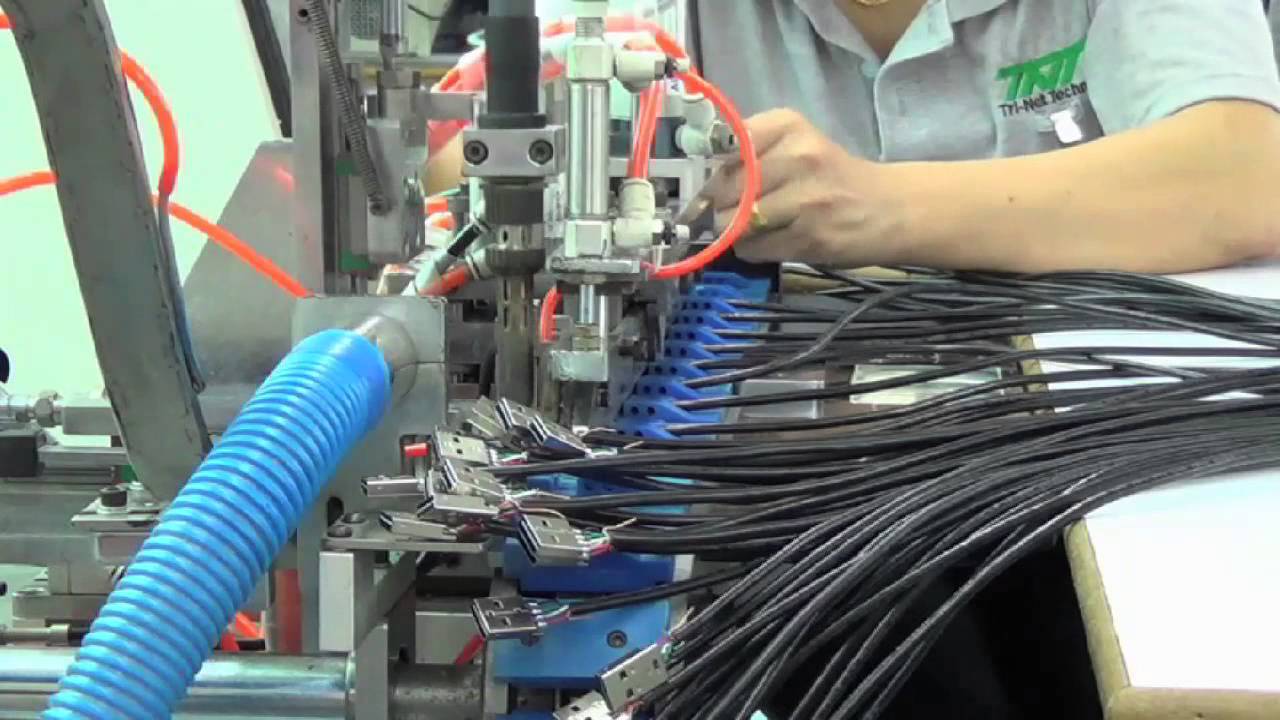

The global USB 3.0 cable market continues to experience robust expansion, driven by rising demand for high-speed data transfer across consumer electronics, industrial applications, and embedded computing systems. According to Grand View Research, the global USB cable market size was valued at USD 4.1 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing adoption of USB 3.0 and later standards in motherboards, external storage devices, and peripherals that require faster data transmission speeds—up to 5 Gbps—compared to earlier USB versions. Additionally, the integration of USB 3.0 ports in PCs, servers, and industrial motherboards has created consistent demand for high-quality, durable cables directly connected to or integrated with motherboard designs. As system manufacturers prioritize performance, signal integrity, and power delivery, the role of reliable USB 3.0 cable and interconnect solutions has become increasingly critical. In this context, leading manufacturers specializing in USB 3.0 cable and onboard connectivity solutions for motherboards are emerging as key enablers of next-generation computing infrastructure. The following list highlights the top seven companies shaping this segment through innovation, volume production, and technical expertise in high-speed interface design.

