The global lifting and rigging equipment market, driven by expanding industrialization and infrastructure development, is projected to grow at a CAGR of 6.8% from 2023 to 2028, according to Mordor Intelligence. Webbing slings, valued for their lightweight design, flexibility, and resistance to load scratching, are a critical component within this sector—particularly in industries such as oil & gas, construction, and logistics. With increasing demand for safer and more efficient material handling solutions, the market for synthetic webbing slings has seen steady traction, bolstered by advancements in high-tenacity polyester and nylon materials. As end-users prioritize durability and compliance with international safety standards, leading manufacturers are investing in R&D and product innovation. Based on market presence, product range, certifications, and global distribution, the following list highlights the top 10 webbing slings manufacturers shaping the current landscape.

Top 10 Webbing Slings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Slingmax® Rigging Solutions

Domain Est. 1996 | Founded: 1986

Website: slingmax.com

Key Highlights: Slingmax has been a trusted supplier of high performance synthetic roundslings to the industrial and heavy lifting markets since 1986….

#2 Premier Web Slings Manufacturer

Domain Est. 1997

Website: ashleysling.com

Key Highlights: Ashley Sling is one of the top nylon and polyester web sling manufacturers in the industry. Our range of web slings for sale are engineered and manufactured to ……

#3 I&I Sling, Inc.

Domain Est. 2002

Website: iandisling.com

Key Highlights: I & I Sling, Inc. manufactures custom slings, hardware, hoists, testing and repair. Serving the Crane and Heavy Lift Industries….

#4 Dawson Lifting Webbing & Round Slings, Ratchet Tie Down Straps …

Domain Est. 2009

Website: dawson-group.com

Key Highlights: Dawson Group Ltd. – the manufacturer and supplier of webbing & round slings, ratchet tie down straps, marine & rigging hardware, lashing equipments, ……

#5 Juli sling

Domain Est. 2023

Website: julislings.com

Key Highlights: Our product lineup includes polyester webbing slings, round slings, ratchet straps, steel wire rope, mooring rope, shackles, chains, hook & rings, elevator ……

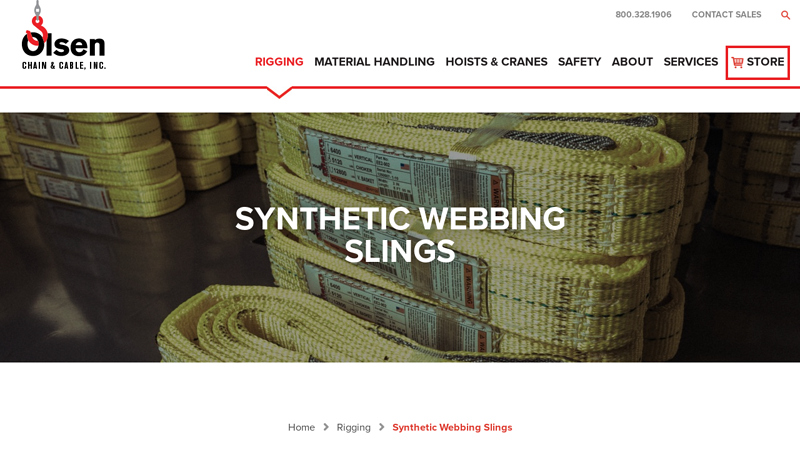

#6 Olsen Chain and Cable – Synthetic Webbing Slings

Domain Est. 1995

Website: olsenchain.com

Key Highlights: Olsen Chain & Cable provides sales and service of synthetic webbing slings for Minnesota, the Midwest, and Across the USA. Always made in America….

#7 Liftex Slings

Domain Est. 1996

Website: liftex.com

Key Highlights: Liftex manufactures web slings, round slings, specialty slings and a diverse range of sling protection for various lifting applications….

