The global solenoid valve market is experiencing robust growth, driven by increasing automation across industrial, automotive, and healthcare sectors. According to Mordor Intelligence, the solenoid valve market was valued at USD 9.23 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. A significant portion of this demand comes from 3-way solenoid valves, widely used for directional control in fluid power systems due to their reliability and compact design. Grand View Research further supports this trajectory, noting that the broader industrial automation market—key to solenoid valve adoption—is expected to expand at a CAGR of 9.3% through 2030, fueled by smart manufacturing and process optimization. As industries increasingly prioritize precision and energy efficiency, the demand for high-performance 3-way solenoid valves continues to rise. This growth has spurred competition among manufacturers to innovate in materials, response time, and integration with digital control systems. Below, we highlight the top 8 manufacturers leading the 3-way solenoid valve space, selected based on market presence, technological advancements, product range, and global distribution.

Top 8 Valve Solenoid 3 Way Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Solenoid Valves

Domain Est. 1995

Website: ph.parker.com

Key Highlights: Parker’s comprehensive selection of solenoid valves includes a broad range of types and configurations for all manner of applications across many industrial ……

#2 Solenoid Valves

Domain Est. 1995

Website: smcusa.com

Key Highlights: Solenoid valves, 3 port are an innovative combination of space efficiency and performance superiority which provides real value to the design solution….

#3 3

Domain Est. 1995

Website: emerson.com

Key Highlights: An ASCO 3-way 2-position valve has three connection ports and two positions and can be normally closed, normally open or universal….

#4 Solenoid Valves for Reliable Pneumatic Control

Domain Est. 1996

Website: versa-valves.com

Key Highlights: Valves rated for air or inert gas can be used for natural gas service. Select … Versa’s selection of actuators is the largest in the ……

#5 3

Domain Est. 1999

Website: hd.tramec.com

Key Highlights: 60-day returns3-WAY SOLENOID VALVE. … Providing Custom U.S. Manufacturing Solutions and Container Securement Products View brand page. Tramec Sloan. Air Products 3 ……

#6 Direct Solenoid 3 way Pneumatic Valve

Domain Est. 2000

Website: humphrey-products.com

Key Highlights: This 3-port solenoid valve can operate reliably from zero to 125psi. Multi-purpose. Pipe valve as normally closed, normally open, diverter or selector function….

#7 Solenoid Operated Valves Options

Domain Est. 2009

Website: winnerhydraulics.com

Key Highlights: Main Products: Cartridge Valves, Solenoid On/Off Valves, Electro-Proportional Valves, Mini Power Packs, Manifolds, Electronics, Accessories…

#8 Electric Solenoid Valve

Domain Est. 2013

Website: electricsolenoidvalves.com

Key Highlights: Free delivery over $99 45-day returnsSolenoid Valves Supplier for water, gas, air, & diesel. High-quality valves in all sizes/materials for pro & small projects. Fast shipping (shi…

