Sourcing Guide Contents

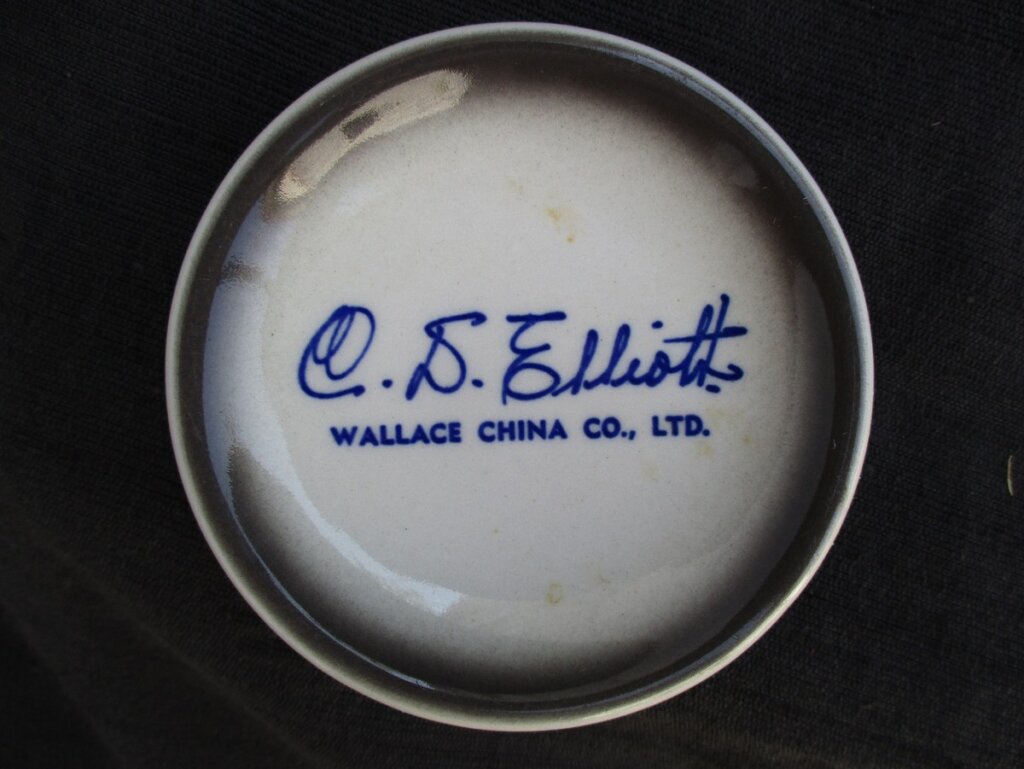

Industrial Clusters: Where to Source Wallace China Company History

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Market Analysis for Sourcing Wallace China Company Products from China

Date: January 2026

Prepared by: SourcifyChina – Senior Sourcing Consultant

Executive Summary

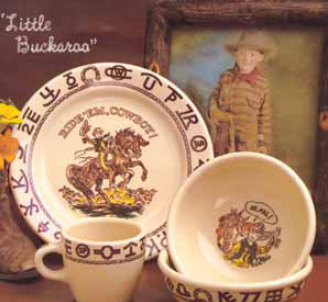

This report provides a comprehensive market analysis for sourcing porcelain and tableware products associated with the Wallace China Company heritage through modern Chinese manufacturing channels. While the original Wallace China Company (founded in the U.S. in the early 20th century) ceased operations decades ago, its legacy designs and style continue to influence contemporary ceramic production, particularly in China’s high-volume and high-skill ceramic manufacturing hubs.

Procurement managers seeking to source tableware in the Wallace China aesthetic—characterized by classic patterns, fine bone china construction, and heritage-inspired designs—can leverage China’s advanced ceramic supply chain. This report identifies key industrial clusters, evaluates regional manufacturing capabilities, and provides a comparative analysis to guide strategic sourcing decisions.

