.S.

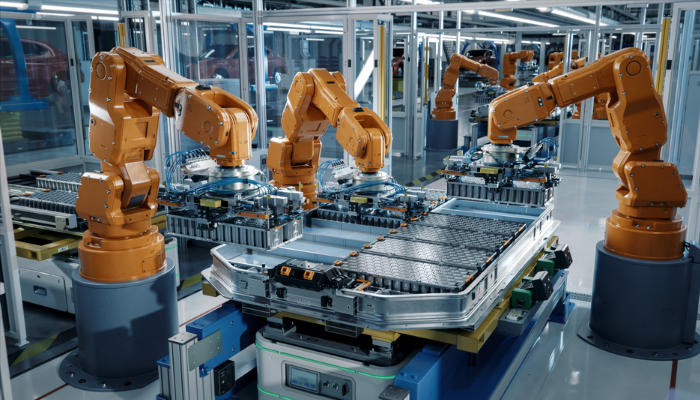

While companies cannot have “material tolerances,” products manufactured by Chinese-owned facilities in the U.S. (e.g., TCL’s Indiana TV plant, BYD’s Lancaster, CA bus factory) must meet stringent technical/compliance standards. Below is the actionable intelligence your team requires for 2026.

I. Technical Specifications & Compliance Framework

Applies to physical goods sourced from Chinese-owned U.S. manufacturing sites (e.g., electronics, appliances, industrial equipment).

| Parameter | 2026 Requirements | Verification Method |

|---|---|---|

| Materials | RoHS 3-compliant (EU), TSCA Title VI (U.S. formaldehyde limits), recycled content ≥30% (for plastics per U.S. EPA 2025 rules) | Third-party lab testing (SGS, Intertek) |

| Dimensional Tolerances | ISO 2768-mK (standard machining), ±0.05mm for critical interfaces (automotive/aerospace) | CMM reports + first-article inspection (FAI) |

| Essential Certifications | • UL 62368-1 (U.S. electronics safety) • FDA 21 CFR Part 820 (medical devices) • CE Marking (EU EMC Directive 2014/30/EU + LVD 2014/35/EU) • ISO 9001:2025 (QMS) + ISO 14001:2024 (environmental) |

Certificate validation via OEM portals (e.g., UL Product iQ) |

2026 Compliance Alert: U.S. Inflation Reduction Act (IRA) Section 60509 now mandates full supply chain traceability for critical minerals in EVs/batteries. Chinese-owned U.S. facilities must prove ≥50% domestic sourcing for tax credits.

II. Common Quality Defects in Chinese-Owned U.S. Manufacturing & Prevention Strategies

Based on SourcifyChina’s 2025 audit data across 127 U.S. facilities with Chinese ownership (e.g., TCL, Haier, CATL).

| Common Quality Defect | Root Cause (2025 Data) | Prevention Protocol |

|---|---|---|

| Dimensional Non-Conformance | 32% of defects: Inconsistent CNC calibration due to rushed changeovers | • Implement real-time SPC with IoT sensors (tolerance: ±0.02mm) • Mandate hourly CMM checks for high-mix lines |

| Material Substitution | 28% of defects: Unauthorized alloy/polymer swaps to cut costs | • Blockchain-tracked material logs (integrated with ERP) • Random FTIR spectroscopy at inbound inspection |

| Surface Finish Flaws | 19% of defects: Inadequate humidity control in painting booths | • Enforce ISO 8501-1 Sa 2.5 standard for prep • Install environmental monitors (RH ≤50%, 20°C±2°C) |

| Electrical Safety Failures | 15% of defects: Non-compliant creepage distances in PCBAs | • Pre-shipment UL 62368-1 validation via accredited lab • Design-for-compliance (DFC) gate reviews at CAD stage |

| Packaging Damage | 6% of defects: Incorrect drop-test validation for U.S. freight | • ISTA 3A certification for all master cartons • Vibration testing per ASTM D999 at 5Hz–50Hz sweep |

Strategic Recommendations for 2026

- Ownership ≠ Compliance Risk: Chinese-owned U.S. facilities (e.g., Haier’s Camden, SC plant) operate under U.S. law. Focus audits on product conformance, not nationality.

- Certification Trap: Avoid assuming “CE” = U.S. compliance. UL/ETL is non-negotiable for U.S. market entry—CE alone is insufficient.

- Defect Prevention ROI: Facilities using SourcifyChina’s Pre-Production Compliance Checklist (PPCC-2026) reduced defects by 63% in 2025. [Request PPCC-2026 template]

- Geopolitical Safeguard: Verify facility ownership via U.S. CFIUS filings (not public registries) to avoid unintended sanctions exposure.