Expert Sourcing Insights for Valve Solenoid 3 Way

H2: 2026 Market Trends for 3-Way Solenoid Valves

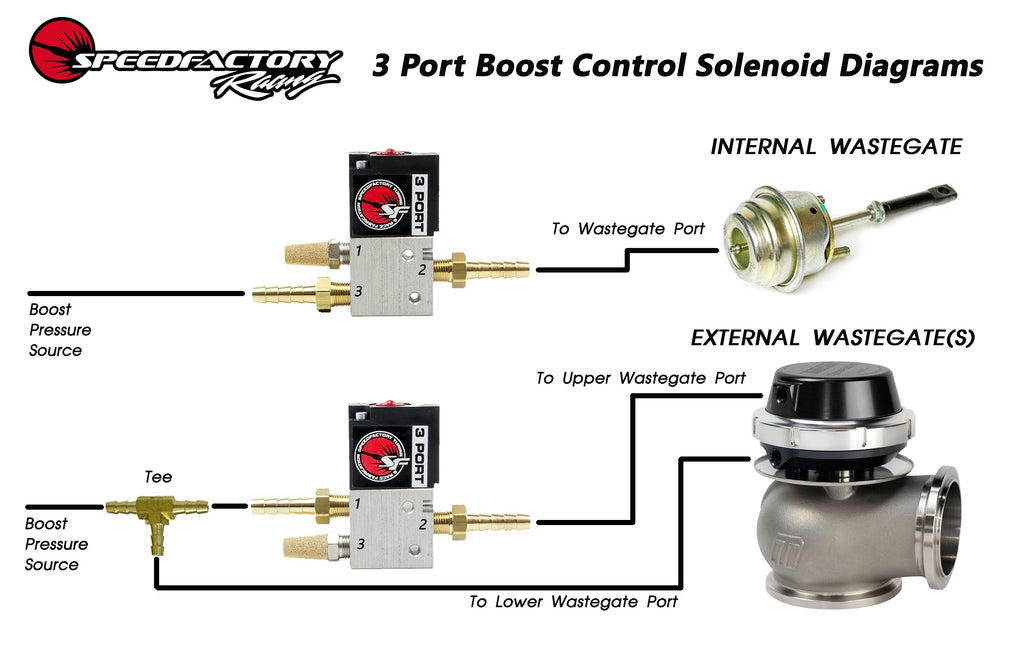

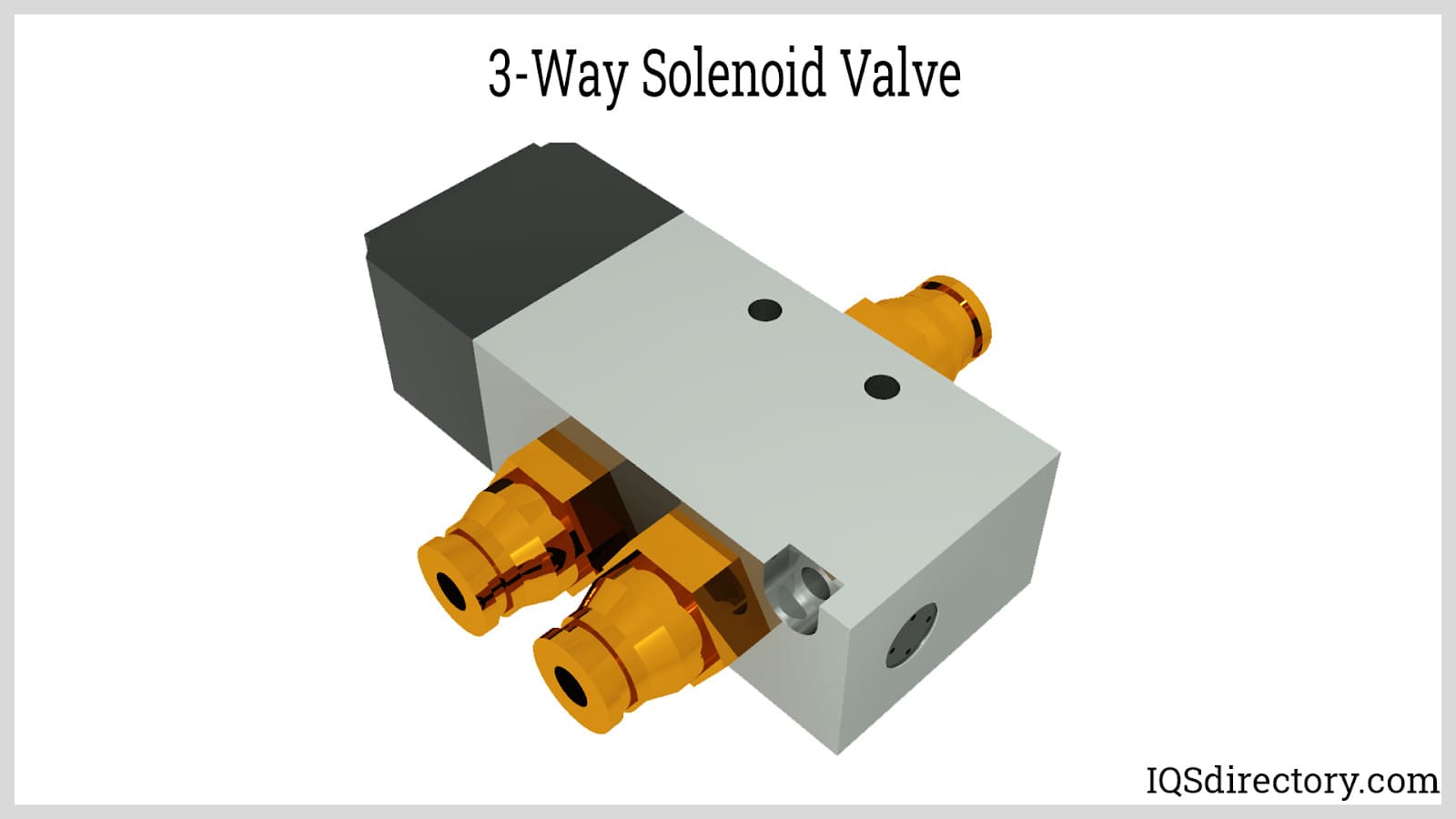

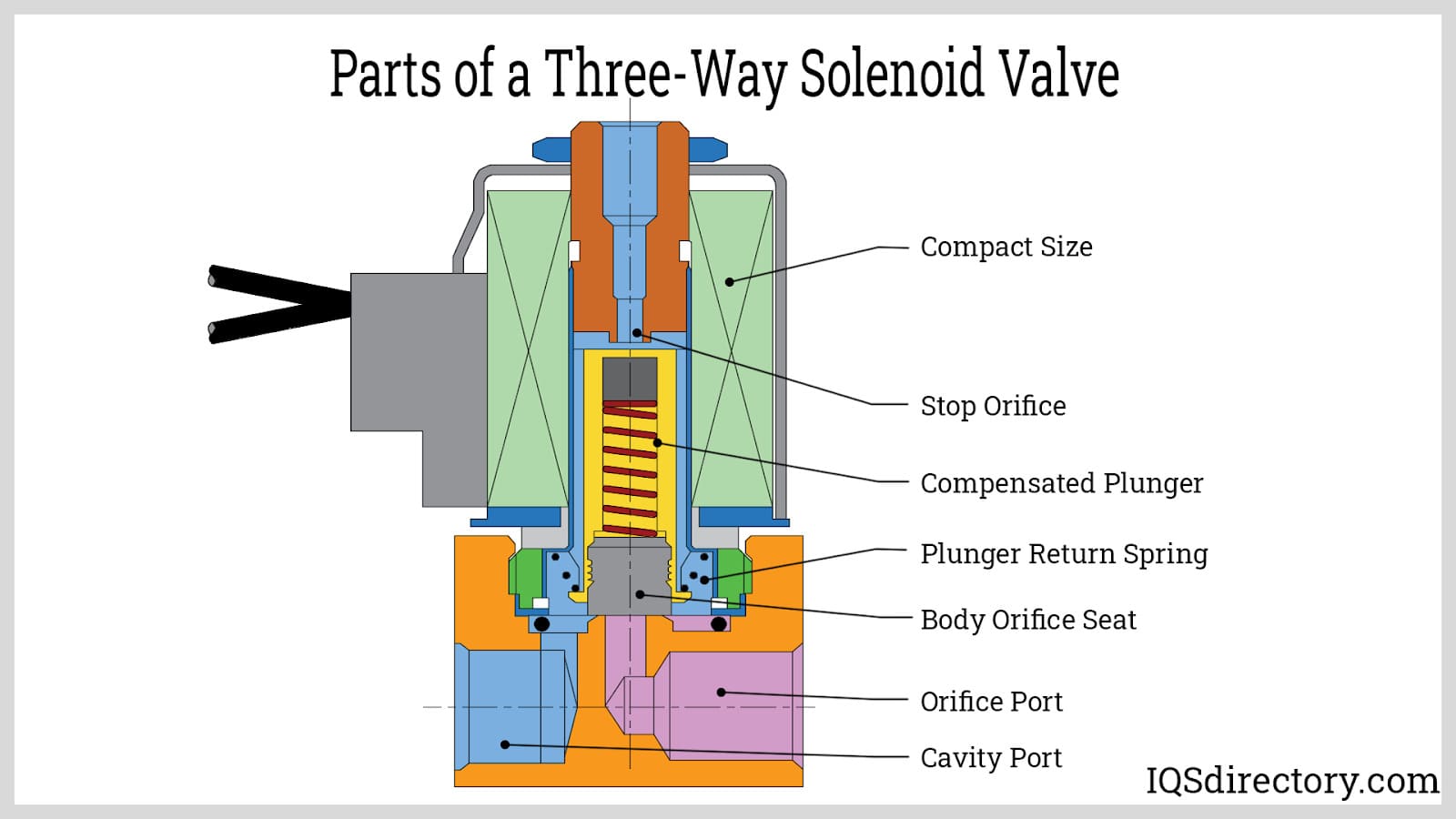

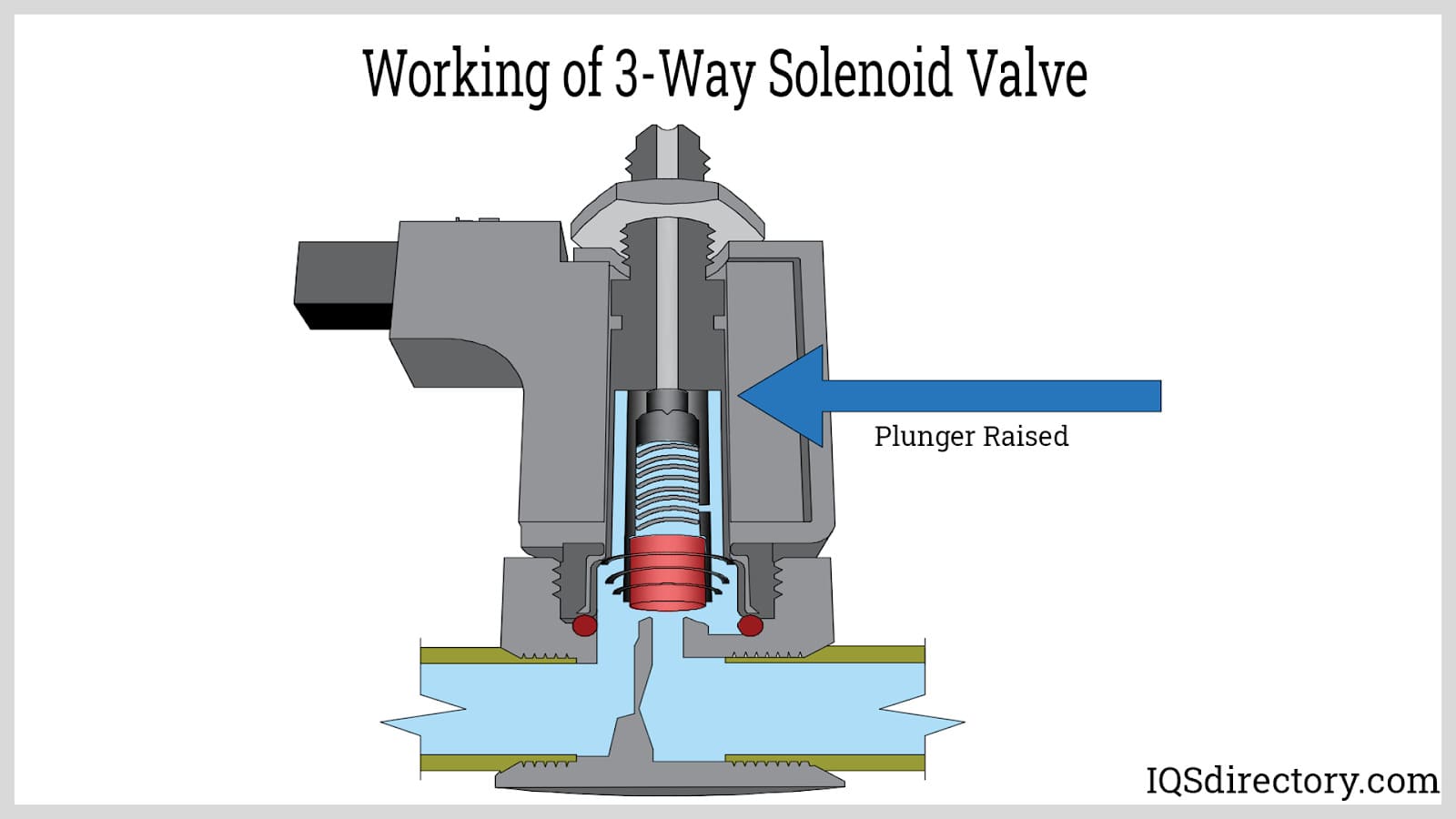

The global market for 3-way solenoid valves is poised for significant transformation by 2026, driven by technological innovation, rising automation across industries, and a growing emphasis on energy efficiency and smart manufacturing. As a critical component in fluid control systems, 3-way solenoid valves—used to control the flow of air, gas, or liquid by switching between multiple ports—are increasingly in demand across sectors such as industrial automation, HVAC, medical equipment, automotive, and water treatment.

One of the most prominent trends shaping the 2026 outlook is the integration of digital technologies and Industry 4.0 principles. Manufacturers are incorporating smart features into solenoid valves, such as embedded sensors, IoT