The global warehouse flooring and safety tape market is experiencing robust growth, driven by increasing emphasis on workplace safety, organizational efficiency, and compliance with regulatory standards. According to a 2023 report by Mordor Intelligence, the industrial flooring market—including safety marking solutions such as floor tape—is projected to grow at a CAGR of 5.8% from 2023 to 2028. Similarly, Grand View Research estimates that the global industrial safety products market will expand at a CAGR of over 6.5% during the same period, fueled by rising automation in logistics and the rapid proliferation of e-commerce fulfillment centers. With warehouse facilities prioritizing clear floor marking for traffic control, zone delineation, and hazard identification, demand for durable, high-performance floor tape has surged. As operations seek materials resistant to abrasion, chemicals, and heavy forklift traffic, manufacturers specializing in industrial-grade adhesive tapes are gaining strategic importance. In this competitive landscape, nine companies have emerged as leaders, combining innovation, product diversity, and reliability to meet evolving supply chain demands.

Top 9 Warehouse Floor Tape Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 tesa tape, inc.

Domain Est. 1997

Website: tesa.com

Key Highlights: tesa North America is a leading manufacturer of adhesive tape solutions. We support industry partners in optimizing their processes & improving their ……

#2 Industrial Marking Tape

Domain Est. 1997

Website: jessupmfg.com

Key Highlights: Jessup Industrial Marking Tape is a aggressive adhesive designed to withstand rigors of fork truck traffic which makes it suitable for any warehouse setting ……

#3 Page

Domain Est. 2008

Website: safetytac.com

Key Highlights: SafetyTac® Industrial Tapes & Shapes are perfect for warehouses, manufacturing facilities, and other locations with high traffic levels. Watch video….

#4 Mighty Line Floor Tape

Domain Est. 2012

Website: mightylinetape.com

Key Highlights: Mighty Line offers a range of industrial strength floor tapes suitable for heavy foot and vehicle traffic, such as in warehouses or factories. These patented ……

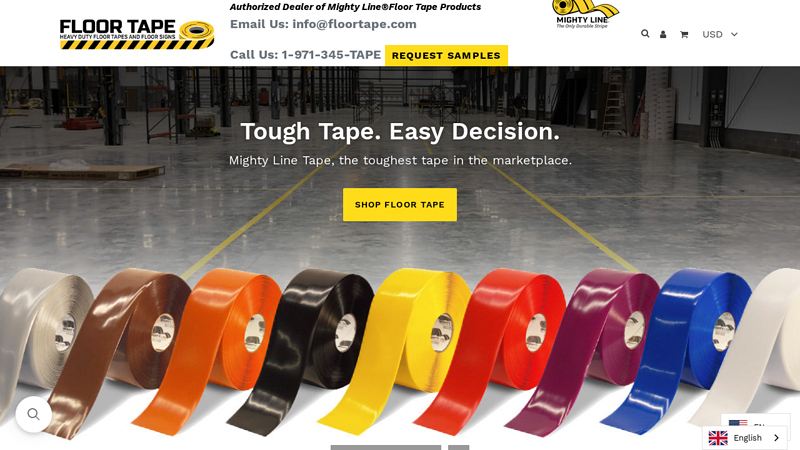

#5 Premium Safety Floor Tape

Domain Est. 2020

Website: floortape.com

Key Highlights: Ready to boost safety and efficiency in your facility? Check out our selection of warehouse floor tape and find the perfect products for your needs….

#6 3M Floor and Safety Marking Tapes

Domain Est. 1988

Website: 3m.com

Key Highlights: Update your floor markings without shutting down production. 3M Floor and Safety Marking Tapes provide the flexibility to make fast changes, ……

#7 Floor Marking Tape

Domain Est. 1998

Website: bradyid.com

Key Highlights: 1-day deliveryAisle and floor marking tape can be used to mark your facility’s aisles, walkways, safety hazards, storage areas and more….

#8 5S Warehouse

Domain Est. 2013

Website: 5swarehouse.com

Key Highlights: 5S Warehouse is an authorized distributor of Mighty Line Safety Floor Tape and Signs. Perfect for 5S and Lean needs in Manufacturing, Warehouse, Hospitals, ……

#9 About

Domain Est. 2014

Website: mightylinefloortape.com

Key Highlights: Mighty Line’s floor marking tapes and labels can help clearly identify storage areas and tool locations, improving organization and accessibility….

Expert Sourcing Insights for Warehouse Floor Tape

H2: 2026 Market Trends for Warehouse Floor Tape

The warehouse floor tape market is poised for significant evolution by 2026, driven by technological advancements, shifting logistics demands, and heightened safety and efficiency priorities. Here’s a breakdown of the key trends shaping the market:

1. Smart & Digitally-Integrated Floor Marking Solutions

By 2026, expect a rise in “smart” floor tape integrated with digital technologies. This includes:

– RFID-Embedded Tapes: Tapes with embedded RFID tags to communicate with automated guided vehicles (AGVs) and warehouse management systems (WMS), enabling real-time asset tracking and dynamic path adjustments.

– Augmented Reality (AR) Compatibility: Floor markings designed to work with AR glasses or mobile devices, providing workers with contextual navigation and safety alerts.