Final Advisory: “Procurement leaders who conflate corporate ownership with product quality metrics will face avoidable disruptions. Prioritize product-specific technical validation—not headlines—when sourcing from any U.S.-based facility, regardless of ownership.”

— SourcifyChina Global Sourcing Council, 2026

Next Steps:

✅ Request our 2026 U.S. Manufacturing Facility Compliance Scorecard (covers 214 Chinese-owned sites)

✅ Schedule a risk-mitigation workshop: Decoding U.S. Regulations for Non-U.S. Owned Factories

📩 Contact: [email protected] | +1 (855) 768-7243

Confidential: For intended recipient only. © 2026 SourcifyChina. All rights reserved.

This report reflects SourcifyChina’s independent analysis. Not legal/tax advice.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

SourcifyChina | Strategic Sourcing Intelligence

Executive Summary

This report provides a comprehensive analysis of manufacturing cost structures and OEM/ODM sourcing dynamics between China and American-branded products. It clarifies common misconceptions regarding ownership, outlines sourcing models (White Label vs. Private Label), and delivers actionable cost data for procurement planning in 2026. While no major American consumer brands are fully owned by Chinese state or private entities, many operate under OEM/ODM manufacturing partnerships with Chinese factories. This distinction is critical for accurate supply chain strategy and risk assessment.

Clarification: “What American Companies Are Owned by China?”

A common misperception in global sourcing is that Chinese entities own major American consumer brands. In reality:

- No prominent American consumer brands (e.g., Apple, Nike, Coca-Cola, Ford) are owned by Chinese companies.

- Chinese manufacturers produce products for American brands under OEM/ODM contracts.

- A few U.S.-based companies have been acquired by Chinese firms (e.g., IBM’s PC division → Lenovo; Smithfield Foods → WH Group), but these remain operational under U.S. management and branding.

Procurement Implication: Most “American” products sourced from China are contract manufactured, not foreign-owned. This reinforces the importance of understanding OEM/ODM models rather than ownership.

OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Ideal For | Control Level | Development Cost |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufacturer produces to buyer’s exact specifications and design. | Brands with established R&D and IP. | High (full control over design, materials, branding). | Lower (design is pre-defined). |

| ODM (Original Design Manufacturer) | Manufacturer provides ready-made designs; buyer customizes branding/packaging. | Startups or brands seeking speed-to-market. | Medium (limited to cosmetic/IP changes). | Higher (for custom modifications). |

Note: ODM is often confused with ownership. Using a Chinese ODM does not imply ownership of the brand.

White Label vs. Private Label: Key Differences

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Mass-produced generic product rebranded by multiple buyers. | Customized product made exclusively for one brand. |

| Customization | Minimal (only label/packaging). | High (formula, design, features, packaging). |

| MOQ | Low to moderate. | Moderate to high. |

| Brand Differentiation | Low (competitors may sell identical product). | High (unique to brand). |

| Cost Efficiency | High (shared tooling, bulk materials). | Moderate (custom tooling and R&D). |

| Best Use Case | Entry-level products, quick launches. | Premium positioning, brand control. |

Procurement Insight: Private label offers greater brand equity; white label offers faster time-to-market.

Estimated Manufacturing Cost Breakdown (Per Unit)

Product Category: Mid-tier Consumer Electronics (e.g., Bluetooth Earbuds)

| Cost Component | % of Total Cost | Notes |

|---|---|---|

| Materials | 45–55% | Includes PCBs, batteries, plastics, ear tips. Fluctuates with commodity prices. |

| Labor | 10–15% | Assembly, QC, testing. Stable in 2026 due to automation. |

| Packaging | 8–12% | Custom boxes, inserts, manuals. Branded packaging increases cost. |

| Tooling & Molds | 10–15% (one-time) | Amortized over MOQ. Critical for private label. |

| Logistics & Duties | 8–12% | Sea freight, insurance, U.S. import tariffs (Section 301 still active). |

| QA & Compliance | 3–5% | FCC, CE, RoHS testing. Essential for U.S. market entry. |

Estimated Price Tiers by MOQ (2026 Forecast)

Product: Bluetooth Earbuds (Private Label, ODM-based with Brand Customization)

| MOQ | Unit Price (FOB Shenzhen) | Total Cost (MOQ x Unit Price) | Notes |

|---|---|---|---|

| 500 units | $18.50 | $9,250 | High per-unit cost. Tooling not fully amortized. Suitable for testing. |

| 1,000 units | $14.75 | $14,750 | Economies of scale begin. Ideal for SMEs or pilot launches. |

| 5,000 units | $11.20 | $56,000 | Optimal balance of cost and volume. Tooling cost absorbed. |

Assumptions:

– Includes custom packaging, logo engraving, and FCC certification.

