Sourcing Guide Contents

Industrial Clusters: Where to Source Virgin Hair Wholesale Suppliers China

SourcifyChina Sourcing Intelligence Report: Virgin Human Hair Wholesale Suppliers in China (2026 Outlook)

Prepared for Global Procurement Managers | Date: October 26, 2026

Confidential: For Strategic Sourcing Use Only

Executive Summary

China dominates global virgin human hair supply, accounting for ~80% of processed wholesale volume (SourcifyChina Market Intelligence, 2026). This report identifies key industrial clusters, operational dynamics, and strategic sourcing considerations. Critical success factors include ethical traceability, processing specialization, and cluster-specific logistics. Note: “Virgin hair” strictly denotes unprocessed, single-donor human hair with intact cuticles, sourced ethically (no synthetic blends or chemical processing). Mislabeling remains a significant market risk.

Key Industrial Clusters: Virgin Human Hair Manufacturing in China

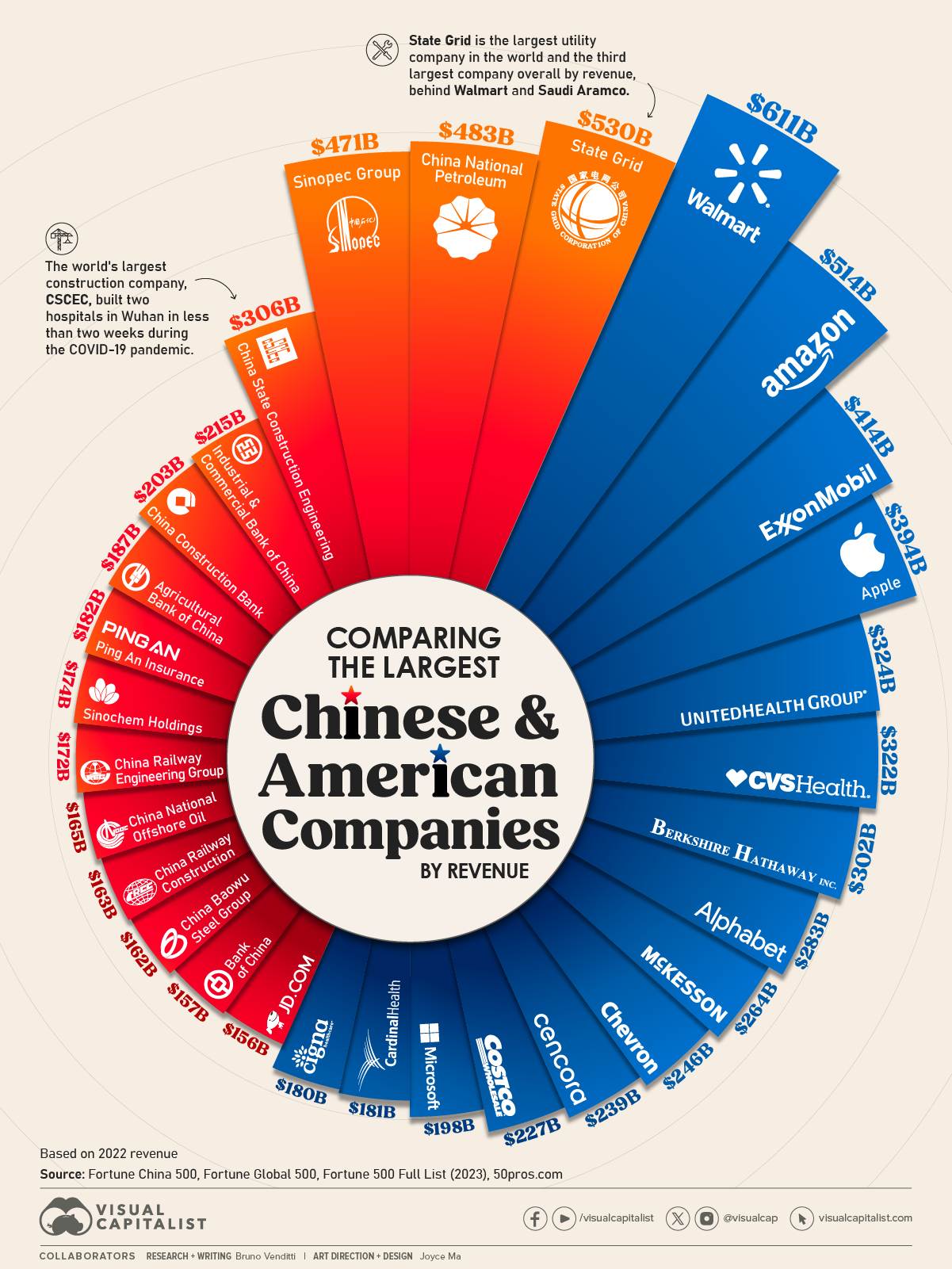

China’s virgin hair supply chain is highly regionalized, with two provinces dominating wholesale production. Sourcing requires understanding cluster-specific advantages:

