The global automotive radiator market is experiencing steady growth, driven by increasing vehicle production and the rising demand for efficient thermal management systems. According to Grand View Research, the global automotive radiator market size was valued at USD 10.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by stricter emissions regulations, the proliferation of advanced cooling technologies, and the continued service demand from older yet durable models like the Volvo 240—a vehicle renowned for its longevity and loyal enthusiast base. As replacement parts remain critical for maintaining these classic vehicles, the need for reliable radiator fan manufacturers has grown. To support consumers in making informed decisions, we’ve compiled a data-driven overview of the top 9 radiator fan manufacturers compatible with the Volvo 240, evaluating each based on product performance, availability, customer reviews, and OEM alignment.

Top 9 Volvo 240 Radiator Fan Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

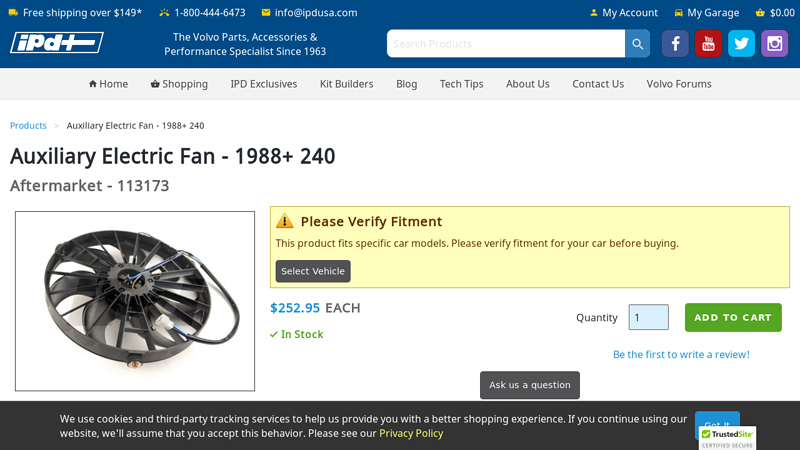

#1 Auxiliary Electric Fan

Domain Est. 1996

Website: ipdusa.com

Key Highlights: In stock Free deliveryThis is a direct replacement for cars with an existing factory auxilary fan. It does not come with mounting hardware or brackets….

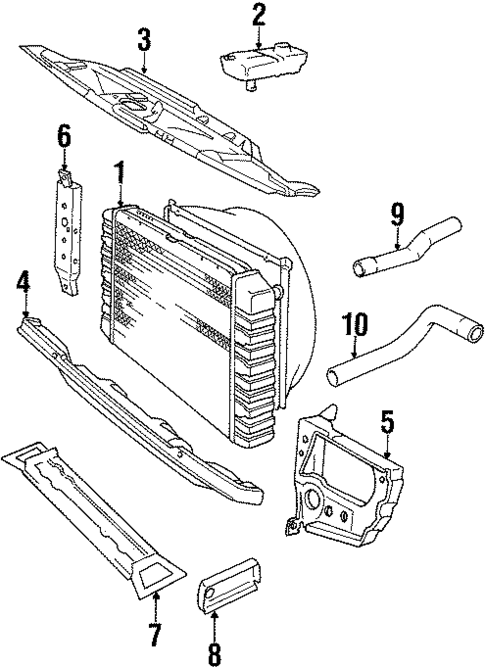

#2 Radiator & Components for 1991 Volvo 240

Domain Est. 2015

Website: volvo.oempartsonline.com

Key Highlights: 3–6 day delivery · 30-day returns1317465 – Cooling System: Fan Blade for Volvo: 240, 244, 245, · Engine Cooling Fan Clutch Blade · Valenti Auto Center · 1317465. Volvo. Fan Blade….

