The global high-pressure water jetting equipment market is experiencing robust growth, driven by increasing demand for efficient, eco-friendly cleaning and surface preparation solutions across industries such as oil & gas, manufacturing, construction, and marine. According to a report by Mordor Intelligence, the high-pressure cleaning equipment market was valued at USD 3.2 billion in 2023 and is projected to grow at a CAGR of over 6.8% from 2024 to 2029. Similarly, Grand View Research estimates that the global water jetting systems market, inclusive of industrial and sanitation applications, will expand at a CAGR of 7.2% during the forecast period of 2023 to 2030, fueled by stringent environmental regulations and the shift toward non-abrasive cleaning methods. With technological advancements enhancing efficiency and automation, leading manufacturers are investing heavily in R&D to deliver high-performance, energy-efficient water jetting machines. As demand surges, selecting the right supplier has become critical for businesses aiming to optimize operational performance and sustainability. Below are the top 10 water jetting machine manufacturers shaping the future of industrial cleaning and surface processing.

Top 10 Water Jetting Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 StoneAge

Domain Est. 1999

Website: stoneagetools.com

Key Highlights: StoneAge, Inc. manufactures high-pressure waterblast tools and automated equipment for industrial cleaning applications. Our products have been an industry ……

#2 NLB Corp

Domain Est. 1996

Website: nlbcorp.com

Key Highlights: Worldwide leader in Water Jet Technology, NLB Corp offers water jet equipment & systems for many applications. Find your water jet solution here!…

