The global water heater market is experiencing steady growth, driven by rising urbanization, increasing residential construction, and a growing emphasis on energy-efficient water heating solutions. According to Grand View Research, the global water heater market size was valued at USD 37.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expanding market has created heightened demand for critical safety components such as water heater bonding products—specifically grounding and bonding hardware that ensure electrical safety in both residential and commercial installations. As building codes and safety standards become more stringent worldwide, manufacturers of reliable bonding solutions are playing an increasingly vital role in the overall water heating ecosystem. In this context, the top 5 water heater bonding manufacturers have distinguished themselves through innovation, compliance with international standards, and strategic partnerships with major HVAC and plumbing brands.

Top 5 Water Heater Bonding Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 About Bond

Domain Est. 2001

Website: bondwater.com

Key Highlights: Bond Water Technologies specializes in cooling water services, boiler water services, wastewater management services, lab and Legionella testing …Missing: heater manufacturer…

#2 WATER HEATER GROUNDING KIT

Domain Est. 1994

Website: southwire.com

Key Highlights: Grounding, Bonding, Splicing. WATER HEATER GROUNDING KIT p-65183240 65183240. Southwire #: 65183240 Model #: HW.GSCRQ10. 0.0. (0). 0.0 out of 5 stars….

#3 Bond Supply

Domain Est. 2000

Website: bondsupply.com

Key Highlights: FEATURED CATEGORIES · Piping · Copper · PVC · Water Heaters. Residential · Commercial · Toilets · One Piece Toilets · Two Piece Toilets · Tubs. American Standard….

#4 WaterFlex™ Expansion Stainless Steel Corrugated Water Heater …

Domain Est. 2001

Website: eastmanplumbing.com

Key Highlights: The WaterFlex™ Water Heater Connector by Eastman is a premium corrugated stainless steel connector designed for exceptional durability and reliability….