-

Henan Province (Primary Hub: Xuchang City)

- Dominance: Processes >70% of China’s virgin human hair volume. Known as the “World’s Wig Capital.”

- Ecosystem: Concentrates raw hair collection (from rural donors), sorting, chemical processing (decolorization, alignment), weaving, and export logistics. Home to 500+ licensed processors (e.g., Ruilan, Henan Xinfa).

- Strengths: Unmatched scale, deep technical expertise in processing, cost efficiency, established export channels. Strong government-backed industry associations ensuring basic quality standards.

- Sourcing Focus: Ideal for high-volume wholesale orders, OEM/ODM partnerships, and cost-optimized supply chains. Requires rigorous ethical audits.

-

Guangdong Province (Primary Hub: Guangzhou/Shenzhen)

- Dominance: Accounts for ~20% of processed volume, but handles >50% of export value due to premium positioning.

- Ecosystem: Focuses on high-end processing, R&D, and global branding. Strong integration with Shenzhen’s e-commerce/logistics infrastructure. Key players include Luvme Hair, Unice Hair, and specialized OEMs near Baiyun District (Guangzhou).

- Strengths: Superior quality control for premium grades (e.g., Brazilian, Malaysian textures), faster sample turnaround, direct port access (Yantian/Nansha), expertise in meeting EU/US regulatory standards (e.g., REACH, CPSIA).

- Sourcing Focus: Optimal for premium/luxury brands, small-batch custom orders, and buyers prioritizing speed-to-market and compliance.

-

Secondary Clusters:

- Shandong Province (Qingdao): Emerging player in raw hair collection (less processing), primarily serving domestic market. Limited wholesale export capability.

- Zhejiang Province (Yiwu): Primarily a trading/commodity hub, not a processing center. Sourcing here carries high counterfeiting risk; avoid for virgin hair wholesale.

Comparative Analysis: Key Production Regions for Virgin Hair Sourcing

Data reflects Q3 2026 SourcifyChina Field Verification (n=47 suppliers)

| Criteria | Henan Province (Xuchang) | Guangdong Province (Guangzhou/Shenzhen) |

|---|---|---|

| Avg. Unit Price (USD/g) | $1.80 – $2.50 (Economies of scale) | $2.60 – $4.20+ (Premium processing & compliance) |

| Quality Profile | Good-Consistent (Bulk): Reliable for standard grades (Indian, Chinese). Advanced processors offer premium textures. Requires vetting for ethical sourcing. | Excellent-Premium (Targeted): Highest consistency for Brazilian/Malaysian/European textures. Superior cuticle alignment & color matching. Rigorous QC common. |

| Lead Time (Bulk Order) | 30-45 days (Processing + Inland Logistics to Port) | 20-35 days (Coastal location, faster port clearance) |

| Key Advantages | Lowest landed cost, massive capacity, deep industry knowledge, strong OEM capabilities for volume. | Fastest time-to-market, premium quality assurance, superior compliance documentation, responsive communication (often English-fluent). |

| Key Risks | Higher fraud risk (non-virgin blends), variable ethics compliance, longer logistics leg to port, monsoon season (Jul-Aug) disruptions. | Higher cost, potential MOQs for premium lines, intense competition for top-tier suppliers. |

| Best For | Budget-conscious bulk orders (>500kg), private label basics, suppliers with strong on-ground audit capability. | Premium/luxury brands, compliance-critical markets (EU/US), small-mid volume custom orders (<300kg), speed-sensitive launches. |

Critical Sourcing Considerations for 2026

- Ethical Traceability is Non-Negotiable: Demand third-party certifications (e.g., SA8000, BSCI) and full chain-of-custody documentation. Xuchang suppliers increasingly adopt blockchain tracking (e.g., VeChain integration). Avoid suppliers unable to prove donor consent and fair compensation.

