The global epoxy floor coatings market is experiencing robust growth, driven by increasing demand across industrial, commercial, and residential sectors for durable, chemical-resistant, and low-maintenance flooring solutions. According to Grand View Research, the global epoxy coatings market was valued at USD 11.2 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2024 to 2030. A key trend accelerating this growth is the rising preference for water-based epoxy formulations, which offer lower volatile organic compound (VOC) emissions and improved environmental and health safety profiles compared to solvent-based alternatives. Mordor Intelligence further highlights a growing regulatory push toward sustainable construction materials, particularly in North America and Europe, which is reshaping product development strategies among manufacturers. As demand for eco-friendly flooring solutions intensifies, a select group of innovators has emerged to lead the water-based epoxy floor paint segment—combining performance, sustainability, and scalable manufacturing. The following list highlights the top 8 manufacturers shaping this dynamic market.

Top 8 Water Based Epoxy Floor Paint Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Endura Paint

Domain Est. 2002

Website: endurapaint.com

Key Highlights: Endura is a manufacturer of high performance polyurethane and epoxy industrial coatings. Product lines include, industrial paint systems, ……

#2 High Performance Flooring

Domain Est. 1998

Website: industrial.sherwin-williams.com

Key Highlights: Sherwin-Williams High Performance Flooring offers durable, seamless resinous systems for commercial and industrial applications. Get in touch with us today!…

#3 EpoxyMaster Epoxy Floor Paint Kits For Garages, Basements …

Domain Est. 2008

Website: epoxymaster.com

Key Highlights: EpoxyMaster is your source for the finest in industrial epoxy floor paint coatings and DIY kits for garages, basements, kitchens, workshops and much more….