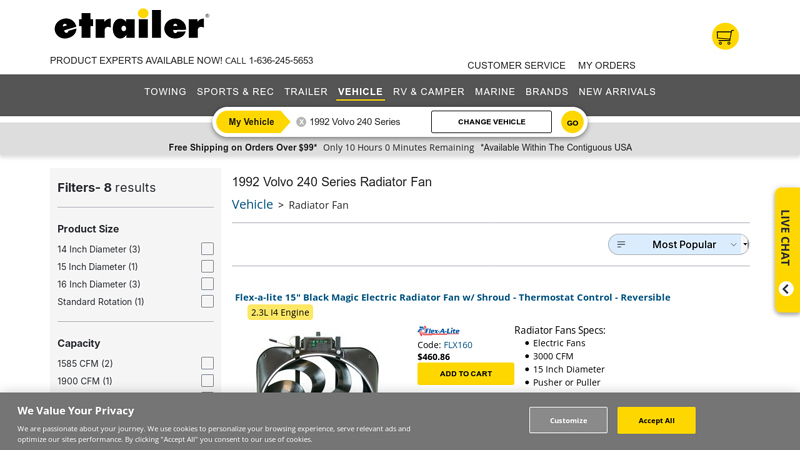

#3 1992 Volvo 240 Series Radiator Fan

Domain Est. 1999

Website: etrailer.com

Key Highlights: Free delivery over $99Shop our comprehensive selection of Radiator Fan for 1992 Volvo 240 Series at etrailer.com and discover quality products backed by expert service and ……

#4 Radiator Fan Assembly

Domain Est. 2001

Website: dormanproducts.com

Key Highlights: 620-881. Radiator Fan Assembly Without Controller. Application Summary: Volvo 240 1993-90, Volvo 244 1989-88, Volvo 245 1989-88. Check Your Fit Where To Buy ……

#5 Radiator fan electric motor Volvo 240 1991

Domain Est. 2010

#6 Volvo Cooling Fan Parts

Domain Est. 2010

Website: fcpeuro.com

Key Highlights: Free delivery over $49.02 · 90-day returnsThe radiator fan in any Volvo provides cool air to the engine block. This fan helps lower engine temperatures, regulate hot and cool air …

#7 Volvo Tropical Heavy Duty Cooling Fan Clutch

Domain Est. 2011

Website: 240turbo.com

Key Highlights: Volvo Tropical Heavy Duty Cooling Fan Clutch. This item is no longer offered here for sale. This page is maintained for its technical interest. ……

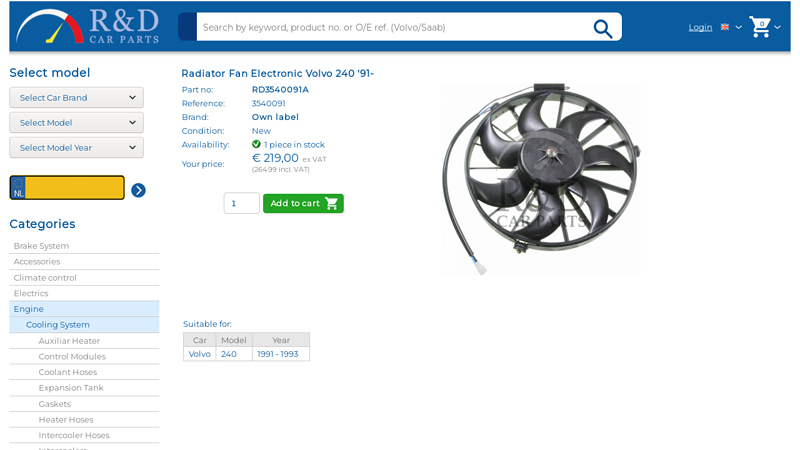

#8 Radiator Fan Electronic Volvo 240, 3540091

Domain Est. 2014

#9 Cooling Fan for 1990 Volvo 240

Domain Est. 2016

Website: volvopartscounter.com

Key Highlights: 3–8 day delivery · 30-day returns…

Expert Sourcing Insights for Volvo 240 Radiator Fan

H2: 2026 Market Trends for Volvo 240 Radiator Fan

As the classic car market continues to evolve, the demand for genuine and high-quality replacement parts for iconic vehicles like the Volvo 240 remains strong. Looking ahead to 2026, the market for the Volvo 240 radiator fan is expected to reflect several key trends driven by the growing popularity of vehicle preservation, the rise of electric conversions, and advancements in aftermarket manufacturing.

