The global welded wire mesh panel market is experiencing robust growth, driven by rising demand in construction, agriculture, and infrastructure sectors. According to a report by Mordor Intelligence, the global wire mesh market was valued at USD 44.68 billion in 2023 and is projected to reach USD 60.37 billion by 2029, growing at a CAGR of 5.14% during the forecast period. This expansion is fueled by increased urbanization, stringent building regulations, and the growing adoption of prefabricated construction materials where welded wire mesh plays a critical structural role. Additionally, Grand View Research highlights the Asia Pacific region’s dominance, attributing it to rapid industrialization and large-scale infrastructure investments in countries like China and India. As demand surges, manufacturers are focusing on product innovation, automation, and sustainable production practices to capture market share. In this competitive landscape, the following ten companies have emerged as leaders, combining scale, technological capability, and global reach to set industry benchmarks in quality and supply reliability.

Top 10 Welded Wire Mesh Panel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

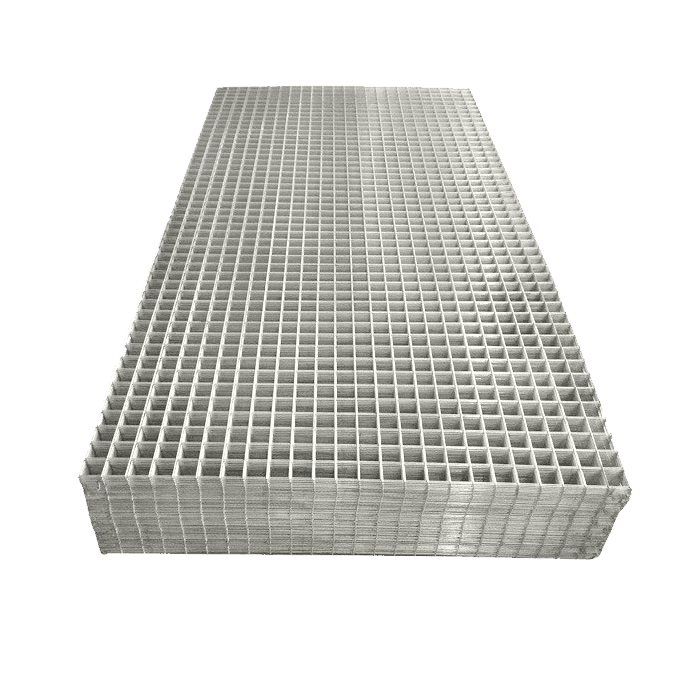

#1 Welded mesh panel

Domain Est. 1997

Website: moreda.com

Key Highlights: The welded mesh panel, also called mesh, is rigid and metallic. It is used in the construction of cages, enclosures and machine security….

#2 Wire Mesh Manufacturers

Domain Est. 2001

Website: wire-cloth.net

Key Highlights: We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles….

#3 Woven & Welded Wire Mesh Options

Domain Est. 1996

Website: wirecrafters.com

Key Highlights: Our signature automated weaving techniques and mesh welding machines allow us to produce woven and welded wire mesh & wire mesh panels at economical prices….

#4 Welded Wire Mesh

Domain Est. 1998

Website: directmetals.com

Key Highlights: Direct Metals is the best place to buy wire mesh. Our welded wire mesh is economical and versatile with a clean appearance and uniform grid patterns….

#5 Welded Wire Mesh Products

Domain Est. 1999

Website: marcospecialtysteel.com

Key Highlights: As one of the leading welded wire mesh suppliers in the United States, Marco Specialty Steel can provide high-quality mesh made from carbon steel, stainless ……

#6 Tree Island Steel

Domain Est. 2000

Website: treeisland.com

Key Highlights: As North America’s supplier of choice for premium quality steel wire and wire products, we are an exceptionally focused team driving excellence….

#7 OK Brand

Domain Est. 2002

Website: okbrand.com

Key Highlights: Welded Wire Reinforcement · Standard Welded Wire Reinforcement · Fabricated Mesh · Retaining Wall Mesh · Erosion Control Mesh · Mine Mesh · Pipe Fabric · Wire ……

#8 Plain Steel Welded & Woven Wire Mesh

Domain Est. 2007

Website: darbywiremesh.com

Key Highlights: Plain steel wire mesh – available from stock or through custom manufacturing – is strong, durable and magnetic. Oftentimes, it is dark in color….