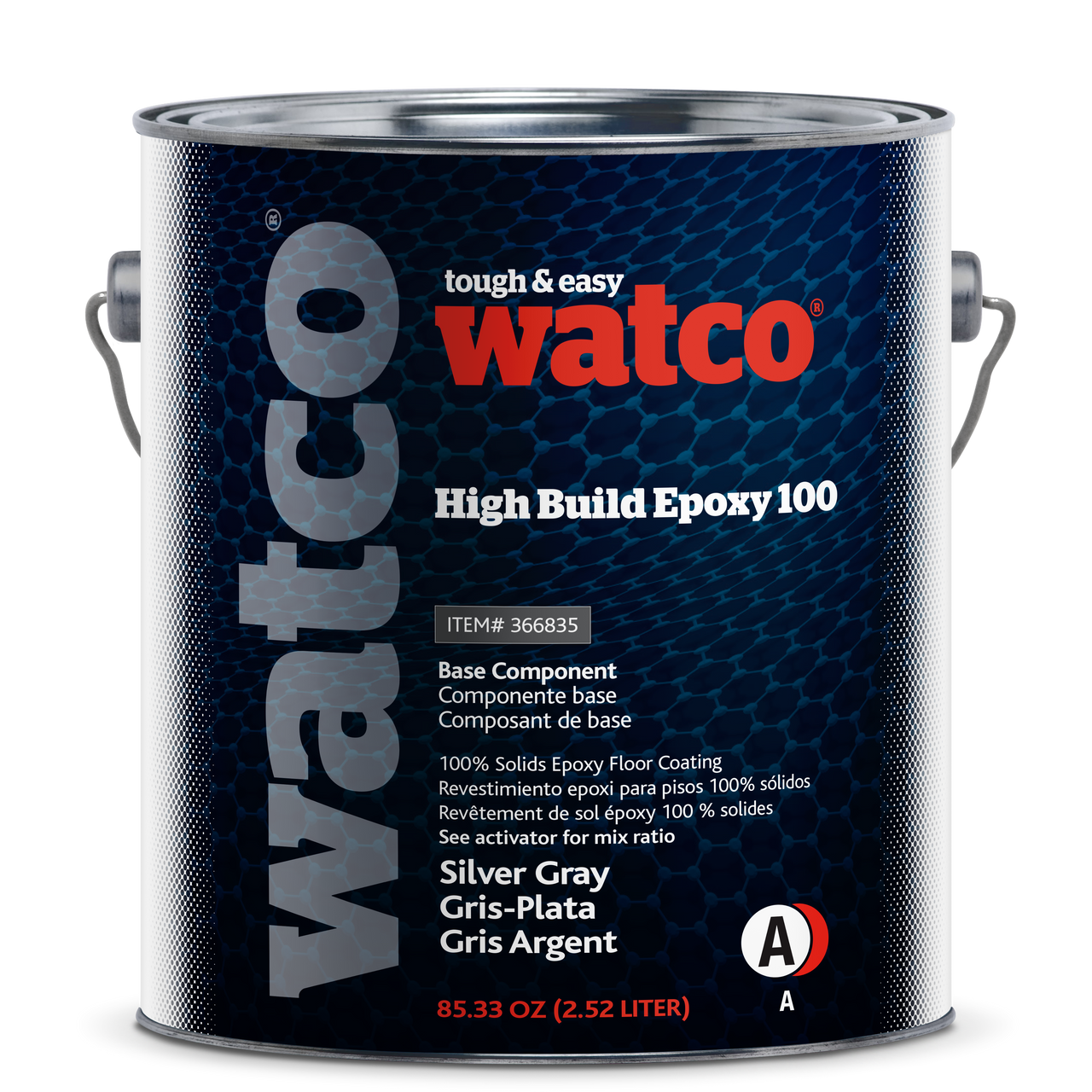

#4 Water Based Epoxy Coat

Domain Est. 2013

Website: watcofloors.com

Key Highlights: Free delivery over $1,250 · 30-day returns…

#5 Epoxy Coatings

Domain Est. 1995

Website: usa.sika.com

Key Highlights: UNIVERSAL TINTABLE EPOXY FLOOR COATING (WATER CLEAR OR PIGMENTED) · Sikafloor®-2570 WB. WATER BASED EPOXY PRIMER/SEALER FOR HIGH PERFORMANCE FLOOR FINISHES ……

#6 High Performance Epoxy Floor Coating

Domain Est. 2002

#7 Water Based Epoxy Floor Coating

Domain Est. 2009

Website: xtremepolishingsystems.com

Key Highlights: In stock $55.41 next-day delivery…

#8 Water Based Paint Chip Epoxy Floor System

Domain Est. 2018

Website: lifespecialtycoatings.com

Key Highlights: The Life Deck Specialty Coatings water based paint chip Epoxy flooring system provides an extremely tough and chemical resistant floor with a decorative paint ……

Expert Sourcing Insights for Water Based Epoxy Floor Paint

H2: Market Trends for Water-Based Epoxy Floor Paint in 2026

The global water-based epoxy floor paint market is poised for significant growth by 2026, driven by increasing environmental regulations, demand for sustainable construction materials, and advancements in coating technologies. This analysis explores key trends expected to shape the industry landscape in 2026 under the H2 heading.

-

Stringent Environmental Regulations Driving Adoption

Governments and environmental agencies worldwide are tightening VOC (Volatile Organic Compound) emission standards across industrial and commercial sectors. Water-based epoxy floor paints, which emit significantly lower VOCs compared to solvent-based counterparts, are becoming the preferred choice in compliance with regulations such as REACH in Europe and EPA standards in the U.S. By 2026, these regulatory pressures are expected to accelerate the shift toward eco-friendly flooring solutions, particularly in construction, automotive, and manufacturing industries. -

Growing Demand in Commercial and Residential Infrastructure

Urbanization and the expansion of commercial infrastructure—such as shopping malls, hospitals, schools, and data centers—are boosting demand for durable, low-maintenance flooring systems. Water-based epoxy coatings offer excellent resistance to abrasion, chemicals, and moisture while providing aesthetic versatility. Their ease of application and faster curing times make them ideal for projects requiring minimal downtime, further increasing their appeal in the construction sector by 2026. -

Technological Advancements Enhancing Performance

Innovation in resin formulations and additives has significantly improved the performance of water-based epoxy systems. By 2026, manufacturers are expected to offer products with enhanced durability, improved gloss retention, and better adhesion on diverse substrates—narrowing the performance gap with solvent-based epoxies. Nanotechnology and hybrid formulations (e.g., water-based epoxy-polyurethane hybrids) are also contributing to improved scratch and UV resistance, expanding applications into outdoor or high-exposure environments. -

Rise of Green Building Certifications

The proliferation of green building rating systems like LEED (Leadership in Energy and Environmental Design) and BREEAM is influencing material selection in construction. Water-based epoxy floor paints contribute to earning points for low-emitting materials and sustainability criteria. As more developers seek certification for their projects, demand for compliant flooring solutions will rise, bolstering market growth through 2026. -

