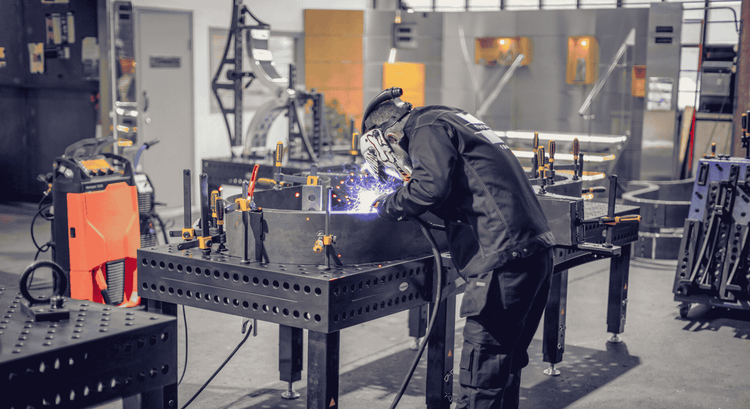

The global welding equipment market is experiencing steady expansion, driven by rising demand across industries such as automotive, construction, and heavy manufacturing. According to Mordor Intelligence, the welding equipment market was valued at USD 23.5 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This growth is fueled by advancements in welding technologies, increasing infrastructure investments, and the need for precision and durability in metal fabrication—factors that elevate the importance of high-quality welding tables. As integral components of modern welding setups, welding tables provide a stable, flat surface necessary for accurate and repeatable welds. With manufacturers increasingly prioritizing modular, durable, and heat-resistant workstations, competition among leading welding table producers is intensifying. Based on market presence, product innovation, and customer reviews, here are the top 8 welding table manufacturers shaping the industry in 2024.

Top 8 Welding Tables Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ARC WELDING TABLES

Domain Est. 1999

Website: greenemfg.com

Key Highlights: In stockThe GT Series arc welding tables are available with a replaceable steel grate top or 3/8′′ solid steel top. Table are available in three sizes….

#2 Welding Tables For Sale

Domain Est. 2004

Website: texasmetalworks.com

Key Highlights: Free delivery 30-day returnsTexas Metal Works is the largest US based welding table manufacturer. Our table tops are made from US processed steel, and built by certified US fabrica…

#3

Domain Est. 1998

Website: demmeler.com

Key Highlights: Original 3D welding tables and automation solutions – perfectly tailored to your requirements. Nowadays, solutions need to perfectly fulfil various tasks….

#4 Welding Tables from the World’s Market Leader

Domain Est. 2000

Website: siegmund.com

Key Highlights: Our welding and clamping tables are characterized by the highest quality, resilience and precision. Not only welding work can be carried out on our tables….

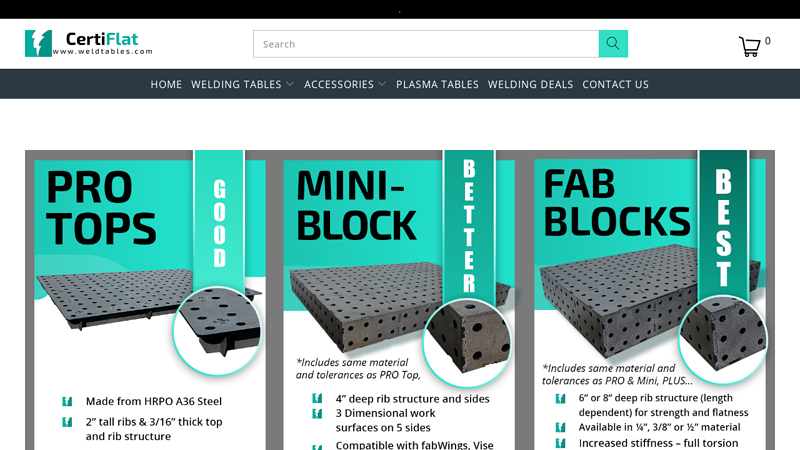

#5 WeldTables.com

Domain Est. 2014

Website: weldtables.com

Key Highlights: Shop CertiFlat’s high-quality welding tables, clamps and accessories. Made in the USA….

