The global market for plumbing fixtures, including critical components like water intake valve toilets, is experiencing steady growth driven by rising urbanization, infrastructure development, and increasing demand for water-efficient sanitary solutions. According to Grand View Research, the global bathroom fixtures market was valued at USD 55.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.9% from 2023 to 2030. Similarly, Mordor Intelligence projects a CAGR of over 5% during the forecast period (2023–2028), fueled by advancements in smart plumbing technologies and growing emphasis on sustainable water use in both residential and commercial construction. As demand for reliable, high-performance water intake valves rises—key components ensuring efficient toilet operation and water conservation—manufacturers are increasingly innovating in materials, flow control, and leak prevention. In this competitive landscape, identifying the top producers becomes essential for contractors, developers, and procurement professionals seeking quality, durability, and compliance with evolving regulatory standards. The following list highlights the top 10 water intake valve toilet manufacturers leading the industry in innovation, market reach, and technical excellence.

Top 10 Water Intake Valve Toilet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Plumbing & Toilet Trim

Domain Est. 1995

Website: lavelle.com

Key Highlights: Lavelle manufactures toilet trim products for OEM applications and home repairs. Our standard OEM products include:…

#2 Zurn

Domain Est. 1995

Website: zurn.com

Key Highlights: Zurn is a leader in commercial, municipal, and industrial markets. We manufacture the largest breadth of engineered water solutions in the industry….

#3 Legend Valve

Domain Est. 1996

Website: legendvalve.com

Key Highlights: Legend provides high quality valves and fittings for plumbing, industrial, commercial and residential markets….

#4 Korky® Toilet Repair

Domain Est. 1995

Website: korky.com

Key Highlights: We are continuously committed to designing repair parts that are universal to fit the majority of toilets. Korky manufactures in the United States to provide ……

#5 BrassCraft

Domain Est. 1995

Website: brasscraft.com

Key Highlights: At BrassCraft our focus is providing the highest quality plumbing products manufactured today. Our products are well-engineered and need-based, with a proven ……