Top 7 Usb 3.0 Cable Motherboard Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Specification X58 Pro

Domain Est. 1991

Website: msi.com

Key Highlights: As a world leading gaming brand, MSI is the most trusted name in gaming and eSports. We stand by our principles of breakthroughs in design, and roll out the ……

#2 USB: Port Types and Speeds Compared

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: A charging cable supporting USB 2.0 can be longer than USB 3.x and USB4 cables but is limited to a 480 Mbps data transfer rate and will not support alt-modes….

#3 GA

Domain Est. 1997

Website: gigabyte.com

Key Highlights: The 870A-USB3 motherboard is designed to offer a stable, high-speed platform for delivering amazingly fast data transfer via revolutionary GIGABYTE Ultra ……

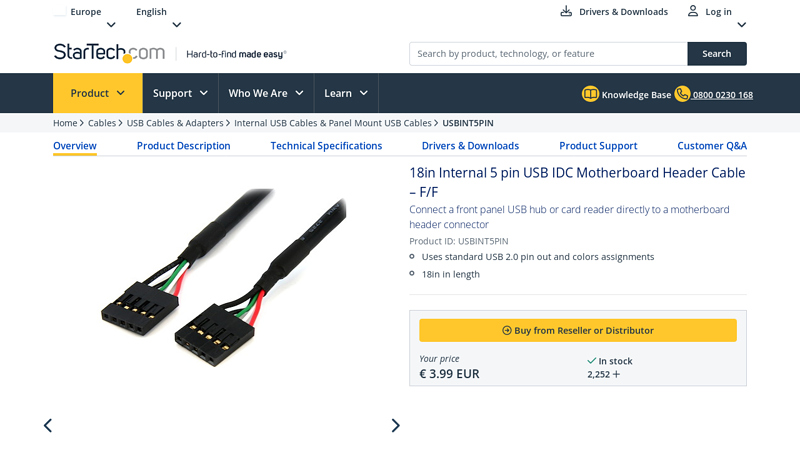

#4 18in Internal 5 pin USB IDC Motherboard Header Cable

Domain Est. 1998

Website: startech.com

Key Highlights: In stock Free deliveryThis 18in internal USB IDC cable features two 5-pin USB motherboard header connectors, allowing you to connect a front panel USB hub or card reader directly t…

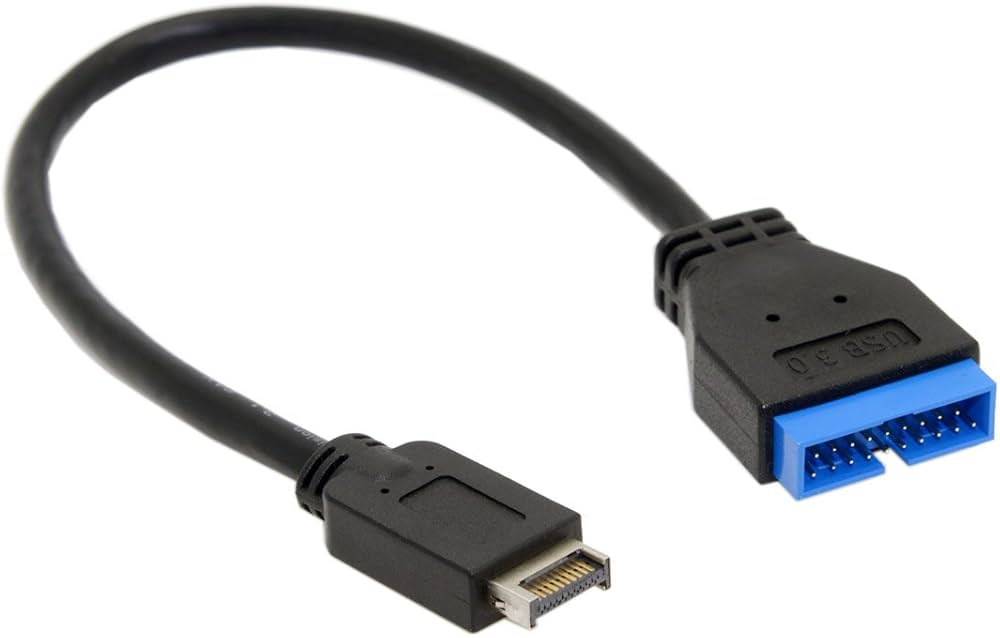

#5 Cablecc USB 3.1 Front Panel Header to USB 3.0 20Pin …

Domain Est. 2000

Website: newegg.com

Key Highlights: Buy Cablecc USB 3.1 Front Panel Header to USB 3.0 20Pin Header Extension Cable 20cm for ASUS Motherboard with fast shipping and top-rated customer service….

