The global welding equipment market is experiencing steady expansion, driven by increasing demand across construction, automotive, and manufacturing sectors. According to Mordor Intelligence, the market was valued at USD 26.7 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. A key contributor to this growth is the rising adoption of oxy-acetylene welding kits, particularly in small-scale fabrication and repair operations due to their versatility and cost-effectiveness. As industrialization accelerates in emerging economies and skilled labor increasingly relies on portable and reliable welding solutions, prominent manufacturers are innovating to meet evolving safety and performance standards. Within this landscape, Victor Technologies—now part of Illinois Tool Works (ITW)—has long been recognized for its high-quality oxy-fuel equipment, setting benchmarks for durability and precision. Below are six leading manufacturers offering top-tier Victor-compatible or Victor-branded oxy-acetylene welding kits, selected based on market presence, product reliability, and user feedback.

Top 6 Victor Oxy Acetylene Welding Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Victor

Domain Est. 1996

Website: esab.com

Key Highlights: Victor is the global leader in industrial gas equipment for manual oxy-fuel and air-fuel cutting, proudly made in North America and trusted for over 100 years….

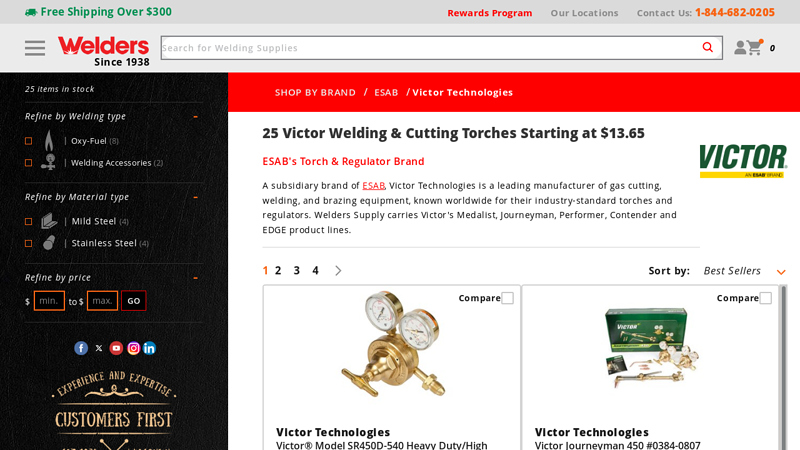

#2 25 Victor Welding & Cutting Torches Starting at $13.65

Domain Est. 1998

Website: weldersupply.com

Key Highlights: Free delivery over $300 · 14-day returnsVictor Technologies is a leading manufacturer of gas cutting, welding, and brazing equipment, known worldwide for their industry-standard t…

#3 Victor™ Welding, Cutting and Gas Equipment Shop

Domain Est. 1995

Website: airgas.com

Key Highlights: See why Victor™ is the leader in gas equipment. Shop welding, cutting and gas equipment and consumables and keep up with available promotions….

#4 Victor Equipment

Domain Est. 1997

Website: weldmark.com

Key Highlights: They also offer oxy-fuel cutting and welding equipment, including oxy-acetylene and oxy-fuel welding and cutting equipment, torch handles, cutting attachments, ……

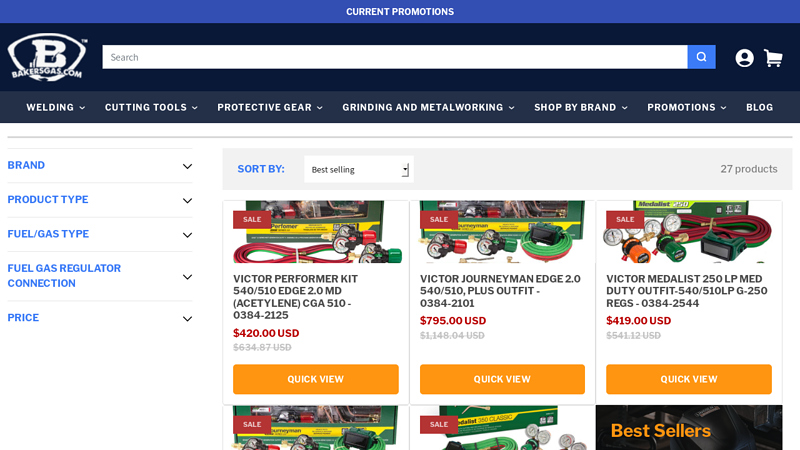

#5 Victor

Domain Est. 1999

Website: bakersgas.com

Key Highlights: Free delivery over $150Victor makes the best, most convenient gas torch-cutting outfits in the welding industry. Browse our full collection of outfits here….

