The global variable AC voltage power supply market is experiencing robust growth, driven by increasing demand for precision power solutions in industrial automation, R&D laboratories, and electronics testing. According to a 2023 report by Mordor Intelligence, the AC power supply market is projected to grow at a CAGR of approximately 4.8% from 2023 to 2028, with rising adoption in renewable energy testing and electric vehicle (EV) powertrain development acting as key catalysts. Similarly, Grand View Research estimates that the broader power supply market will expand at a CAGR of over 5% through 2030, underpinned by advancements in power electronics and stricter energy efficiency regulations. As industries require more sophisticated, programmable, and stable AC power sources, manufacturers are focusing on higher power density, improved waveform fidelity, and enhanced digital control. This growing demand has propelled innovation among leading suppliers, setting the stage for a competitive landscape defined by reliability, scalability, and smart integration. In this context, the following nine manufacturers have emerged as leaders, delivering high-performance variable AC voltage power supplies that meet the evolving needs of modern applications.

Top 9 Variable Ac Voltage Power Supply Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ABB Drives

Domain Est. 1990

Website: abb.com

Key Highlights: ABB Drives is a global technology leader serving industries, infrastructure and machine builders with world-class drives, drive systems and packages….

#2 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: Universal AC Input/ Full Range; Built-in Active PFC; High efficiency up to 94.5%; air cooling by built-in DC fan; Output voltage and constant current level ……

#3 Variable AC Power Source

Domain Est. 2016

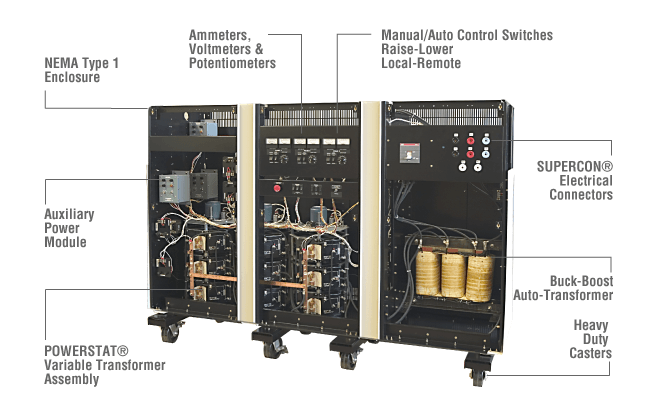

Website: specialtyproducttechnologies.com

Key Highlights: Superior Electric designs, manufacturers, and markets variable AC power sources using our wide range of POWERSTAT® and Volt- Pac® Variable Auto-Transformers….

#4 AC

Domain Est. 1995

Website: kepcopower.com

Key Highlights: Kepco Power Supplies · Program output voltage, current, power, voltage limit and current limit. · Constant voltage, constant current, constant power modes….

#5 Power Supply Products

Domain Est. 1996

Website: coselusa.com

Key Highlights: COSEL USA, now the LITEON Power Master Distributor, offers diverse power supply solutions, latest product releases, tech support, and sample programs….

#6 Product Families

Domain Est. 1996

Website: advancedenergy.com

Key Highlights: Advanced Energy’s CoolX modular product family offers a versatile series of configurable AC-DC solutions, ranging from 600 W to 3000 W. This family ……

#7 Variable AC & DC Power Supplies

Domain Est. 1996

Website: circuitspecialists.com

Key Highlights: Free delivery over $149 · 30-day returnsShop for power supplies including benchtop, programmable, and 12 volt power supplies as well as variacs and step up/down transformers….

#8 AC

Domain Est. 2000

Website: xppower.com

Key Highlights: Our diverse range includes thousands of AC-DC products, easily searchable by power, voltage, format and application. · Format · Package Type · Power · No of Outputs….