#6 USB 2.0 & USB 3.0 / 3.1

Domain Est. 2009

Website: microsatacables.com

Key Highlights: Free delivery over $100 30-day returns…

#7 USB 3.0 Male To Motherboard 20pin Header Cable For Front Panel

Domain Est. 2022

Website: kaiwin-link.com

Key Highlights: This is super speed motherboard 20pin To USB3.0 A Male Y splitter cable. It has dual USB 3.0 A type male ports at one end, and a motherboard 20pin port at the ……

Expert Sourcing Insights for Usb 3.0 Cable Motherboard

H2: 2026 Market Trends for USB 3.0 Cable Motherboard Connectivity

As the global technology landscape evolves toward faster data transfer and improved peripheral integration, the role of USB 3.0 cable motherboard connectivity is undergoing significant transformation by 2026. While newer standards such as USB 3.2, USB4, and Thunderbolt 4 are gaining traction, USB 3.0 remains a critical interface in legacy systems, budget computing, and industrial applications—ensuring its continued relevance in motherboard design and market demand.

1. Sustained Demand in Entry-Level and Industrial Systems

Despite the rise of faster protocols, USB 3.0 maintains strong adoption in cost-sensitive markets. In 2026, many entry-level desktops, small-form-factor PCs, and embedded systems continue to integrate USB 3.0 headers on motherboards due to their cost-effectiveness and compatibility. Industries such as manufacturing, healthcare, and point-of-sale (POS) systems rely on proven USB 3.0 technology for peripherals like barcode scanners, medical devices, and industrial cameras—driving steady motherboard demand with USB 3.0 support.

2. Transition Phase Amid USB-C and Higher-Speed Standards

The market is transitioning toward USB-C and higher bandwidth interfaces, but this shift is gradual. By 2026, most mid-to-high-end motherboards support USB 3.2 Gen 2×2 (20 Gbps) or USB4, yet manufacturers still include USB 3.0 (5 Gbps) headers to maintain backward compatibility. This dual-interface approach ensures users can connect older peripherals via front-panel USB 3.0 cables, making USB 3.0 motherboard headers a transitional bridge rather than a discontinued feature.

3. Niche Growth in DIY and Retro Computing

The DIY PC enthusiast and retro computing communities show renewed interest in USB 3.0. In 2026, there is a niche but growing market for motherboards that support both modern CPUs and legacy I/O, including USB 3.0 internal headers. Custom builds, retro gaming rigs, and home labs often require USB 3.0 for connecting vintage peripherals or external storage, supporting continued production and availability of USB 3.0 cable-compatible motherboards.

4. Supply Chain and Component Availability

Component manufacturers continue producing USB 3.0 controllers and internal headers due to their reliability and low power consumption. In 2026, economies of scale and mature manufacturing processes keep costs low, making USB 3.0 a cost-efficient option for OEMs. As a result, many budget and mainstream motherboard SKUs still feature at least one internal USB 3.0 header, especially in ATX and microATX form factors.

5. Decline in High-End Segments, Stability in Mid-Tier

While flagship motherboards for gaming and workstation use increasingly prioritize USB-C and Thunderbolt, the mid-tier market remains stable for USB 3.0 integration. Motherboard vendors like ASUS, MSI, and Gigabyte continue offering models with USB 3.0 internal ports to cater to users upgrading older chassis or using legacy front-panel connectors. This ensures that USB 3.0 motherboard connectivity remains viable through 2026, even as it recedes in premium segments.