Asia-Pacific as a Key Growth Region

The Asia-Pacific region is anticipated to lead market expansion by 2026 due to rapid industrialization, infrastructure development, and increasing awareness of environmental safety in countries like China, India, and South Korea. Government initiatives promoting sustainable manufacturing and urban development are creating favorable conditions for water-based epoxy adoption in both new constructions and renovation projects. -

Competitive Landscape and Strategic Partnerships

Major players such as PPG Industries, Sherwin-Williams, AkzoNobel, and Hempel are investing in R&D and expanding production capacities for water-based formulations. Strategic collaborations with construction firms and distributors are enabling broader market penetration. By 2026, consolidation and innovation are expected to intensify competition, leading to improved product availability and pricing. -

Consumer Preference Shift Toward Health and Safety

End-users, including facility managers and homeowners, are increasingly prioritizing indoor air quality and worker safety. Water-based epoxy systems, being non-toxic and odorless during application, align with these health-conscious preferences. This trend is particularly evident in healthcare, food processing, and educational facilities, where stringent hygiene standards apply.

In conclusion, the water-based epoxy floor paint market in 2026 will be shaped by regulatory mandates, technological innovation, and a growing emphasis on sustainability. With expanding applications and strong regional growth, particularly in Asia-Pacific, the market is set for sustained expansion, positioning water-based solutions as a mainstream choice in the global flooring industry.

Common Pitfalls Sourcing Water-Based Epoxy Floor Paint (Quality & IP)

Sourcing water-based epoxy floor paint involves navigating several potential pitfalls, especially concerning quality assurance and intellectual property (IP) protection. Overlooking these can lead to project failures, legal issues, and financial losses.

Poor Quality Control and Inconsistent Performance

One of the most prevalent issues is inconsistent product quality. Some manufacturers may cut costs by using substandard raw materials or outdated formulations, resulting in:

- Inadequate Film Formation: Poor coalescence due to low-quality resins or improper surfactant balance can lead to a weak, porous, or uneven film, compromising durability.

- Reduced Chemical and Stain Resistance: Inferior epoxy resins or hardeners may not provide the necessary resistance to common industrial or commercial spills, leading to premature degradation.

- Poor Adhesion: Subpar adhesion promoters or improper formulation can result in peeling, delamination, or blistering, especially on marginally prepared substrates.

- Extended Drying/Curing Times: Formulations lacking efficient coalescing agents or using low-reactivity hardeners can significantly delay return-to-service times, disrupting operations.

- Inconsistent Batch-to-Batch Performance: Lack of rigorous quality control can cause variations in viscosity, color, gloss, and cure profile, affecting application and final appearance.

To mitigate this, always request third-party test reports (e.g., ASTM, ISO standards), conduct on-site trials, and verify the manufacturer’s quality certifications (e.g., ISO 9001).

Intellectual Property (IP) Infringement Risks

The formulation of high-performance water-based epoxy coatings often involves proprietary chemistry. Sourcing from unreliable suppliers increases the risk of:

- Counterfeit or Knockoff Products: Unscrupulous manufacturers may replicate branded formulations without authorization, selling inferior or potentially unsafe products under misleading labels.

- Unauthorized Use of Patented Technologies: The supplier might be using patented resin systems, curing agents, or additives without proper licensing, exposing the buyer to legal liability if the infringement is discovered.

- Lack of Formulation Transparency: Suppliers may hide the true composition, making it impossible to verify IP compliance or ensure safety and environmental standards are met.

To protect against IP risks, conduct due diligence on the supplier’s reputation, request documentation on formulation ownership or licensing, and consider legal agreements that include IP indemnification clauses.

Inadequate Technical Support and Documentation

A significant pitfall is sourcing from suppliers who lack robust technical support. This includes:

- Insufficient Application Guidance: Missing or unclear instructions for surface preparation, mixing ratios, application methods, and environmental conditions (temperature, humidity) can lead to application failures.

- Lack of MSDS and Technical Data Sheets (TDS): Absence of up-to-date, accurate documentation hinders compliance with safety regulations and proper handling procedures.

- Poor Troubleshooting Assistance: When issues arise during or after application, inaccessible or unqualified technical support can delay resolution and increase costs.

Ensure the supplier provides comprehensive, accessible technical resources and has a responsive support team before finalizing procurement.

