The global floor drain market is experiencing steady growth, driven by increasing construction activities, stringent hygiene regulations, and rising demand for efficient wastewater management systems in commercial, residential, and industrial sectors. According to a report by Mordor Intelligence, the global floor drain market was valued at USD 2.1 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029. Similarly, Grand View Research notes that expanding infrastructure developments and the growing emphasis on sanitary building designs are key factors fueling market expansion. With washroom applications accounting for a significant share of demand—especially in healthcare, hospitality, and public facilities—manufacturers specializing in durable, code-compliant, and low-maintenance floor drains are gaining strategic importance. In this evolving landscape, innovation in materials such as stainless steel, PVC, and engineered polymers, alongside advancements in anti-odor and pest-resistant designs, are setting new benchmarks for performance and safety. To support informed procurement and design decisions, here’s a data-driven look at the top 9 washroom floor drain manufacturers shaping the industry’s future.

Top 9 Washroom Floor Drain Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Jay R. Smith Mfg. Co.

Domain Est. 1996

Website: jrsmith.com

Key Highlights: Jay R. Smith Mfg. Co. is a leading manufacturer of quality engineered plumbing and drainage products in the non-residential construction industry….

#2 Floor Drains & Channels Product Selector

Domain Est. 1996

Website: blucher.com

Key Highlights: Floor Drains & Channels Product Selector. Please select one of the following categories to narrow down your product search. Pipes & …Missing: washroom manufacturer…

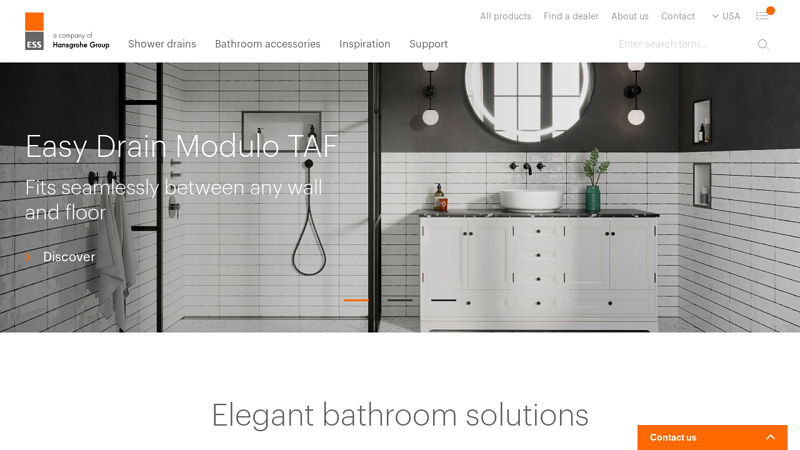

#3 Shower drains & trendsetting bathroom solutions

Domain Est. 2013

Website: easydrainusa.com

Key Highlights: We are the inventor, manufacturer and official supplier of Easy Drain shower drains. Create the bathroom of your dreams with our innovative solutions….

#4 Floor Drains

Domain Est. 1995

Website: zurn.com

Key Highlights: Commercial floor drains from Zurn provides a complete plumbing fixtures of line floor drains that are durable and easy to install….

