The global vermiculite market is experiencing steady growth, driven by increasing demand for fire-resistant, thermally insulating, and lightweight construction materials. According to a report by Grand View Research, the global vermiculite market size was valued at USD 1.25 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by rising construction activities, expanded use in industrial insulation, and growing adoption in horticulture and fire protection systems. As demand for vermiculite-based products rises, vermiculite boards—known for their excellent thermal stability, low thermal conductivity, and passive fire protection capabilities—have become critical components in commercial buildings, HVAC systems, and manufacturing facilities. With key players investing in product innovation and sustainable production methods, the competitive landscape is evolving. Based on market presence, production capacity, geographic reach, and compliance with international safety standards, the following eight manufacturers have emerged as leading suppliers of vermiculite boards worldwide.

Top 8 Vermiculite Board Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Vermiculite Board Manufacturer, Factory

Domain Est. 2016

Website: huayuanmica.com

Key Highlights: Vermiculite boards produced by our company use high-grade vermiculite from Xinjiang Province as raw material which is free of asbestos and no content of ……

#2 Products

Domain Est. 2023

Website: insulationsboards.com

Key Highlights: china quality Vermiculite Insulation Board & Steel Casting Ladle supplier and Good price Vermiculite Insulation Board for sale online….

#3 Vermiculite insulation boards & panels

Domain Est. 1996

Website: skamol.com

Key Highlights: Insulate your gas fire with custom designed insulation systems. In-house technical experts. Fast and simple mounting. Noncombustible materials….

#4 Vermiculite Building Boards

Domain Est. 1997

Website: vermiculite.org

Key Highlights: Vermiculite Building Boards. Exfoliated vermiculite is used in building boards to: Reduce density; Improve insulation properties; Enhance fire resistance….

#5 Vermiculite boards

Domain Est. 1999

Website: texpack.it

Key Highlights: These fireproof vermiculite boards are made from exfoliated vermiculite and special inorganic binders that provide a high level of resistance to high ……

#6 Products • Dupré Minerals

Domain Est. 2008

Website: dupreminerals.com

Key Highlights: Vermiculite Boards Provide fire resistance, insulation and thermal stability Micalite MicaliteTM Vermiculite Boards provide fire resistance, insulation and ……

#7 Vermiculite Board

Domain Est. 2012

Website: hitexinsulation.com

Key Highlights: Vermiculite board is made from a naturally occurring aluminium-magnesium silicate layer that has been already expanded with the application of heat….

#8 Vermiculite boards

Domain Est. 2017

Website: gteek.com

Key Highlights: These fireproof vermiculite boards are made from exfoliated vermiculite and special inorganic binders that provide a high level of resistance to high ……

Expert Sourcing Insights for Vermiculite Board

2026 Market Trends for Vermiculite Board: Key Drivers, Challenges, and Opportunities

The global market for vermiculite board is poised for steady growth through 2026, driven by increasing demand for fire protection, thermal insulation, and lightweight construction materials. This analysis examines the key trends shaping the sector in the coming years.

Rising Demand in Construction and Fire Safety Applications

A primary driver for vermiculite board growth by 2026 is stringent fire safety regulations in both residential and commercial construction. As urbanization accelerates globally, building codes are becoming more rigorous, especially in high-rise and public infrastructure projects. Vermiculite board, known for its exceptional fire resistance (up to 1,000°C), is increasingly specified for fire doors, wall linings, and structural protection. The adoption of passive fire protection systems in smart buildings and sustainable developments will further bolster demand.