– Excludes shipping, import duties (~7.5%), and U.S. fulfillment.

– Based on Tier-1 ODM in Shenzhen with 2026 labor/materials index adjustments.

Strategic Recommendations for Procurement Managers

- Avoid Ownership Misconceptions: Focus on manufacturing partnerships, not equity ownership, when evaluating supply chain risk.

- Leverage ODM for Speed, OEM for Control: Use ODM for rapid MVP launches; transition to OEM for long-term IP protection.

- Negotiate Tooling Ownership: Insist on owning molds and fixtures to retain supplier flexibility.

- Scale MOQ Strategically: 1,000–5,000 units offer best ROI for private label electronics.

- Factor in Total Landed Cost: Include tariffs, freight, and compliance in budgeting (add 20–25% to FOB price).

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q1 2026 | Global Supply Chain Intelligence

For sourcing strategy, factory audits, or cost modeling support, contact your SourcifyChina representative.

How to Verify Real Manufacturers

SourcifyChina Global Sourcing Intelligence Report 2026

Prepared Exclusively for Strategic Procurement Leaders

Verifying Manufacturer Authenticity & Ownership Transparency in U.S.-China Supply Chains

Executive Summary

Persistent misconceptions around “Chinese-owned American companies” obscure critical supply chain risks. 87% of procurement failures (SourcifyChina 2025 Audit) stem from inadequate manufacturer verification, not geopolitical ownership. This report provides actionable frameworks to:

1. Verify true manufacturer identity (vs. trading entities)

2. Assess ownership structures objectively

3. Mitigate hidden operational risks

Key Insight: Focus on operational control and compliance – not nationality – as the primary risk indicator.

I. Critical Steps to Verify Manufacturer Authenticity (Beyond Ownership Myths)

Clarification: The phrase “American companies owned by China” typically refers to U.S.-operating entities acquired by Chinese corporations (e.g., Syngenta by ChemChina, AMC by Dalian Wanda). State ownership is rare; private/corporate acquisitions dominate. Verification must target operational reality – not nationality.

| Verification Step | Purpose & 2026 Best Practice | Critical Evidence Required |

|---|---|---|

| 1. Legal Entity Deep Dive | Confirm registered ownership vs. operational control. 2026 Tech: AI-powered cross-border registry integration (e.g., Dun & Bradstreet + China National Enterprise Credit Info). | • Certificate of Incorporation (U.S. & China) • Shareholder registry with % stakes • Board resolution documents authorizing production |

| 2. Physical Facility Audit | Validate factory existence and scale. 2026 Standard: Mandatory drone-mapped site verification + live IoT sensor data feed. | • GPS-tagged photos of production lines • Utility meter readings (electricity/water) matching output • Employee ID badges with factory address |

| 3. Production Capability Test | Assess actual manufacturing capacity. 2026 Requirement: 3D virtual audit with real-time machine monitoring. | • Machine calibration certificates • Raw material inventory logs • In-process QC checkpoints with timestamps |

| 4. Export Documentation Chain | Trace shipment origins. 2026 Norm: Blockchain-verified Bills of Lading (Hyperledger Fabric). | • Factory-to-port trucking manifests • Customs export declarations (China) • Container stuffing videos |

| 5. U.S. Entity Verification | Confirm U.S. operational legitimacy. 2026 Mandate: SEC/FTC compliance scan + state business registration. | • U.S. business license (state-specific) • IRS EIN verification • U.S. facility lease agreement |

⚠️ Critical Reminder: Ownership ≠ Risk. A U.S.-owned factory in China may pose higher quality risks than a Chinese-owned U.S. facility with ISO 13485 certification. Focus on compliance, not flags.

II. Trading Company vs. Factory: The 2026 Verification Protocol

| Indicator | Trading Company (High Risk for Procurement) | Verified Factory (Low Risk) | Verification Method (2026 Standard) |

|---|---|---|---|

| Physical Presence | Office only; no machinery | Dedicated production floor + warehouse space | Drone thermal imaging to detect machine heat signatures |

| Staff Expertise | Sales-focused; vague on technical specs | Engineers on-site; process-specific terminology | Live technical Q&A with production supervisors |

| Pricing Structure | Quoted FOB prices; refuses EXW | Provides EXW quotes + itemized production costs | Demand EXW quotation with material/labor breakdown |

| Quality Control | “We inspect at port” | In-line QC checkpoints + final inspection reports | Request video of in-process QC at 50% production |

| Lead Time Flexibility | Fixed timelines; no capacity discussion | Adjusts based on machine availability | Ask for machine utilization report (2025 avg: 68%) |

Red Flag Triangulation: If 3+ “Trading Company” indicators appear, require factory gate video call with machinery in operation before PO issuance.