#8 Lift-It® Manufacturing

Domain Est. 1999

Website: lift-it.com

Key Highlights: MADE IN THE U.S.A.. Proudly handcrafted in Pomona CA. by a dedicated team for over 40 years! … Lift-It’s sales team is not only knowledgeable but also ……

#9 Synthetic web slings

Domain Est. 2009

Website: hhilifting.com

Key Highlights: 2–5 day delivery 10-day returnsExplore our selection of polyester web slings for safe and efficient lifting. Also available python, hammerhead, chain, and storm surge slings. Shop …

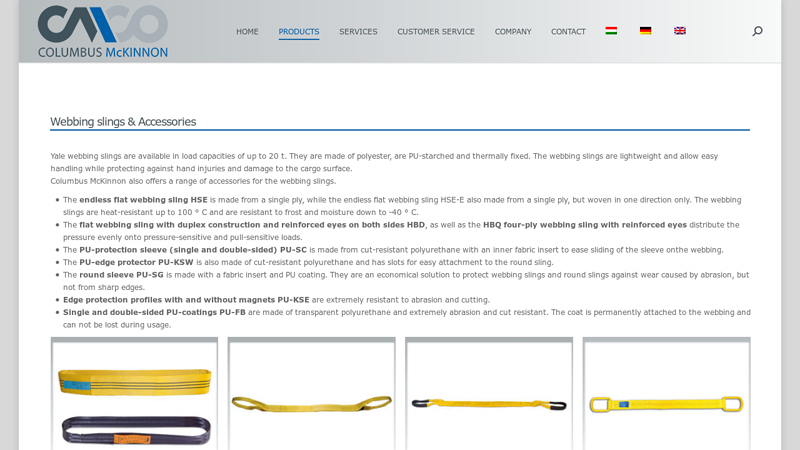

#10 Webbing slings & Accessories

Website: cmco.hu

Key Highlights: Yale webbing slings are available in load capacities of up to 20 t. They are made of polyester, are PU-starched and thermally fixed….

Expert Sourcing Insights for Webbing Slings

2026 Market Trends for Webbing Slings

The global webbing slings market is poised for significant transformation by 2026, driven by evolving industrial demands, technological advancements, and a growing emphasis on safety and sustainability. Webbing slings—used extensively in lifting, rigging, and load securement across industries such as construction, logistics, oil & gas, and manufacturing—are adapting to meet the requirements of modern material handling operations.

Rising Demand in Industrial and Construction Sectors

A key driver shaping the 2026 market landscape is the continued expansion of infrastructure and industrial projects worldwide, particularly in emerging economies. Governments in Asia-Pacific, Latin America, and Africa are investing heavily in smart cities, transportation networks, and renewable energy installations—all of which require reliable lifting equipment. Webbing slings, with their lightweight, flexibility, and resistance to corrosion, are increasingly favored over traditional wire rope slings in delicate or repetitive lifting applications.

Technological Advancements and Material Innovation

By 2026, manufacturers are expected to integrate advanced synthetic materials such as ultra-high-molecular-weight polyethylene (UHMWPE) and high-tenacity polyester into webbing sling designs. These materials offer higher strength-to-weight ratios, improved UV and chemical resistance, and longer service life. Additionally, smart slings embedded with load sensors and RFID tags are gaining traction, allowing real-time monitoring of load conditions and compliance with safety standards—aligning with Industry 4.0 and IoT trends.

Emphasis on Safety and Regulatory Compliance

Workplace safety regulations are becoming stricter globally, especially in North America and Europe. This is pushing companies to adopt webbing slings that meet updated standards such as ASME B30.9, ISO 10566, and EN 1492-1. By 2026, the market will likely see increased demand for color-coded, abrasion-resistant slings with enhanced traceability features, ensuring compliance and reducing accident risks.

Growth in E-Commerce and Digital Distribution Channels

The procurement of webbing slings is shifting toward digital platforms. Industrial suppliers are leveraging e-commerce marketplaces and B2B platforms to reach a broader customer base. By 2026, online sales are expected to account for a growing share of the market, supported by detailed product specifications, virtual product demonstrations, and digital certification tracking.