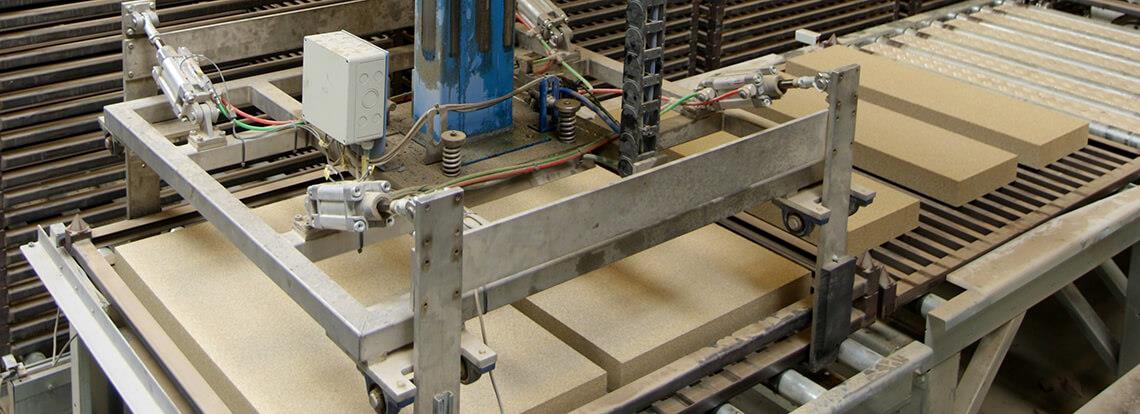

Growth in Industrial and Manufacturing Sectors

Vermiculite board is critical in industrial applications such as furnace linings, boiler insulation, and foundry operations due to its thermal stability and low thermal conductivity. As manufacturing activity rebounds post-pandemic and industries focus on energy efficiency, demand for high-performance insulation materials like vermiculite board will rise. The shift toward green manufacturing and energy-saving technologies will encourage the use of vermiculite-based solutions in kilns, ductwork, and HVAC systems.

Sustainability and Eco-Friendly Material Trends

The push for sustainable building materials supports the vermiculite board market. Vermiculite is a naturally occurring mineral, non-toxic, and recyclable, aligning with green building standards such as LEED and BREEAM. As environmental regulations tighten and consumer awareness grows, vermiculite board gains a competitive edge over synthetic insulation materials. Manufacturers are investing in eco-friendly production processes and low-emission formulations to meet sustainability goals, enhancing market appeal.

Technological Advancements and Product Innovation

By 2026, expect increased innovation in vermiculite board composites, including hybrid materials that enhance strength, moisture resistance, and acoustic performance. Developments in bonding agents and reinforcement fibers (e.g., glass or basalt fibers) are improving durability without compromising fire performance. Customizable board thicknesses and modular panel systems are also emerging, catering to prefabricated construction and retrofitting projects.

Supply Chain and Raw Material Challenges

Despite positive trends, the market faces challenges related to the supply of raw vermiculite. Limited mining sources—particularly after the closure of the Libby, Montana mine—have led to reliance on suppliers from South Africa, Brazil, and China. Geopolitical instability and transportation costs may impact pricing and availability. Companies are responding by diversifying sourcing strategies and investing in vertical integration to secure supply chains.

Regional Market Dynamics

Asia-Pacific is expected to lead market growth through 2026, fueled by rapid urbanization in India, China, and Southeast Asia. Government infrastructure initiatives and industrial expansion are key demand drivers. North America and Europe will maintain steady growth due to building code upgrades and retrofitting projects. The Middle East and Africa are emerging markets, with increasing investment in oil & gas and construction sectors creating new opportunities.

Competitive Landscape and Market Consolidation

The vermiculite board market is moderately consolidated, with key players including Promat, Morgan Advanced Materials, and National Fireproofing Corporation. By 2026, expect increased competition and potential consolidation as companies expand product portfolios and geographic reach. Strategic partnerships with construction firms and distributors will be crucial for market penetration.

In conclusion, the 2026 vermiculite board market will be shaped by safety regulations, industrial growth, sustainability demands, and innovation. While supply chain risks remain, strategic investments and product development are likely to ensure continued expansion across key global regions.

Common Pitfalls Sourcing Vermiculite Board (Quality, IP)

Sourcing vermiculite board can present several challenges, particularly concerning material quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure you procure a reliable product and safeguard your business interests.