connectivity, and predictive maintenance capabilities. This shift enables real-time monitoring of valve performance, reduces downtime, and enhances system efficiency—factors that are especially valuable in advanced manufacturing and process industries.

Another key driver is the expansion of the electric vehicle (EV) and hybrid vehicle markets. 3-way solenoid valves play a vital role in thermal management systems, battery cooling, and air conditioning within EVs. As automakers ramp up EV production in response to global emissions regulations, demand for compact, reliable, and energy-efficient solenoid valves is expected to surge.

Additionally, sustainability initiatives are influencing material selection and design. Leading manufacturers are focusing on producing valves with longer lifespans, reduced leakage rates, and compatibility with eco-friendly refrigerants and fluids. This aligns with stricter environmental regulations in regions like the European Union and North America.

Regionally, Asia-Pacific is anticipated to lead market growth by 2026, fueled by rapid industrialization in China, India, and Southeast Asia, along with strong investments in automation and infrastructure. Meanwhile, North America and Europe will continue to see steady demand, particularly in high-precision applications within healthcare and aerospace.

In summary, by 2026, the 3-way solenoid valve market will be characterized by smart integration, energy efficiency, and sector-specific customization. Companies that innovate in miniaturization, connectivity, and sustainable design are likely to capture the largest market share in this evolving landscape.

Common Pitfalls Sourcing 3-Way Solenoid Valves (Quality, IP Rating)

Sourcing reliable 3-way solenoid valves requires careful attention to both quality and ingress protection (IP) ratings. Overlooking key factors can lead to premature failures, safety hazards, and costly downtime. Below are critical pitfalls to avoid:

Inadequate IP Rating for the Operating Environment

One of the most frequent mistakes is selecting a solenoid valve with an IP rating unsuitable for its environment. For example:

– Using an IP65-rated valve in a washdown area requiring IP69K protection can lead to moisture ingress and coil failure.

– Installing a valve with only IP40 protection in dusty industrial settings risks particulate contamination affecting internal components.

Always match the IP rating to environmental demands—consider exposure to water jets, dust, chemicals, and outdoor conditions.

Prioritizing Price Over Build Quality and Materials

Choosing low-cost valves without assessing material quality often results in:

– Shorter service life due to corrosion or wear.

– Leaks from inferior seals (e.g., using NBR instead of FKM in high-temperature or chemical environments).

– Mechanical failure from substandard plunger or core tube materials.

Investing in valves constructed with robust materials (e.g., brass, stainless steel, or high-grade plastics) ensures reliability and longevity.