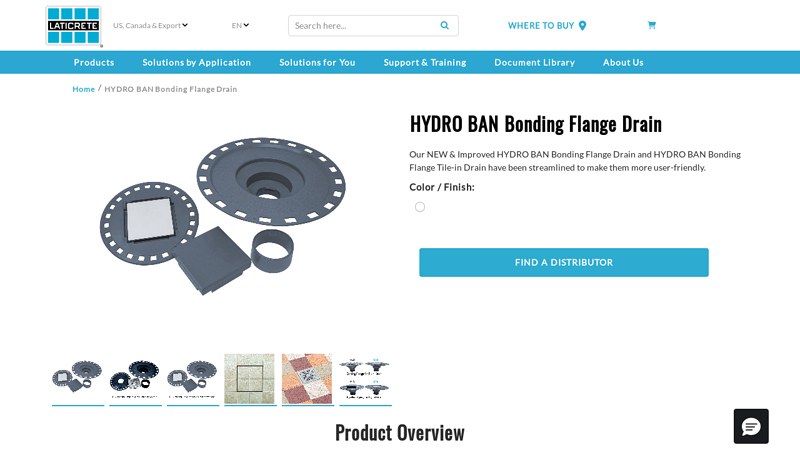

#5 HYDRO BAN Bonding Flange Drains

Domain Est. 1995

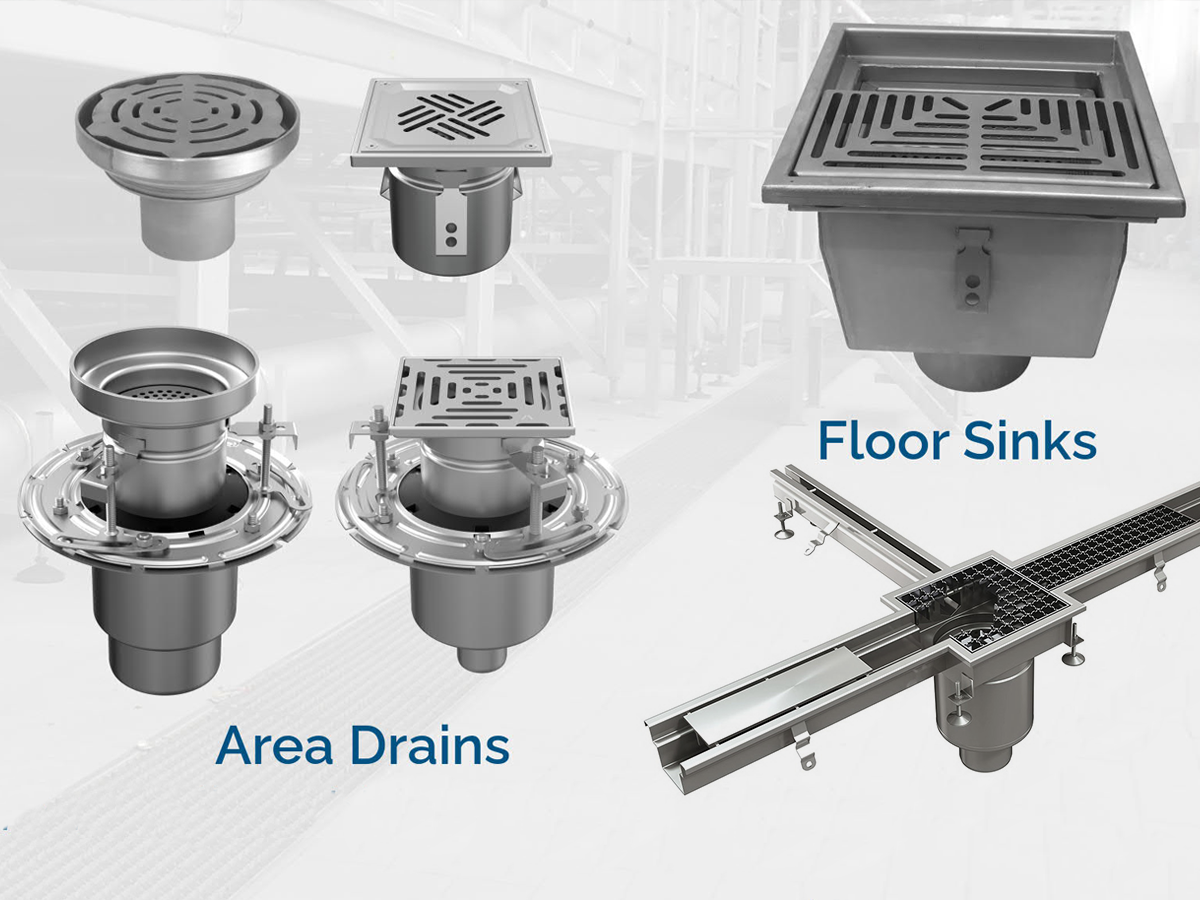

#6 Floor & Area Drains

Domain Est. 1995

Website: watts.com

Key Highlights: There’s no corner cutting with Watts specification grade floor and area drains. Epoxy coating, ductile iron grating, and solid nickel bronze top assemblies….