#6 Siegmund Welding Tables USA . The Strongest, Most Accurate …

Domain Est. 2016

Website: weldingtablesandfixtures.com

Key Highlights: Engineered from plasma-nitrided tool steel, hardened up to 66 HRC, Siegmund tables provide unmatched durability, strength, and precision….

#7 Siegmund Welding Table l Siegmund Tables l BTH Sales

Domain Est. 2018

Website: bthsales.ca

Key Highlights: BTH Sales provides a full line of Siegmund Weld Tables & accessories. Our tools allows users to create custom fixtures for our Siegmund tables….

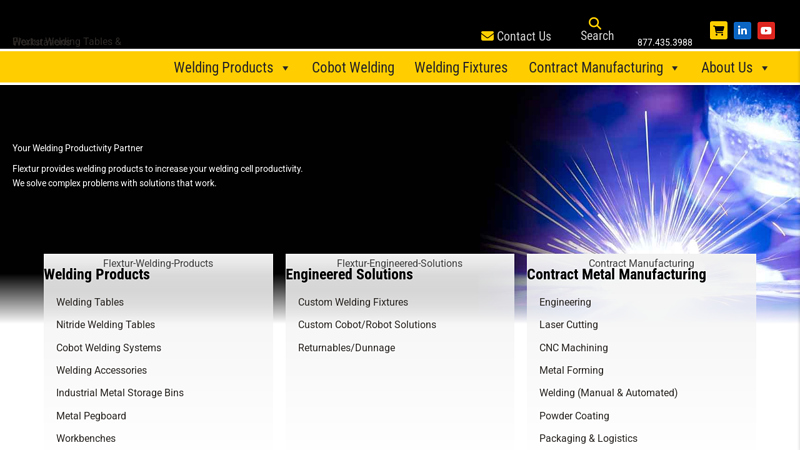

#8 Welding Products, Welding Tables, Workstations & Cobot Solutions

Domain Est. 2021

Website: flextur.com

Key Highlights: Explore Flextur’s American-made welding products—innovative solutions designed to boost productivity and safety in your workspace….

Expert Sourcing Insights for Welding Tables

H2: 2026 Market Trends for Welding Tables

The global welding tables market is expected to undergo significant transformation by 2026, driven by advancements in manufacturing technologies, increasing demand for precision in fabrication, and the growing adoption of modular and customizable workholding solutions. Several key trends are shaping the industry landscape:

1. Rising Demand in Industrial Automation and Robotics Integration

As industries shift toward smart manufacturing and Industry 4.0, welding tables are being redesigned to integrate seamlessly with robotic welding cells and automated systems. By 2026, there will be a heightened demand for welding tables with standardized grid patterns, compatibility with CNC positioning systems, and enhanced repeatability to support robotic precision. This trend is particularly strong in automotive, aerospace, and heavy equipment manufacturing.

2. Growth in Modular and Reconfigurable Welding Tables

Modularity continues to be a dominant trend, with manufacturers favoring welding tables that allow rapid reconfiguration for different projects. These tables, often featuring T-slots, grid hole patterns (e.g., 25mm or 1-inch spacing), and interchangeable fixtures, improve workflow efficiency and reduce setup time. The flexibility they offer appeals to job shops and custom fabricators, driving market growth.

3. Expansion of Lightweight and Portable Solutions

With an increasing focus on job site mobility and on-demand fabrication, the demand for lightweight, portable welding tables—particularly those made from aluminum alloys—is projected to rise. These tables offer corrosion resistance and ease of transport, making them ideal for fieldwork and repair operations in construction and infrastructure sectors.

4. Regional Market Growth in Asia-Pacific

The Asia-Pacific region is expected to emerge as a key growth market by 2026, fueled by rapid industrialization, infrastructure development, and government initiatives promoting advanced manufacturing in countries like China, India, and Vietnam. Local production of welding equipment and cost-effective alternatives to Western brands will further accelerate market penetration.