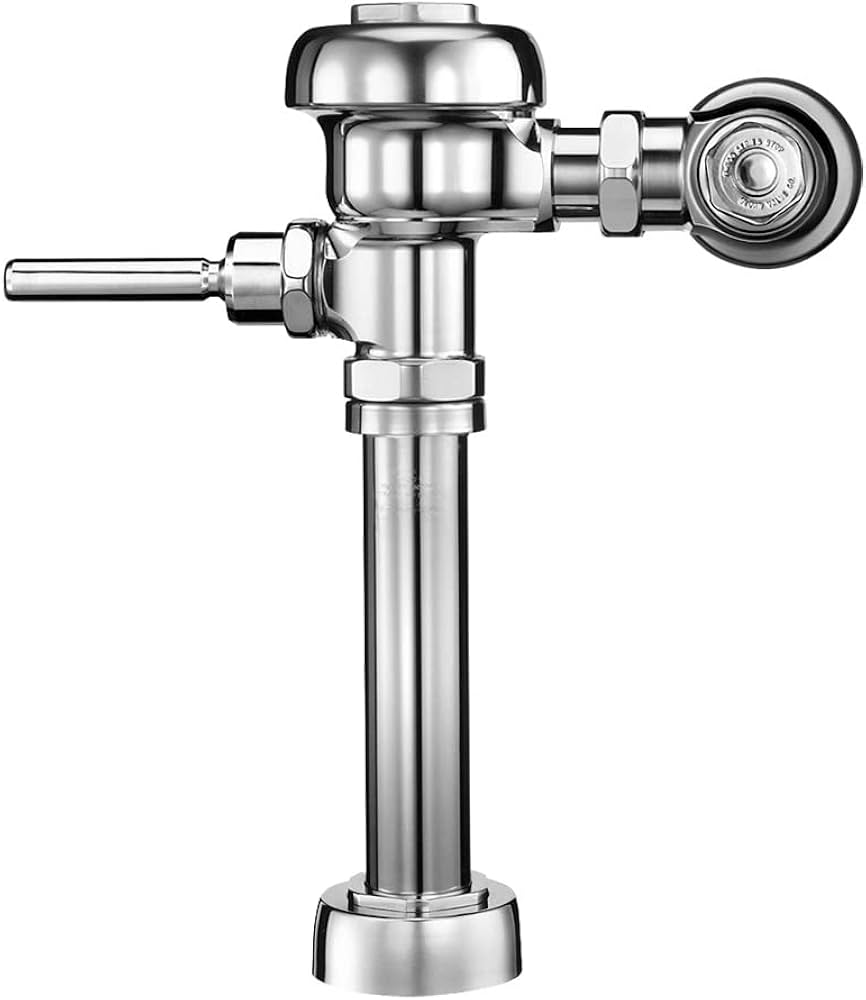

#6 Sloan: Water

Domain Est. 1998

Website: sloan.com

Key Highlights: Sloan is committed to water-efficient commercial bathroom products & sustainable solutions. Shop our selection for faucets, sinks, toilets, urinals & more….

#7 Mansfield Plumbing

Domain Est. 1998

Website: mansfieldplumbing.com

Key Highlights: Sleek and sophisticated 2-piece toilet. Broadway is a class look with classic Mansfield quality – and that’s worth a curtain call….

#8 McGuire Manufacturing

Domain Est. 1999

Website: mcguiremfg.com

Key Highlights: McGuire Manufacturing—Over 50 years of quality commercial plumbing. Professionals’ choice for traps, stops, supplies, drains, and strainers….

#9 dahl Valve

Domain Est. 2000

Website: dahlvalve.com

Key Highlights: dahl Valve manufactures premium plumbing valves, parts, and fittings. Made in Canada with 100% American brass….

#10 Geberit fill valves and flush valves

Domain Est. 2021 | Founded: 1964

Website: geberit-global.com

Key Highlights: Geberit offers compatible fill and flush valves for every Geberit concealed cistern made since 1964 and for surface-mounted and other cisterns from many ceramic ……

Expert Sourcing Insights for Water Intake Valve Toilet

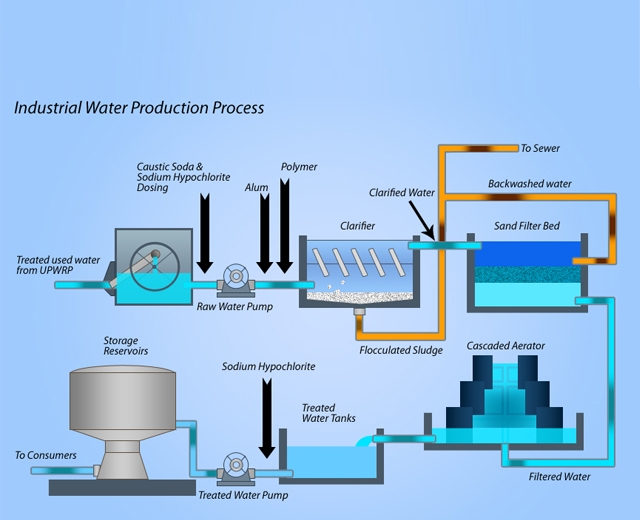

H2: Projected 2026 Market Trends for Water Intake Valve Toilets

The global market for water intake valve toilets is poised for significant transformation by 2026, driven by technological innovation, environmental regulations, and shifting consumer preferences. As sustainability and water conservation rise in priority, the demand for efficient and smart toilet systems—particularly those incorporating advanced water intake valve mechanisms—is expected to grow steadily.

-

Increased Demand for Water-Efficient Fixtures

By 2026, stricter water conservation regulations in regions such as North America, Western Europe, and parts of Asia-Pacific will accelerate the adoption of high-efficiency toilets (HETs). Water intake valves will play a critical role in ensuring precise water delivery, minimizing waste, and complying with standards like the U.S. Environmental Protection Agency’s WaterSense program. Manufacturers are expected to focus on valves that optimize flush performance using 1.28 gallons per flush (gpf) or less. -

Integration with Smart Toilet Technology

Smart toilets are becoming mainstream, and by 2026, water intake valves will increasingly be integrated with digital controls, sensors, and IoT connectivity. These intelligent valves will adjust water volume based on usage patterns, detect leaks in real-time, and communicate with home automation systems. This trend will be fueled by rising disposable incomes and consumer interest in hygiene, convenience, and data-driven home management. -