Misrepresentation of Environmental and Safety Claims

Water-based epoxies are often marketed as eco-friendly, but some suppliers may exaggerate or misrepresent their credentials:

- Hidden VOCs or Hazardous Additives: Some formulations may contain co-solvents or additives that increase VOC levels or include restricted substances not disclosed on safety sheets.

- Greenwashing: Claims of “zero VOC” or “non-toxic” may be misleading if not backed by independent certification (e.g., GREENGUARD, LEED compliance).

Always verify environmental claims with certified test reports and ensure full ingredient disclosure in compliance with regulations like REACH or TSCA.

By recognizing and proactively addressing these common pitfalls, buyers can ensure they source reliable, high-quality, and legally compliant water-based epoxy floor paint for successful flooring projects.

H2: Logistics & Compliance Guide for Water-Based Epoxy Floor Paint

Water-based epoxy floor paint offers a lower-VOC, more environmentally friendly alternative to solvent-based epoxies. However, safe and compliant handling, storage, transport, and disposal are essential. This guide outlines key logistics and compliance considerations.

H3: Safety Data Sheet (SDS) Compliance

- Mandatory Reference: Always obtain and review the specific Safety Data Sheet (SDS) provided by the manufacturer for the exact product SKU. Regulations (e.g., OSHA HazCom 2012 in the US, CLP in the EU) mandate SDS availability.

- Hazard Classification: Water-based epoxies are often classified as:

- Skin Irritant (H315): Can cause skin irritation.

- Eye Irritant (H319): Can cause serious eye irritation.

- Respiratory Sensitizer (H334 – Check SDS): May cause allergy or asthma symptoms or breathing difficulties if inhaled (component-dependent, e.g., certain amines).

- Aquatic Hazard (H411 – Check SDS): Toxic to aquatic life with long-lasting effects (due to surfactants, co-solvents, or trace components). Never allow into drains, waterways, or soil.

- First Aid Measures: Follow SDS instructions strictly for skin contact, eye contact, inhalation, and ingestion.

H3: Personal Protective Equipment (PPE)

- Mandatory: Use appropriate PPE during handling, mixing, application, and cleanup:

- Gloves: Chemical-resistant gloves (e.g., Nitrile, Neoprene – check SDS compatibility). Avoid latex.

- Eye Protection: Chemical splash goggles (safety glasses are insufficient).

- Respiratory Protection: Typically not required for general use due to low VOC. However, required if: SDS lists respiratory sensitizer (H334), during extensive sanding/abraded surface prep generating dust, or in poorly ventilated confined spaces. Use NIOSH-approved respirator (e.g., N95 for dust, half-mask with organic vapor cartridges if solvent exposure is possible from trace co-solvents or surface contaminants).

- Skin Protection: Wear long sleeves, long pants, and chemical-resistant apron. Wash skin immediately if contact occurs.

- Footwear: Closed-toe shoes, preferably chemical-resistant boots.

H3: Handling & Application

- Ventilation: Ensure adequate ventilation (natural or mechanical) during application and curing, especially in confined spaces. This removes moisture and any trace VOCs, and prevents vapor buildup.

- Mixing: Mix Part A (Resin) and Part B (Hardener) exactly according to manufacturer instructions. Use clean, dedicated tools. Mix thoroughly to ensure proper cure. Never mix more than can be applied within the pot life.

- Surface Preparation: Critical for adhesion. Follow manufacturer specs (e.g., cleaning, degreasing, profiling via grinding, shot blasting, or acid etching). Remove all dust, oil, grease, and loose material. Ensure substrate is dry.

- Application: Apply using recommended tools (roller, squeegee, trowel). Maintain consistent film thickness. Avoid applying in direct sunlight, high humidity (>85%), or temperatures outside the specified range (typically 50°F/10°C to 90°F/32°C). Protect from moisture during cure.

- Spills: Contain immediately using inert absorbents (e.g., sand, vermiculite, commercial spill kits). Do not wash into drains. Collect waste material for proper disposal. Clean area with water and detergent.

H3: Storage

- Original Containers: Store in tightly closed, original manufacturer’s containers.

- Environment: Store in a cool, dry, well-ventilated area away from heat, sparks, open flames, and direct sunlight. Temperature range typically 50°F (10°C) to 80°F (27°C). Avoid freezing.

- Segregation: Store away from strong oxidizers, acids, and bases. Keep Part A and Part B together but separate from other hazardous materials.