– IoT-Connected Markers: Tapes that interface with IoT sensors for monitoring foot traffic, identifying wear patterns, or triggering alerts when zones are breached.

2. Growth in E-Commerce and Automated Warehousing

The continued expansion of e-commerce will drive demand for highly efficient and automated fulfillment centers. Floor tape will play a critical role in:

– Defining Zones for Automation: Clear, high-contrast tape lines to guide AGVs, AMRs (Autonomous Mobile Robots), and robotic picking systems.

– Modular Layouts: Increased use of temporary or repositionable tapes to support flexible warehouse layouts that adapt rapidly to changing inventory and order patterns.

– Safety Buffer Zones: Enhanced marking for human-robot collaboration areas to prevent accidents.

3. Sustainability and Eco-Friendly Materials

Environmental regulations and corporate sustainability goals will push manufacturers toward greener alternatives:

– Biodegradable and Recyclable Tapes: Development of tapes made from recycled materials or plant-based adhesives.

– Low-VOC and Non-Toxic Formulations: Reduced environmental impact during application and disposal.

– Longer-Lasting Products: Durable tapes that reduce replacement frequency and waste.

4. Enhanced Durability and Performance

With increasing warehouse traffic and harsh environments, demand will grow for high-performance tapes:

– Extreme Adhesion and Wear Resistance: Tapes that withstand heavy forklift traffic, temperature fluctuations, and chemical exposure.

– UV-Resistant and Fade-Proof Options: Ideal for facilities with significant sunlight exposure.

– Anti-Slip and Textured Surfaces: Safety-focused tapes that reduce slip hazards, especially in wet or oily environments.

5. Standardization and Compliance Focus

Global logistics operations will drive demand for standardized floor marking systems:

– Adoption of ISO and ANSI Standards: Widespread use of color-coded systems (e.g., red for danger, yellow for caution) aligned with international safety standards.

– Custom Compliance Solutions: Tapes tailored to meet regional safety regulations (OSHA, EU directives) with certification labeling.

6. Customization and Branding Opportunities

Beyond safety, floor tape will be used for branding and operational clarity:

– Custom Colors, Logos, and Messages: Companies using floor markings to reinforce brand identity or convey specific instructions (e.g., “Scan Here,” “Charging Zone”).

– Pre-Cut and Pre-Printed Tapes: Increased availability of kits for rapid deployment and consistent application.

7. Regional Market Growth

Emerging markets in Asia-Pacific (especially India and Southeast Asia) and Latin America will see accelerated adoption due to:

– Rapid industrialization and warehouse construction.

– Growing investment in supply chain infrastructure.

– Adoption of modern logistics practices.

Conclusion

By 2026, warehouse floor tape will transition from a simple safety tool to a strategic component of smart logistics ecosystems. Innovation in materials, digital integration, and sustainability will define market leadership, while the convergence of automation and human workflows will amplify the importance of clear, durable, and intelligent floor marking solutions. Companies investing in next-generation tapes will gain competitive advantages in safety, efficiency, and operational agility.

Common Pitfalls When Sourcing Warehouse Floor Tape (Quality and Intellectual Property)

Sourcing warehouse floor tape is more complex than it may initially appear. While the product seems simple, poor sourcing decisions can lead to safety hazards, reduced durability, compliance issues, and even intellectual property (IP) risks. Below are key pitfalls to avoid related to quality and IP concerns.

1. Overlooking Material Quality and Durability

One of the most common mistakes is selecting tape based on price rather than performance. Low-quality tapes may peel, fade, or lose adhesion quickly under heavy foot or forklift traffic. This not only increases replacement costs but can also create tripping hazards or confusion in safety zones.

- Pitfall: Choosing vinyl tapes with weak adhesives or thin substrates.

- Solution: Specify high-performance materials like PVC or polyethylene with aggressive adhesives designed for industrial environments. Look for tapes tested for abrasion resistance, UV stability, and chemical exposure.

2. Ignoring Compliance with Safety Standards

Not all floor tapes meet OSHA, ANSI, or ISO safety standards for visibility, reflectivity, or slip resistance. Using non-compliant tape can result in failed audits or liability in case of workplace accidents.

- Pitfall: Assuming all yellow or striped tape meets safety requirements.

- Solution: Verify that the tape meets relevant standards (e.g., ANSI Z535 for safety colors and symbols) and request compliance documentation from suppliers.

3. Failing to Assess Environmental Suitability

Warehouse conditions vary—some are dry and climate-controlled, while others are cold, wet, or oily. Tapes not suited for specific environments will degrade rapidly.

- Pitfall: Using standard indoor tape in freezer or outdoor areas.

- Solution: Match tape specifications to the operating environment—e.g., cold-weather adhesive for refrigerated warehouses or oil-resistant backing for manufacturing floors.

4. Assuming Brand-Name Equivalents Are Interchangeable

Many suppliers offer “compatible” or “equivalent” versions of well-known brands (e.g., 3M, Seton). These may look similar but often lack the same quality control, testing, or longevity.

- Pitfall: Substituting a premium brand with a no-name alternative to cut costs.

