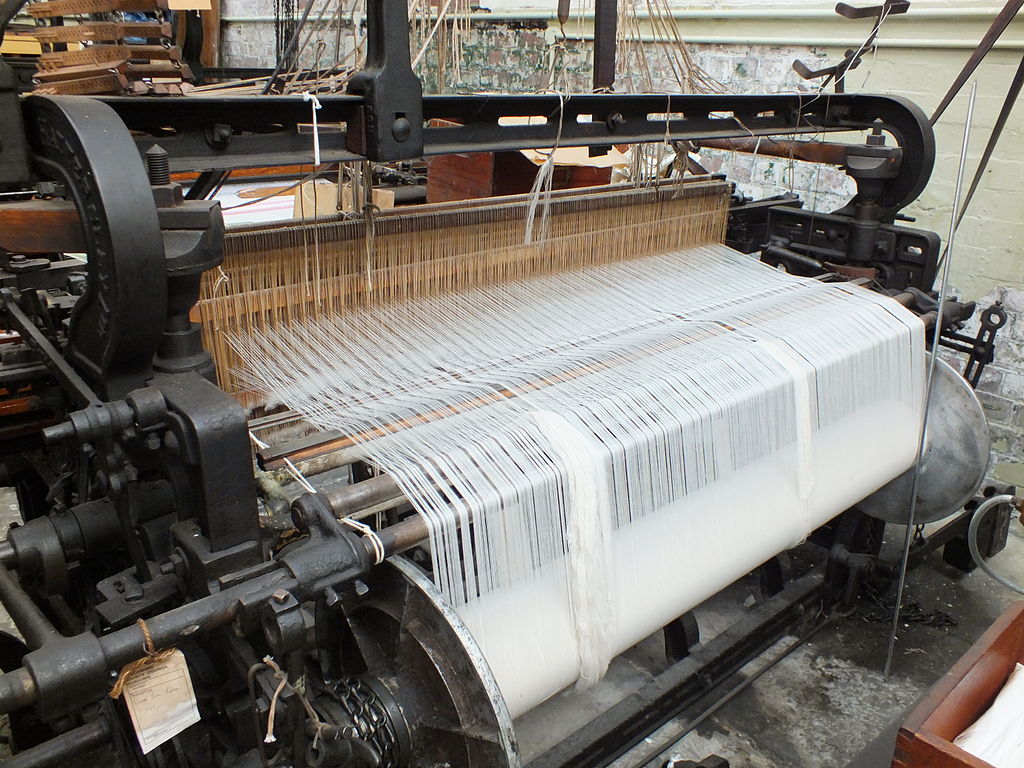

The global hair weave and extension market has experienced robust growth over the past decade, driven by rising consumer demand for versatile hair solutions and the expansion of the beauty and personal care industry. According to a 2023 report by Grand View Research, the global human hair market was valued at USD 6.2 billion and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects steady growth in the beauty accessories sector, citing increased investments in manufacturing efficiency and automation as key drivers. Central to this evolution are advancements in weave machine technology—equipment that enables faster, more precise, and scalable production of wefted hair extensions. As demand surges across North America, Europe, and emerging markets in Asia-Pacific and Africa, a competitive landscape of machine manufacturers has emerged. These companies are leveraging innovation, durability, and customization to meet industry needs. In this context, identifying the top 10 weave machine manufacturers offers critical insight for suppliers, salons, and distributors aiming to optimize production quality and efficiency in a rapidly expanding market.

Top 10 Weave Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Picanol Weaving Machines

Domain Est. 1995

Website: picanol.be

Key Highlights: Picanol develops, produces and markets high-tech weaving machines, based on airjet or rapier technology. Best quality and worldwide service guaranteed….

#2 Weaving Machinery

Domain Est. 2000

Website: toyota-industries.com

Key Highlights: Toyota Industries develops and manufacturers air jet looms which insert the weft yarn using air, and water jet looms which insert the weft yarn using water….