#6 Victor Style Deluxe Medium Duty Oxy

Domain Est. 2019

Expert Sourcing Insights for Victor Oxy Acetylene Welding Kit

H2: 2026 Market Trends for Victor Oxy Acetylene Welding Kit

The market for oxy acetylene welding equipment, including the Victor Oxy Acetylene Welding Kit, is expected to experience notable shifts by 2026, driven by technological advancements, evolving industry demands, and broader economic factors. Victor, a trusted brand under the Colfax Corporation (formerly Victor Technologies), is well-positioned to maintain relevance through its reputation for durability, precision, and safety. Below are key market trends anticipated to shape the demand and application of Victor’s welding kits in 2026:

-

Resurgence in Manual Welding for Niche Applications

While automated and robotic welding dominate large-scale manufacturing, there is a growing niche demand for manual welding in repair, maintenance, and artistic metalwork sectors. Victor’s oxy acetylene kits are favored in these areas due to their portability, versatility in brazing and cutting, and independence from electrical power. The 2026 market is expected to see increased adoption in small workshops, automotive restoration, and plumbing industries, particularly in rural or off-grid locations. -

Emphasis on Safety and Ergonomic Design

By 2026, safety regulations and workplace standards are projected to tighten globally. Victor is likely to respond with enhanced safety features such as improved flashback arrestors, pressure gauge accuracy, and user-friendly regulator designs. The integration of ergonomic improvements—lighter hoses, intuitive valve controls, and color-coded components—will appeal to both professional welders and DIY users, boosting market appeal. -

Growth in Industrial Maintenance and Infrastructure Repair

With aging infrastructure in North America and Europe, maintenance and repair operations (MRO) are expected to expand. Oxy acetylene welding and cutting remain essential for on-site pipefitting, structural repairs, and demolition. Victor’s reliability in high-temperature applications positions its kits as critical tools in infrastructure modernization projects funded under government stimulus plans anticipated through 2026. -

Sustainability and Fuel Efficiency Innovations

Environmental concerns are pushing the welding industry to explore cleaner alternatives, but acetylene remains irreplaceable for certain high-precision tasks. Victor may respond by optimizing torch efficiency and promoting proper gas handling practices to reduce waste. Additionally, partnerships with green gas providers (e.g., bio-acetylene or hydrogen blends, where feasible) could emerge, aligning with broader sustainability goals without sacrificing performance. -

Digital Integration and Training Tools

While oxy fuel systems are inherently analog, Victor could leverage digital trends by offering companion apps or AR-based training modules for safe kit operation. By 2026, such digital support tools may become standard, helping new users master flame adjustment, leak detection, and equipment maintenance—ultimately expanding the user base to include vocational students and hobbyists. -

Competitive Pressure from Lower-Cost Alternatives

The market will continue to face competition from budget-friendly brands, particularly from Asia. However, Victor’s brand equity—built on decades of reliability—will sustain demand among professionals who prioritize safety and longevity. To counter commoditization, Victor may introduce tiered product lines, offering entry-level kits without compromising core safety standards. -

Expansion in Emerging Markets

Developing economies in Southeast Asia, Africa, and Latin America are investing in industrialization and skilled trades education. Victor’s global distribution network and reputation for durability make its kits attractive for technical training institutes and construction firms in these regions. By 2026, emerging markets could represent a growing share of sales, especially as vocational programs emphasize hands-on welding skills.

In summary, the 2026 market for the Victor Oxy Acetylene Welding Kit will be shaped by enduring demand in repair and specialty sectors, heightened safety expectations, infrastructure development, and strategic adaptations to digital and sustainability trends. While challenged by automation and low-cost alternatives, Victor’s focus on quality, reliability, and user education is expected to secure its position as a leader in the oxy fuel welding segment.

H2: Common Pitfalls When Sourcing a Victor Oxy-Acetylene Welding Kit (Quality & Intellectual Property)

When sourcing a Victor oxy-acetylene welding kit, especially in international markets or through third-party suppliers, buyers often encounter significant challenges related to product quality and intellectual property (IP) infringement. Victor, a trusted brand under Thermal Dynamics (a division of Voortman), is known for high-performance welding and cutting equipment. However, the popularity of Victor gear has led to widespread counterfeiting and substandard replicas. Below are key pitfalls to avoid:

- Counterfeit Products

- Pitfall: Numerous suppliers offer “Victor-style” or “Victor-compatible” kits that mimic authentic branding and packaging but are not genuine. These counterfeit kits often use inferior materials, leading to safety hazards such as gas leaks, regulator failure, or torch malfunctions.