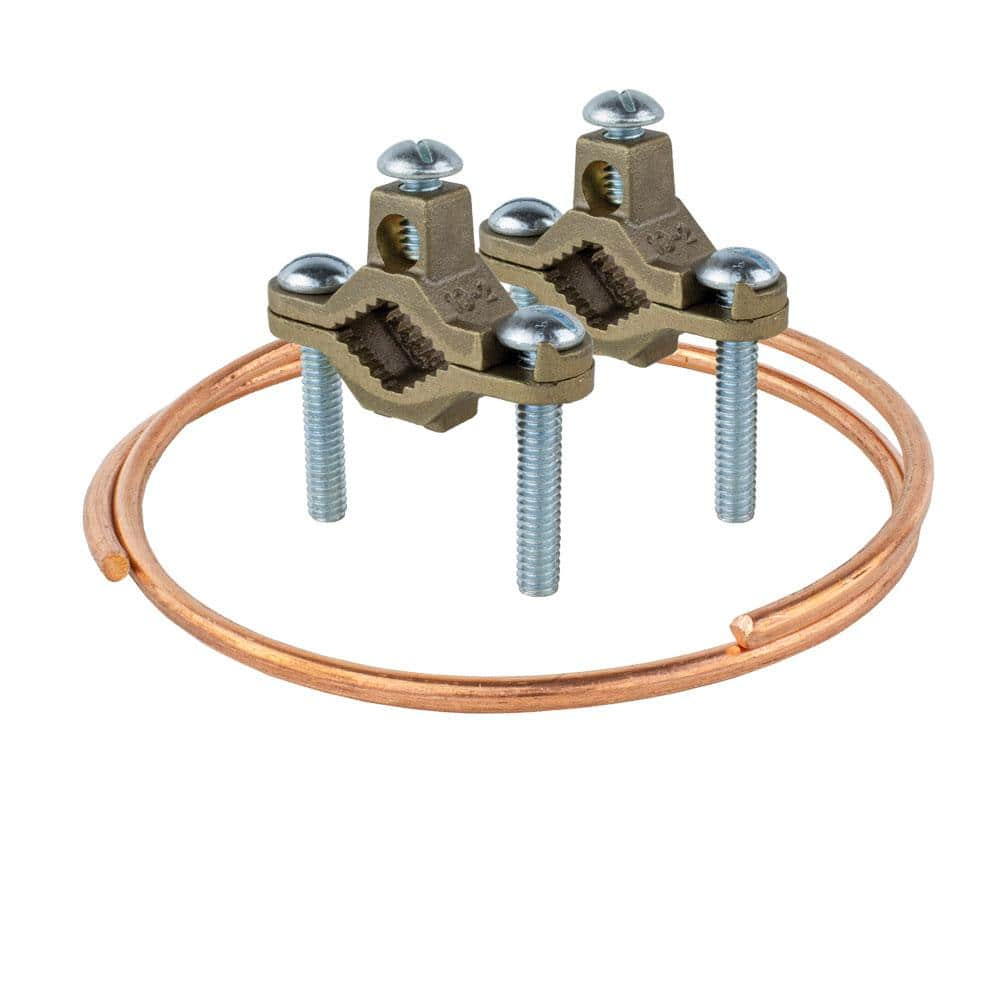

#5 Water Heater Bonding Kit 2 AWG 10AWG

Domain Est. 2012

Website: conversionstech.com

Key Highlights: In stock $5 deliveryThis bonding kit includes all necessary components for proper grounding of water heaters, including bonding wires, clamps, and connectors. It is suitable for …..

Expert Sourcing Insights for Water Heater Bonding

H2: Projected 2026 Market Trends for Water Heater Bonding

The water heater bonding market is poised for notable evolution by 2026, driven by regulatory compliance, technological advancements, and increased focus on electrical safety in residential and commercial infrastructure. Water heater bonding—commonly required by the National Electrical Code (NEC)—ensures that metal water piping systems are electrically bonded to the electrical grounding system to prevent shock hazards and eliminate potential differences in voltage.

Key trends expected to shape the market in 2026 include:

-

Regulatory Expansion and Enforcement

As building codes continue to be updated to enhance occupant safety, stricter enforcement of bonding requirements—particularly in retrofit and renovation projects—is anticipated. Jurisdictions across North America and parts of Europe are likely to adopt more rigorous inspections, boosting demand for compliant bonding solutions such as bonding straps, clamps, and grounding conductors. -

Growth in Residential Construction and Retrofitting

With the ongoing expansion of housing markets, especially in emerging economies and suburban developments, new installations of water heaters will drive the need for proper bonding. Additionally, aging infrastructure in developed regions will spur retrofitting activities, where bonding upgrades are often mandated during electrical system modernization. -

Adoption of Corrosion-Resistant and Durable Bonding Materials

Manufacturers are increasingly investing in bonding components made from tinned copper, stainless steel, and other corrosion-resistant materials. These materials extend the lifespan of bonding connections, especially in areas with hard water or high humidity—key considerations for long-term reliability. -

Integration with Smart and Energy-Efficient Water Heaters

The rise of smart water heaters and hybrid heat pump systems introduces more complex electrical systems, increasing the importance of proper grounding and bonding. By 2026, bonding components may be designed to integrate seamlessly with smart monitoring systems, enabling diagnostics for grounding integrity. -

Increased Awareness and Training

Industry training programs for electricians and plumbers are expected to place greater emphasis on proper bonding techniques. Enhanced awareness among contractors and homeowners about electrical safety risks—such as stray voltage and galvanic corrosion—will support higher adoption rates of compliant bonding practices. -

Sustainability and Material Sourcing

Environmental concerns may influence the sourcing of raw materials used in bonding components. Recycled copper and sustainably produced metals could gain preference among green building certifications like LEED, affecting procurement trends in the supply chain.

In conclusion, the water heater bonding market in 2026 will be shaped by heightened safety standards, technological integration, and sustainable practices. Stakeholders—including manufacturers, installers, and regulators—will need to align with these evolving demands to ensure reliable and code-compliant electrical systems in both new and existing buildings.

Common Pitfalls Sourcing Water Heater Bonding (Quality, IP)

Sourcing water heater bonding components—specifically bonding jumpers and related hardware—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to safety hazards, compliance failures, and legal risks. Below are the most common pitfalls encountered during procurement.