-

Increased Demand Due to Classic Car Enthusiasm

The Volvo 240, renowned for its durability and timeless design, has seen a resurgence in popularity among classic car collectors and restorers. As more owners aim to keep their vehicles operational rather than treat them as static displays, the need for reliable cooling components like the radiator fan is rising. This sustained interest is projected to boost demand for both OEM-style and upgraded radiator fans through 2026. -

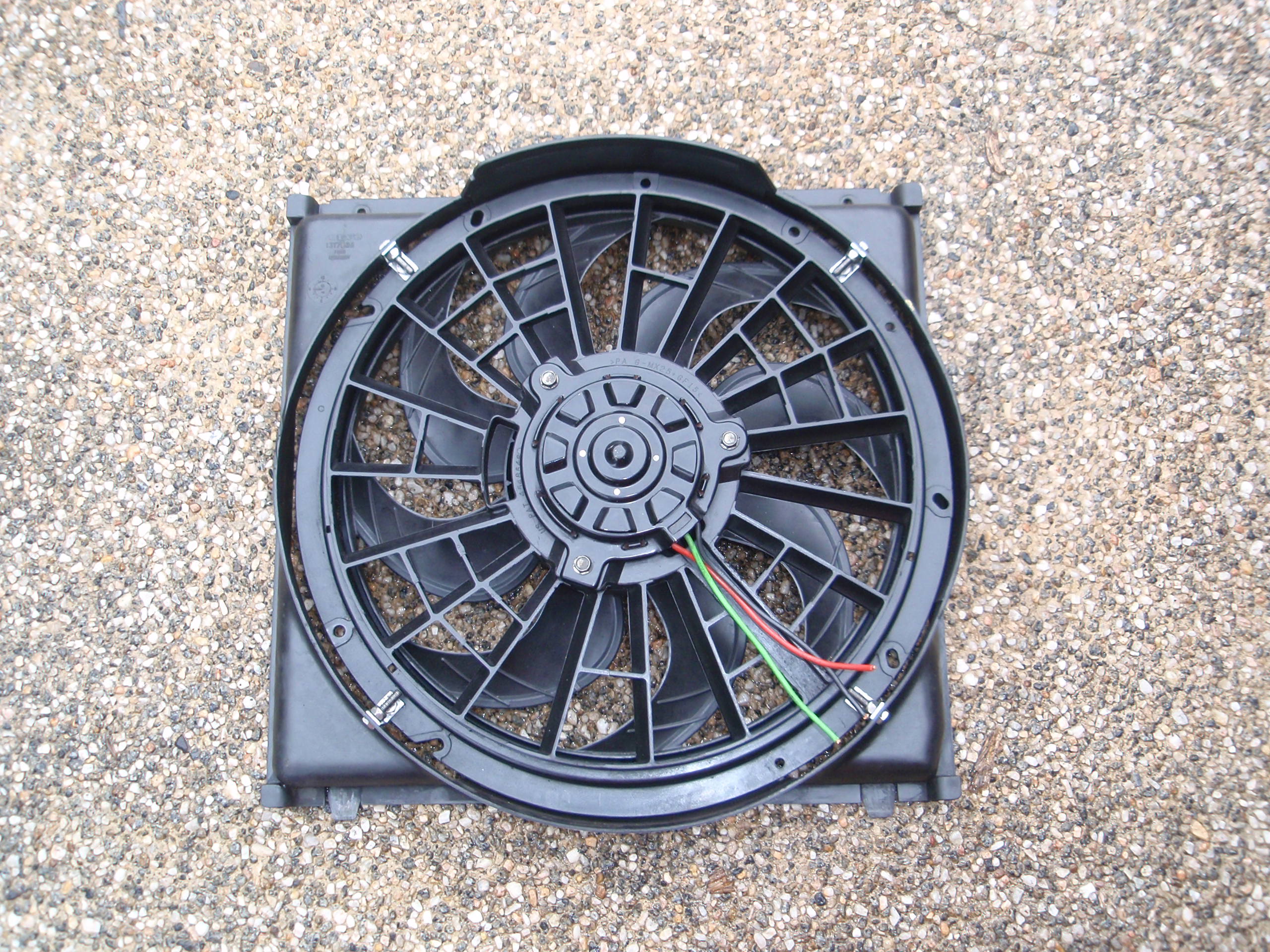

Growth in Aftermarket and Performance Upgrades

While original equipment fans are still sought after, many Volvo 240 owners are opting for modern aftermarket radiator fans with improved efficiency, quieter operation, and better thermal management. By 2026, expect to see a broader range of high-performance electric fan kits designed specifically for the 240’s cooling system, often featuring thermostatic controls and dual-fan setups for enhanced reliability. -

Shift Toward Electric and Retrofit Solutions

With the increasing trend of converting classic Volvos to electric powertrains (e.g., EV conversions), traditional engine-driven cooling systems are being replaced with electric radiator fans managed by smart controllers. This shift is driving innovation in fan technology, including programmable fan speeds and integration with digital temperature monitoring systems—key growth areas in the 2026 market landscape. -

Supply Chain Challenges and Niche Manufacturing

As original Volvo 240 radiator fans become scarcer, suppliers are turning to specialized manufacturers and 3D printing technologies to reproduce discontinued parts. Companies focusing on niche classic car components are expected to dominate the market by offering durable, exact-fit replacements. However, fluctuating raw material costs and global logistics may impact pricing and availability. -

Sustainability and Longevity Focus