#3 Louet hand

Domain Est. 2000

Website: louet.nl

Key Highlights: Louët craftsmanship at its finest. Our products are designed for hobby crafts people for large and small project sizes….

#4 AVL Looms

Domain Est. 2019

Website: avllooms.com

Key Highlights: AVL Looms is a global manufacturer and marketer of looms, software and weaving accessories. We are widely known for our innovation in the handwoven ……

#5 Weaving Machinery

Domain Est. 2022 | Founded: 1983

Website: weaving-machinery.com

Key Highlights: Established in 1983, Weaving Machinery is a family-run agricultural machinery manufacturer and importer specialising in low disturbance farming equipment….

#6

Domain Est. 1997

Website: vandewiele.com

Key Highlights: Textile machines & components. Global revolution for filament, weaving, tufting and finishing machines & components. Knitting and flat weaving components….

#7 Bally Ribbon Mills

Domain Est. 1997

Website: ballyribbon.com

Key Highlights: We manufacture specialized woven fabrics, webbing and tapes for industries in aerospace, defense, medical, safety & automotive fields….

#8 Itema

Domain Est. 2000

Website: itemagroup.com

Key Highlights: Itema is a global leader in advanced weaving solutions, offering state-of-the-art weaving machines, spare parts, and integrated services with rapier, ……

#9 Lindauer DORNIER GmbH

Domain Est. 2004

Website: lindauerdornier.com

Key Highlights: Innovation for over 75 years: Lindauer DORNIER machines and systems for weaving, film production and lightweight construction….

#10 Weaving Machines

Domain Est. 2015

Website: smitweaving.com

Key Highlights: All SMIT loom machines are designed and made in Italy, combining some of the most reliable SMIT features with new groundbreaking solutions….

Expert Sourcing Insights for Weave Machine

H2: 2026 Market Trends Analysis for Weave Machine

As we approach 2026, the market landscape for Weave Machine—presumably a company or technology platform operating in the domains of industrial automation, textile manufacturing, AI-driven design, or smart manufacturing systems—will be shaped by several converging macroeconomic, technological, and consumer-driven trends. This analysis explores key developments expected to influence Weave Machine’s market position, competitive environment, and growth opportunities in 2026.

-

Accelerated Adoption of Smart Manufacturing

The global push toward Industry 4.0 will continue to accelerate in 2026, with smart manufacturing systems integrating IoT, AI, and real-time data analytics. Weave Machine is poised to benefit from increased demand for automated, flexible, and efficient textile and material production solutions. Manufacturers will prioritize equipment that enables predictive maintenance, adaptive workflows, and seamless integration with digital supply chains—all areas where intelligent weaving systems can add value. -

Sustainability as a Competitive Imperative

Environmental regulations and consumer preferences will place sustainability at the core of textile production. By 2026, Weave Machine must align with circular economy principles, including energy-efficient operations, waste reduction, and compatibility with recycled or bio-based fibers. Companies investing in low-carbon footprint technologies and transparent supply chains will gain market share, creating both pressure and opportunity for innovation. -

Growth in Customization and On-Demand Production

Driven by fashion tech and e-commerce trends, demand for mass customization will rise. Weave Machine can leverage digital weaving platforms capable of small-batch, on-demand production with minimal setup time. The integration of AI-assisted design tools and cloud-based order management systems will enable faster turnaround and personalized textile output, meeting the demands of niche markets and direct-to-consumer brands. -

Expansion in Emerging Markets

Asia-Pacific, particularly India, Vietnam, and Indonesia, will remain hubs for textile manufacturing. Simultaneously, nearshoring trends in North America and Europe may open new markets for localized, high-tech weaving facilities. Weave Machine can expand its footprint by offering modular, scalable systems tailored to regional needs—balancing automation with labor cost dynamics. -