- Solution: Conduct side-by-side testing and request performance data. If using a branded product, ensure authenticity through authorized distributors.

5. Overlooking Intellectual Property (IP) Risks

Some suppliers may offer tapes that mimic patented designs, colors, or patterns protected by IP rights. Using counterfeit or infringing products—even unknowingly—can expose your organization to legal liability.

- Pitfall: Sourcing tapes with proprietary patterns (e.g., specific hazard stripes or branded floor marking systems) from unauthorized vendors.

- Solution: Work with reputable suppliers who can provide IP indemnification. Avoid vendors offering “exact copies” of patented tape systems.

6. Skipping Sample Testing and Vendor Vetting

Relying solely on product descriptions or datasheets without real-world testing can lead to poor performance.

- Pitfall: Bulk ordering without a pilot test.

- Solution: Request samples, conduct wear tests in high-traffic zones, and evaluate ease of application and removal. Vet suppliers for certifications, customer reviews, and traceability.

7. Not Considering Total Cost of Ownership

Cheaper tapes may need frequent replacement, increasing labor and downtime costs over time.

- Pitfall: Focusing only on upfront price.

- Solution: Calculate long-term costs, including installation time, durability, and replacement frequency. Invest in higher-quality tape where it provides operational savings.

By being aware of these quality and IP-related pitfalls, procurement teams can make smarter decisions that enhance safety, ensure compliance, and protect their organization from avoidable risks.

Logistics & Compliance Guide for Warehouse Floor Tape

Proper selection, handling, and application of warehouse floor tape are essential for maintaining safety, organization, and regulatory compliance within your facility. This guide outlines key logistics considerations and compliance requirements to ensure effective use of floor tape in your operations.

Selection & Procurement

Choose floor tape that meets both operational demands and compliance standards. Consider factors such as:

– Material: PVC, vinyl, or rubber-based tapes offer different levels of durability, adhesion, and resistance to chemicals, moisture, and traffic.

– Width & Color: Standard widths (2″, 4″, 6″) and OSHA-recommended colors (e.g., yellow for caution, red for danger, blue for information) ensure visibility and regulatory alignment.

– Compliance Certification: Ensure tapes meet relevant standards such as OSHA 29 CFR 1910.144 (Safety Color Code), ANSI Z535, or ISO 3864 for safety signage.

– Supplier Reliability: Source from reputable vendors providing spec sheets, safety data sheets (SDS), and traceability documentation.

Storage & Handling

Proper storage maintains tape integrity and performance:

– Store in a cool, dry environment away from direct sunlight, extreme temperatures, and moisture.

– Keep rolls upright and avoid stacking heavy items on top to prevent deformation.

– Handle with clean hands or gloves to avoid contaminating adhesive surfaces.

– Rotate stock using FIFO (First In, First Out) to prevent degradation of older inventory.

Application Guidelines

To ensure durability and compliance:

– Clean and dry the floor surface thoroughly before application; remove oil, dust, and debris.

– Apply tape at recommended ambient temperatures (typically 60°F–85°F / 15°C–30°C).

– Use proper tools (e.g., squeegees) to eliminate air bubbles and ensure full adhesion.

– Follow layout plans that align with safety zones, traffic aisles, emergency exits, and storage areas as per facility maps and OSHA requirements.

– Avoid placing tape over expansion joints or uneven surfaces where lifting may occur.

Maintenance & Inspection

Regular upkeep ensures ongoing compliance and safety:

– Inspect floor tape weekly for wear, lifting, fading, or damage.

– Replace damaged or worn tape promptly to maintain visibility and prevent tripping hazards.

– Clean with non-abrasive cleaners; avoid solvents that may degrade adhesive or print.

– Update tape layout as workflows or storage configurations change.

Regulatory Compliance

Ensure adherence to key regulations:

– OSHA 1910.144: Requires the use of safety colors to mark physical hazards and designate traffic paths.

– OSHA 1910.22: Mandates that walking-working surfaces be kept in safe condition, including clear markings.

– NFPA 1: Fire Code recommends marking aisles and exits for emergency egress.

– ADA Guidelines: While not directly governing tape, ensure markings do not create trip hazards and support accessibility.

Training & Documentation

- Train warehouse staff on the meaning of tape colors and patterns to promote awareness.

- Maintain records of tape specifications, SDS, installation dates, and inspection logs.

- Include floor marking standards in safety manuals and audits.

By following this logistics and compliance guide, your warehouse can maintain a safer, more organized, and regulation-compliant environment using floor tape effectively.

In conclusion, sourcing warehouse floor tape requires careful consideration of durability, visibility, adhesion, and compliance with safety standards. Selecting the right type—such as PVC, vinyl, or abrasion-resistant tape—based on environmental conditions and specific warehouse needs ensures long-term effectiveness and safety. Evaluating suppliers for quality, cost-efficiency, and reliability is crucial to maintaining operational efficiency and reducing long-term maintenance costs. Additionally, choosing floor tape in standardized colors and patterns supports clear workplace organization and enhances overall safety. A well-informed sourcing decision not only improves warehouse workflow and compliance but also contributes to a safer, more productive working environment.