Conclusion

By 2026, USB 3.0 cable motherboard connectivity is no longer at the forefront of innovation but remains embedded in the ecosystem due to compatibility, cost, and industrial necessity. While the market momentum shifts toward USB4 and USB-C, USB 3.0 persists as a dependable, widely supported standard—particularly in budget, industrial, and enthusiast applications. Its role is evolving from primary to supplementary, yet it continues to influence motherboard design and peripheral connectivity strategies.

Common Pitfalls When Sourcing USB 3.0 Cable Motherboard Connectors (Quality and Intellectual Property)

Sourcing USB 3.0 cable assemblies for motherboard connections involves several potential pitfalls, particularly concerning product quality and intellectual property (IP) compliance. Being aware of these issues can help avoid performance problems, reliability failures, and legal risks.

Poor Signal Integrity Due to Substandard Materials

Low-quality USB 3.0 cables often use inferior conductors, shielding, and insulation materials that fail to meet USB 3.0’s high-speed (5 Gbps) transmission requirements. Thin gauge wires, inadequate braided shielding, or poor dielectric materials can lead to signal attenuation, crosstalk, and electromagnetic interference (EMI), resulting in data errors, reduced transfer speeds, or unstable device connections.

Non-Compliance with USB-IF Specifications

Many budget cables do not adhere to the official specifications set by the USB Implementers Forum (USB-IF). This includes incorrect pinouts, improper differential pair routing, and failure to meet impedance standards (typically 90Ω ±10% differential). Such deviations compromise compatibility and reliability, especially across different motherboard and peripheral brands.

Lack of Proper Shielding and Ferrite Cores

Effective shielding is critical for maintaining signal integrity and minimizing EMI. Inexpensive cables may skimp on foil shielding, braid coverage, or omit ferrite cores altogether. This can lead to interference with nearby components on the motherboard, affecting audio, Wi-Fi, or other high-speed interfaces.

Counterfeit or Misrepresented Components

Some suppliers offer cables that falsely claim USB 3.0 speeds but are actually wired for USB 2.0 (lacking the additional differential pairs for SuperSpeed data). These counterfeit products often use cheaper internal wiring and connectors, deceiving buyers and resulting in non-functional high-speed capabilities.

Intellectual Property (IP) Infringement Risks

Using connector designs or cable layouts that replicate patented technologies from established manufacturers can expose buyers to IP litigation. Some third-party cables copy proprietary housing designs, latch mechanisms, or internal layouts protected under patents held by companies like Amphenol, Molex, or TE Connectivity. Sourcing such products—especially from unverified vendors—may lead to legal liability.

Inadequate Mechanical Durability

Low-cost cables often feature flimsy connectors, weak strain reliefs, and brittle housing materials. Repeated insertion and removal, especially in compact or hard-to-reach motherboard headers, can lead to broken latches, bent pins, or conductor detachment, reducing product lifespan.

Absence of Certification and Traceability

Reputable USB 3.0 cables are often USB-IF certified, indicating compliance with technical and interoperability standards. Sourced cables lacking certification or traceable manufacturing origins pose higher risks in terms of both performance and IP safety. Without proper documentation, it’s difficult to verify authenticity or resolve quality issues.

Supply Chain and Vendor Reliability Issues

Relying on unknown or unverified suppliers—particularly from regions with lax regulatory enforcement—increases the likelihood of receiving inconsistent or non-compliant batches. Poor quality control, lack of testing documentation, and unreliable delivery schedules can disrupt production timelines and increase total cost of ownership.

Avoiding these pitfalls requires due diligence: sourcing from reputable suppliers, verifying compliance certifications, inspecting samples for build quality, and conducting signal integrity testing when integrating USB 3.0 cables into motherboard designs.

Logistics & Compliance Guide for USB 3.0 Cable for Motherboard

Product Identification and Specifications

The USB 3.0 cable for motherboard is a high-speed internal cable designed to connect front-panel USB 3.0 ports on a computer case to the corresponding header on the motherboard. It supports data transfer speeds up to 5 Gbps and is typically used in desktop PC builds. The cable features a 20-pin (or 19+1 pin) connector on the motherboard end and a standardized plug for case integration. Ensure compatibility with motherboard specifications (e.g., USB 3.0 header type: 20-pin or 19-pin).