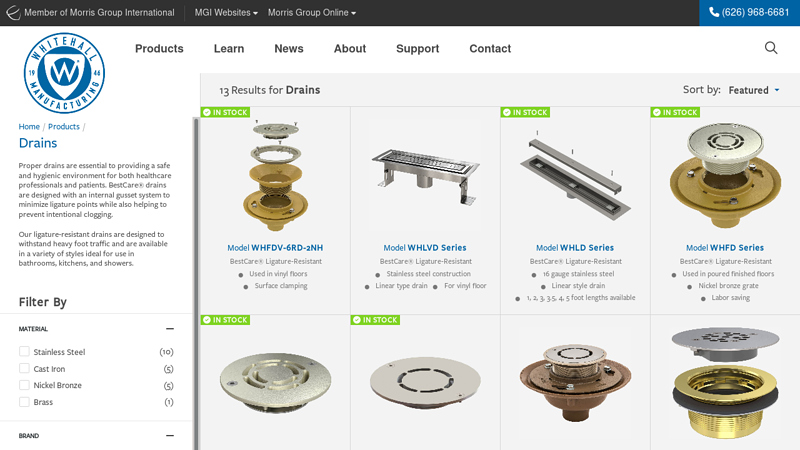

#7 Ligature Resistant Drains

Domain Est. 1996

Website: whitehallmfg.com

Key Highlights: BestCare® drains come in a variety of styles that minimize ligature points while also helping to prevent intentional clogging. View our selection here….

#8 Linear Shower Drains

Domain Est. 2003

Website: quickdrain.com

Key Highlights: QuickDrain offers linear shower drain solutions, in-wall wall drains, and complete shower systems, including pre-sloped shower pans….

#9 Drains Unlimited

Domain Est. 2018

Website: drains-unlimited.com

Key Highlights: Drains Unlimited has been involved in the design and manufacture of stainless steel floor drains, grease traps, strip channels, shower channels, and linear ……

Expert Sourcing Insights for Washroom Floor Drain

H2: 2026 Market Trends for Washroom Floor Drains

The global washroom floor drain market is poised for significant transformation by 2026, driven by advancements in building technologies, growing emphasis on hygiene and sustainability, and shifting construction dynamics across residential, commercial, and public sectors. Key trends shaping the market include:

-

Increased Demand for Hygienic and Antimicrobial Solutions

In the wake of heightened global health awareness, there is a rising preference for washroom floor drains with antimicrobial coatings and seamless designs that inhibit bacterial growth. Manufacturers are integrating silver-ion technology and non-porous materials such as stainless steel and engineered polymers to meet stringent hygiene standards in healthcare facilities, hospitality, and high-traffic public buildings. -

Growth in Green Building and Sustainable Drainage Systems

The expansion of green building certifications (e.g., LEED, BREEAM) is pushing demand for sustainable drainage solutions. By 2026, floor drains with water-saving features, recyclable materials, and compatibility with greywater recycling systems are expected to gain prominence. Linear and channel drains made from recycled stainless steel or composite materials are becoming preferred choices in eco-conscious construction projects. -

Rise of Smart and Connected Drainage Systems

Smart building technologies are beginning to influence washroom infrastructure. Innovations such as sensor-based clog detection, water flow monitoring, and IoT-enabled maintenance alerts are being integrated into premium floor drain systems. These smart features help facility managers prevent water damage and reduce maintenance costs, particularly in large commercial and institutional buildings. -

Shift Toward Aesthetic and Architectural Floor Drains

As modern interior design emphasizes minimalism and open wet rooms, floor drains are evolving into architectural elements. Linear trench drains with slim, customizable grates in various finishes (e.g., brushed brass, matte black) are gaining popularity in luxury residential and boutique hospitality projects. This trend is especially strong in Europe and North America. -