Quality-Related Pitfalls

Inconsistent Material Composition

Vermiculite board quality heavily depends on the purity of the raw vermiculite and the manufacturing process. Low-cost suppliers may use impure vermiculite or excessive binders, reducing thermal insulation performance and mechanical strength. Boards with inconsistent density or thickness can fail under high-temperature applications.

Lack of Performance Certification

Reputable vermiculite boards should meet international standards (e.g., ASTM, EN) for fire resistance, thermal conductivity, and mechanical durability. Sourcing from suppliers who cannot provide valid test certifications risks receiving substandard material that may not perform as expected in critical applications.

Poor Batch-to-Batch Consistency

Some manufacturers, especially smaller or less experienced ones, struggle with process control. This leads to variations in board properties across production runs, which can compromise safety and reliability in industrial or construction settings.

Moisture Sensitivity and Durability Issues

While vermiculite is naturally fire-resistant, improper curing or sealing during manufacturing can make boards prone to moisture absorption. This degrades insulation performance and structural integrity over time, especially in humid environments.

Intellectual Property (IP) Risks

Counterfeit or Copycat Products

High-performance vermiculite board formulations are often protected by patents or trade secrets. Unscrupulous suppliers may replicate branded products without authorization, offering “equivalent” boards that infringe on IP rights. Purchasing such products exposes your company to legal liability.

Unverified Technical Claims

Suppliers may exaggerate product capabilities (e.g., claiming higher temperature resistance or lower thermal conductivity) to win contracts. Without independent verification or access to patented technical data, you risk investing in underperforming materials.

Lack of Transparency in Sourcing and Manufacturing

Opaque supply chains make it difficult to confirm whether a supplier legally produces the material or merely rebrands counterfeit or stolen IP. This is especially common with offshore manufacturers offering unusually low prices.

No IP Indemnification in Contracts

Many procurement agreements fail to include clauses where the supplier assumes responsibility for IP infringement. If your project faces a legal challenge due to the supplier’s IP violations, your organization may bear the cost and reputational damage.

To mitigate these risks, conduct thorough due diligence: verify certifications, request performance data, audit suppliers when possible, and ensure contracts include IP protection clauses.

Logistics & Compliance Guide for Vermiculite Board

Overview of Vermiculite Board

Vermiculite board is a lightweight, fire-resistant, and thermally insulating material commonly used in industrial, construction, and refractory applications. It is composed of exfoliated vermiculite bonded with inorganic or organic binders. Due to its composition and physical characteristics, specific logistics and compliance considerations must be followed during handling, transportation, storage, and use.

Material Classification and Regulatory Status

Vermiculite board is generally classified as a non-hazardous material for transport under most international regulations, provided it does not contain regulated contaminants (e.g., asbestos). However, historical concerns exist due to past asbestos contamination in some vermiculite sources (notably from the Libby, Montana mine). Modern vermiculite boards are typically sourced from asbestos-free deposits and are tested to ensure compliance.

- GHS Classification: Generally not classified as hazardous under the Globally Harmonized System (GHS).

- UN Number: Not assigned when non-hazardous; may require classification if contaminated.

- Regulatory Compliance: Ensure product certification confirming asbestos-free status (e.g., ASTM E2942 or ISO 22267 testing).

Packaging and Handling Requirements

Proper packaging and handling are essential to maintain the integrity of vermiculite board and ensure worker safety.

- Packaging: Boards should be packaged in moisture-resistant wrapping (e.g., plastic film) and palletized with edge protection to prevent chipping or breakage.

- Handling: Use mechanical aids (e.g., forklifts, pallet jacks) to move pallets. Avoid dropping or dragging boards. Workers should wear gloves and protective clothing to prevent skin irritation from dust or sharp edges.