Advancements in Material Science and AI Optimization

By 2026, innovations in smart textiles—such as conductive fibers, biodegradable composites, and performance-enhancing weaves—will create new applications in healthcare, wearables, and automotive sectors. Weave Machine can differentiate itself by incorporating AI-driven pattern optimization, real-time quality control via computer vision, and adaptive tensioning algorithms that improve yield and reduce defects. -

Competitive Pressure and Consolidation

The industrial automation space will see continued consolidation, with larger players acquiring niche innovators. Weave Machine must either fortify its technological moat or consider strategic partnerships to maintain competitiveness. Open API ecosystems and interoperability with broader manufacturing software (e.g., MES, PLM) will become key differentiators.

Conclusion

In 2026, Weave Machine will operate in a dynamic environment defined by digital transformation, sustainability mandates, and evolving customer expectations. Success will depend on agility in R&D, strategic market positioning, and the ability to deliver intelligent, scalable, and eco-conscious weaving solutions. Companies that embrace data-driven manufacturing and circular design principles will lead the next phase of industrial innovation.

Common Pitfalls Sourcing Weave Machines (Quality, IP)

Sourcing Weave machines—typically referring to industrial textile looms used in weaving fabrics—can present significant challenges, particularly concerning quality assurance and intellectual property (IP) protection. Being aware of these pitfalls is crucial for minimizing risk and ensuring a successful procurement process.

Poor Quality Control and Inconsistent Performance

One of the most prevalent issues when sourcing Weave machines, especially from low-cost manufacturers or emerging markets, is inconsistent build quality. Machines may use substandard materials, lack precision engineering, or suffer from premature wear and mechanical failure. Buyers often discover that machines fail to maintain tension, produce fabric defects, or require frequent maintenance—leading to production downtime and increased operating costs. Without rigorous on-site inspections or third-party quality audits, it’s difficult to verify manufacturer claims about durability and performance.

Lack of Technical Support and Spare Parts Availability

Many suppliers, particularly smaller or offshore manufacturers, fail to provide adequate after-sales support. This includes limited availability of spare parts, delayed technical assistance, and a lack of trained service personnel. When a machine breaks down, the absence of readily available components or knowledgeable support can halt production for days or weeks, significantly impacting ROI.

Misrepresentation of Machine Specifications and Capabilities

Some suppliers exaggerate machine capabilities, such as output speed, fabric width, or compatibility with certain yarn types. Buyers may receive equipment that cannot handle the intended production requirements, leading to inefficiencies or the need for costly upgrades. Clear technical specifications, verification through sample runs, and third-party validation are essential to avoid such misrepresentations.

Intellectual Property Infringement Risks

Sourcing Weave machines from certain regions may expose buyers to IP infringement risks. Some manufacturers produce machines that closely copy patented designs, control systems, or proprietary technologies owned by established brands (e.g., Picanol, Toyota, or Sulzer). Purchasing such machines—even unknowingly—can result in legal liability, shipment seizures, or reputational damage. Conducting IP due diligence and sourcing from reputable, licensed manufacturers helps mitigate this risk.

Inadequate Documentation and Compliance Issues

Poorly documented machines—missing operation manuals, electrical schematics, or compliance certificates—can create safety hazards and complicate integration into existing production lines. Additionally, machines may not meet regional safety or environmental standards (e.g., CE, UL), leading to import restrictions or regulatory penalties.

Hidden Costs and Unreliable Delivery Schedules

Low initial quotes can be misleading. Hidden costs such as shipping, import duties, installation, and training may significantly increase the total cost of ownership. Moreover, unreliable delivery timelines can disrupt production planning and supply chain operations, especially when suppliers lack proven logistics experience.

To avoid these pitfalls, buyers should conduct thorough due diligence, including factory audits, reference checks, sample testing, and legal review of IP and compliance documentation. Partnering with experienced sourcing agents or established OEMs can further reduce risks associated with quality and intellectual property.