Poor Material Quality and Non-Compliance

One of the biggest risks in sourcing bonding components is receiving substandard materials that fail to meet electrical safety standards. Common issues include:

- Incorrect Conductor Gauge: Using undersized bonding jumpers (e.g., less than 6 AWG copper as typically required by the National Electrical Code – NEC Article 250) compromises conductivity and increases resistance, leading to ineffective bonding.

- Low-Grade Copper or Substitutes: Some suppliers may use copper-clad steel or alloys that do not provide adequate conductivity or corrosion resistance, especially in wet environments like water heater installations.

- Lack of Certification: Components may lack UL, CSA, or other recognized certification marks, indicating they haven’t been tested for safety and performance.

Result: Poor-quality bonding fails to ensure equal electrical potential, increasing the risk of electric shock, equipment damage, or fire.

Counterfeit or Non-Genuine Products

The market, especially online and in regions with weak regulatory oversight, is flooded with counterfeit electrical components that mimic reputable brands.

- Fake Branding: Products may bear the logos of well-known manufacturers but are produced without authorization, often with inferior materials and construction.

- Missing Documentation: Counterfeit items frequently lack datasheets, test reports, or traceability, making it difficult to verify compliance.

Result: Using counterfeit bonding hardware can void system warranties and expose contractors or facility owners to liability in the event of an electrical incident.

Intellectual Property Infringement

Sourcing components from unauthorized or copycat manufacturers can lead to IP violations, particularly with patented designs.

- Patented Terminal Designs: Some bonding clamps and connectors are covered by utility patents. Copying these designs without licensing constitutes infringement.

- Proprietary Configurations: Custom-engineered bonding solutions (e.g., pre-assembled kits with unique geometries) may be protected under IP law. Sourcing clones of these products risks legal action from the IP holder.

Result: Legal disputes, product seizures, and reputational damage for contractors or distributors involved in distributing infringing products.

Inadequate Documentation and Traceability

Lack of proper documentation is a red flag for both quality and IP authenticity.

- Missing Mill Certificates: No proof of copper purity or mechanical properties.

- No Compliance Statements: Absence of RoHS, REACH, or NEC compliance declarations.

- Untraceable Supply Chain: Inability to verify the manufacturer or production origin increases the risk of receiving non-compliant or stolen goods.

Result: Difficulty passing electrical inspections or justifying sourcing decisions during audits.

Cost-Driven Sourcing Without Due Diligence

Opting for the lowest-cost option often leads to the pitfalls above.

- Unrealistic Pricing: Extremely low prices may indicate material substitution, lack of certification, or IP infringement.

- Bypassing Reputable Distributors: Buying from unknown online sellers or gray-market suppliers increases exposure to risky components.

Result: Short-term savings lead to long-term costs due to rework, failed inspections, safety incidents, or legal issues.

Conclusion

To avoid these pitfalls, always source water heater bonding components from authorized, reputable suppliers with full product traceability and recognized certifications. Verify material specifications, ensure compliance with NEC and local codes, and confirm that products do not infringe on existing intellectual property. Prioritizing quality and legitimacy protects safety, ensures regulatory compliance, and mitigates legal risk.

H2: Logistics & Compliance Guide for Water Heater Bonding

Ensuring proper bonding of water heaters is critical for electrical safety, code compliance, and long-term system reliability. This guide outlines the logistical considerations and compliance requirements for the correct installation and verification of bonding at water heater installations.

Purpose of Bonding

Bonding connects metallic components of the water heater and associated piping to the electrical grounding system. This ensures:

– Equalization of electrical potential between metal parts.

– Safe path for fault current in the event of an electrical short.

– Prevention of electric shock hazards.

– Compliance with national and local electrical codes.

Regulatory & Code Compliance

1. National Electrical Code (NEC) Requirements

- NEC Article 250.104(A): Requires metal water piping systems, including those connected to water heaters, to be bonded to the electrical service grounding electrode system.

- Bonding Conductor Size: Based on the size of the largest ungrounded service-entrance conductor (per NEC Table 250.102(C)(1)).