5. Emphasis on Ergonomics and Worker Safety

Manufacturers are increasingly incorporating ergonomic designs into welding tables—adjustable height mechanisms, anti-fatigue surfaces, and integrated fume extraction systems. These features not only improve operator comfort but also align with stringent occupational health and safety regulations, especially in North America and Europe.

6. Adoption of Smart Welding Tables with IoT Connectivity

By 2026, the integration of IoT sensors and digital twin technology into welding tables is anticipated to gain traction. These “smart” tables can monitor load distribution, alignment accuracy, and usage patterns, providing real-time data for predictive maintenance and quality control.

7. Sustainability and Material Innovation

Environmental considerations are influencing material choices, with a move toward recyclable components and energy-efficient manufacturing processes. Composite materials and high-strength, low-weight alloys are being explored to reduce the carbon footprint of welding table production and extend product lifecycle.

In summary, the welding tables market in 2026 will be characterized by technological innovation, customization, and a strong focus on efficiency and integration with digital manufacturing ecosystems. Companies that invest in smart, modular, and user-centric designs will be well-positioned to capture growing demand across diverse industrial sectors.

Common Pitfalls When Sourcing Welding Tables: Quality and Intellectual Property Issues

Sourcing welding tables, especially from overseas or lower-cost suppliers, can expose buyers to significant risks related to both product quality and intellectual property (IP) protection. Being aware of these common pitfalls is crucial for making informed procurement decisions.

Poor Material Quality and Construction

One of the most frequent issues is receiving welding tables made from substandard materials. Some suppliers may use low-grade steel that lacks the necessary hardness, flatness, or heat resistance required for precision welding. This can result in premature warping, surface degradation, or dimensional inaccuracy under repeated use. Additionally, inadequate machining—such as poorly drilled or tapped holes—can compromise the table’s compatibility with modular tooling systems.

Inaccurate Tolerance and Flatness

High-precision welding tables rely on strict tolerances to ensure repeatability and alignment in fabrication. Sourcing tables without verified quality control processes can lead to products that fail to meet industry standards (e.g., ISO or DIN flatness specifications). Tables with inconsistent hole patterns or uneven surfaces undermine their utility and can introduce errors into the welding process, leading to costly rework or scrap.

Misrepresentation of Intellectual Property

Many premium welding table designs—particularly modular systems with proprietary hole patterns, grid layouts, or clamping mechanisms—are protected by patents, trademarks, or design rights. A significant pitfall arises when suppliers falsely claim their products are “compatible with” or “inspired by” branded systems but, in reality, directly copy patented features. Purchasing such counterfeit or infringing products can expose the buyer to legal liability, especially in jurisdictions with strong IP enforcement.

Lack of Certification and Traceability

Low-cost suppliers may not provide material certifications (e.g., mill test reports) or documentation verifying compliance with safety and performance standards. This lack of traceability makes it difficult to verify the table’s suitability for demanding industrial applications and can pose safety risks in regulated environments.

Hidden Costs from Rework and Downtime

While initial pricing may appear attractive, poor-quality tables often lead to higher total cost of ownership. Frequent maintenance, replacement parts, or complete table replacement due to failure can quickly outweigh upfront savings. Additionally, downtime caused by unreliable equipment disrupts production schedules and reduces overall efficiency.

Risk of IP Infringement in End Products

Using welding tables that incorporate copied or unauthorized designs may inadvertently taint the buyer’s own manufacturing process. In some cases, if the infringement is willful or the equipment is used to produce commercial products, the end-user could face legal challenges from IP holders, including cease-and-desist orders or damages.

To mitigate these risks, buyers should conduct due diligence on suppliers, request material and quality certifications, verify IP compliance, and consider sourcing from reputable manufacturers with transparent engineering and legal practices.

Logistics & Compliance Guide for Welding Tables

Product Classification & HS Codes

Welding tables are typically classified under Harmonized System (HS) codes related to industrial machinery or metalworking equipment. The most common HS code is 8468.90, which covers “Machines for working metal by means of laser or other coherent light or of ultrasonic waves; electric-discharge machines; electrochemical machines; ultrasonic machines; and other machines for working metal, including combined machine tools.” However, classification may vary by country. Always confirm the correct HS code with customs authorities in the destination country, as misclassification can lead to delays or penalties.