- Shelf Life: Adhere strictly to the manufacturer’s shelf life (usually 12-24 months). Mark containers with receipt and opening dates. Do not use expired product.

H3: Transportation (Non-DOT / Non-ADR – General Handling)

- Classification: Water-based epoxy paints are generally NOT classified as hazardous materials for transport under major regulations (e.g., US DOT 49 CFR, UN ADR/RID/ADN, IATA/IMDG) if they meet specific criteria (low flash point > 200°F/93°C, low flammability, non-toxic, non-corrosive). VERIFY THE SDS SECTION 14 (Transport Information) FOR THE SPECIFIC PRODUCT.

- Packaging: Transport in original, securely closed containers within sturdy, leak-proof outer packaging (e.g., cardboard boxes, crates). Prevent damage and leakage.

- Segregation: Do not transport with foodstuffs, animal feed, or incompatible chemicals (oxidizers, acids).

- Labeling: While often not requiring hazardous labels, clear labeling of contents (“Water-Based Epoxy Paint – Part A”, “Part B”) and manufacturer information is essential. Follow SDS Section 14 requirements.

- Securement: Ensure containers are immobilized within the vehicle to prevent movement, tipping, or damage during transit.

- Spill Kits: Carry appropriate spill containment and cleanup materials (absorbents, gloves, goggles) in the vehicle.

H3: Waste Disposal

- Regulatory Compliance: Dispose of waste (empty containers, spill cleanup materials, leftover mixed paint, wash water) in accordance with all applicable federal, state/provincial, and local regulations.

- Contaminated Wash Water: NEVER pour down drains, storm sewers, or onto the ground. Collect wash water (from cleaning tools, mops, spills) and allow solids to settle. Decant clear water (if permitted by local regulations after testing) or solidify entire slurry with absorbent. Dispose of solidified waste as hazardous or non-hazardous waste based on local regulations and testing. Consult local environmental authorities.

- Empty Containers: Triple-rinse containers (rinsate added to wash water waste stream) or use container disposal technology (e.g., puncture, drain). Dispose of rinsed containers according to local regulations (often as non-hazardous solid waste, but confirm). Check for local container return schemes.

- Leftover Mixed Paint: Allow to fully cure/harden in a thin layer in a well-ventilated, non-combustible area. Dispose of cured solids as non-hazardous solid waste (verify locally) or as hazardous waste if testing indicates.

- Documentation: Maintain records of waste disposal, including manifests if required.

H3: Key Regulatory Frameworks

- United States: OSHA Hazard Communication Standard (29 CFR 1910.1200), EPA regulations (Clean Water Act – stormwater, CERCLA – hazardous substances), DOT 49 CFR (if applicable), State/Local Air Quality Regulations (VOC limits).

- European Union: CLP Regulation (EC) No 1272/2008, REACH Regulation (EC) No 1907/2006, ADR for road transport, national implementation of EU directives.

- Other Regions: Consult local environmental, health, safety, and transport authorities (e.g., Health Canada, Environment Canada, WorkSafeBC, EPA Australia, national equivalents).

Disclaimer: This guide provides general information. ALWAYS CONSULT THE SPECIFIC PRODUCT’S SAFETY DATA SHEET (SDS) AND COMPLY WITH ALL APPLICABLE LOCAL, STATE/PROVINCIAL, AND NATIONAL REGULATIONS. Regulations and product formulations vary significantly.

Conclusion for Sourcing Water-Based Epoxy Floor Paint

Sourcing water-based epoxy floor paint presents a sustainable, health-conscious, and cost-effective solution for both industrial and commercial flooring applications. With growing environmental regulations and increased awareness of indoor air quality, water-based formulations offer a lower volatile organic compound (VOC) alternative to traditional solvent-based epoxies, without compromising on durability, adhesion, or chemical resistance.

When sourcing, it is essential to evaluate suppliers based on product performance specifications, environmental certifications (such as GREENGUARD or LEED compliance), technical support, and consistency in supply. Additionally, considering factors like ease of application, drying time, and compatibility with different substrates ensures optimal results and long-term performance.

By choosing reputable manufacturers and adhering to best practices in selection and application, businesses can achieve high-quality, eco-friendly flooring solutions that meet regulatory standards, enhance occupant well-being, and contribute to sustainable building initiatives. Ultimately, investing in high-performance water-based epoxy coatings supports both environmental responsibility and operational efficiency.