- Dust Control: Although low risk, cutting or sanding may generate nuisance dust. Use local exhaust ventilation and wear appropriate respiratory protection (e.g., N95 mask) when machining.

Storage Guidelines

To preserve performance and safety, vermiculite boards must be stored under controlled conditions.

- Environment: Store indoors in a dry, well-ventilated area. Protect from moisture, rain, and direct ground contact.

- Stacking: Keep pallets stacked no higher than recommended by the manufacturer to prevent collapse. Avoid placing heavy loads on top of boards.

- Shelf Life: Typically indefinite if stored properly. Inspect for moisture damage or physical degradation before use.

Transportation and Shipping

Transportation of vermiculite board must comply with regional and international shipping regulations.

- Domestic (e.g., U.S. DOT): Classified as a non-hazardous material when asbestos-free. No special placarding required.

- International (e.g., IMDG, IATA): Generally not regulated as dangerous goods. Confirm with supplier certificates of analysis.

- Documentation: Include safety data sheet (SDS), certificate of compliance (asbestos-free), and bill of lading. Ensure SDS is GHS-compliant and up to date.

Safety Data Sheet (SDS) Requirements

The SDS for vermiculite board must be accessible and include the following key sections:

- Section 3 – Composition: Confirm vermiculite content and absence of asbestos or hazardous additives.

- Section 8 – Exposure Controls: Recommend PPE (gloves, dust mask) for cutting operations.

- Section 11 – Toxicological Information: Clarify low toxicity; potential respiratory irritation from dust.

- Section 15 – Regulatory Information: Reference compliance with OSHA, EPA, REACH, etc.

Environmental and Disposal Considerations

Vermiculite board is inert and non-toxic under normal conditions but must be disposed of responsibly.

- Disposal: Can typically be disposed of as non-hazardous industrial waste in compliance with local landfill regulations.

- Recycling: Not commonly recycled; check with local waste authorities for options.

- Environmental Impact: Low impact; does not leach harmful substances.

Compliance with International Standards

Ensure vermiculite board meets relevant international and industry standards:

- ASTM E136: Standard test method for assessing behavior of materials in a vertical tube furnace (non-combustibility).

- EN 13501-1: Fire classification of construction products (typically achieves A1 – non-combustible).

- REACH & RoHS: Confirm no restricted substances are present.

- Building Codes: Comply with local fire and insulation requirements (e.g., IBC, NFPA).

Certification and Documentation

Prior to shipment or use, verify the following documentation is available:

- Certificate of Analysis (CoA) confirming asbestos-free status

- Test reports for fire resistance and thermal performance

- GHS-compliant Safety Data Sheet (SDS)

- Declaration of Conformity (for EU markets under CE marking, if applicable)

Conclusion

Vermiculite board is a safe and compliant material when handled and documented properly. Adhering to logistics best practices and regulatory requirements ensures product integrity, worker safety, and environmental protection. Always obtain up-to-date documentation from suppliers and verify compliance with regional regulations before transport or installation.

Conclusion for Sourcing Vermiculite Board:

After a thorough evaluation of suppliers, material quality, pricing, and logistical considerations, sourcing vericulite board from qualified and reliable suppliers is both feasible and advantageous for meeting insulation, fire protection, and high-temperature application requirements. The material’s excellent thermal stability, low thermal conductivity, and non-combustible properties make it a preferred choice across industrial, construction, and manufacturing sectors.

Key factors in successful sourcing include verifying product specifications (such as density and thickness), ensuring compliance with relevant safety and environmental standards (e.g., ASTM, ISO), and establishing relationships with suppliers offering consistent quality and timely delivery. Additionally, comparing regional availability and transportation costs can significantly impact overall project economics.

In conclusion, a strategic sourcing approach—focused on quality assurance, supplier reliability, and cost-efficiency—will ensure the effective integration of vermiculite board into applications requiring durable, heat-resistant insulation solutions. Continuous supplier evaluation and market monitoring are recommended to maintain supply chain resilience and performance.