Environmental awareness is influencing consumer choices, with a preference for long-lasting, recyclable, and energy-efficient components. Radiator fans made from sustainable materials or designed for extended service life will gain favor, aligning with broader automotive sustainability trends.

In conclusion, the 2026 market for the Volvo 240 radiator fan will be shaped by the enduring appeal of classic cars, technological innovation in cooling systems, and evolving owner needs—ranging from preservation to modernization. Suppliers who offer reliable, adaptable, and future-ready solutions will be best positioned to meet this dynamic demand.

Common Pitfalls When Sourcing a Volvo 240 Radiator Fan (Quality and IP Rating)

Sourcing a replacement radiator fan for a classic Volvo 240 can be tricky, especially with the rise of third-party and aftermarket parts. Avoiding these common pitfalls ensures reliable cooling performance and longevity.

Choosing Low-Quality Aftermarket Fans

Many aftermarket radiator fans marketed for the Volvo 240 cut corners on materials and design. These fans often use inferior plastic blades prone to warping under heat, weak motors that burn out quickly, or poorly balanced assemblies that cause excessive vibration. Such components may fit physically but fail prematurely, leading to overheating and potential engine damage. Always prioritize reputable brands or OEM-equivalent parts with proven durability.

Ignoring IP (Ingress Protection) Rating

The IP rating indicates a fan’s resistance to dust and moisture—critical under the hood where the fan is exposed to road spray, rain, and engine bay debris. A low or unlisted IP rating (e.g., less than IP55) means the motor and electronics are vulnerable to water ingress and corrosion. This can lead to short circuits, fan failure, or erratic operation. Ensure the replacement fan has a suitable IP rating (IP55 or higher is recommended) for reliable performance in all weather conditions.