- Example: For a 200A service with 2/0 AWG copper conductors, a minimum 4 AWG copper bonding jumper is required.

- Bonding Location: Must be installed on the supply side of the water heater and within 5 feet of where the piping enters the building or connects to the water heater (NEC 250.104(A)(1)).

2. Local Amendments

- Verify with the Authority Having Jurisdiction (AHJ) for any local code amendments.

- Some municipalities require bonding on both inlet and outlet pipes, even if plastic sections are present downstream.

3. Manufacturer Specifications

- Consult water heater installation manuals—some manufacturers mandate bonding even when non-metallic connectors are used.

Logistics of Installation

1. Pre-Installation Planning

- Site Assessment: Identify metallic water piping materials (copper, galvanized steel, etc.). Note presence of any dielectric unions, plastic piping, or water softeners that may interrupt continuity.

- Material Procurement:

- Copper bonding conductor (stranded or solid, per NEC requirements).

- Listed bonding clamp (UL 467 listed) compatible with pipe material (e.g., brass clamp for copper).

- Proper connectors and tools (wire stripper, crimp tool if needed, torque screwdriver).

- Permitting: Confirm whether an electrical permit is required for bonding work.

2. Installation Best Practices

- Conductor Routing: Run bonding conductor in a straight, continuous path—avoid sharp bends or strain.

- Clamp Installation:

- Clean pipe surface to bare metal before clamp placement.

- Secure clamp tightly to ensure low-resistance connection.

- Do not use pipe joints, unions, or valves as bonding points.

- Connection to Grounding System:

- Terminate the bonding conductor to the service grounding electrode conductor, grounding busbar, or cold water pipe within 5 feet of building entry.

- Use listed connectors and ensure tight, corrosion-resistant connections.

3. Special Scenarios

- Plastic Piping Systems: If the water supply line is non-metallic (e.g., PEX), bonding is still required on the metallic section of pipe immediately upstream of the water heater, if present.

- Dielectric Unions: Bond across dielectric unions using a bonding jumper to maintain electrical continuity.

- Retrofit Situations: In older homes lacking bonding, install bonding per current code—retrofit may require access to main electrical panel or grounding electrode.

Inspection & Verification

1. Visual Inspection

- Confirm bonding conductor is continuous, properly sized, and securely connected at both ends.

- Check for corrosion, damage, or loose clamps.

2. Continuity Testing

- Use a multimeter or continuity tester to verify electrical continuity between:

- The water heater tank (metal casing).

- The cold water inlet pipe.

- The main grounding system.

- Resistance should be near zero ohms.

3. Documentation

- Maintain records of bonding conductor size, clamp type, and inspection results.

- Provide documentation to homeowner and include in service records.

Safety & Maintenance

- De-energize: Always turn off power to the water heater before working on bonding.

- Annual Check: Recommend annual inspection for corrosion or loose connections, especially in humid environments.

- Repairs: Replace corroded or damaged bonding components immediately.

Summary

Proper water heater bonding is not optional—it’s a life-safety requirement. Adhering to NEC standards, local codes, and manufacturer guidance ensures that all metallic components are electrically continuous with the grounding system. Effective logistics—from planning and material selection to installation and inspection—ensure compliance, minimize liability, and protect occupants from electrical hazards.

Conclusion for Sourcing Water Heater Bonding:

Proper bonding of a water heater is a critical component of electrical safety in residential and commercial plumbing systems. It ensures electrical continuity and grounding, minimizing the risk of electric shock, equipment damage, and potential fire hazards. When sourcing materials for water heater bonding, it is essential to use approved components—such as a properly gauged copper bonding wire (typically #6 AWG), compatible clamps, and connectors—that meet local electrical codes and standards (e.g., NEC Article 250).

Sourcing these materials from reputable suppliers ensures compliance, durability, and safety. Additionally, correct installation by a qualified electrician or plumbing professional is vital to maintain system integrity and adherence to safety regulations. In conclusion, sourcing the right bonding materials and ensuring proper installation not only protects property and occupants but also ensures compliance with electrical and plumbing codes, contributing to a safe and reliable water heating system.