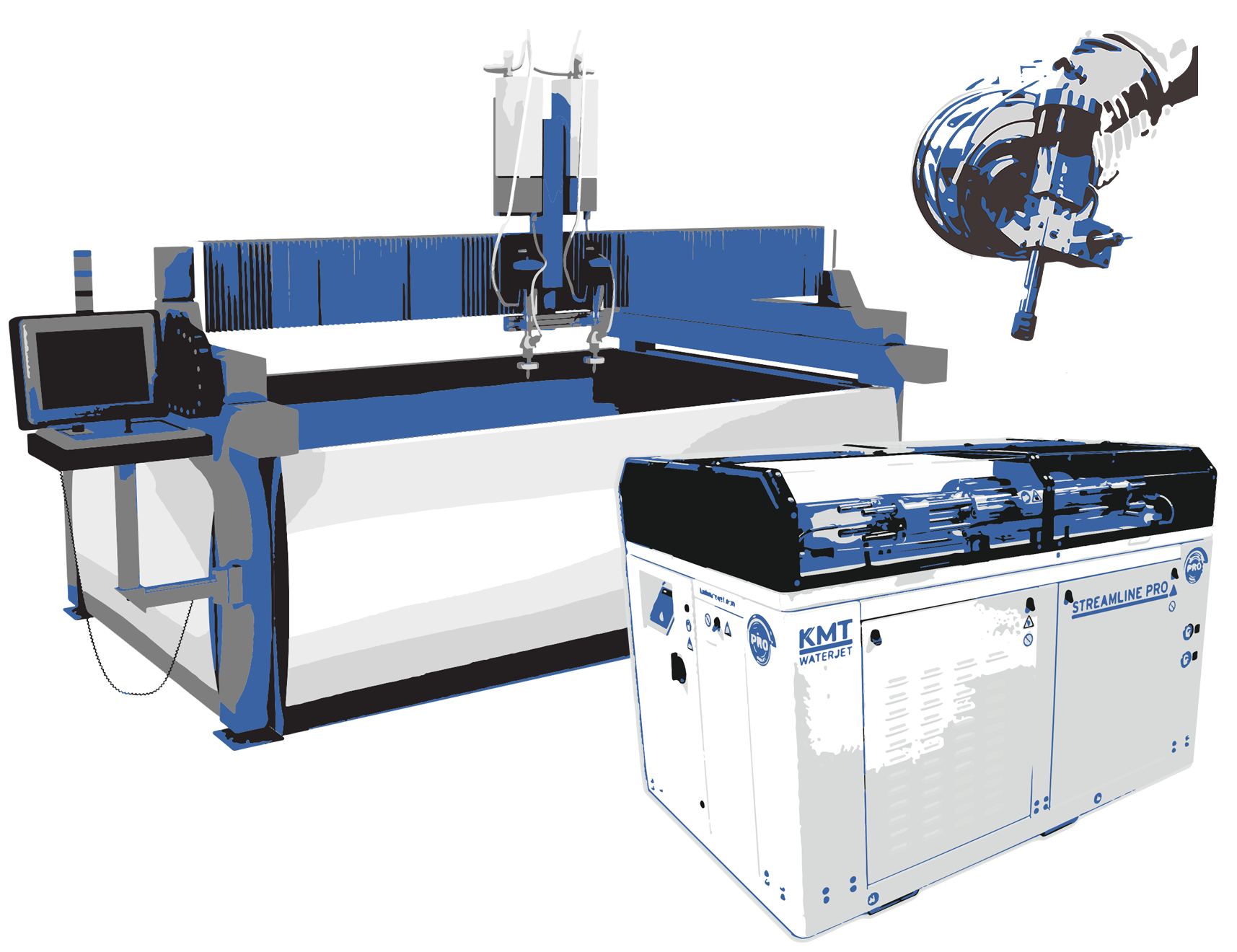

#3 KMT Waterjet

Domain Est. 2003

Website: kmtwaterjet.com

Key Highlights: KMT Waterjet: Pioneers in waterjet cutting technology. Discover pumps, parts, and complete systems for precision solutions….

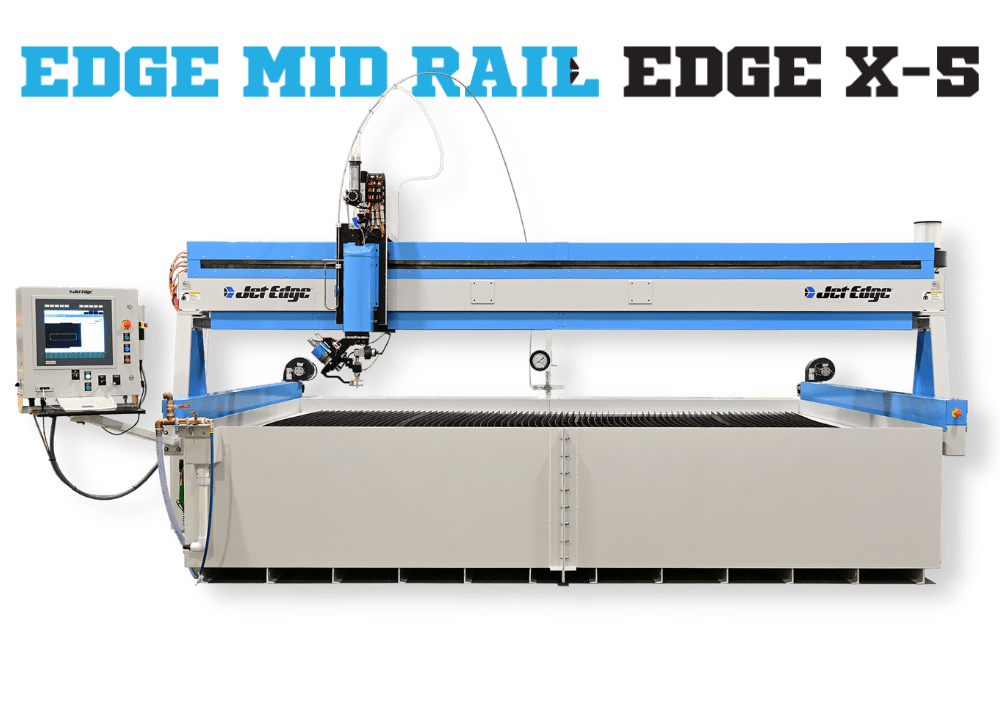

#4 Jet Edge Waterjet Systems

Domain Est. 2018

Website: jetedgewaterjets.com

Key Highlights: Jet Edge Waterjet Systems is a leading manufacturer of waterjet and abrasive waterjet Cutters, ultra high pressure pumps, and accessories….