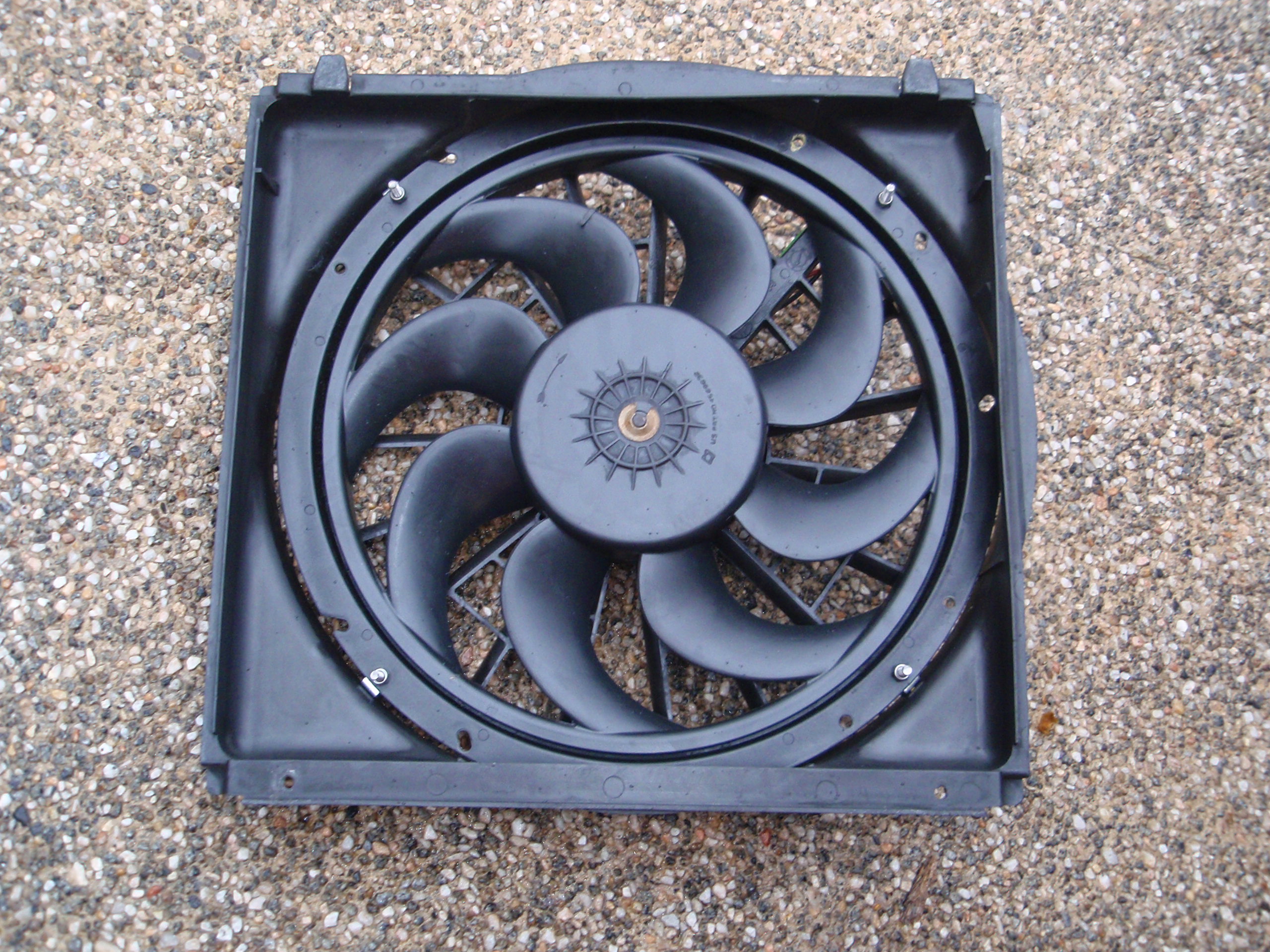

Using Non-Compatible or Modified Mounting Designs

Some aftermarket fans alter the original mounting configuration or shroud design to cut costs. These changes can result in improper fitment, airflow gaps, or interference with surrounding components like belts or hoses. Even a small misalignment reduces cooling efficiency and can cause noise or mechanical wear. Verify that the fan matches the original dimensions, bolt pattern, and shroud shape for seamless integration.