#9 AMETEK Programmable Power

Domain Est. 2007

Website: programmablepower.com

Key Highlights: The AMETEK Programmable Power designs, manufactures, and markets precision, ac & dc programmable power supplies, electronic loads, application-specific ……

Expert Sourcing Insights for Variable Ac Voltage Power Supply

2026 Market Trends for Variable AC Voltage Power Supply

Market Growth and Demand Drivers

The global market for Variable AC Voltage Power Supplies is projected to experience steady growth through 2026, driven by increasing demand across industrial automation, renewable energy, and advanced testing applications. Key industries such as manufacturing, aerospace, automotive, and electronics are adopting variable AC power supplies for precise control and simulation of real-world power conditions. Additionally, the expansion of smart grid infrastructure and the rising need for energy-efficient power solutions are contributing to market momentum.

Growth is further accelerated by the proliferation of electric vehicles (EVs) and EV charging stations, which require reliable and adjustable AC power during testing and validation phases. As regulatory standards for electromagnetic compatibility (EMC) and power quality become stricter, especially in Europe and North America, the demand for programmable and high-precision AC power supplies continues to rise.

Technological Advancements

By 2026, technological innovation will play a pivotal role in shaping the variable AC voltage power supply market. Key advancements include the integration of digital controls, IoT connectivity, and energy recovery features. Modern systems are increasingly incorporating digital signal processors (DSPs) and microcontrollers to enhance accuracy, stability, and responsiveness.

Moreover, manufacturers are focusing on compact, modular designs that support higher power densities and reduced thermal output. Wide-bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) are being adopted to improve efficiency and switching speeds. These technologies enable power supplies to deliver cleaner waveforms, lower harmonic distortion, and faster transient response—critical for sensitive testing environments.

Another emerging trend is the development of bidirectional variable AC power supplies, which support regenerative energy feedback. This not only improves energy efficiency but also reduces operational costs in high-power testing labs.

Regional Market Dynamics

Regionally, North America and Europe are expected to maintain leadership in the variable AC voltage power supply market due to stringent power quality regulations, strong R&D infrastructure, and high adoption of automation technologies. The Asia-Pacific region, particularly China, Japan, and South Korea, is anticipated to register the highest compound annual growth rate (CAGR) through 2026. This growth is fueled by expanding electronics manufacturing, government investments in renewable energy, and rising demand for industrial automation.

India and Southeast Asian countries are also emerging as key markets, supported by growing industrialization and infrastructure development. Local manufacturers are increasingly partnering with global technology providers to enhance product capabilities and meet international standards.

Competitive Landscape

The competitive landscape is characterized by a mix of established players and innovative startups. Leading companies such as Keysight Technologies, AMETEK, Chroma ATE, and Kikusui are investing heavily in R&D to differentiate their offerings through smart features, remote monitoring, and cloud-based data analytics. Strategic mergers, acquisitions, and collaborations are common as firms aim to expand their product portfolios and geographic reach.

Customization and application-specific solutions are becoming key differentiators. For example, specialized variable AC power supplies tailored for medical device testing, avionics, or photovoltaic inverter validation are gaining traction.

Challenges and Outlook

Despite strong growth potential, the market faces challenges such as supply chain volatility, fluctuating raw material prices (especially semiconductors), and the need for skilled personnel to operate advanced systems. Cybersecurity concerns related to networked power supplies are also emerging as a focus area.

Looking ahead to 2026, the variable AC voltage power supply market is poised for transformation driven by digitalization, energy efficiency demands, and the integration of renewable energy systems. As industries continue to prioritize reliability and precision in power testing and conditioning, variable AC power supplies will remain a critical component in next-generation electrical and electronic systems.

Common Pitfalls When Sourcing a Variable AC Voltage Power Supply (Quality and IP)

Sourcing a variable AC voltage power supply requires careful evaluation to avoid compromising on performance, safety, and longevity. Below are key pitfalls related to quality and IP (Ingress Protection) that buyers often encounter.

Poor Build Quality and Component Selection

Many low-cost variable AC power supplies use substandard components such as inferior transformers, capacitors, and regulators. This leads to inconsistent voltage output, excessive waveform distortion (THD), and premature failure. Always verify manufacturer specifications and look for certifications (e.g., CE, UL, ISO) that indicate adherence to quality standards.

Lack of Proper IP Rating for Intended Environment

A common oversight is selecting a power supply without considering the Ingress Protection (IP) rating relative to the operating environment. For example:

– Using an IP20-rated unit in a dusty industrial setting risks internal contamination.