Regional Market Expansion in Asia-Pacific and the Middle East

Rapid urbanization, infrastructure development, and tourism-led construction in countries like India, China, UAE, and Saudi Arabia are fueling demand for high-performance washroom drainage systems. These regions are adopting international standards, creating opportunities for global manufacturers to introduce advanced products tailored for high-humidity and high-usage environments. -

Regulatory Influence and Standardization

Stricter plumbing codes and accessibility regulations (such as ADA compliance in the U.S. and EN standards in Europe) are driving product innovation. By 2026, floor drains will increasingly feature slip-resistant surfaces, barrier-free designs, and improved water evacuation rates to meet safety and accessibility requirements. -

Material Innovation and Durability Focus

There is a growing shift from traditional PVC and cast iron toward durable, corrosion-resistant materials like 304 and 316L stainless steel, especially in commercial applications. These materials offer longer lifespans and better resistance to chemicals and temperature fluctuations, reducing lifecycle costs.

In conclusion, the 2026 washroom floor drain market will be characterized by a convergence of hygiene, sustainability, smart technology, and design innovation. Stakeholders—from manufacturers to architects—will need to align with these evolving demands to maintain competitiveness in a rapidly advancing built environment.

Common Pitfalls Sourcing Washroom Floor Drains (Quality, IP)

Sourcing washroom floor drains involves critical considerations around quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to premature failure, hygiene issues, safety hazards, and costly replacements. Below are the most common pitfalls to avoid:

1. Prioritizing Cost Over Build Quality

One of the most frequent mistakes is selecting the cheapest available drain to cut initial costs. Low-cost models often use inferior materials such as thin-gauge stainless steel, low-grade plastics, or poorly plated metals. These materials are prone to corrosion, warping, or cracking under regular use and exposure to cleaning chemicals. Always verify the material specifications (e.g., 304 or 316 stainless steel) and construction quality to ensure durability and long-term performance.

2. Ignoring IP Rating Requirements

The Ingress Protection (IP) rating indicates a fixture’s resistance to dust and water ingress. In washroom environments—especially in public or commercial buildings—drains and associated components (like grates and traps) may be exposed to constant moisture and high-pressure cleaning. A common oversight is selecting a drain with insufficient IP protection (e.g., IPX4 instead of IPX7 or higher for wet zones). This can lead to water seepage into subfloor areas, damaging structural elements and promoting mold growth.

3. Mismatched Material for Environment

Not all washrooms present the same challenges. For example, a spa or poolside washroom will have higher exposure to chlorinated or saltwater compared to a standard office restroom. Using standard 304 stainless steel in such corrosive environments can lead to pitting and rust. Failing to match the drain material (e.g., upgrading to 316 marine-grade steel or polypropylene) to the specific environment is a frequent quality oversight.