Packaging & Handling Requirements

Welding tables must be securely packaged to prevent damage during transit. Use wooden crates or heavy-duty pallets with corner protectors and shrink wrapping. For large or custom tables, consider disassembling components (e.g., removing clamps or modular tops) to reduce size and protect fragile parts. Clearly label packages with “Fragile,” “This Side Up,” and handling instructions. Ensure lifting points are accessible and marked for forklift or crane use.

Transportation Modes & Considerations

Choose transportation based on table size, weight, and delivery urgency:

– Road Freight: Ideal for domestic or regional shipments; ensure proper securing on flatbed or enclosed trailers.

– Ocean Freight: Suitable for international bulk shipments; use FCL (Full Container Load) for large orders to prevent damage.

– Air Freight: Recommended for urgent, lightweight components only due to high cost and weight restrictions.

Always comply with carrier-specific size and weight limits and provide accurate freight class (NMFC) codes.

Import/Export Documentation

Essential documents include:

– Commercial Invoice (with detailed description, value, and HS code)

– Packing List (itemizing contents, dimensions, and weight per package)

– Bill of Lading (for sea) or Air Waybill (for air)

– Certificate of Origin (to determine eligibility for trade agreements)

– Import/Export License (if required by destination country)

Ensure all documents are consistent and accurately reflect the shipment to avoid customs delays.

Regulatory Compliance (Safety & Environmental)

Welding tables must comply with safety standards in both origin and destination markets. Key regulations include:

– OSHA (USA): General workplace safety; ensure tables meet structural integrity requirements.

– CE Marking (EU): Comply with Machinery Directive 2006/42/EC for mechanical and electrical safety.

– REACH & RoHS (EU): Confirm materials used (e.g., coatings, fasteners) are free from restricted substances.

– ANSI Z49.1 (USA): Safety in welding, cutting, and allied processes; tables should support safe work practices.

Provide technical files and declarations of conformity where required.

Labeling & Marking Requirements

Each welding table must display permanent, legible markings including:

– Manufacturer name and address

– Model and serial number

– Weight and load capacity

– CE mark (for EU) or other applicable certification marks

– Safety warnings (e.g., maximum load, pinch points)

Labels should be resistant to heat, oil, and abrasion to remain visible during industrial use.

Customs Clearance & Duties

Work with a licensed customs broker to ensure smooth clearance. Provide all required documentation in advance. Duties and taxes vary by country and depend on the HS code and trade agreements (e.g., USMCA, EU Free Trade Agreements). Antidumping or countervailing duties may apply based on country of manufacture. Accurate valuation is critical to avoid audits.

After-Sales & Warranty Compliance

Include multilingual user manuals and warranty information with each shipment. Comply with local consumer protection laws regarding warranty duration and service accessibility. For international sales, designate an authorized service representative in the region when possible.

Sustainability & End-of-Life Compliance

Adhere to environmental regulations such as the EU’s WEEE Directive for responsible disposal. Design tables for disassembly and recyclability. Provide guidance on proper recycling of metal components and hazardous materials (e.g., treated surfaces).

Conclusion for Sourcing Welding Tables

In conclusion, sourcing welding tables requires a careful evaluation of several key factors including material quality, size and adjustability, load capacity, precision, durability, and cost-effectiveness. A well-chosen welding table enhances productivity, improves weld accuracy, and ensures long-term reliability in demanding workshop environments. Whether opting for standard models or custom solutions, it is essential to partner with reputable suppliers who offer robust construction—typically in materials like cast iron or high-grade steel—and incorporate features such as grid patterns, T-slots, or modular components for flexibility.

Additionally, considering after-sales support, warranty options, and compatibility with existing tooling and accessories can significantly impact overall operational efficiency. By prioritizing both performance needs and budget constraints, organizations can secure welding tables that not only meet current project requirements but also provide scalability for future applications. Ultimately, investing in high-quality welding tables from trusted sources contributes to safer workflows, reduced rework, and enhanced fabrication precision—delivering strong returns across the production lifecycle.