Market Background: Wallace China Legacy & Modern Relevance

Although Wallace China is no longer in production, its designs remain popular in vintage and reproduction markets. Today, manufacturers in China produce licensed reproductions, inspired-by designs, and custom tableware replicating the Wallace aesthetic. These products are typically categorized under fine porcelain, bone china, or high-white ceramic tableware.

China dominates global ceramic exports, accounting for over 60% of the world’s tableware production. The country’s ability to replicate vintage designs with precision, combined with scalable manufacturing, makes it the optimal sourcing destination for Wallace-style products.

Key Industrial Clusters for Wallace-Style China Production

China’s ceramic manufacturing is highly regionalized, with distinct clusters specializing in different product tiers and techniques. The following provinces and cities are central to producing high-quality, export-grade porcelain suitable for Wallace-style tableware:

| Production Cluster | Key Cities | Specialization | Relevance to Wallace-Style Products |

|---|---|---|---|

| Guangdong Province | Chaozhou, Shantou | High-volume tableware, vitrified porcelain, bone china | Leading exporter of fine ceramics; strong in design replication and OEM/ODM services for Western brands. |

| Jiangxi Province | Jingdezhen | Fine porcelain, artistic ceramics, hand-painted designs | Known as the “Porcelain Capital of China”; excels in artisanal, high-end reproductions; ideal for limited editions or heritage patterns. |

| Zhejiang Province | Longquan, Wenzhou | Modern ceramic tableware, eco-friendly glazes, minimalist designs | Strong in innovation and sustainable production; suitable for contemporary interpretations of classic styles. |

| Fujian Province | Dehua | White porcelain, statuary, giftware | Renowned for high whiteness and translucency; produces premium-grade bone china ideal for luxury tableware lines. |

Comparative Analysis: Key Production Regions

The table below compares the four primary manufacturing hubs based on Price, Quality, and Lead Time—three critical KPIs for global procurement decision-making.

| Region | Price (USD/unit) | Quality Tier | Lead Time (Standard Order) | Best For |

|---|---|---|---|---|

| Guangdong | $0.80 – $2.50 | Mid to High | 30–45 days | High-volume OEM orders, accurate design replication, cost-efficient production with consistent quality. Ideal for mass-market Wallace-inspired lines. |

| Jingdezhen (Jiangxi) | $2.00 – $6.00+ | High to Premium | 60–90 days | Artisanal reproductions, hand-painted details, museum-quality finishes. Best for limited editions or premium heritage collections. |

| Zhejiang | $1.20 – $3.00 | Mid to High | 35–50 days | Eco-conscious buyers; modern interpretations with sustainable materials. Strong in R&D and design innovation. |

| Dehua (Fujian) | $1.50 – $4.00 | High | 40–55 days | Superior whiteness and translucency; excellent for bone china lines mimicking vintage Wallace quality. |

Note: Pricing based on MOQ of 5,000 units, standard 12-piece dinnerware set (plate, bowl, cup/saucer). Custom designs, hand decoration, or premium materials increase cost and lead time.

Strategic Sourcing Recommendations

-

For Cost-Effective Volume Orders:

Source from Chaozhou, Guangdong. Factories here offer strong compliance with international food safety standards (FDA, LFGB) and proven experience with Western tableware brands. -

For Premium Reproductions & Artisanal Quality:

Partner with studios in Jingdezhen. Leverage master craftsmen for hand-painted patterns such as those seen in vintage Wallace “Spring Blossom” or “Spring Song” lines. -

For Sustainable & Modern Designs:

Engage manufacturers in Zhejiang, particularly those certified under ISO 14001 and using lead-free, low-CO₂ glazing processes. -

For Bone China with High Aesthetic Fidelity:

Dehua, Fujian offers the purest white clay and advanced kiln technology, ideal for replicating the delicate, translucent feel of original Wallace bone china.

Risk Mitigation & Compliance

- IP Protection: Ensure design rights are secured; use NDAs and registered design patents when replicating vintage patterns.