Growth in Emerging Markets

Urbanization and infrastructure development in countries like India, Indonesia, and Brazil will drive demand for modern sanitation solutions. Water intake valve toilets—especially affordable, durable models—will see increased penetration in both residential and commercial sectors. Local manufacturing and partnerships with global brands are likely to expand market reach. -

Eco-Friendly Materials and Sustainable Manufacturing

Environmental concerns will push manufacturers to adopt recyclable materials and low-impact production methods for water intake valves. By 2026, valves made from lead-free brass, PEX, or advanced polymers will dominate, aligning with green building certifications such as LEED and BREEAM. -

Rise of Dual-Flush and Precision-Flow Valves

Dual-flush mechanisms, which allow users to choose between full and partial flushes, will continue gaining traction. Next-generation precision-flow valves will offer variable water delivery, reducing average water consumption without compromising performance. These innovations will be especially prominent in eco-conscious markets like Scandinavia and Germany. -

Competitive Landscape and Innovation

Key players such as Kohler, TOTO, American Standard, and Jaquar are expected to intensify R&D efforts focused on valve reliability, noise reduction, and anti-siphon features. Patent filings related to adaptive water intake systems are projected to rise, reflecting a competitive push for differentiation.

In conclusion, the 2026 market for water intake valve toilets will be shaped by a convergence of regulatory pressure, smart technology integration, and sustainability imperatives. Manufacturers that prioritize innovation, water efficiency, and user-centric design will be best positioned to capture growing market share.

Common Pitfalls Sourcing Water Intake Valve for Toilets (Quality, IP)

Sourcing reliable water intake valves for toilets—especially in contexts requiring specific quality standards or Ingress Protection (IP) ratings—can be fraught with challenges. Overlooking key aspects can lead to premature failures, leaks, poor performance, and increased maintenance costs. Below are common pitfalls to avoid:

1. Prioritizing Cost Over Quality

One of the most frequent mistakes is selecting the cheapest available valve to cut initial costs. Low-cost components often use inferior materials (e.g., brittle plastics, low-grade brass, or substandard rubber seals), leading to:

– Shorter lifespan

– Cracking or leaking under pressure

– Corrosion in hard water environments

– Inconsistent water flow or fill performance

Solution: Invest in valves from reputable manufacturers with proven track records. Perform a total cost of ownership (TCO) analysis, factoring in durability and maintenance.

2. Ignoring Ingress Protection (IP) Ratings

In damp or outdoor environments (e.g., public restrooms, external facilities), IP ratings are crucial. The water intake valve may be part of a flush system with electronic or solenoid components that require protection against moisture and dust.

Common Pitfall: Assuming all valves are equally resistant to water ingress. Standard mechanical valves may not have IP ratings, while solenoid-driven or sensor-based valves do.

Solution: Verify the IP rating (e.g., IP65, IP67) matches the installation environment. For wet locations, a minimum of IP65 is typically recommended.

3. Mismatched Specifications and Standards

Valves must comply with regional plumbing codes and standards (e.g., ASSE 1002 in the USA, WRAS in the UK, or DVGW in Germany). Sourcing non-compliant valves can lead to:

– Installation rejections

– Voided warranties

– Health and safety risks

Solution: Confirm valves meet local regulatory standards and are certified by recognized bodies.

4. Poor Material Compatibility

Valves exposed to aggressive water (high chlorine, mineral content, or chemical cleaners) degrade quickly if materials aren’t compatible.

Pitfall: Using brass valves without lead-free certification or plastic valves prone to hydrolysis.

Solution: Select materials such as dezincification-resistant (DZR) brass, food-grade polypropylene, or PPSU for longevity and safety.

5. Inadequate Flow Rate and Pressure Tolerance

Valves must operate efficiently across expected water pressure ranges. Using a valve not rated for local supply pressures (e.g., high-rise buildings with boosted pressure) can result in:

– Noisy operation

– Hammering (water hammer)

– Seal failure

Solution: Match valve specifications (e.g., 1–10 bar operating range) to site conditions. Consider pressure-reducing features if necessary.

6. Overlooking Installation and Maintenance Needs

Complex or non-standard valves may require specialized tools or training for installation and servicing.

Pitfall: Choosing proprietary designs that lock you into a single supplier or increase downtime during repairs.