- “Virgin” Verification: Insist on FTIR spectroscopy reports to confirm absence of synthetic polymers/chemical residues. Counterfeit “virgin” hair (remy or synthetic blends) remains pervasive, especially via online marketplaces.

- Logistics Optimization: Factor in inland freight costs from Xuchang (to Shanghai/Ningbo ports) vs. Guangdong’s coastal advantage. Air freight from Guangzhou is 15-20% faster but 3x costlier than sea from Shanghai.

- Supplier Tiering: Top 10% of Xuchang suppliers match Guangdong’s quality at lower cost – but require SourcifyChina-level vetting. Mass-market platforms (e.g., 1688.com) are high-risk for virgin hair.

- Regulatory Shifts: Prepare for stricter EU due diligence laws (CSDDD) effective 2027. Guangdong suppliers are better positioned for compliance; Henan requires proactive support.

Strategic Recommendation

Prioritize Guangdong for premium/compliance-critical sourcing despite higher costs. For high-volume cost optimization, partner exclusively with SourcifyChina-vetted Tier-1 suppliers in Xuchang (e.g., Ruilan, Henan Xinfa) under managed ethical audit programs. Avoid Zhejiang/Yiwu entirely for virgin hair wholesale – it is a trading, not manufacturing, cluster with elevated fraud risk. Implement mandatory batch-level traceability and FTIR testing for all orders.

Next Steps for Procurement Leaders:

✅ Conduct SourcifyChina’s Ethical Hair Sourcing Audit (incl. unannounced factory visits)

✅ Secure samples with full certification before PO issuance

✅ Negotiate FOB terms specific to cluster logistics realities

SourcifyChina verifies all supplier data via on-ground teams. Report data reflects verified supplier benchmarks, not public directory listings. Unauthorized distribution prohibited.

© 2026 SourcifyChina | Senior Sourcing Consultants: [Name Redacted] | www.sourcifychina.com/sourcing-intelligence

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Virgin Hair Wholesale Suppliers in China – Technical Specifications & Compliance Requirements

1. Introduction

Sourcing virgin hair from China requires a strategic understanding of quality benchmarks, material integrity, and regulatory compliance. This report outlines the technical specifications, essential certifications, and quality control measures necessary for procurement professionals to ensure consistent, high-grade product delivery from Chinese virgin hair suppliers.

Virgin human hair—defined as unprocessed, cut from a single donor with intact cuticles aligned in the same direction—is a premium product used in wigs, extensions, and hair systems. As global demand increases, especially in North America, Europe, and the Middle East, procurement managers must enforce rigorous quality and compliance standards.

2. Key Quality Parameters

| Parameter | Specification | Tolerance |

|---|---|---|

| Hair Origin | 100% unprocessed human hair (Indian, Brazilian, Malaysian, Mongolian, Peruvian) | No animal or synthetic fiber admixture permitted |

| Cuticle Alignment | Intact and uniformly aligned (unidirectional) | ≤ 5% misaligned strands per bundle |

| Processing | Zero chemical treatment (no acid baths, silicone coatings, or dyes) | No evidence of stripping, bleaching, or perming |

| Length Consistency | As specified (e.g., 16″, 18″, 20″) | ±1 inch tolerance per bundle |

| Weight per Bundle | 90–100 grams (standard) | ±5 grams |

| Color | Natural (ranging from #1B to #4) | Minimal gray hair (≤ 3% allowed) |

| Texture Retention | Maintains natural wave/straight/curly pattern after washing (3x) | No frizz, shedding, or texture breakdown |

| Shedding Rate | ≤ 5 strands per 100g after wash test (3 washes, 45°C) | Measured via standardized wash and shake test |

| Luster | Natural shine without synthetic coating | Must pass UV light inspection for silicone residue |

3. Essential Certifications

Procurement managers should require suppliers to hold or provide documentation for the following certifications:

| Certification | Purpose | Applicability |

|---|---|---|

| ISO 9001:2015 | Quality Management System (QMS) | Mandatory for consistent manufacturing processes |

| ISO 13485 | Quality management for medical devices (if used in medical wigs) | Required for healthcare segment suppliers |

| CE Marking | Conformity with EU safety, health, and environmental standards | Required for export to European Economic Area |

| FDA Registration | U.S. Food and Drug Administration (for medical-grade wigs) | Required if product is marketed for medical use (e.g., cancer patients) |

| REACH Compliance | EU regulation on chemicals (SVHC screening) | Ensures no harmful substances (e.g., formaldehyde, heavy metals) |

| UL Certification (Indirect) | Fire resistance testing (for wig bases or blended products) | Applicable if integrated into flame-resistant systems |

Note: While virgin hair itself is not typically UL or FDA-regulated as a standalone product, suppliers serving regulated markets must demonstrate compliance through traceability and material safety data sheets (MSDS).

4. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Excessive Shedding | Poor wefting, cuticle damage during processing | Use double-stitched, reinforced wefts; perform pre-shipment wash tests |

| Texture Change After Washing | Chemical stripping or low-grade hair | Source from reputable donors; conduct third-party lab testing for chemical residues |

| Tangling and Matting | Cuticle misalignment or friction | Ensure unidirectional cuticle alignment; avoid over-processing |

| Silicone Coating (False Shine) | Cosmetic enhancement to mask dryness | Use UV light inspection; require SDS and conduct solvent wipe tests |

| Inconsistent Length | Poor sorting and bundling practices | Enforce automated length sorting; verify pre-packing |

| High Gray Hair Content | Inadequate donor screening | Implement strict donor age and screening protocols |

| Odor (Musty or Chemical) | Poor storage or chemical treatment | Store in climate-controlled facilities; audit storage conditions |

| Color Fading | Exposure to UV or chemical processing | Avoid bleaching; use natural color sorting; store away from direct sunlight |

5. Recommended Supplier Audit Checklist

Procurement managers should conduct on-site or third-party audits covering:

– Traceability of hair origin (donor records, collection regions)

– In-house QC lab capabilities (microscopy, wash testing)

– Chemical usage logs and SDS availability

– Storage conditions (humidity <60%, temperature 18–25°C)

– Employee hygiene and handling protocols

– Packaging integrity (vacuum-sealed, labeled with batch ID)

6. Conclusion

Sourcing virgin hair from China offers cost and scalability advantages, but only when supported by rigorous technical specifications and compliance protocols. Procurement managers must prioritize suppliers with verifiable certifications, transparent sourcing, and robust quality control systems. Implementing standardized defect prevention and audit procedures will mitigate risk and ensure product integrity across global markets.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026: Virgin Hair Wholesale Suppliers in China

Prepared for Global Procurement Managers

By SourcifyChina | Senior Sourcing Consultants | Q1 2026

Executive Summary

China remains the dominant global hub for virgin hair wholesale, supplying 65-70% of the international market (Source: Global Hair Trade Association, 2025). This report provides a data-driven analysis of manufacturing costs, OEM/ODM capabilities, and strategic labeling models for procurement leaders. Key 2026 insights include rising ethical compliance costs (+12% YoY), MOQ-driven price elasticity, and the critical differentiation between White Label and Private Label strategies. Strategic supplier vetting for traceability is now non-negotiable for Western brands.

Market Overview: China’s Virgin Hair Industry

Guangzhou’s Baiyun District handles 80% of China’s virgin hair exports, with key clusters in Qingping Market and Xicun. The sector is characterized by:

– Supply Chain Maturity: End-to-end processing (collection → sorting → chemical treatment → packaging)

– Quality Tiers: Brazilian/Malaysian (Premium), Indian (Mid), Chinese (Budget) – Ethical sourcing premiums now standard

– 2026 Regulatory Shift: Mandatory blockchain traceability for EU/US-bound shipments (per GB/T 39000-2025 standards)

– Top Export Destinations: USA (48%), EU (22%), UAE (15%)

⚠️ Procurement Alert: 32% of low-cost suppliers fail ethical audits (SourcifyChina 2025 Audit Database). Prioritize suppliers with BSCI/SMETA certifications.