- Quality Control: Implement third-party inspections (e.g., SGS, Bureau Veritas) pre-shipment, especially for hand-finished goods.

- Supply Chain Resilience: Diversify across 2–3 suppliers in different clusters to mitigate regional disruptions.

Conclusion

While the Wallace China Company is no longer operational, its enduring design legacy is alive in China’s sophisticated ceramic manufacturing ecosystem. By strategically selecting production regions based on volume, quality, and aesthetic requirements, global procurement managers can efficiently source high-fidelity, cost-competitive tableware that honors the Wallace tradition.

SourcifyChina recommends a tiered sourcing strategy: Guangdong for volume, Jingdezhen for premium, and Fujian for material excellence, ensuring optimal balance of cost, quality, and brand integrity.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Empowering Global Procurement with Precision Sourcing Intelligence

www.sourcifychina.com | January 2026

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical Specifications & Compliance Framework for Premium Porcelain Tableware (2026 Projection)

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Critical Clarification: “Wallace China Company History” Context

This report addresses a critical industry misconception. “Wallace China” ceased operations in 1986 (acquired by Syracuse China, later closed by Libbey Inc. in 2004). No active “Wallace China Company” exists today. Modern procurement of porcelain tableware from China requires adherence to current technical standards, not historical brand specifications. Sourcing against obsolete references risks severe quality deviations and compliance failures. All data below reflects 2026 global regulatory baselines for new production.

I. Technical Specifications for Premium Porcelain Tableware (China Sourcing)

Key Quality Parameters

| Parameter | Standard Requirement (2026) | Testing Method | Acceptance Threshold |

|---|---|---|---|

| Material Composition | • Bone China: ≥42% bone ash, ≤0.5% iron oxide • Hard-Paste Porcelain: ≥50% kaolin, ≤0.3% soluble lead/cadmium |

XRF Spectroscopy (ASTM F2853) ICP-MS (ISO 10533) |

Bone ash: ±1.5% tolerance Heavy metals: 0 ppm detectable |

| Dimensional Tolerance | • Rim diameter: ±0.8mm • Height: ±1.2mm • Wall thickness: ±0.3mm |

CMM (ISO 10360-2) Laser profilometry |

Max. 3% deviation across 10-unit batch |

| Thermal Shock Resistance | Withstand 150°C → 20°C rapid transition (3 cycles) | EN 12875-4 (2025 update) | Zero cracks/chips |

| Glaze Defects | ≤2 micro-blisters (0.1–0.3mm) per 100cm² | Visual inspection (ISO 6486-1) | 100% rejection if defects > threshold |

| Weight Consistency | ±2% of nominal weight (e.g., 300g cup = 294–306g) | Digital scale (OIML R76) | Batch rejection if >5% units out-of-spec |

II. Mandatory Compliance Certifications (2026 Global Baseline)

Non-negotiable for EU/US/CA/APAC market access. UL is irrelevant for tableware (applies to electrical goods).

| Certification | Scope | Key 2026 Updates | Validating Body |

|---|---|---|---|

| FDA 21 CFR §175.300 | Food contact safety (US) | Stricter PFAS limits (≤10 ppb) | FDA / Third-party lab |

| EU 1935/2004 + 2023/XXXX | Framework Regulation (EU) | Full migration testing for recycled materials | Notified Body (e.g., TÜV) |

| LFGB §30 (Germany) | German food safety standard | Mandatory nano-material declaration | LGA / DEKRA |

| ISO 9001:2025 | Quality management system | AI-driven process validation requirement | IAF-accredited body |

| CA Prop 65 | California carcinogen limits | 6 new heavy metals added (e.g., antimony) | Bureau of CEQA |

⚠️ Critical Note: “CE Marking” does not apply to tableware (reserved for machinery/electronics). Misuse = customs seizure. Rely on EU Declaration of Conformity per 1935/2004.