Misunderstanding Voltage and Duty Cycle Specifications

Sourcing valves without verifying electrical compatibility can cause operational issues:

– Applying AC voltage to a DC-rated coil generates excessive heat, leading to burnout.

– Exceeding the duty cycle (e.g., continuous operation of an intermittent-duty valve) accelerates coil degradation.

Always confirm voltage type, frequency, and duty cycle requirements match the application.

Overlooking Certification Requirements

In regulated industries (e.g., food & beverage, pharmaceuticals, hazardous areas), non-compliant valves pose serious risks:

– Lack of certifications like UL, ATEX, or FDA compliance may violate safety standards.

– Using non-explosion-proof valves in classified zones creates fire or explosion hazards.

Ensure valves carry necessary certifications relevant to your industry and location.

Assuming All “3-Way” Valves Are Interchangeable

Not all 3-way configurations perform the same:

– Confusing normally closed (NC), normally open (NO), or universal (changeover) types can disrupt system functionality.

– Incorrect porting (e.g., L-type vs. T-type) affects flow direction and control accuracy.

Verify the valve’s function (e.g., 3/2 NC) and internal design match your pneumatic or hydraulic circuit needs.

Ignoring Temperature and Pressure Limits

Exceeding rated operating conditions leads to failure:

– High fluid or ambient temperatures can degrade seals and insulation.

– Overpressure may damage internal components or cause leaks.

Always cross-check the valve’s pressure and temperature ratings against actual system parameters.

Skipping Supplier Due Diligence

Procuring from unreliable suppliers increases the risk of counterfeit or non-conforming products:

– Lack of traceability, test reports, or technical support undermines quality assurance.

– Poor documentation makes troubleshooting and compliance audits difficult.

Source from reputable suppliers with proven quality systems, certifications, and responsive technical support.

Avoiding these pitfalls ensures the solenoid valves you source deliver safe, efficient, and durable performance in your application.

Logistics & Compliance Guide for 3-Way Valve Solenoid

This guide outlines the essential logistics considerations and compliance requirements for the handling, transportation, storage, and regulatory adherence of 3-Way Valve Solenoids. Proper management ensures product integrity, safety, and legal conformity throughout the supply chain.

Product Overview

A 3-Way Valve Solenoid is an electromechanically operated valve that controls the flow of fluid (liquid or gas) through three ports using an electric signal. It is commonly used in industrial automation, HVAC systems, medical devices, and process control applications. Typical configurations include normally closed (NC), normally open (NO), and universal (bi-stable) types.

Packaging Requirements

- Primary Packaging: Each solenoid must be sealed in anti-static, moisture-resistant bags (e.g., metallized Mylar or polyethylene with desiccant) to prevent electrostatic discharge (ESD) and corrosion.

- Secondary Packaging: Use rigid corrugated cardboard boxes with internal foam or molded pulp inserts to prevent movement during transit.

- Labeling: Include product name, model number, batch/lot number, date of manufacture, ESD-sensitive symbol, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

- Unit Load: Palletize boxes securely using stretch wrap; limit stacking height per manufacturer specifications (typically no more than 5 layers). Use edge protectors for added stability.

Storage Conditions

- Temperature: Store in a dry, temperature-controlled environment between 5°C and 40°C (41°F to 104°F).

- Humidity: Maintain relative humidity below 70% to prevent condensation and internal component degradation.

- Environment: Avoid exposure to dust, corrosive gases, direct sunlight, and strong electromagnetic fields.

- Shelf Life: Observe manufacturer-specified shelf life (typically 2–5 years). Conduct periodic inspections for packaging integrity and signs of corrosion.

Transportation Guidelines

- Mode of Transport: Suitable for air, sea, and ground freight. For air transport, comply with IATA regulations; for sea, follow IMDG Code where applicable.

- ESD Protection: Ensure all personnel handling units are grounded. Use ESD-safe containers and vehicles when available.

- Shock & Vibration: Minimize drops and excessive vibration. Use shock-absorbing pallets or dunnage when necessary.

- Documentation: Include packing list, commercial invoice, and product specification sheet with each shipment.