#9 WMC

Domain Est. 2009

Website: wmc-us.com

Key Highlights: We are committed to building infrastructures which last a lifetime, by manufacturing the highest quality of wire products….

#10 Welded Wire Mesh Panels for Fences or Building

Domain Est. 2010

Website: weldedwiremeshpanel.com

Key Highlights: We are welded wire mesh panel supplier and exporter. Products include galvanized welded panel, stainless steel welded mesh panel, reinforcing welded mesh….

Expert Sourcing Insights for Welded Wire Mesh Panel

2026 Market Trends for Welded Wire Mesh Panels

The global welded wire mesh panel market is poised for significant transformation by 2026, driven by advancements in construction technologies, infrastructure development, and growing demand for durable and cost-effective materials. This analysis explores key trends expected to influence the market in the coming years.

Rising Infrastructure Investments

Governments worldwide are increasing investments in infrastructure projects, especially in emerging economies across Asia-Pacific, Latin America, and Africa. These initiatives—spanning highways, bridges, railways, and urban housing—are major drivers for welded wire mesh panels, which are widely used in concrete reinforcement. By 2026, public and private sector construction projects are expected to boost demand, particularly in countries like India, Indonesia, and Nigeria, where urbanization rates are accelerating.

Growth in Prefabricated and Modular Construction

The construction industry is shifting toward prefabricated and modular building methods to improve efficiency, reduce labor costs, and shorten project timelines. Welded wire mesh panels are ideal for prefabrication due to their uniformity, ease of assembly, and strength. By 2026, the adoption of off-site construction techniques is expected to rise significantly, especially in developed markets such as North America and Western Europe, further increasing demand for standardized welded mesh solutions.

Sustainability and Green Building Standards

Environmental concerns and stricter building regulations are encouraging the use of sustainable materials. Welded wire mesh panels, often made from recyclable steel, contribute to green building certifications such as LEED and BREEAM. Manufacturers are responding by enhancing production efficiency and reducing carbon footprints. By 2026, eco-friendly manufacturing practices and the use of recycled content in mesh panels are expected to become competitive advantages.

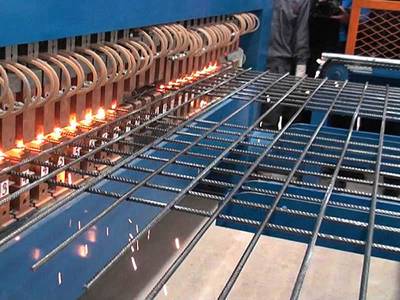

Technological Advancements in Manufacturing

Automation and digitalization are transforming the production of welded wire mesh. Smart factories equipped with IoT-enabled machinery allow for precise control over mesh dimensions, weld quality, and material efficiency. By 2026, these advancements will not only improve product consistency but also enable customization for niche applications such as architectural facades, security fencing, and agricultural enclosures.

Expansion in Non-Construction Applications

Beyond traditional construction, welded wire mesh panels are finding growing use in agriculture (e.g., fencing, animal enclosures), industrial screening, and even solar farm installations. The demand for durable, corrosion-resistant mesh in harsh environments is driving innovation in coatings, such as PVC or galvanized finishes. By 2026, diversification into these sectors is expected to open new revenue streams for manufacturers.

Regional Market Dynamics

Asia-Pacific will remain the largest market for welded wire mesh panels by 2026, led by China and India’s massive infrastructure and housing programs. North America and Europe will see steady growth due to renovation projects and stringent safety standards. Meanwhile, the Middle East and Africa are emerging as high-potential regions, supported by government-led urban development plans.

Competitive Landscape and Consolidation

The market is witnessing increased consolidation, with larger players acquiring regional manufacturers to expand their distribution networks and product portfolios. Additionally, companies are investing in R&D to develop high-tensile, lightweight, and corrosion-resistant mesh variants. By 2026, differentiation through product innovation and value-added services will be critical for market leadership.

In conclusion, the welded wire mesh panel market in 2026 will be shaped by infrastructure growth, technological innovation, sustainability imperatives, and expanding application areas. Companies that adapt to these evolving trends will be well-positioned to capture market share in a competitive and dynamic global landscape.