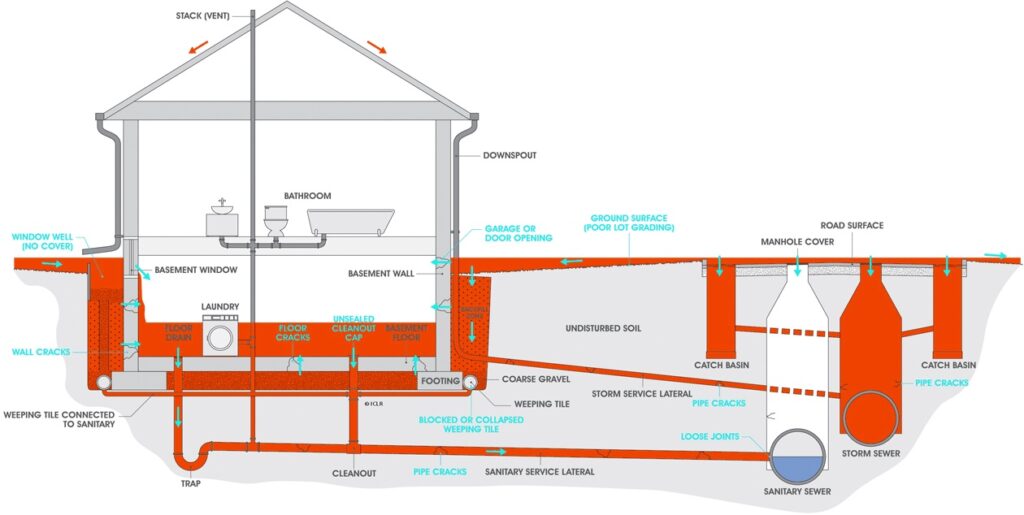

4. Overlooking Trap Design and Maintenance Access

A poorly designed trap (P-trap, S-trap, or linear channel trap) can cause odors, blockages, and hygiene issues. Some low-quality drains feature traps that are difficult to clean or lack proper water seals, allowing sewer gases to escape. Additionally, units with inaccessible cleaning points increase maintenance time and costs. Always verify that the trap design supports easy access and complies with local plumbing codes.

5. Inadequate Load Rating for High-Traffic Areas

Drains installed in commercial or public washrooms must withstand heavy foot traffic and occasional equipment movement (e.g., cleaning trolleys). Selecting a drain with a low load rating (e.g., Class A for light domestic use) in a commercial setting risks grate deformation or breakage. Ensure the drain meets appropriate load classifications (e.g., Class B, C, or D as per EN 1253 standards) based on the expected usage.

6. Assuming All “Stainless Steel” Drains Are Equal

Suppliers may advertise a drain as “stainless steel” without specifying the grade. Lower grades or thin coatings can wear off, exposing underlying materials to corrosion. Always request material certifications and verify the actual steel grade. Counterfeit or misrepresented products are common in global sourcing—reputable suppliers should provide test reports or compliance documentation.

7. Neglecting Compliance with Local Regulations

Different regions have specific plumbing codes and hygiene standards (e.g., UPC, IPC, WRAS, or AS/NZS). Sourcing drains that don’t comply with local regulations can lead to failed inspections, legal liabilities, or insurance issues. Always confirm that the product meets the required certifications for the installation location.

8. Poor Grate Design Affecting Safety and Function

The grate is a critical component affecting both safety and performance. Grates with sharp edges, wide gaps, or slippery surfaces pose trip and fall risks. Additionally, narrow slot designs can clog easily with hair or debris. Avoid generic grates—select models designed for washroom use, with anti-slip finishes, optimal flow rates, and easy removal for cleaning.

9. Inadequate Flow Capacity for Drainage Needs

Underestimating water load (e.g., from showers or floor washing) can result in poor drainage and standing water. Drains with low flow rates (measured in liters per minute) may not handle peak usage, increasing slip hazards. Always calculate expected water volume and select a drain with sufficient hydraulic performance.

10. Skipping Site-Specific Installation Considerations

Even high-quality drains can fail if not suited to the installation method (e.g., tile-in, surface-mounted, or retrofit). Mismatches in dimensions, slope requirements, or compatibility with floor finishes can lead to leaks or uneven surfaces. Work with suppliers who provide detailed installation guides and offer technical support.

By avoiding these common pitfalls—particularly those related to material quality, IP rating, compliance, and application suitability—buyers can ensure reliable, safe, and long-lasting washroom floor drain performance.

H2: Logistics & Compliance Guide for Washroom Floor Drains

Ensuring smooth logistics and full regulatory compliance for washroom floor drains is essential for timely project delivery, safety, and adherence to building standards. This guide outlines key considerations across the supply chain and regulatory landscape.

H3: Logistics Considerations

1. Product Sourcing & Procurement

– Supplier Selection: Choose reputable manufacturers or distributors with proven track records in plumbing and drainage products. Verify availability of required materials (e.g., stainless steel, PVC, cast iron) and configurations (linear, square, round).

– Lead Times: Confirm manufacturing and delivery timelines, especially for custom or specialty drains. Account for potential delays due to material shortages or seasonal demand.

– Documentation: Obtain product data sheets, cut sheets, and submittal documents early in the procurement process for design validation.

2. Transportation & Handling

– Packaging: Ensure drains are securely packaged to prevent deformation or damage during transit—especially critical for stainless steel and polymer models.