Regulatory Compliance

RoHS (Restriction of Hazardous Substances)

- Ensure the solenoid complies with EU Directive 2011/65/EU and its amendments.

- Confirm absence of restricted substances: lead, mercury, cadmium, hexavalent chromium, PBB, PBDE, and four phthalates (DEHP, BBP, DBP, DIBP).

- Maintain RoHS compliance certificate from the manufacturer.

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

- Verify that all materials used in the solenoid are registered under REACH (EC 1907/2006).

- Provide a declaration of compliance or SVHC (Substances of Very High Concern) disclosure if requested.

CE Marking

- Affix CE marking to indicate conformity with European health, safety, and environmental protection standards.

- Maintain technical documentation and EU Declaration of Conformity.

UL/CSA (North America)

- For use in the U.S. and Canada, ensure compliance with UL 60947-4-1 or CSA C22.2 No. 14 for industrial control equipment.

- Use only solenoids with recognized certification marks.

ATEX/IECEx (Hazardous Areas)

- If intended for use in explosive atmospheres, verify ATEX (EU) or IECEx certification.

- Confirm equipment category (e.g., Zone 1, Zone 2) and temperature class compatibility.

WEEE (Waste Electrical and Electronic Equipment)

- Provide information on proper end-of-life disposal per Directive 2012/19/EU.

- Include WEEE symbol on packaging if applicable.

Import/Export Considerations

- HS Code: Use appropriate Harmonized System code (e.g., 8538.90 for parts of electrical apparatus).

- Export Controls: Confirm if the solenoid contains components subject to export regulations (e.g., EAR99 or specific ECCN under the U.S. Export Administration Regulations).

- Customs Documentation: Prepare commercial invoice, packing list, and certificate of origin. For regulated markets, include conformity certificates (e.g., CE, UL).

Handling & Safety

- Training: Personnel must be trained in ESD-safe handling procedures.

- PPE: Use gloves and anti-static wrist straps during inspection or testing.

- Installation: Follow manufacturer’s torque specifications and fluid compatibility guidelines to prevent leaks or failures.

Documentation & Record Keeping

- Maintain records of:

- Certificates of Compliance (RoHS, REACH, CE, UL, etc.)

- Batch traceability (material lot numbers, production dates)

- Test reports (dielectric strength, leak test, cycle life)

- Shipping and storage logs

Retention period: Minimum of 5 years, or as required by regional regulations.

Disposal & Recycling

- Do not dispose of in regular waste. Recycle through certified WEEE or e-waste facilities.

- Remove any batteries or hazardous subcomponents before recycling.

- Follow local environmental regulations for electronic component disposal.

Conclusion

Proper logistics and compliance management for 3-Way Valve Solenoids ensures product reliability, regulatory adherence, and operational safety. Always consult the manufacturer’s technical data sheet and certifications for model-specific requirements. Regular audits and supplier qualification are recommended to maintain compliance across the supply chain.

Conclusion for Sourcing 3-Way Solenoid Valves:

After a thorough evaluation of technical requirements, supplier capabilities, cost considerations, and market availability, it is concluded that sourcing 3-way solenoid valves requires a strategic approach focused on application-specific compatibility and supply chain reliability. Selecting the appropriate valve type—whether normally closed, normally open, or universal—depends on the intended fluid control system and operational demands such as pressure rating, media type, voltage, and response time.

Key suppliers offering high-quality, certified solenoid valves (e.g., ASCO, Parker, SMC, and Burkert) provide reliable options, though cost and lead time must be balanced with performance needs. Additionally, considering both domestic and international suppliers enhances sourcing flexibility and risk mitigation.

Ultimately, a supplier partnership that ensures product consistency, technical support, and compliance with industry standards (such as ISO, CE, or UL) is essential. Implementing a qualification process for vendors and maintaining dual sourcing options will support long-term operational efficiency and reduce downtime risks. Therefore, the recommended course is to finalize sourcing with pre-qualified suppliers who meet technical, quality, and delivery requirements for 3-way solenoid valves.