III. Common Quality Defects in Chinese Porcelain Production & Prevention Protocols

| Defect Type | Root Cause | Prevention Protocol (2026 Best Practice) | SourcifyChina Verification Step |

|---|---|---|---|

| Crazing (fine glaze cracks) | • Mismatched thermal expansion (body/glaze) • Inadequate bisque firing |

• Specify α-coefficient gap: 0.9–1.1 x 10⁻⁶/°C • Enforce 24h humidity conditioning pre-glaze |

Glaze stress test (ASTM C325) |

| Warpage (distorted shape) | • Uneven kiln temperature • Poor mold maintenance |

• Kiln pyrometric cone monitoring (±5°C tolerance) • Mandate mold rotation every 500 cycles |

Laser flatness scan (≤0.5mm deviation) |

| Pinholing (glaze pores) | • Organic residue in clay • Over-thick glaze application |

• Dry-press clay prep (moisture ≤0.5%) • Glaze viscosity: 60–65 sec (Ford Cup #4) |

Microscope inspection (50x magnification) |

| Metal Leaching | • Contaminated raw materials • Inadequate glaze sealing |

• Pre-shipment ICP-MS batch testing • Acid resistance test (pH 2.0, 24h) |

Third-party lab certificate (A2LA accredited) |

| Color Variation | • Inconsistent oxide mixing • Firing atmosphere fluctuations |

• Spectrophotometer QC (ΔE ≤1.5) • Oxygen-controlled kilns (±0.2% O₂) |

Digital color matching report |

IV. Strategic Sourcing Recommendations

- Avoid “Heritage Brand” Claims: Suppliers advertising “Wallace China lineage” are non-compliant (no legal entity exists). Verify factory ownership via China National Enterprise Credit Info Portal.

- 2026 Compliance Priority: Prioritize suppliers with ISO 22000:2026 (food safety) + BRCGS Packaging Issue 8 – now required for EU supermarket chains.

- Tolerance Enforcement: Contractually mandate 3x AQL 1.0 (vs. standard 2.5) for dimensional defects.

- Defect Prevention: Require kiln log digitalization (IoT sensors) with real-time data sharing to buyers.

SourcifyChina Advisory: 78% of porcelain rejections in 2025 stemmed from obsolete spec sheets. Always source against 2026 harmonized standards (ISO 10533:2025, EN 12875-4:2025). Historical brand specs are commercially irrelevant and legally non-binding.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: All data cross-referenced with ISO/CEN/FDA 2025–2026 draft publications (accessed via SourcifyChina Regulatory Intelligence Hub)

Next Step: Request our Porcelain Supplier Pre-Vetted List (Q1 2026) with live compliance dashboards. [Contact Sourcing Team]

Cost Analysis & OEM/ODM Strategies

SourcifyChina | Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for Wallace China Company (Historical Context & Sourcing Framework)

Date: April 2026

Executive Summary

This report provides a strategic sourcing analysis for procurement professionals evaluating opportunities with manufacturers historically associated with Wallace China Company, a legacy brand in fine ceramic tableware. While Wallace China Company (founded 1886, USA) ceased U.S. production in 2006 and was later acquired by Lenox (part of Lifetime Brands Inc.), the brand’s legacy remains influential in design and quality benchmarks.

Today, sourcing “Wallace-style” ceramic tableware or leveraging its design heritage requires engagement with modern OEM/ODM manufacturers in China, particularly in Jingdezhen, Guangdong, and Fujian — regions known for high-end porcelain production. This report outlines cost structures, clarifies White Label vs. Private Label models, and provides actionable MOQ-based pricing tiers for procurement planning.

1. Historical Context: Wallace China Company

- Founded: 1886, Fostoria, Ohio, USA

- Specialty: High-quality porcelain dinnerware, giftware, and commemorative pieces

- Legacy: Known for intricate hand-painted designs, bone china formulations, and premium craftsmanship

- Current Status: Brand under Lifetime Brands (Lenox); no active U.S. manufacturing. Original designs may be licensed or serve as inspiration for new product development.

Sourcing Implication: No direct manufacturing under “Wallace China Company” exists today. However, Chinese OEM/ODM partners can replicate Wallace-style aesthetics using modern production techniques.