Common Pitfalls When Sourcing Welded Wire Mesh Panels (Quality, IP)

Sourcing welded wire mesh panels involves several potential pitfalls, especially concerning product quality and intellectual property (IP) considerations. Avoiding these issues is critical to ensuring structural integrity, compliance, and long-term performance. Below are some of the most common challenges buyers face:

Poor Material Quality and Non-Compliance with Standards

One of the most frequent issues is receiving welded wire mesh panels made from substandard materials. Some suppliers may use low-grade steel or incorrect wire diameters that don’t meet ASTM, ISO, or project-specific standards. This compromises the strength, durability, and corrosion resistance of the mesh. Always verify mill test certificates and ensure compliance with standards such as ASTM A185 or A497 for welded wire reinforcement.

Inconsistent Weld Quality

Weak or inconsistent weld points can significantly reduce the structural performance of the mesh. Poor welding leads to joints that break under stress, especially in applications like concrete reinforcement. Visual inspection alone is insufficient—request quality control reports and, if possible, conduct third-party testing to evaluate weld integrity.

Inaccurate Mesh Dimensions and Tolerances

Suppliers may deliver mesh panels with incorrect spacing (apertures), wire diameters, or overall panel sizes. Even minor deviations can impact installation and structural performance. Clearly specify dimensional tolerances in procurement documents and verify them upon delivery.

Inadequate Surface Treatment and Corrosion Protection

Galvanizing is often used to protect welded wire mesh from corrosion. However, some suppliers apply insufficient zinc coatings or skip post-weld galvanizing (which is essential for full corrosion protection). Ensure compliance with ASTM A641 or ISO 1461 for proper galvanization, and confirm whether the mesh is electro-galvanized or hot-dip galvanized, as the latter offers superior protection.

Misrepresentation of Product Specifications

Some suppliers may falsely claim compliance with certain standards or exaggerate product capabilities. This is especially common when sourcing from regions with less stringent oversight. Always request documentation such as test reports, certifications, and samples before placing large orders.

Intellectual Property Infringement Risks

When sourcing custom-designed or proprietary mesh patterns (e.g., for architectural facades or specialized industrial use), there’s a risk of IP infringement. Some manufacturers may replicate patented designs without authorization. To mitigate this, work with reputable suppliers, conduct due diligence on design ownership, and include IP indemnification clauses in contracts.

Lack of Traceability and Documentation

Reputable projects require full traceability of materials. Panels without proper batch numbers, heat numbers, or certification documents can lead to rejection during inspections. Ensure your supplier provides full documentation for material traceability and quality assurance.

Overlooking Logistics and Handling Damage

Welded wire mesh panels are prone to deformation during transport if not properly packaged. Poor handling can lead to warping or broken welds. Specify packaging requirements (e.g., bundling, edge protection) and inspect panels upon arrival for shipping damage.

By being aware of these pitfalls and implementing a rigorous sourcing and quality verification process, buyers can ensure they receive reliable, compliant, and fit-for-purpose welded wire mesh panels.

Logistics & Compliance Guide for Welded Wire Mesh Panel

Product Overview and Specifications

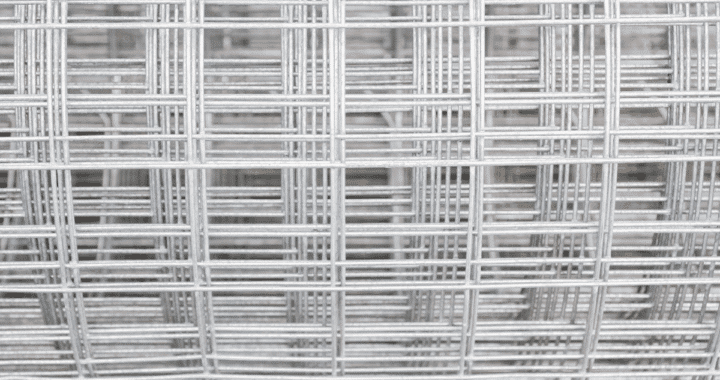

Welded wire mesh panels are prefabricated steel grids used in construction, fencing, reinforcement, and industrial applications. These panels consist of cold-drawn steel wires welded at intersection points to form a rigid structure. Common specifications include wire diameter (e.g., 2mm to 6mm), mesh size (e.g., 50mm x 50mm), panel dimensions (e.g., 2m x 2.4m), and surface finish (galvanized, PVC-coated, or painted).