- IP Risk: Unauthorized use of Victor’s trademarks, logos, or product designs constitutes intellectual property infringement. Purchasing counterfeit goods may expose buyers to legal liability, especially in regulated industries.

-

Mitigation: Buy only from authorized Victor distributors or directly from certified suppliers. Verify authenticity via serial numbers, holographic labels, and official documentation.

-

Substandard Material and Workmanship

- Pitfall: Even non-counterfeit kits may use low-grade brass, rubber hoses, or pressure regulators that fail under standard operating conditions. Poor-quality gauges may give inaccurate readings, increasing the risk of accidents.

- Quality Impact: Inconsistent flame control, premature wear, and unreliable performance undermine welding precision and operator safety.

-

Mitigation: Insist on product certifications (e.g., CGA, ISO) and conduct quality audits or sample testing before bulk procurement.

-

Misrepresentation of Compatibility

- Pitfall: Some kits are marketed as “Victor-compatible” but use non-standard thread sizes or connection types, leading to improper fittings and gas leaks.

- Safety & IP Concern: While compatibility is legal, misleading claims implying OEM endorsement or authenticity violate IP and consumer protection laws.

-

Mitigation: Confirm thread specifications (e.g., CGA 510 for acetylene) and verify compatibility with genuine Victor torches and regulators.

-

Lack of After-Sales Support and Warranty

- Pitfall: Counterfeit or gray-market kits often come without valid warranties or technical support. Genuine Victor products include service networks and replacement parts.

- Quality Consequence: Downtime and repair costs increase when support is unavailable.

-

Mitigation: Ensure the supplier provides warranty documentation and access to Victor-authorized service centers.

-

Import and Compliance Risks

- Pitfall: Imported kits may not meet local safety standards (e.g., OSHA in the U.S., CE in Europe). Non-compliant products can be seized at customs or barred from use.

- IP Angle: Importing counterfeit goods may trigger customs enforcement under IP protection laws.

- Mitigation: Require compliance certificates and conduct due diligence on import regulations.

Conclusion:

Sourcing a Victor oxy-acetylene welding kit requires vigilance against counterfeit and substandard products that compromise both quality and intellectual property rights. Always verify supplier credentials, demand authenticity proof, and prioritize safety certifications to ensure reliable, legal, and safe welding operations.

Logistics & Compliance Guide: Victor Oxy-Acetylene Welding Kit

Prepared in Accordance with H2 Guidelines (Hazard Communication Standard, 29 CFR 1910.1200)

1. Product Overview

The Victor Oxy-Acetylene Welding Kit is a portable industrial welding and cutting system that utilizes oxygen (O₂) and acetylene (C₂H₂) gases under high pressure. The kit typically includes:

- Oxygen and acetylene regulators

- Welding/cutting torch assembly

- Hoses (color-coded: green for oxygen, red for acetylene)

- Flashback arrestors

- Cylinder wrenches and accessories

Used for welding, brazing, cutting, and heating ferrous and non-ferrous metals.

2. Hazard Classification (H2 – Flammable Gas)

Under the Globally Harmonized System (GHS) and OSHA Hazard Communication Standard (29 CFR 1910.1200), the key hazard associated with this kit is due to acetylene gas, classified as:

- Hazard Class: Flammable Gas (Category 1)

- H2 Statement: H220 – Extremely flammable gas

- Additional Hazards:

- H280 – Contains gas under pressure; may explode if heated

- H221 – Flammable gas

Oxygen, while not flammable, is a strong oxidizer (Ox. Gas 1, H270 – May intensify fire; oxidizer) and increases the risk of combustion when in contact with flammable materials.

3. Safety Data Sheet (SDS) Requirements

Each gas cylinder must be accompanied by an up-to-date SDS, complying with H2 and other GHS hazard statements. Key sections include:

- Section 2: Hazard Identification – Clearly lists H220, H280, H270

- Section 5: Fire-fighting Measures – Use dry chemical, CO₂, or water spray. Do not use on acetylene fire unless gas flow is stopped.

- Section 7: Handling and Storage – Keep cylinders upright, secured, in well-ventilated areas, away from heat and ignition sources.