Logistics & Compliance Guide for Weave Machine

This guide outlines the essential logistics and compliance considerations for the shipment, handling, installation, and operation of the Weave Machine. Adherence to these guidelines ensures regulatory compliance, safety, and optimal performance.

Shipping & Handling

Ensure the Weave Machine is shipped via a certified freight carrier capable of handling heavy industrial equipment. Use original packaging or equivalent protective crating to prevent damage during transit. Label all shipments with appropriate hazard and handling symbols (e.g., “Fragile,” “This Side Up,” “Heavy Equipment”). Confirm that receiving facilities have proper lifting equipment (e.g., forklifts, hoists rated for the machine’s weight) to unload and move the unit safely.

Import/Export Compliance

Verify that the Weave Machine meets export control regulations, including but not limited to the Export Administration Regulations (EAR) and International Traffic in Arms Regulations (ITAR), if applicable. Classify the machine under the correct Harmonized System (HS) code and obtain necessary export licenses. For international shipments, ensure compliance with destination country import requirements, including conformity assessments, certifications, and documentation such as commercial invoices, packing lists, and certificates of origin.

Regulatory Certifications

The Weave Machine must carry applicable safety and regulatory certifications prior to deployment. Ensure certification marks such as CE (European Union), UKCA (United Kingdom), FCC (for electromagnetic compatibility in the U.S.), and CSA/UL (North America) are present and valid. Maintain up-to-date technical documentation, including Declaration of Conformity (DoC), risk assessments, and technical files, for audit purposes.

Installation & Site Requirements

Install the Weave Machine in accordance with local building, electrical, and fire safety codes. Confirm that the installation site meets specified requirements for floor loading capacity, ventilation, power supply (voltage, phase, grounding), and environmental conditions (temperature, humidity). Only qualified personnel should perform installation and initial calibration. Retain all installation records for compliance and warranty validation.

Operational Safety & Training

Operators and maintenance personnel must receive documented training on safe operation, emergency procedures, and lockout/tagout (LOTO) protocols. Provide multilingual operator manuals and safety signage where required. Conduct periodic safety audits and maintain records of training and equipment inspections to comply with OSHA (U.S.) or equivalent occupational health and safety regulations.

Maintenance & Recordkeeping

Follow the manufacturer’s preventive maintenance schedule to ensure continued compliance and machine reliability. Keep detailed logs of all maintenance, repairs, software updates, and component replacements. These records may be required during regulatory inspections or for warranty claims.

Environmental & Waste Compliance

Dispose of machine components, consumables, and packaging materials in accordance with local environmental regulations. For end-of-life disposal, follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Ensure proper handling of any hazardous materials (e.g., lubricants, batteries) per EPA, REACH, or equivalent standards.

Data Privacy & Cybersecurity (if applicable)

If the Weave Machine collects, processes, or transmits operational data, ensure compliance with data protection laws such as GDPR (EU), CCPA (California), or other regional privacy regulations. Implement cybersecurity measures to protect against unauthorized access, including secure firmware updates and network segmentation. Document data flows and retention policies accordingly.

Audit & Documentation

Maintain a centralized compliance file containing all certifications, shipping documents, training records, maintenance logs, and regulatory correspondence. This documentation supports audit readiness and demonstrates due diligence in regulatory compliance.

Conclusion for Sourcing a Weave Machine

After a thorough evaluation of technical specifications, cost considerations, supplier reliability, and long-term operational needs, sourcing a weave machine requires a strategic approach that balances quality, efficiency, and budget. It is essential to partner with reputable manufacturers or suppliers who offer proven machine performance, reliable after-sales support, and compatibility with current and future production requirements. Automation features, energy efficiency, and ease of integration into existing workflows should be prioritized to ensure scalability and competitiveness. Ultimately, the right weave machine will enhance productivity, improve fabric quality, and provide a strong return on investment. Conducting due diligence during the sourcing process will lay the foundation for sustainable manufacturing success.