Packaging and Handling Requirements

Proper packaging is essential to prevent deformation and corrosion during transport. Panels should be bundled securely using steel or plastic strapping, with wooden or plastic edge protectors to avoid edge damage. For galvanized or coated panels, non-abrasive materials should be used between layers to prevent scratching. Bundles must be clearly labeled with product details, batch number, and handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”).

Storage Guidelines

Store welded wire mesh panels in a dry, well-ventilated area off the ground using pallets or racks. Avoid direct contact with soil or standing water to prevent rusting, especially for non-galvanized variants. If stored outdoors, cover bundles with waterproof tarpaulins, ensuring adequate airflow to reduce condensation. Rotate stock using a first-in, first-out (FIFO) system to minimize long-term exposure.

Transportation and Shipping

Panels are typically shipped via flatbed trucks, containers, or open-sided freight carriers. Secure loads with straps or chains to prevent shifting. For container shipments, ensure panels are packed efficiently to maximize space without overloading. Comply with national and international transport regulations (e.g., ADR for hazardous goods, if applicable) and adhere to weight and dimension limits. Notify carriers of the product’s rigid and potentially sharp nature for safe handling.

International Trade Compliance

When exporting welded wire mesh panels, ensure compliance with destination country regulations. Required documentation may include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Test Reports (e.g., tensile strength, weld shear strength)

– ISO or EN certification (e.g., EN 10223-3 for steel wire for fencing)

Verify import tariffs and anti-dumping duties, particularly in regions such as the EU, USA, and Canada, where steel products may be subject to trade remedies.

Material and Safety Standards

Welded wire mesh must conform to relevant industry standards, which may include:

– ASTM A185/A185M: Standard for welded steel wire reinforcement

– ASTM A497/A497M: For deformed steel wire reinforcement

– EN 10223-3: European standard for steel wire and wire products

– BS 4483: Specification for steel fabric for concrete reinforcement (UK)

Panels intended for structural use should be accompanied by mill test certificates and quality assurance documentation.

Environmental and Regulatory Considerations

Ensure manufacturing and coating processes comply with environmental regulations (e.g., REACH, RoHS) where applicable. Galvanizing processes must adhere to local emissions and waste disposal standards. Declare any hazardous substances used in coating (e.g., hexavalent chromium) according to GHS labeling requirements.

Quality Assurance and Inspection

Implement pre-shipment inspections to verify:

– Dimensional accuracy

– Weld integrity

– Surface finish quality

– Corrosion protection (e.g., zinc coating weight for galvanized panels)

Third-party inspections may be required by customers or regulatory bodies, especially for large infrastructure projects.

Import Restrictions and Customs Clearance

Be aware of import restrictions or quotas on steel products in certain countries. Customs brokers should classify products using the correct HS Code—typically 7314.31 or 7314.39 for steel wire mesh, depending on composition and use. Accurate classification ensures correct duty assessment and avoids delays.

Conclusion

Efficient logistics and strict compliance ensure welded wire mesh panels reach customers in optimal condition while meeting regulatory and safety requirements. From proper packaging and transport to adherence to international standards, every step must be managed with precision to maintain product integrity and avoid legal or commercial issues.

Conclusion for Sourcing Welded Wire Mesh Panels

Sourcing welded wire mesh panels requires a strategic approach that balances quality, cost, durability, and supplier reliability. After evaluating various suppliers, material specifications, and application requirements, it is evident that selecting the right welded wire mesh involves careful consideration of factors such as wire gauge, mesh size, coating type (e.g., galvanized or PVC-coated), and compliance with industry standards.

A successful sourcing strategy emphasizes establishing partnerships with reputable manufacturers or distributors who offer consistent product quality, timely delivery, and competitive pricing. Additionally, conducting due diligence—such as requesting samples, verifying certifications, and assessing after-sales support—helps mitigate risks and ensures that the mesh panels meet project-specific needs, whether for construction, agriculture, fencing, or industrial applications.

In conclusion, an informed and proactive sourcing process not only ensures the acquisition of high-performance welded wire mesh panels but also contributes to long-term project efficiency, structural integrity, and cost savings. Continuous supplier evaluation and staying updated on market trends will further enhance procurement outcomes.