#5 Derc Salotech: Water Jetting Equipment

Domain Est. 2022

Website: dercsalotech.nl

Key Highlights: We offer everything from hand-held waterjet guns to fully automated solutions for cleaning tubes, pipes, surfaces, (oil) storage tanks and sewers….

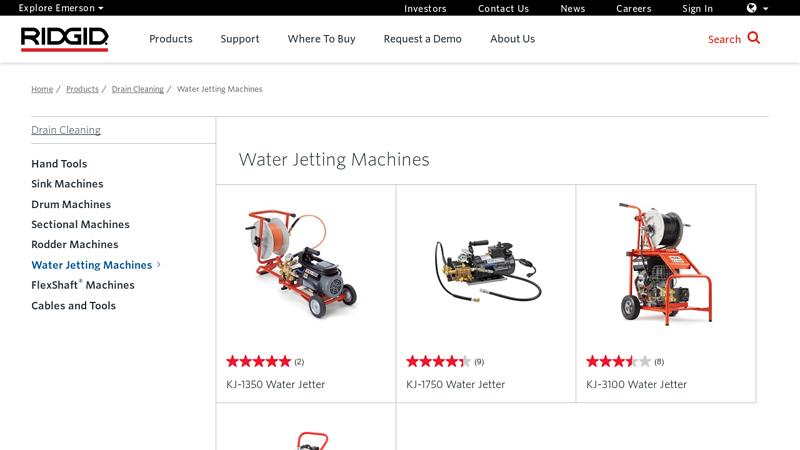

#6 Drain Cleaning Machines – Sewer Jetters

Domain Est. 1995

Website: ridgid.com

Key Highlights: RIDGID sewer jetter machines are ideal for clearing grease, sludge sewage or soap clogged lines. Shop our line here….

#7 Tailored Waterjet Solutions

Domain Est. 2000

Website: wardjet.com

Key Highlights: We’ve built and installed thousands of waterjet machines across a diverse industry portfolio to suit specific manufacturing and material cutting needs….

#8 Water Jetting Equipment

Domain Est. 2001

Website: alljetting.com

Key Highlights: Find premier water jetting equipment at All Jetting Technologies. Explore our USA-made nozzles, hoses, and more. Get expert advice and custom solutions ……

#9 Flow Waterjet

Domain Est. 2003

Website: flowwaterjet.com

Key Highlights: At Flow, we manufacture the entire waterjet system, including the pump, cutting head, XY table, and software. This means we’ve got a seamlessly integrated ……

#10 Waterjet Corporation

Domain Est. 2003

Website: waterjetcorp.com

Key Highlights: Waterjet Corporation is specialised in the production of high-performance, innovative machinery for cutting and hydrofinishing with water jets. Find out more ……

Expert Sourcing Insights for Water Jetting Machine

H2: 2026 Market Trends for Water Jetting Machines

The global water jetting machine market is poised for significant transformation by 2026, driven by technological advancements, sustainability demands, and expanding industrial applications. As industries continue to prioritize precision, efficiency, and environmentally friendly manufacturing processes, water jetting technology is emerging as a preferred cutting solution across sectors such as automotive, aerospace, construction, and metal fabrication.

One of the key trends shaping the 2026 landscape is the integration of automation and smart manufacturing technologies. Water jetting machines are increasingly being equipped with IoT-enabled sensors, AI-driven controls, and real-time monitoring systems. These enhancements improve operational accuracy, reduce downtime, and allow for remote diagnostics and predictive maintenance—critical features in Industry 4.0 environments.

Another major driver is the growing emphasis on eco-friendly production methods. Unlike laser or plasma cutting, water jetting uses no heat and minimal consumables, making it ideal for reducing carbon emissions and thermal distortion. This aligns with global sustainability goals and regulations, prompting more manufacturers to adopt water jet systems, particularly those utilizing abrasive-free or recycled abrasive materials.