– Installing a non-IP-rated supply in outdoor or humid conditions increases the risk of moisture ingress and electrical faults.

Ensure the IP rating (e.g., IP54 for dust and splash resistance) matches the environmental demands.

Misleading Specifications and False Claims

Some suppliers exaggerate performance metrics such as output stability, frequency range, or efficiency. Be wary of units that claim wide voltage/frequency ranges without supporting test reports. Request third-party validation or lab data when accuracy and reliability are critical.

Insufficient Thermal Management

Low-quality units often lack adequate cooling mechanisms, leading to overheating under continuous load. This reduces lifespan and can trigger thermal shutdowns during operation. Check for effective ventilation, heatsinks, or forced cooling—especially for high-power models.

Inadequate Safety and Isolation Features

Poor isolation between input and output or lack of overvoltage, overload, and short-circuit protection can pose serious safety risks. Ensure the unit includes reinforced insulation, ground fault protection, and meets relevant safety standards (e.g., IEC 61010).

Ignoring Electromagnetic Compatibility (EMC)

Supplies with poor EMC design can emit excessive electromagnetic interference (EMI), disrupting nearby equipment. Verify that the unit complies with EMC directives (e.g., FCC, CE-EMC) to avoid operational issues in sensitive environments.

By addressing these pitfalls early in the sourcing process, buyers can ensure reliable, safe, and durable performance from their variable AC voltage power supply.

Logistics & Compliance Guide for Variable AC Voltage Power Supply

Product Classification and Regulatory Overview

Variable AC Voltage Power Supplies are electronic devices designed to adjust and deliver alternating current (AC) voltage within a specified range. These units are subject to various international, national, and regional regulations depending on their intended use, power output, and destination market. Proper classification under Harmonized System (HS) codes is essential for customs clearance and duty assessment. Typical HS codes include 8504.40 (static converters) or 8543.70 (electrical apparatus for modifying electrical voltage), though exact classification may vary by country.

Safety and Electromagnetic Compatibility (EMC) Standards

Compliance with electrical safety and EMC standards is mandatory in most markets:

– IEC/EN 61326-1: Applies to electrical equipment for measurement, control, and laboratory use, ensuring EMC performance in industrial environments.

– IEC/EN 62368-1: Safety standard for audio/video, information, and communication technology equipment, widely adopted in North America, Europe, and Asia.

– FCC Part 15 (USA): Regulates electromagnetic emissions to prevent interference with radio communications.

– CE Marking (EU): Requires conformity with the Low Voltage Directive (2014/35/EU) and EMC Directive (2014/30/EU).

Manufacturers must obtain certification from accredited testing laboratories and maintain technical documentation for market surveillance.

Environmental and Chemical Compliance

Variable AC power supplies must comply with environmental regulations restricting hazardous substances:

– RoHS (EU Directive 2011/65/EU): Limits the use of lead, mercury, cadmium, and other hazardous materials in electrical and electronic equipment.

– REACH (EC 1907/2006): Requires disclosure of Substances of Very High Concern (SVHC) and registration of chemicals used in production.

– China RoHS: Similar restrictions applicable to products sold in China.

Ensure suppliers provide compliance declarations and material declarations (e.g., IPC-1752) for all components.

Packaging, Labeling, and Shipping Requirements

Proper packaging and labeling are critical for safe transport and customs compliance:

– Use anti-static and shock-resistant packaging to protect sensitive electronics.

– Label units with CE, FCC, or other applicable conformity marks, input/output specifications, model number, serial number, and manufacturer details.

– Include multilingual user manuals and safety instructions where required (e.g., EU and Canada).

– For international shipping, complete commercial invoices, packing lists, and certificates of conformity. Classify shipments accurately under Incoterms® 2020 (e.g., FOB, DDP) to clarify responsibilities.

Import/Export Controls and Documentation

- Verify if the power supply is subject to export controls under regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation (EC 428/2009). Most standard variable AC power supplies are EAR99 and do not require a license for most destinations.

- Maintain records of export transactions for a minimum of five years.