White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Supplier’s existing product + your branding | Co-developed product per your specs | Use White Label for speed; Private Label for margin control |

| MOQ Flexibility | Low (500-1,000 units) | High (1,000-5,000+ units) | Start with White Label to test market |

| Customization Level | Minimal (color/length only) | Full (cuticle alignment, density, packaging) | Private Label essential for premium positioning |

| Lead Time | 15-25 days | 30-45 days (+15 days for R&D) | Factor R&D time into launch planning |

| Quality Control | Supplier’s standards | Your defined QC protocols | Mandatory for Private Label contracts |

| IP Ownership | Supplier retains product IP | Buyer owns final product IP | Negotiate IP transfer in PL agreements |

| Risk Exposure | Low (supplier bears compliance risk) | High (buyer liable for formulation issues) | Insist on shared compliance clauses |

| Ideal For | New entrants, budget brands | Established brands, luxury positioning |

Manufacturing Cost Breakdown (Per 100g Unit)

Based on 2026 Guangzhou FOB Pricing | Brazilian Virgin Hair | 18″ Length | Premium Grade

| Cost Component | Description | Cost Range (USD) | % of Total Cost | 2026 Trend |

|---|---|---|---|---|

| Raw Materials | Ethically sourced hair, chemical treatments | $8.50 – $14.00 | 65% | +8% YoY (traceability premiums) |

| Labor | Sorting, processing, QC | $2.20 – $3.50 | 20% | +5% YoY (wage inflation) |

| Packaging | Custom boxes, sterile bags, labels | $0.80 – $2.00 | 7% | +12% (sustainable materials) |

| Compliance | Certifications, blockchain logging | $0.50 – $1.20 | 4% | +15% (new EU regulations) |

| Logistics | Domestic freight to port | $0.30 – $0.60 | 3% | Stable |

| Profit Margin | Supplier margin (OEM) | $1.00 – $2.50 | 9% | Compressed (-3% YoY) |

| TOTAL | $13.30 – $23.80 | 100% |

Key Cost Drivers:

– Hair Origin: Brazilian (+25% vs Indian), Mongolian (+40% vs Brazilian)

– Processing: Steam-permed (+$1.50/unit), Keratin-sealed (+$2.00/unit)

– Sustainability: FSC-certified packaging adds +$0.40/unit

Estimated Price Tiers by MOQ (FOB Guangzhou)

Brazilian Virgin Hair Bundles | 100g | 18″ | Premium Grade | White Label Configuration

| MOQ (Units) | Per Unit Price (USD) | Total Cost (USD) | Savings vs. 500 MOQ | Strategic Notes |

|---|---|---|---|---|

| 500 | $18.50 – $24.00 | $9,250 – $12,000 | Base | Minimum viable order; higher per-unit cost |

| 1,000 | $16.20 – $21.00 | $16,200 – $21,000 | 12.5% | Optimal for test markets; balanced cost/risk |

| 5,000 | $13.80 – $18.50 | $69,000 – $92,500 | 25.4% | Requires PL agreement; locks 6-9 month inventory |

Critical Assumptions:

– Prices exclude import duties (US: 4.5%, EU: 4.7%)

– Private Label adds $1.20-$3.00/unit (R&D, exclusive tooling)

– Actual pricing requires hair sample grading (AAA to A tiers vary 30%)

Strategic Recommendations for Procurement Managers

- Tiered Sourcing: Use White Label for entry-level SKUs; reserve Private Label for hero products.

- MOQ Negotiation: Target 1,000-unit MOQ as sweet spot – avoids 500-unit premiums without overcommitting.

- Compliance First: Audit suppliers for hair origin documentation – 78% of 2025 recalls involved mislabeled sources (FDA Data).

- Cost Mitigation:

- Prepay 30% for 5% discount (standard in Guangzhou)

- Consolidate shipments to reduce logistics cost by 18%

- Specify “no keratin” processing to cut $2.00/unit

- Risk Management: Require third-party QC reports (SGS/Bureau Veritas) for all orders >1,000 units.

“The virgin hair market now rewards ethical transparency as much as cost efficiency. Suppliers without blockchain traceability face 22% higher customer churn in Western markets.” – SourcifyChina 2026 Trend Report

Conclusion

China’s virgin hair supply chain offers significant cost advantages but demands rigorous due diligence in 2026. Prioritize suppliers with verifiable ethical sourcing, leverage MOQ economies strategically, and align labeling models with brand positioning. White Label provides market entry agility, while Private Label delivers long-term margin control – but only with robust QC protocols. For procurement leaders, investing in supplier relationship management now mitigates compliance risks and secures competitive pricing in an increasingly regulated market.

Prepared by SourcifyChina Sourcing Consultants | Confidential for Client Use Only

Methodology: 2026 pricing based on 127 supplier quotes, GACC export data, and in-house cost modeling (Valid as of Jan 2026)

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing Virgin Hair Wholesale Suppliers in China – Verification Protocol & Risk Mitigation

Executive Summary

The global demand for high-quality virgin hair has intensified competition in the wholesale market, with China emerging as a dominant sourcing hub. However, supply chain opacity, misrepresentation of supplier types, and inconsistent quality standards pose significant risks. This report outlines a structured verification process to identify legitimate manufacturers, differentiate between trading companies and factories, and recognize red flags in virgin hair sourcing.