The market is also seeing a rise in demand for ultra-high-pressure (UHP) water jet systems capable of cutting thicker and more complex materials. Advancements in pump technology—such as direct-drive and intensifier pumps with improved efficiency and lifespan—are enhancing performance while lowering maintenance costs. Additionally, portable and compact water jetting units are gaining traction in maintenance, cleaning, and surface preparation applications, especially in oil & gas and infrastructure sectors.

Regionally, Asia-Pacific is expected to lead market growth by 2026, fueled by rapid industrialization, infrastructure development, and increasing investments in manufacturing automation in countries like China, India, and South Korea. Meanwhile, North America and Europe continue to innovate in high-precision industrial applications, with strong support from aerospace and defense sectors.

In conclusion, the 2026 water jetting machine market reflects a convergence of sustainability, digitalization, and performance optimization. Companies investing in R&D for energy-efficient systems, smart integration, and multi-material processing capabilities are likely to dominate this evolving landscape.

Common Pitfalls When Sourcing Water Jetting Machines: Quality and Intellectual Property (IP) Concerns

Sourcing water jetting machines, especially from overseas suppliers or lesser-known manufacturers, presents several risks related to quality and intellectual property. Being aware of these pitfalls can help buyers make informed decisions and avoid costly mistakes.

Poor Build Quality and Substandard Components

Many low-cost suppliers cut corners by using inferior materials and components to reduce manufacturing costs. This includes weaker pumps, lower-grade seals, and less durable cutting heads. The result is reduced machine lifespan, frequent breakdowns, higher maintenance costs, and inconsistent cutting performance. Buyers may initially save money but face significantly higher total cost of ownership due to downtime and part replacements.

Inaccurate or Exaggerated Performance Specifications

Some suppliers inflate technical specifications such as cutting pressure (e.g., claiming 60,000 psi when actual output is much lower), cutting speed, or precision capabilities. Without independent verification or third-party testing data, it can be difficult to assess true performance. This misrepresentation can lead to the machine failing to meet production requirements, impacting project timelines and quality.

Lack of Quality Control and Certification

Reputable water jetting machines should adhere to international quality and safety standards (e.g., ISO, CE, UL). Suppliers without proper quality management systems may lack consistent inspection processes, leading to variability between units. Purchasing equipment without recognized certifications increases the risk of safety hazards and non-compliance with regional regulations.

Intellectual Property Infringement

A significant concern when sourcing from certain regions is the potential for IP violations. Some manufacturers reverse-engineer designs from leading brands without licensing the technology. This not only raises legal risks for buyers who import or use such machines but also often results in lower reliability and performance due to unoptimized design and lack of R&D investment.

Limited Technical Support and Spare Parts Availability

Even if a machine initially performs well, long-term success depends on support infrastructure. Many low-cost suppliers offer minimal technical assistance, lack English-speaking engineers, or delay spare part shipments. This can result in extended downtime. Additionally, proprietary components with copied designs may not be compatible with standard industry parts, making repairs difficult and expensive.

Hidden Costs from Warranty and Service Limitations

Warranties offered by some suppliers may appear comprehensive but often exclude key components like pumps or high-pressure seals. Service may require shipping the machine back to the country of origin, incurring significant logistics costs and delays. Buyers should scrutinize warranty terms and service agreements before purchase.

Risk of Counterfeit or Clone Machines

Some suppliers market machines as “compatible with” or “similar to” well-known brands, but in reality, they are unauthorized clones. These machines may use stolen designs or misleading branding, posing legal exposure for distributors and end users. Additionally, clone machines typically lack innovation and long-term software or hardware updates.

Conclusion

To mitigate these risks, buyers should conduct thorough due diligence: request performance validation, inspect manufacturing facilities if possible, verify IP compliance, and prioritize suppliers with proven track records, certifications, and robust after-sales support. Investing in quality and authenticity from the outset protects both operational efficiency and legal standing.

Logistics & Compliance Guide for Water Jetting Machine

This guide outlines the essential logistics and compliance considerations for the transportation, import/export, installation, and operation of a water jetting machine. Adhering to these guidelines ensures safe handling, legal compliance, and operational efficiency.