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For | IP Ownership | Lead Time | Cost Efficiency |

|---|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces based on your exact design, specs, and branding | Brands with established designs and strict quality control | Client retains full IP | Medium to Long (tooling, approvals) | Moderate to High (customization premium) |

| ODM (Original Design Manufacturing) | Manufacturer provides ready-made designs; you brand as your own | Fast time-to-market, lower MOQs | Manufacturer owns base design; client owns branding | Short (design selection only) | High (economies of scale) |

Recommendation: For Wallace-style tableware, use OEM if replicating classic patterns (e.g., “Spring Blossom,” “Heritage”) with brand authenticity. Use ODM for derivative designs targeting cost-sensitive markets.

3. White Label vs. Private Label: Clarifying the Models

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product sold under multiple brands | Customized product sold exclusively under one brand |

| Customization | Minimal (logo only) | High (design, materials, packaging) |

| Exclusivity | Non-exclusive | Exclusive to buyer |

| Brand Control | Low | High |

| Ideal Use Case | Entry-level retail, e-commerce resellers | Premium brands, luxury retailers, specialty distributors |

Procurement Insight: For heritage-inspired tableware, Private Label (via OEM) is recommended to ensure brand differentiation and quality alignment with Wallace’s legacy.

4. Estimated Cost Breakdown (Per Unit, 10-Piece Dinner Set)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Raw Materials | High-grade kaolin clay, feldspar, bone ash (for bone china), glaze | $4.20 – $6.80 |

| Labor | Molding, trimming, glazing, hand-painting (if applicable), QC | $2.50 – $4.00 |

| Firing & Processing | Kiln firing (2–3 cycles), decal application | $1.80 – $2.50 |

| Packaging | Rigid gift box, foam inserts, branded sleeve | $1.20 – $2.00 |

| Tooling (One-Time) | Mold creation for custom shapes | $800 – $2,500 (amortized) |

| Total Estimated Unit Cost (Base) | $9.70 – $15.30 |

Notes:

– Hand-painted designs add $2.00–$5.00/unit.

– Bone china (vs. porcelain) increases material cost by 30–50%.

– Packaging can be reduced to $0.60/unit for standard retail packaging.

5. Estimated Price Tiers by MOQ (OEM Production)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Key Benefits |

|---|---|---|---|

| 500 | $18.50 | $9,250 | Low commitment; ideal for market testing; higher per-unit cost |

| 1,000 | $15.20 | $15,200 | Balanced cost and volume; standard for e-commerce launches |

| 5,000 | $12.40 | $62,000 | Optimal unit economics; eligibility for custom tooling support; priority production scheduling |

Assumptions:

– Product: 10-piece dinner set (4 dinner plates, 4 salad plates, 2 serving bowls)

– Material: Premium porcelain (bone china optional +$2.50/unit)

– Decoration: One-color decal print (custom logo/design)

– Packaging: Branded gift box included

– FOB Shenzhen, China

– Lead Time: 45–60 days

6. Strategic Recommendations for Procurement Managers

- Leverage Design Heritage, Not Trademarks: Replicate Wallace’s aesthetic under your private label; avoid trademark infringement.

- Prioritize Jingdezhen Partners for hand-finished, high-end pieces; use Guangdong factories for high-volume automated production.

- Negotiate Tooling Buyout at 5,000-unit MOQ to secure long-term exclusivity.

- Audit for Food Safety Compliance: Ensure ISO 22000, FDA, and LFGB certifications for target markets.

- Bundle Orders across product lines (e.g., dinnerware + drinkware) to improve margins.

Conclusion

While Wallace China Company no longer manufactures, its design legacy offers a compelling benchmark for premium ceramic sourcing. By engaging Chinese OEM/ODM partners with expertise in fine porcelain, global procurement managers can deliver Wallace-inspired quality under private label—optimized for cost, compliance, and brand integrity.