Packaging and Labeling Requirements

All USB 3.0 motherboard cables must be packaged in anti-static bags or protective packaging to prevent electrostatic discharge (ESD) damage. Each unit or batch should include clear labeling with the product name, model number, compliance markings (e.g., CE, RoHS), manufacturer details, and date of production. Barcodes or QR codes for traceability should be included on the outer packaging for inventory and logistics tracking.

International Shipping and Customs Compliance

When shipping internationally, ensure the product is classified under the correct Harmonized System (HS) code—typically 8544.42 (electrical conductors for machine wiring). Provide commercial invoices detailing product description, value, country of origin (usually China or Taiwan), and quantity. Comply with destination country regulations such as FCC certification in the United States, CE marking in the European Union, and KC certification in South Korea if applicable. Declare accurate weight and dimensions for freight calculation and customs clearance.

Environmental and Safety Regulations

USB 3.0 cables must comply with Restriction of Hazardous Substances (RoHS) directives, ensuring they are free from lead, mercury, cadmium, and other restricted materials. In the EU, compliance with the Waste Electrical and Electronic Equipment (WEEE) directive requires proper take-back and recycling instructions. Additionally, cables should meet flammability standards (e.g., UL 94 V-0 for plastic components) and be free of substances listed under REACH regulations.

Import/Export Documentation

Prepare and retain the following documents for compliance:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– RoHS and CE Compliance Declarations (for EU)

– FCC Declaration of Conformity (for U.S.)

– Any additional country-specific certifications (e.g., UKCA, EAC)

These documents must be accurate and readily available for customs audits or inspections.

Storage and Handling Guidelines

Store USB 3.0 cables in a dry, temperature-controlled environment (15–25°C) away from direct sunlight and sources of electromagnetic interference. Handle with ESD-safe practices, including grounding straps and conductive flooring in warehouse settings. Avoid bending or pinching cables during storage to prevent internal wire damage. Implement FIFO (First In, First Out) inventory rotation to minimize aging and obsolescence.

Quality Assurance and Testing

Prior to shipment, each batch must undergo quality control checks including continuity testing, signal integrity verification, and visual inspection for defects. Maintain records of test results and perform periodic audits of manufacturing partners to ensure consistent compliance with USB-IF (USB Implementers Forum) specifications. Non-compliant units must be quarantined and reworked or scrapped.

Warranty and Returns Management

Offer a standard warranty period (e.g., 1–3 years) and establish a clear returns process for defective or non-compliant units. Include Return Merchandise Authorization (RMA) procedures with tracking to monitor return reasons and improve product quality. Ensure compliance with consumer protection laws in target markets regarding warranty obligations and repair/replacement timelines.

End-of-Life and Recycling

Develop a product end-of-life plan in accordance with WEEE and local e-waste regulations. Provide customers with information on proper disposal and recycling options. Partner with certified e-waste recyclers to responsibly manage returned or obsolete inventory and maintain compliance with environmental responsibilities.

Conclusion: Sourcing a USB 3.0 Cable for Motherboard

Sourcing the correct USB 3.0 internal header cable for a motherboard requires careful attention to compatibility, quality, and proper specifications. USB 3.0 internal cables (typically connecting front-panel or external USB 3.0 ports to the motherboard’s 19-pin USB 3.0 header) must match the pin layout and signaling requirements of the motherboard to ensure reliable high-speed data transfer and power delivery.

Key considerations when sourcing such a cable include verifying the connector type (e.g., 20-pin plug with one pin blocked), ensuring compliance with USB 3.0 SuperSpeed standards, and selecting cables from reputable manufacturers to avoid signal degradation or connection issues. Additionally, cable length, shielding, and build quality impact performance, especially for maintaining data integrity over longer runs.

In conclusion, while USB 3.0 internal cables are widely available, choosing the right one involves matching motherboard specifications, prioritizing build quality, and confirming compatibility with the chassis or external enclosure. Proper sourcing ensures optimal performance, minimizes the risk of damage, and supports the full bandwidth capabilities of USB 3.0 devices.