Shipping and Transportation

Ensure the water jetting machine is securely crated and protected against moisture, vibration, and impact during transit. Use skids or pallets suitable for forklift handling. Confirm that all loose components (nozzles, fittings, hoses) are separately packaged and labeled. Choose a freight carrier experienced in handling industrial machinery, and verify insurance coverage for high-value equipment. For international shipments, provide accurate weight, dimensions, and material composition details to avoid customs delays.

Import/Export Regulations

Comply with international trade regulations when shipping across borders. Obtain necessary export licenses if required by the country of origin (e.g., U.S. Department of Commerce for certain high-pressure technologies). Ensure all documentation—including commercial invoice, packing list, and bill of lading—accurately describes the machine and includes Harmonized System (HS) codes (commonly 8465.95 or similar for machining centers, but verify based on configuration). Check import restrictions, duties, and taxes in the destination country. Machines with electrical components must meet regional standards (e.g., CE for Europe, UKCA for the UK, EAC for Russia).

Customs Clearance

Prepare complete customs documentation to facilitate swift clearance. Include technical specifications, end-use statements, and certification of conformity where applicable. Declare the total value of the shipment correctly to avoid penalties. For dual-use items (equipment that may have industrial or military applications), additional scrutiny may apply—ensure compliance with export control regimes such as Wassenaar Arrangement guidelines.

Installation and Site Requirements

Verify that the installation site meets structural, electrical, and plumbing requirements. The machine requires a stable, level foundation capable of supporting its operational weight. Electrical supply must match the machine’s voltage, phase, and amperage specifications (e.g., 480V 3-phase in North America). Provide adequate water supply with proper filtration and drainage for wastewater, which may contain abrasive particles or contaminants. Ensure sufficient clearance for maintenance and operator access.

Safety and Operational Compliance

Comply with occupational health and safety standards such as OSHA (USA), HSE (UK), or ISO 12100 for machinery safety. Equip the machine with appropriate guards, emergency stops, and pressure relief valves. Operators must be trained in high-pressure system hazards, including injection injuries and equipment failure. Follow safe operating procedures for abrasive water jetting, including proper use of personal protective equipment (PPE) such as face shields, gloves, and hearing protection.

Environmental Regulations

Manage wastewater and spent abrasives according to local environmental laws. Install filtration or settling systems to prevent hazardous material discharge. Dispose of used abrasives (e.g., garnet) through licensed waste handlers if contaminated. Monitor noise levels and implement controls if they exceed permissible exposure limits (e.g., OSHA or EU Directive 2003/10/EC).

Certification and Documentation

Maintain up-to-date technical files, user manuals, and compliance certificates. The machine should carry relevant marks such as CE, UKCA, or EAC, indicating conformity with regional safety, health, and environmental standards. Keep records of maintenance, pressure testing, and operator training for audit purposes.

Maintenance and Recertification

Follow the manufacturer’s maintenance schedule to ensure safe and compliant operation. Conduct periodic inspections of high-pressure tubing, seals, and safety systems. Recertify pressure vessels or pumps as required by local regulations (e.g., ASME standards in the U.S.). Document all maintenance activities and retain records for the machine’s operational life.

Conclusion for Sourcing a Water Jetting Machine

After a thorough evaluation of operational needs, technical specifications, budget constraints, and long-term maintenance requirements, sourcing a water jetting machine is a strategic investment that enhances cutting precision, operational efficiency, and material versatility. By selecting a machine that aligns with production demands—whether for industrial manufacturing, aerospace, automotive, or stone fabrication—the organization can achieve cleaner cuts, reduced waste, and lower environmental impact compared to traditional thermal cutting methods.

Key factors such as pressure rating, pump type (integrative vs. direct drive), automation compatibility, and after-sales support from the supplier must be prioritized during procurement. Additionally, opting for reputable manufacturers with proven reliability, comprehensive service networks, and training support ensures optimal uptime and return on investment.

Ultimately, the right water jetting machine not only meets current project requirements but also offers scalability for future applications. With proper selection and integration into existing workflows, it positions the organization for increased productivity, superior product quality, and a competitive edge in the market.