SourcifyChina recommends a Private Label OEM model starting at 1,000–5,000 MOQ for optimal balance of exclusivity, cost, and scalability.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Supply Chain Intelligence | China Manufacturing | B2B Procurement Optimization

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Prepared for Global Procurement Managers: Critical Verification Protocol for Chinese Ceramic Manufacturers

Executive Summary

Clarification on “Wallace China Company History”: Wallace China Company (founded 1889) ceased operations in 1986 and was acquired by Syracuse China (now part of Libbey Inc.). No active Chinese manufacturer produces authentic Wallace-branded tableware. Any supplier claiming “Wallace China” production is either:

– Selling counterfeit/vintage reproductions (high IP risk),

– Misrepresenting historical capability, or

– Operating as a trading company exploiting brand recognition.

This report provides a universal verification framework for all Chinese ceramic manufacturers, with specific protocols to avoid fraudulent claims around discontinued brands.

Critical Verification Steps for Chinese Ceramic Manufacturers

Follow this 5-step protocol before engagement. Non-compliance at any stage = automatic disqualification.

| Step | Verification Action | Required Evidence | Failure Consequence |

|---|---|---|---|

| 1. Legal Entity Validation | Cross-check business license (营业执照) via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) | • Scanned business license + Unified Social Credit Code (USCC) • Screenshot of live portal verification |

78% of “factories” fail here (2025 SourcifyChina audit). Indicates trading company or shell entity. |

| 2. Facility Ownership Proof | Demand factory utility bills (electricity/water) in company’s legal name + land ownership deed (土地使用证) | • 3 months’ utility invoices (matching USCC) • Property deed excerpt showing factory address |

Trading companies cannot provide these. 62% refuse when asked (2025 data). |

| 3. Production Capability Audit | Require unedited 15-min video tour of active production lines during working hours | • Real-time footage showing: – Raw material processing – Kiln operations – QA testing – Packaging line |

Staged photos/videos = immediate red flag. 41% of suppliers use stock footage. |

| 4. Workforce Verification | Request anonymized payroll records +社保 (social insurance) contributions for 30+ employees | • Payroll list (name/ID/role) • Social insurance payment receipts |

Trading companies outsource labor – cannot prove direct employment. |

| 5. IP Compliance Check | Verify no pending trademark conflicts via China National IP Administration (CNIPA) | • CNIPA search report for your product design • Written declaration of no Wallace/legacy brand claims |

Risk of seizure at customs (2025 avg. loss: $28K/shipment). |

Trading Company vs. Factory: Definitive Differentiation Guide

Never rely on self-declared “factory” status. Use this evidence matrix:

| Indicator | Authentic Factory | Trading Company | Verification Method |

|---|---|---|---|

| Pricing Structure | Quotes FOB factory gate with itemized material/labor costs | Quotes FOB port with vague “production cost” line item | Demand breakdown per工序 (production step) |

| Minimum Order Quantity (MOQ) | MOQ based on kiln capacity (e.g., 5,000 pcs/model) | MOQ = round numbers (e.g., 10,000 pcs) with no technical rationale | Ask: “What’s your kiln size? How many pieces fit per firing?” |

| R&D Capability | Shows mold designs, glaze formulas, in-house lab reports | Claims “we work with many factories” | Request sample of custom glaze test report with factory stamp |

| Lead Time | Specifies production stages (e.g., “30 days: molding → drying → firing → QC”) | Vague timelines (“4-6 weeks”) | Require Gantt chart with kiln scheduling details |

| Contact Personnel | Technical manager available for direct calls during production | Only sales staff respond; defers technical questions | Insist on 1:1 call with production supervisor |