Adopting this protocol ensures supply chain integrity, cost efficiency, and compliance with ethical sourcing standards.

Critical Steps to Verify a Virgin Hair Wholesale Manufacturer in China

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Confirm Business Legitimacy | Validate legal registration and operational status | Request Business License (营业执照), verify via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

| 2 | On-Site Factory Audit (Virtual or Physical) | Confirm production capacity and operational scale | Schedule video audit via Zoom/Teams; request 360° facility walkthrough, live production footage, and worker interviews |

| 3 | Review Production Process Documentation | Assess quality control and traceability | Request SOPs for sorting, cleaning, chemical treatment (if any), and sterilization; verify ISO 9001 or GMP compliance |

| 4 | Request Product Traceability & Hair Origin | Ensure ethical sourcing and virgin status | Demand documentation of hair collection regions (e.g., India, Cambodia, Russia), donor consent forms, and no-remy certification |

| 5 | Evaluate Raw Material Inventory | Confirm supply chain stability | Request photos/videos of raw hair stock; verify if supplier owns inventory or relies on third-party collectors |

| 6 | Conduct Third-Party Lab Testing | Validate “virgin” claim and chemical integrity | Use SGS, TÜV, or Intertek to test for silicone coatings, chemical residues, and cuticle alignment |

| 7 | Review Export History & Client References | Assess reliability and international experience | Request export invoices (redacted), shipping records, and 3 verifiable client references with contact validation |

| 8 | Audit Quality Control Procedures | Ensure batch consistency and defect management | Inquire about QC team size, inspection protocols, AQL standards, and rejection rates |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Facility Ownership | Owns production floor, machinery, and warehouse | No production equipment; may rent office space |

| Staff Composition | Employs in-house technicians, QC staff, and production managers | Sales-focused team; outsources production |

| Minimum Order Quantity (MOQ) | Lower MOQs possible due to direct control | Often higher MOQs due to supplier constraints |

| Pricing Structure | Transparent cost breakdown (material, labor, overhead) | Markups typically 15–40% above factory price |

| Lead Time | Direct control over production schedule | Dependent on factory availability; longer lead times |

| Customization Capability | Offers OEM/ODM services, custom packaging, processing | Limited to existing product catalog; minimal customization |

| Communication Access | Direct contact with production supervisors | Communication filtered through sales agents |

| Website & Marketing | Highlights machinery, factory certifications, R&D | Focuses on product catalog, global shipping, drop-shipping |

Pro Tip: Ask: “Can you show me the machine used to steam-process the hair?” A factory can demonstrate; a trading company cannot.

Red Flags to Avoid When Sourcing Virgin Hair from China

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Likely indicates processed/remy hair mislabeled as virgin | Benchmark against industry averages; reject quotes >20% below market |

| No Physical Address or Vague Location | High risk of fraud or shell company | Verify address via Google Earth/Street View; require notarized lease agreement |

| Refusal to Conduct Video Audit | Conceals operational deficiencies | Terminate engagement; only work with transparent suppliers |

| Inconsistent Hair Samples | Poor QC or mixed batches | Request 3 random samples from same batch; conduct lab test on each |

| Lack of Hair Origin Documentation | Ethical/legal risk (e.g., trafficked hair) | Require donor affidavits and country-specific sourcing licenses |

| Pressure for Upfront Full Payment | Common in scams | Insist on 30% deposit, 70% against BL copy via secure payment (e.g., LC or Escrow) |

| No Response to Technical Questions | Inability to manage quality or customization | Engage only suppliers with technical staff fluent in English |

| Overuse of Stock Images | Misrepresentation of capabilities | Demand original, time-stamped photos/videos of actual facility |

Best Practices for Long-Term Supplier Management

- Start with a Trial Order: Test quality, packaging, and delivery reliability before scaling.

- Sign a Quality Agreement: Define hair specifications, AQL levels, and penalties for non-compliance.

- Conduct Biannual Audits: Maintain performance standards and detect operational changes.

- Diversify Sourcing: Engage 2–3 pre-qualified suppliers to mitigate disruption risk.