Solution: Opt for valves with universal fittings (e.g., 3/8″ compression, 1/2″ NPT) and modular designs for easy maintenance.

7. Neglecting Supplier Reliability and Support

Even high-quality valves can fail if sourced from unreliable suppliers with poor quality control or inconsistent supply chains.

Pitfall: Receiving mixed batches with varying quality or counterfeit components.

Solution: Audit suppliers, request sample testing, and establish long-term contracts with performance clauses.

8. Assuming All “IP-Rated” Valves Are Suitable

Some suppliers may misleadingly claim IP protection without third-party certification.

Pitfall: Purchasing valves labeled “water-resistant” without verified IP ratings.

Solution: Demand test reports or certification from accredited labs (e.g., TÜV, UL) confirming IP ratings.

By addressing these pitfalls proactively, procurement teams and facility managers can ensure reliable, code-compliant, and long-lasting water intake valve performance in toilet systems.

Logistics & Compliance Guide for Water Intake Valve (Toilet)

This guide outlines key logistics considerations and regulatory compliance requirements for the distribution and sale of water intake valves used in toilets. Adherence to these guidelines ensures product safety, market access, and operational efficiency.

Product Identification and Specifications

- Product Name: Water Intake Valve (also known as Fill Valve, Ballcock)

- Primary Function: Controls the flow of water into the toilet tank after flushing, automatically shutting off when the tank reaches the preset water level.

- Key Components: Float mechanism (cup or ball), inlet shank, refill tube, overflow tube, adjustment screw/knob.

- Common Materials: Brass (inlet shank), ABS plastic, polypropylene, silicone/rubber seals.

- Standard Dimensions: Typically designed to fit standard toilet tank configurations (e.g., center outlet, side outlet). Shank diameter and thread pitch are critical for compatibility.

- Performance Requirements: Must reliably shut off at the correct water level, withstand typical household water pressure (e.g., 20-80 psi), and resist corrosion.

Regulatory Compliance

Plumbing Codes and Standards (North America)

- Uniform Plumbing Code (UPC) / International Plumbing Code (IPC): Mandate that all plumbing fixtures and fittings, including fill valves, must be approved for use. Products must bear evidence of certification.

- ASSE 1002: Standard for Performance Requirements for Individual Flush Valves (Water Closets and Urinals). While primarily for flush valves, fill valves are often evaluated under similar principles for backflow prevention and reliability. Compliance ensures the valve prevents back-siphonage.

- ASSE 1019: Standard for Performance Requirements for Water Supply System Components Using Materials Other Than Metallics. Relevant for plastic components, ensuring material compatibility and pressure/temperature resistance.

- NSF/ANSI 61: Drinking Water System Components – Health Effects. CRITICAL. The valve (especially wetted surfaces like the shank, internal passages, seals, and any plastic parts contacting water) MUST be certified to NSF/ANSI 61. This certification verifies that the materials do not leach harmful contaminants into drinking water. Look for the NSF 61 or NSF-pw (parts per million) mark.

- NSF/ANSI 372: Drinking Water System Components – Lead Content. CRITICAL. The valve must comply with lead content restrictions (maximum 0.25% weighted average lead content in wetted surfaces). This is often included in NSF 61 certification (look for NSF 61/372 or NSF-pw/372). Compliance is mandatory in the US (Safe Drinking Water Act) and similar regulations exist elsewhere.

Regulatory Compliance (European Union)

- Construction Products Regulation (CPR) 305/2011/EU: Requires CE marking for construction products placed on the EU market, including plumbing components. The specific harmonized standard for tapware and valves is EN 817 (Taps and mixing taps for sanitary purposes – General technical specifications) or EN 1111 (Chemical toilet devices – Taps and flush valves – General technical specifications). The valve must be assessed and declared compliant.

- Drinking Water Safety: Member states have national regulations, but compliance with WRAS (UK) approval or equivalent national schemes (e.g., DVGW in Germany, KIWA in Netherlands) is often required or expected to demonstrate material safety for potable water contact. These assess both health effects and material performance.

Regulatory Compliance (Other Regions)

- Australia/New Zealand: Must comply with the WaterMark certification scheme (AS/NZS 3500.2:2021 – Plumbing and drainage – Sanitary plumbing and drainage) for plumbing products. WaterMark Level 1 or 2 certification is typically required, including material safety (AS/NZS 4020) and performance testing.