Sustainability and Environmental Considerations

Environmental concerns are influencing material sourcing and end-of-life disposal practices. Leading manufacturers are developing recyclable webbing slings and adopting greener production methods to meet corporate sustainability goals. This trend is expected to gain momentum by 2026, particularly in regions with strong ESG (Environmental, Social, and Governance) regulations.

Regional Market Dynamics

While North America and Europe remain mature markets with steady growth due to replacement demand and safety upgrades, the Asia-Pacific region is projected to be the fastest-growing market. Countries like China, India, and Vietnam are experiencing rapid industrialization and infrastructure development, fueling demand for cost-effective and versatile lifting solutions such as webbing slings.

Conclusion

By 2026, the webbing slings market will be shaped by innovation, digitalization, and regulatory evolution. Companies that invest in advanced materials, smart technologies, and sustainable practices will be well-positioned to capture market share. As industries prioritize efficiency, safety, and environmental responsibility, webbing slings will continue to play a critical role in modern material handling ecosystems.

Common Pitfalls When Sourcing Webbing Slings: Quality and Intellectual Property Risks

Poor Material Quality and Substandard Manufacturing

One of the most frequent issues when sourcing webbing slings is encountering subpar materials and inadequate manufacturing processes. Low-cost suppliers may use inferior polyester or nylon webbing that lacks the necessary tensile strength, UV resistance, or abrasion durability. This can lead to premature failure under load, posing serious safety hazards. Additionally, inconsistent stitching, poorly sealed edges, or inadequate heat treatment can compromise sling integrity. Always verify material certifications (e.g., ISO 10545, EN 1492-1) and conduct third-party testing to ensure compliance with safety standards.

Lack of Traceability and Certification

Many suppliers, particularly in unregulated markets, fail to provide full traceability or verifiable test certifications for their webbing slings. Without mill test reports, lot numbers, or conformity declarations, it becomes difficult to confirm that the product meets required safety and performance specifications. This lack of documentation also complicates liability in the event of a failure, making it essential to source only from suppliers who offer complete certification and batch traceability.

Misrepresentation of Load Capacity and Safety Factors

Some suppliers may inflate working load limits (WLL) or misrepresent safety factors to appear more competitive. Webbing slings are typically manufactured with a 7:1 safety ratio, but counterfeit or non-compliant products may not adhere to this standard. Buyers must validate load ratings through independent testing and ensure that sling labels and tags include accurate, permanent markings for width, WLL, standard compliance, and manufacturer details.

Intellectual Property Infringement and Counterfeit Products

Sourcing from regions with weak IP enforcement increases the risk of receiving counterfeit or cloned slings that mimic well-known brands. These replicas often copy logos, labeling, and packaging but deliver significantly lower performance and reliability. Using such products not only violates intellectual property rights but also exposes end users to legal liability and safety risks. Always verify supplier authenticity and avoid deals that seem too good to be true.

Inadequate Customization and Design IP Protection

When requesting custom webbing slings (e.g., unique fittings, lengths, or color codes), there’s a risk that suppliers may replicate or resell your proprietary designs without permission. Without proper non-disclosure agreements (NDAs) or contractual IP protections, your design innovations could be compromised. Ensure that contracts explicitly state ownership of custom designs and prohibit unauthorized reproduction.

Failure to Meet Regional Safety and Compliance Standards

Different markets have specific regulatory requirements (e.g., OSHA in the U.S., LOLER in the UK, DGUV in Germany). Sourcing slings that comply only with minimal local standards—rather than international benchmarks—can result in non-compliance during inspections. Always confirm that slings meet the target market’s regulatory framework and are marked accordingly to avoid project delays or penalties.

Logistics & Compliance Guide for Webbing Slings

Webbing slings are essential lifting and rigging tools used across industries for safe and efficient material handling. Ensuring their proper logistics management and compliance with regulatory standards is critical for workplace safety and legal adherence. This guide outlines key considerations for the transportation, storage, inspection, and regulatory compliance of webbing slings.