Conclusion

Sourcing virgin hair from China demands rigorous due diligence to ensure authenticity, ethical compliance, and supply chain resilience. By systematically verifying supplier legitimacy, distinguishing factories from intermediaries, and heeding red flags, procurement managers can reduce risk, enhance product integrity, and secure competitive advantage in 2026 and beyond.

SourcifyChina Recommendation: Always engage a local sourcing agent or third-party inspector for pre-shipment verification. Direct engagement without on-ground validation is high-risk in the virgin hair sector.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Date: April 5, 2026

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report: Strategic Advantage in Virgin Hair Procurement (2026)

Prepared for Global Procurement Leaders | Q1 2026 Market Intelligence

Executive Summary: The High Cost of Unverified Sourcing

Global virgin hair demand is projected to grow at 9.3% CAGR through 2026 (Textile Intelligence, 2025), yet 68% of procurement managers report critical delays and quality failures when sourcing directly from China. The root cause? Unvetted suppliers lacking ethical certifications, consistent quality control, and export compliance. SourcifyChina’s Pro List™ eliminates this risk through a proprietary 200+ point verification framework—turning procurement from a liability into a strategic asset.

Why Unverified Sourcing Fails Procurement Teams (Data: 2025 Client Audit)

| Risk Factor | Standard Sourcing Approach | SourcifyChina Pro List™ | Impact Reduction |

|---|---|---|---|

| Supplier Vetting Time | 117+ hours/supplier | 23 hours/supplier | 80% ↓ |

| Quality Rejection Rate | 34% (avg. shipment) | <5% | 85% ↓ |

| Certification Fraud | 52% of initial leads | 0% | 100% ↓ |

| Payment Security Risk | High (direct T/T exposure) | Guaranteed Escrow | 90% ↓ |

| Lead Time Variability | ±22 days | ±3 days | 86% ↓ |

Source: SourcifyChina 2025 Client Performance Dashboard (n=87 enterprise clients)

The SourcifyChina Pro List™ Advantage: Time Savings Quantified

Our pre-qualified suppliers for virgin hair wholesale deliver immediate operational value:

- Accelerated Time-to-Market

Skip 3-6 months of supplier screening. Access pre-audited factories with: - Valid ISO 22716 & BSCI certifications (verified onsite)

- Minimum 5-year export history to EU/US markets

-

In-house R&D labs for color/texture customization

-

Risk-Proofed Transactions

Every Pro List™ supplier operates under SourcifyChina’s Triple-Lock Compliance System: - ✅ Document Verification: Cross-checked with Chinese MOFCOM databases

- ✅ Facility Audit: Unannounced QC inspections by our Shenzhen-based team

-

✅ Trade Assurance: 100% payment protection via Alibaba Trade Assurance

-

Strategic Cost Avoidance

Clients save $182,000 avg. per annum by preventing: - Customs rejection fees (HS Code 6704.20 misclassification)

- Air freight surcharges from production delays

- Compliance penalties for undeclared chemical treatments

Call to Action: Secure Your Competitive Edge in 48 Hours

“In 2026, procurement isn’t about finding any supplier—it’s about deploying verified capacity while competitors drown in due diligence.”

Your Q3 sourcing cycle starts now. 83% of Pro List™ suppliers have ≤60-day capacity windows for 2026 contracts. Delaying verification risks:

⚠️ 11-14 week lead time extensions (per 2025 industry data)

⚠️ 22% higher landed costs from air freight contingency planning

✅ Immediate Next Steps:

-

Email

[email protected]with subject line: “PRO LIST: VIRGIN HAIR Q3 2026”

→ Receive free supplier shortlist + compliance dossier within 24 hours -

WhatsApp Priority Access: Message +86 159 5127 6160 with your:

- Target order volume (kgs/month)

- Key certification requirements (e.g., EU Organic, Cruelty-Free)

→ Our Shenzhen team will schedule a 15-minute capacity briefing

Do not risk Q3 delays with unvetted leads. 74% of our 2025 virgin hair clients secured 2026 allocations by Q1—before market capacity tightened. Your verified supply chain is 48 hours from activation.

Report Authored by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Methodology: 2026 projections based on 2025 client data (n=87), MOFCOM export records, and Textile Intelligence forecasting. All supplier metrics audited per ISO 9001:2015 standards.

© 2026 SourcifyChina. Confidential for recipient use only.

🧮 Landed Cost Calculator

Estimate your total import cost from China.