- For destinations like Russia, India, or Brazil, additional local certifications (e.g., EAC, BIS, INMETRO) may be required—verify country-specific requirements in advance.

Maintenance of Compliance and Market Surveillance

- Retain technical construction files (TCF), test reports, and conformity assessments for at least 10 years (EU).

- Implement a system for monitoring regulatory updates and issuing product revisions or recalls if non-compliance is identified.

- Register products with national databases where applicable (e.g., UKCA registration post-Brexit, South Korea KC certification).

Adhering to this logistics and compliance framework ensures smooth international distribution, minimizes legal risk, and supports product safety and market acceptance.

Conclusion: Sourcing a Variable AC Voltage Power Supply

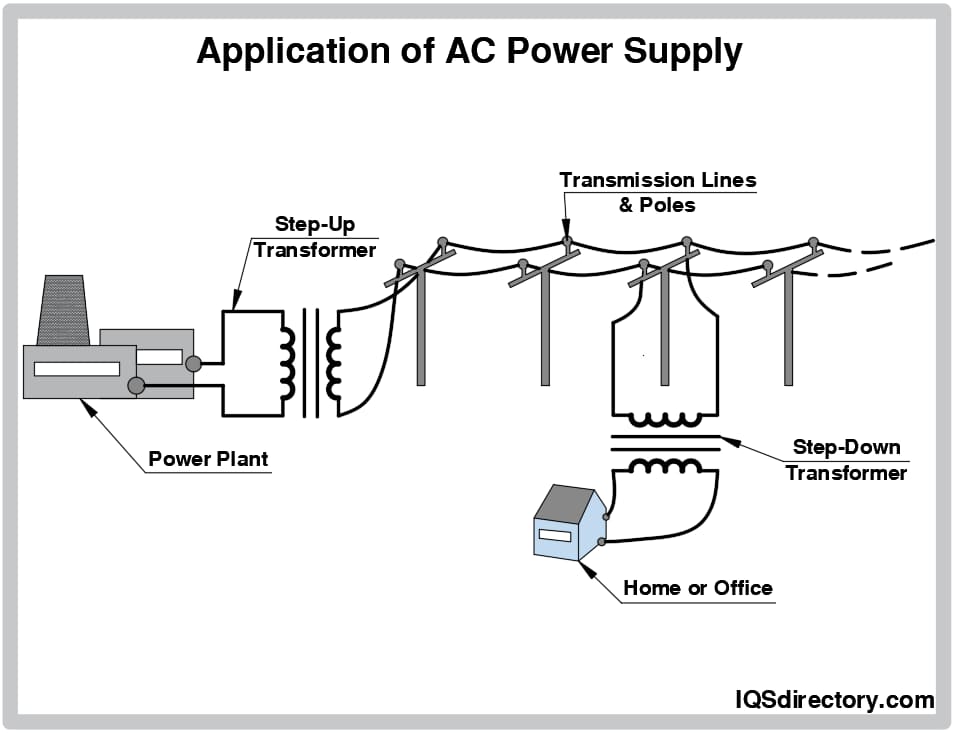

In conclusion, sourcing a variable AC voltage power supply requires careful consideration of application requirements, technical specifications, safety standards, and budget constraints. Whether for laboratory testing, industrial equipment calibration, or research and development, selecting the right power supply involves evaluating key factors such as voltage and frequency range, power output capacity, waveform quality (e.g., pure sine wave vs. modified output), efficiency, and control interfaces (analog, digital, or programmable).

Off-the-shelf solutions such as AC variable transformers (Variacs), programmable AC power sources, or power inverters with adjustable outputs are readily available from reputable manufacturers and distributors. Alternatively, custom solutions may be necessary for specialized needs, though they entail higher costs and longer lead times.

Reliability, compliance with international standards (e.g., CE, UL), and technical support are also critical when selecting a supplier. Advances in power electronics have made modern variable AC power supplies more compact, efficient, and feature-rich, enabling precise control and monitoring.

Ultimately, a well-informed sourcing decision ensures optimal performance, safety, and longevity of both the power supply and the equipment under test, supporting consistent and accurate results in any AC-powered application.