Transportation and Handling

Proper transportation prevents damage and maintains the integrity of webbing slings. Always transport slings in protective containers or bags to shield them from dirt, moisture, UV exposure, and physical damage. Avoid dragging slings across rough surfaces, and ensure they are securely fastened during transit to prevent shifting or crushing. When handling, inspect slings for signs of wear, cuts, or contamination before and after transport.

Storage Requirements

Store webbing slings in a clean, dry, and well-ventilated area away from direct sunlight, extreme temperatures, and harmful chemicals such as acids, alkalis, or solvents. Hang slings on designated racks or store them coiled neatly in bins to prevent kinking, twisting, or abrasion. Avoid stacking heavy objects on top of stored slings. Label storage areas clearly to ensure quick identification and proper inventory management.

Inspection and Maintenance

Regular inspection is mandatory for compliance and safety. Conduct pre-use visual inspections to check for cuts, burns, abrasions, fraying, discoloration, or damaged fittings. Perform documented formal inspections by a qualified person at least every 12 months, or more frequently under severe conditions (e.g., high usage, harsh environments). Retire slings immediately if any defect is found. Do not attempt to repair damaged webbing slings—replace them according to manufacturer guidelines.

Regulatory Compliance Standards

Webbing slings must comply with regional and international safety standards. In the United States, adherence to OSHA 29 CFR 1910.184 and ASME B30.9 is required. In Europe, compliance with the Lifting Operations and Lifting Equipment Regulations (LOLER) and EN 1492-1:2000 is mandatory. These standards govern sling design, marking, safe working load (SWL), identification, and usage limitations. Ensure all slings are legibly labeled with critical information, including SWL, manufacturer, material type, and compliance certification.

Training and Documentation

Personnel involved in the use, inspection, or management of webbing slings must receive proper training on safe handling, load limits, sling angles, and hazard recognition. Maintain detailed records of sling inspections, repairs (if applicable), retirements, and training sessions. Documentation supports compliance during audits and helps track sling lifecycle performance.

Environmental and Chemical Exposure

Be mindful of environmental conditions that can degrade webbing materials. Prolonged UV exposure weakens synthetic fibers like polyester and nylon. Chemical exposure can lead to hidden strength loss. Always consult the manufacturer’s chemical resistance guide and avoid using slings in environments where incompatible substances are present. Rinse slings with clean water after exposure to contaminants, but do not use cleaning agents unless approved by the manufacturer.

Marking and Traceability

Each webbing sling must have a durable tag or label containing essential data: rated capacity, sling type, material, number of legs (if applicable), manufacturing date, and compliance standard. Tags should remain legible throughout the sling’s service life. Lost or damaged tags require sling removal from service until identity and capacity can be verified. Implement a traceability system—such as barcode or serial numbering—to support inspection logs and compliance tracking.

End-of-Life Management

Establish a clear protocol for retiring and disposing of webbing slings. Defective, aged, or non-compliant slings must be taken out of service and physically destroyed (e.g., cut into pieces) to prevent accidental reuse. Maintain a disposal log as part of compliance records. When replacing slings, ensure new equipment meets current safety standards and is compatible with existing lifting operations.

Following this logistics and compliance guide ensures the safe, legal, and efficient use of webbing slings, protecting both personnel and equipment across all lifting operations.

Conclusion for Sourcing Webbing Slings:

Sourcing high-quality webbing slings is a critical step in ensuring operational safety, efficiency, and compliance in lifting and rigging applications. When selecting suppliers, it is essential to prioritize manufacturers or distributors that adhere to international standards such as EN 1492-1 or ASME B30.9, provide clear load rating and traceability information, and use durable, abrasion-resistant materials like polyester or nylon. Evaluating factors such as working load limit, environmental resistance, certifications, and traceable quality control processes helps mitigate risks and ensures long-term reliability. Additionally, partnering with reputable suppliers who offer comprehensive product documentation, inspection guidance, and technical support contributes to a safer and more cost-effective supply chain. Ultimately, a strategic and informed sourcing approach to webbing slings enhances workplace safety, reduces downtime, and supports compliance with industry regulations.