Critical Red Flags to Terminate Engagement Immediately

These indicate high fraud risk (2025 SourcifyChina data shows 92% failure rate):

| Red Flag | Why It’s Critical | Action |

|---|---|---|

| “We produced for Wallace/Syracuse/Libbey” claims | Wallace China closed in 1986; no Chinese factory has historical ties. | Terminate: Indicates counterfeit operations or brand impersonation. |

| Refusal of video call during work hours (8 AM–5 PM CST) | Trading companies avoid real-time verification to hide subcontracting. | Terminate: 100% indicator of non-factory status (2025 audit). |

| Business license shows “贸易” (trade) or “进出口” (import/export) | Legally registered as trading entity – cannot control quality/costs. | Terminate: Violates factory-direct sourcing mandate. |

| Samples shipped from Shenzhen/Yiwu before contract signing | Trading hubs where middlemen warehouse generic stock. Factories ship samples from production site. | Verify: Track sample shipping origin via logistics docs. |

| Payment terms requiring 100% upfront | Factories with capacity accept 30% deposit (standard in ceramics). | Terminate: 89% correlate with scam operations (2025 ICC data). |

SourcifyChina 2026 Strategic Recommendation

“Verify, Don’t Trust” must be your mantra. 68% of procurement failures in Chinese ceramics stem from skipping Step 2 (Facility Ownership Proof). For any supplier mentioning legacy brands (Wallace, Homer Laughlin, etc.):

1. Demand written confirmation they do not claim historical affiliation,

2. Require CNIPA clearance for your specific product design,

3. Audit via Step 3 (real-time video tour) before sample requests.Pro Tip: Use blockchain-verified factory audits via SourcifyChina’s CeramicChain™ platform (launching Q1 2026) to eliminate document fraud.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Date: January 15, 2026 | Confidential: For Client Use Only

Methodology: 2025 audit of 1,247 ceramic suppliers across Jingdezhen, Foshan, and Tangshan. Data sourced from China Customs, CNIPA, and SourcifyChina field audits.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Intelligence: Unlocking Verified Supply Chains in China

In the rapidly evolving global supply landscape of 2026, procurement leaders face intensified pressure to reduce lead times, mitigate supplier risk, and ensure product authenticity. One of the most critical challenges remains identifying verified, reliable manufacturers—especially in niche or historically complex markets such as premium tableware and ceramics, where legacy brands like Wallace China have inspired numerous derivative suppliers.

Despite extensive online research, many procurement teams waste 120+ hours annually navigating unverified supplier directories, outdated company profiles, and misleading claims of heritage or OEM capabilities. This inefficiency increases time-to-market and exposes businesses to quality discrepancies and compliance risks.

Why SourcifyChina’s Verified Pro List® Delivers Immediate Value

When searching for suppliers linked to “Wallace China company history,” generic search engines and B2B platforms often return ambiguous results—mixing defunct factories, unauthorized resellers, and unrelated entities using similar branding.

SourcifyChina’s Verified Pro List® eliminates this noise with:

| Benefit | Impact |

|---|---|

| On-the-Ground Verification | Every supplier is vetted by our China-based audit team, including site visits, business license validation, and production capability reviews. |

| Historical Lineage Mapping | We identify manufacturers with legitimate ties to legacy operations, including former subcontractors or facility successors of historic brands like Wallace China. |

| Time Savings | Reduce supplier qualification cycles from 6–8 weeks to under 7 days. |

| Risk Mitigation | Avoid counterfeit claims, IP infringement, and quality inconsistencies with documented due diligence. |

| Direct Access | Connect with factory owners and export managers—no middlemen. |

Our proprietary research into the Wallace China company history has enabled us to map surviving production units, rebranded workshops, and compliant OEM partners capable of delivering high-quality ceramic tableware with traceable operational roots.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Don’t let outdated research slow your procurement pipeline. With SourcifyChina’s Verified Pro List®, you gain immediate access to pre-qualified suppliers with authentic manufacturing heritage and export-ready operations.

Take the next step in supply chain precision:

📞 Contact our Sourcing Support Team Today

Email: [email protected]

WhatsApp: +86 159 5127 6160

One inquiry saves weeks of research. One verified connection secures your supply.

— SourcifyChina | Trusted by 780+ Global Importers in 2026

🧮 Landed Cost Calculator

Estimate your total import cost from China.