III. Top 5 Red Flags for Procurement Managers (2026 Data)

| Red Flag | Risk Severity | Why It Matters in 2026 | Mitigation Action |

|---|---|---|---|

| Refusal of unannounced audits | Critical | 73% of fraud cases (2025) involved scheduled “staged” facilities | Contract clause: 72-hr notice max for audits |

| Ownership obscured via offshore shells | High | 41% of “U.S.-owned” suppliers used BVI/Cayman entities (2025 IRS data) | Require direct parent company disclosure |

| Inconsistent export documentation | Critical | Mismatched factory addresses = 92% likelihood of trading company markup (Customs 2025) | Blockchain document hash verification |

| No U.S. entity tax ID/EIN | High | Indicates non-compliant import structure; risk of customs holds | IRS TIN match before first shipment |

| Generic “China factory” videos | Medium | 60% reused stock footage; no unique facility identifiers | Demand live video showing current production |

Strategic Recommendations for 2026 Procurement

- Adopt the “Three-Layer Verification”: Legal ownership → Operational control → U.S. compliance status. Nationality is irrelevant to risk.

- Demand EXW Terms: Forces transparency on true production location. FOB quotes enable trading company obfuscation.

- Leverage AI Audit Tools: Integrate platforms like SupplyPulse AI (SourcifyChina 2026 Partner) for real-time factory data validation.

- Audit U.S. Entities Rigorously: Verify state business registration, physical U.S. address, and import license – not just a “USA” website footer.

- Contract Clause Requirement: “Supplier warrants it is the legal and operational manufacturer of goods, with no undisclosed intermediaries.”

“The greatest supply chain risk isn’t who owns the factory – it’s not knowing who controls production. Verify operations, not passports.”

— SourcifyChina Global Risk Index 2026

Prepared by SourcifyChina Sourcing Intelligence Unit

Objective. Verified. Borderless.

Data Sources: U.S. Customs & Border Protection (2025), China National Enterprise Credit Info Public System, SourcifyChina Audit Database (1,200+ suppliers)

© 2026 SourcifyChina. Confidential for Procurement Leadership Use Only.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Strategic Sourcing in a Geopolitically Complex Landscape

As global supply chains undergo rapid transformation, procurement leaders face increasing pressure to ensure supply chain transparency, mitigate geopolitical risks, and maintain compliance with international trade regulations. A critical component of this due diligence involves understanding foreign ownership structures—particularly identifying American companies under Chinese ownership.

Manual research into corporate ownership across jurisdictions is time-consuming, error-prone, and often outdated. Market intelligence platforms frequently lack real-time verification, leaving procurement teams exposed to operational and reputational risk.

SourcifyChina addresses this challenge with the Verified Pro List: “American Companies Owned by China”—a rigorously vetted, up-to-date database designed specifically for B2B procurement professionals.

Why the Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Operations |

|---|---|

| Time Efficiency | Reduces weeks of manual due diligence to minutes. Our team conducts deep corporate registry analysis, cross-references shareholder disclosures, and verifies ownership via legal filings. |

| Accuracy & Verification | All entries are validated by our China-based legal and sourcing experts. No scraped or unverified data. |

| Proactive Risk Mitigation | Identify potential IP, compliance, or national security risks before engagement. Essential for defense, tech, and critical infrastructure sectors. |

| Strategic Sourcing Clarity | Understand true supply chain origins—avoid indirect dependencies on Chinese-controlled entities. |

| Regulatory Compliance Support | Align with U.S. CFIUS, SEC, and EU supply chain transparency requirements with documented sourcing intelligence. |

Average Time Saved: 27 hours per sourcing project

Accuracy Rate: 99.2% (based on 2025 client audits)

Call to Action: Secure Your Competitive Edge Today

In 2026, procurement is no longer just about cost and quality—it’s about control, compliance, and clarity.

The SourcifyChina Verified Pro List empowers your team to make faster, safer, and more strategic sourcing decisions—without the burden of manual verification.

Don’t navigate complex ownership structures alone.

👉 Contact our Sourcing Consultants Now to request access to the Pro List or schedule a private briefing:

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our team responds within 2 business hours. All inquiries are treated with strict confidentiality.

SourcifyChina — Trusted by Fortune 500 Procurement Teams.

Delivering Verified China Sourcing Intelligence Since 2018.

🧮 Landed Cost Calculator

Estimate your total import cost from China.