– Fragility: Handle grates, frames, and components with care to avoid scratches, dents, or warping.

– Load Planning: Optimize loading to avoid shifting; use protective padding between units.

– Storage: Store in a dry, level area protected from weather, debris, and heavy traffic. Keep packaging intact until installation.

3. Inventory & Delivery Coordination

– Just-in-Time (JIT) Delivery: Coordinate with contractors to minimize on-site storage and reduce theft or damage risk.

– Delivery Verification: Inspect shipments upon arrival for completeness and damage. Report discrepancies immediately to the supplier.

– Traceability: Maintain lot numbers and certifications for quality assurance and warranty claims.

H3: Compliance Requirements

1. Building & Plumbing Codes

– International Plumbing Code (IPC): Floor drains must comply with IPC Chapter 10 (Traps, Interceptors, and Separators) and Chapter 11 (Drainage Systems), including proper slope, trap seal, and venting requirements.

– Uniform Plumbing Code (UPC): Adhered to in many U.S. jurisdictions; mandates similar standards for drainage fixture units (DFUs), trap depth, and material suitability.

– Local Amendments: Verify regional code variations (e.g., seismic requirements, accessibility standards).

2. Accessibility Standards

– ADA (Americans with Disabilities Act): Drain grates must have slot openings no greater than ½ inch in the direction of travel. Surface must be slip-resistant and flush with surrounding floor finish to prevent tripping hazards.

– IEC 60364 / EN 81 (EU): In Europe, floor drains in public washrooms must comply with accessibility and electrical safety standards, particularly in wet zones.

3. Material & Environmental Standards

– NSF/ANSI 61: Required for components in contact with potable water or drainage in commercial/residential buildings—ensures material safety and limits leaching of contaminants.

– LEED & Green Building: Consider drains with recycled content or low-impact manufacturing for sustainability credits.

– RoHS & REACH (EU): Applies to metallic components; restricts hazardous substances in electrical and electronic components (if applicable, e.g., sensor-activated drains).

4. Fire & Safety Compliance

– Fire-Rated Assemblies: In multi-story buildings, floor drains penetrating fire-rated floors must maintain the assembly’s fire rating using approved firestop systems.

– OSHA & Workplace Safety: Installation must not create slip, trip, or fall hazards. Temporary protection required during construction.

5. Certification & Documentation

– Third-Party Testing: Look for drains certified by IAPMO, CSA, or UL to confirm code compliance.

– Submittal Packages: Provide cut sheets, test reports, and installation instructions to architects and inspectors.

– Warranty & Liability: Ensure supplier provides a warranty covering material and workmanship; retain compliance documentation for audits.

H3: Best Practices for Seamless Execution

- Pre-Construction Meeting: Align logistics, delivery schedules, and compliance requirements with all stakeholders (architects, contractors, inspectors).

- Quality Assurance Checks: Conduct periodic inspections during shipping and installation.

- Training: Ensure installers are trained on proper alignment, slope, and sealant application to prevent leaks and code violations.

- As-Built Documentation: Record installed product models, locations, and compliance certificates for facility management and future inspections.

By integrating efficient logistics planning with rigorous compliance protocols, washroom floor drain installations will meet performance, safety, and regulatory standards across residential, commercial, and institutional projects.

Conclusion for Sourcing Washroom Floor Drain:

Sourcing the appropriate floor drain for a washroom involves careful consideration of material quality, hygienic design, drainage efficiency, compliance with local plumbing codes, and long-term durability. After evaluating various options, it is essential to select a floor drain that ensures effective water removal, prevents odor ingress through a proper trap mechanism, and resists corrosion and clogging in high-moisture environments. Stainless steel or high-grade polymer drains are recommended for their longevity and ease of maintenance. Additionally, choosing a reputable supplier that offers certified products, consistent availability, and responsive technical support will contribute to a reliable and cost-effective solution. Ultimately, investing in a well-designed, properly sourced floor drain enhances hygiene, safety, and functionality in washroom facilities.