- Canada: Requires compliance with NSF/ANSI 61 and NSF/ANSI 372 (as in the US). Certification by a SCC-accredited body (e.g., CSA, IAPMO R&T) is standard.

- General Principle: Always verify the specific plumbing code and potable water material safety regulations of the target market country/region.

Packaging and Labeling Requirements

- Compliance Markings: Clearly display required certification marks on the product and/or packaging:

- NSF 61, NSF 61/372, or NSF-pw (US/Canada)

- WRAS Approval, DVGW, KIWA mark (EU/UK/DACH/Benelux)

- WaterMark (Australia/NZ)

- CE Marking (EU)

- Product Information: Label must include:

- Manufacturer/Importer name and address

- Product name/model number

- Size/Specifications (e.g., 3/8″ inlet, center outlet)

- Applicable standards met (e.g., “Complies with NSF/ANSI 61 & 372”, “Conforms to EN 817”)

- Installation instructions (or reference to where they can be found)

- Batch/lot number for traceability

- Language: Labels and instructions must be in the official language(s) of the destination country.

- Packaging: Must protect the valve from damage during transit. Use anti-corrosion measures if necessary. Include sufficient sealing washers/gaskets.

Logistics and Supply Chain Considerations

- Storage:

- Store in a clean, dry, well-ventilated area.

- Protect from direct sunlight, extreme temperatures (avoid freezing), and moisture to prevent degradation of plastics and seals.

- Keep away from chemicals, solvents, and oils.

- Store off the ground on pallets.

- Handling:

- Handle with care to avoid damaging threads, the float mechanism, or plastic components.

- Avoid dropping or applying excessive force.

- Transportation:

- Pack securely within outer cartons to prevent movement and impact damage.

- Use appropriate dunnage (packing material) to fill voids.

- Follow standard freight classification for plumbing fixtures.

- Ensure temperature-controlled transport if moving through extreme environments.

- Provide clear handling instructions on outer packaging (e.g., “Fragile”, “This Side Up”).

- Documentation:

- Maintain Certificates of Conformity (CoC) for all certifications (NSF, WRAS, WaterMark, CE Declaration of Performance).

- Keep detailed product specifications and test reports.

- Ensure accurate commercial invoices, packing lists, and bills of lading.

- For international shipments, ensure Harmonized System (HS) code is correct (e.g., 8481.80 for other taps, cocks, and valves).

- Inventory Management:

- Implement a First-In, First-Out (FIFO) system to manage shelf life, especially for seals which can degrade over time.

- Regularly inspect stock for damage or signs of material degradation.

Quality Assurance and Traceability

- Supplier Qualification: Source valves only from manufacturers with established quality management systems (e.g., ISO 9001) and proven compliance with relevant standards.

- Incoming Inspection: Implement checks upon receipt to verify packaging integrity, correct labeling, and absence of visible damage.

- Batch Traceability: Maintain records linking each batch/lot of valves to its manufacturing origin and associated compliance documentation (CoC, test reports). This is crucial for recalls.

- Customer Support: Be prepared to provide compliance documentation and technical support to distributors, retailers, and plumbers upon request.

Summary

Successful logistics and compliance for toilet water intake valves hinge on verifiable certification to potable water safety standards (NSF 61/372, WRAS, WaterMark, etc.) and adherence to regional plumbing codes (UPC/IPC, CPR/EN). Robust packaging, clear labeling, careful handling, proper storage, and meticulous documentation are essential throughout the supply chain to ensure product integrity and market access. Always prioritize compliance with the regulations of the specific destination market.

In conclusion, sourcing a water intake valve for a toilet requires careful consideration of compatibility, quality, and reliability. It is essential to identify the correct valve type—such as a ballcock or fill valve—based on the toilet model and manufacturer specifications. Prioritizing durable materials like ceramic or high-grade plastic ensures long-term performance and reduces the risk of leaks or malfunctions. Sourcing from reputable suppliers or trusted brands helps guarantee authenticity and access to warranties or customer support. Additionally, considering ease of installation and availability of replacement parts can save time and maintenance costs in the future. By making an informed choice when sourcing a water intake valve, homeowners and plumbers can ensure efficient water usage, reliable operation, and extended toilet lifespan.