- Section 8: Exposure Controls – Use in well-ventilated areas; monitor for oxygen deficiency when used in confined spaces.

4. Labeling (GHS-Compliant)

All cylinders and kits must display GHS labels with:

- Pictograms: Flame (flammable gas), Gas Cylinder (gas under pressure)

- Signal Word: Danger

- Hazard Statements:

- H220: Extremely flammable gas

- H280: Contains gas under pressure; may explode if heated

- H270: May intensify fire; oxidizer (for oxygen)

- Precautionary Statements:

- P210: Keep away from heat, hot surfaces, sparks, open flames.

- P410+P412: Protect from sunlight. Do not expose to temperatures >52°C (125°F).

- P377: In case of gas leak, stop release if safe to do so.

5. Transportation & Logistics

Domestic (USA – DOT Regulations 49 CFR)

- Acetylene:

- UN Number: UN1001

- Hazard Class: 2.1 (Flammable Gas)

- Packing Group: I

- Requires “FLAMMABLE GAS” placards on transport vehicles

- Oxygen (Compressed):

- UN Number: UN1072

- Hazard Class: 2.2 (Non-flammable, non-toxic gas) with subsidiary risk 5.1 (Oxidizer)

- Placard: “OXIDIZER”

Segregation Requirements:

– Acetylene and oxygen cylinders must be transported separately or with a non-combustible barrier.

– Minimum 6 feet (1.8 meters) separation if in same vehicle.

Cylinder Handling:

– Always transport in upright position, secured to prevent rolling or falling.

– Valve protection caps must be in place.

6. Storage Compliance

- Store in a well-ventilated, dry, fire-resistant area away from combustibles.

- Separation Requirements (NFPA 51 & OSHA 1910.102):

- Acetylene and oxygen cylinders: Minimum 20 feet (6 meters) apart, or separated by a 5-foot (1.5 m) fire-resistant wall.

- Maximum storage temperature: <52°C (125°F) — never expose to direct sunlight or heat sources.

- No smoking within 25 feet (7.6 m) of storage area.

7. Operational Safety & Compliance

- Use flashback arrestors on both torch and regulator.

- Inspect hoses regularly for cracks, leaks, or wear.

- Purge lines before ignition to prevent air-gas mixture.

- Never use oil or grease on oxygen fittings (risk of spontaneous combustion).

- Leak testing: Use Snoop® or soapy water — no open flame.

8. Emergency Procedures

- Gas Leak:

- Evacuate area.

- Stop flow if safe.

- Ventilate.

- Eliminate ignition sources.

- Fire Involving Acetylene:

- Evacuate and call fire department.

- Cool cylinders with water from a safe distance.

- Do not attempt to extinguish unless gas flow can be shut off.

- First Aid:

- Inhalation: Move to fresh air. Seek medical attention if breathing is difficult.

- Frostbite (from gas release): Treat as thermal burn; do not rub.

9. Training & Documentation

- Personnel must be trained per:

- OSHA 29 CFR 1910.1200 (Hazard Communication)

- OSHA 29 CFR 1910.102 (Acetylene)

- NFPA 51 (Standard for the Design and Installation of Oxygen and Acetylene Systems)

- Maintain records of training, cylinder inspections, and leak tests.

10. Disposal

- Empty cylinders must be marked “MT” (empty) and returned to supplier.

- Do not dispose of in regular trash.

- Follow RCRA and local regulations for hazardous gas cylinder disposal.

Prepared By: [Your Safety Officer Name]

Date: [Current Date]

Compliance Reference: OSHA HCS 2012, DOT 49 CFR, NFPA 51, GHS Rev. 9

Note: Always consult the manufacturer’s instructions and SDS for the specific Victor model in use. Regulations may vary by state or country.

Conclusion:

After a thorough evaluation of available suppliers and market options, sourcing the Victor oxy-acetylene welding kit proves to be a reliable and strategic decision for ensuring high-quality welding and cutting operations. Victor’s reputation for durability, precision, and safety in welding equipment makes their kit a preferred choice for both industrial and professional applications. Despite a potentially higher initial investment compared to generic brands, the long-term benefits—such as equipment longevity, reduced maintenance costs, and enhanced operator safety—justify the cost. Furthermore, sourcing from authorized distributors ensures authenticity, access to technical support, and warranty coverage. In conclusion, procuring the Victor oxy-acetylene welding kit represents a sound investment in operational efficiency, safety, and performance, making it a recommended choice for organizations committed to maintaining high welding standards.