Overlooking Electrical Compatibility

Volvo 240s use specific voltage requirements and fan control circuits (often via a thermal switch or relay). Aftermarket fans with incompatible electrical specs—such as incorrect amperage draw or non-standard plug connectors—can overload the vehicle’s wiring, damage relays, or fail to engage properly. Always confirm electrical compatibility and, if necessary, use adapters or relays designed for the application.

Relying Solely on Brand Name or Price as a Quality Indicator

While OEM parts are generally reliable, not all OEM-pattern fans are equal—some are manufactured by lower-tier suppliers. Conversely, extremely cheap fans often signal poor quality, but inflated prices don’t guarantee better performance. Research specific part reviews, look for certifications, and consult Volvo enthusiast communities to identify trustworthy suppliers and avoid misleading marketing.

Logistics & Compliance Guide for Volvo 240 Radiator Fan

Product Identification and Specifications

The Volvo 240 radiator fan is a critical cooling component designed specifically for Volvo 240 series vehicles manufactured between 1974 and 1993. It typically includes the electric motor, fan blades, shroud, and mounting hardware. Ensure compatibility by verifying the engine type (e.g., B230F) and model year. OEM part numbers (e.g., 1306356, 3076276) should be cross-referenced with supplier catalogs to confirm fitment.

Packaging and Labeling Requirements

All radiator fans must be packaged in durable, crush-resistant materials to prevent damage during transit. Each unit should be individually wrapped in protective foam or bubble wrap and placed in a corrugated cardboard box with adequate cushioning. Labels must include:

– Product name and OEM/aftermarket part number

– “Fragile” and “This Side Up” handling indicators

– Country of manufacture

– Barcode for inventory tracking

– Compliance marks (e.g., CE, if applicable)

Shipping and Transportation Guidelines

Ship via ground or air freight depending on urgency and destination. For international shipments, use freight forwarders compliant with IATA (air) or IMDG (sea) regulations if batteries or electronic components are included. Maintain a temperature-controlled environment (15–30°C) to avoid warping of plastic components. Avoid prolonged exposure to moisture and direct sunlight during storage and transit.

Import and Export Compliance

Verify import regulations in the destination country, including customs documentation (commercial invoice, packing list, bill of lading). For shipments to the EU, ensure compliance with REACH and RoHS directives regarding restricted hazardous substances. For U.S. imports, adhere to EPA and DOT guidelines. Declare accurate Harmonized System (HS) codes—typically under 8414.59 (other fans and ventilating equipment).

Environmental and Safety Regulations

Dispose of packaging materials in accordance with local recycling regulations. If the fan contains electronic components, comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Ensure no hazardous substances (e.g., lead, mercury) exceed permissible limits as defined by global standards. Provide Safety Data Sheets (SDS) upon request for any chemical components used in manufacturing.

Documentation and Record Keeping

Retain shipping documents, compliance certificates, and product conformity statements for a minimum of five years. Maintain a traceability log linking batch numbers to shipment details for recall readiness. Digital records should be securely backed up and accessible for audit purposes.

Warranty and Returns Logistics

Clearly communicate warranty terms (e.g., 12-month or 12,000-mile limited warranty) on packaging and invoices. For returns, use prepaid return labels and inspect returned units for damage or misuse. Process replacements or refunds within 14 business days of receipt. Track return reasons to improve product quality and logistics handling procedures.

In conclusion, sourcing a radiator fan for a Volvo 240 requires careful consideration of compatibility, quality, and cost. Whether opting for original equipment manufacturer (OEM) parts, aftermarket alternatives, or used components from salvage yards, it is essential to verify fitment based on the model year, engine type, and cooling system configuration. Online marketplaces, Volvo specialists, and community forums can provide valuable resources and recommendations. Prioritizing reliability and proper function ensures the cooling system maintains optimal engine temperature, preserving the longevity and performance of the classic Volvo 240. With due diligence, a suitable and durable radiator fan can be sourced efficiently and cost-effectively.