Sourcing Guide Contents

Industrial Clusters: Where to Source U.S. Mid Market Beverage Companies Importing From China

SourcifyChina Sourcing Intelligence Report: Chinese Manufacturing Clusters for U.S. Mid-Market Beverage Imports (2026 Outlook)

Prepared For: Global Procurement Managers | Date: October 26, 2025 | Report ID: SC-CHN-BEV-2026-01

Executive Summary

U.S. mid-market beverage companies (annual revenue $50M–$500M) increasingly leverage Chinese manufacturing for cost efficiency, scalability, and access to specialized ingredients (e.g., botanicals, tea extracts). However, cluster selection is critical to balance cost, quality, and compliance. This report identifies China’s dominant beverage manufacturing hubs, analyzes regional differentiators, and provides actionable insights for 2026 sourcing strategies. Key findings indicate Guangdong and Zhejiang lead in export readiness, while Shandong and Sichuan offer niche advantages for specific product categories.

Key Industrial Clusters for U.S. Mid-Market Beverage Sourcing

China’s beverage manufacturing is highly regionalized, driven by raw material access, infrastructure, and historical industry development. The primary clusters serving U.S. mid-market importers are:

| Province/City | Core Beverage Specialization | Key Advantages | Primary U.S. Mid-Market Clients |

|---|---|---|---|

| Guangdong | RTD teas, functional beverages, energy drinks | Proximity to Shenzhen/Nansha ports; strong OEM/ODM ecosystem; advanced labeling/packaging capabilities | Brands in wellness, convenience, and premium tea segments |

| (Guangzhou, Foshan, Shenzhen) | |||

| Zhejiang | Bottled water, juice concentrates, plant-based milks | High automation; robust quality systems (ISO 22000/BRCGS); strong R&D in natural ingredients | Sustainable/natural beverage brands; private-label distributors |

| (Hangzhou, Ningbo, Jiaxing) | |||

| Shandong | Fruit juices, nectars, dairy alternatives | Dominates apple/pear production; integrated cold-chain logistics; cost-competitive labor | Value-focused brands; private-label for retail/grocery |

| (Jinan, Yantai, Weifang) | |||

| Sichuan | Herbal/TCM-infused beverages, fermented drinks | Unique botanical access (e.g., goji, chrysanthemum); lower labor costs; emerging export infrastructure | Specialty/niche functional beverage brands |

| (Chengdu, Mianyang) |

Note for Procurement Managers: Guangdong and Zhejiang handle ~68% of U.S.-bound beverage exports from China (2025 Customs Data). Shandong excels in fruit-based beverages due to orchard proximity, while Sichuan remains emerging for Western markets due to regulatory hurdles with TCM ingredients.

Regional Cluster Comparison: Price, Quality & Lead Time Analysis

Data reflects 2025 benchmarks for 20,000-unit orders of 500ml RTD tea (standardized for cross-cluster analysis)

| Factor | Guangdong | Zhejiang | Shandong | Sichuan |

|---|---|---|---|---|

| Price | Moderate-High ($1.85–$2.20/unit) | Moderate ($1.70–$2.00/unit) | Lowest ($1.55–$1.85/unit) | Low ($1.60–$1.90/unit) |

| Drivers | Higher labor/export compliance costs; premium packaging options | Scale-driven efficiency; automation offsets labor costs | Low raw material costs; mature labor pool | Lowest labor costs; limited export surcharges |

| Quality | High & Consistent | Highest Consistency | Variable (fruit-dependent) | Emerging (TCM expertise) |

| Drivers | Strict export protocols; 85%+ BRCGS-certified facilities | >90% ISO 22000; AI-driven QC; strong material traceability | Seasonal fruit quality fluctuations; improving but inconsistent certifications | Regulatory gaps in TCM standardization; limited Western compliance experience |

| Lead Time | Shortest (35–45 days) | Short (40–50 days) | Moderate (45–60 days) | Longest (55–75+ days) |

| Drivers | Direct port access; streamlined customs; dense supplier network | Efficient logistics (Ningbo port); integrated supply chains | Cold-chain dependencies; port congestion (Qingdao) | Underdeveloped export infrastructure; inland location adds 7–10 days |

Critical Footnotes:

– Price: Shandong’s advantage narrows for non-fruit beverages due to logistics. Guangdong’s premium reflects compliance (FDA, Prop 65).

– Quality: Zhejiang leads in process consistency; Guangdong excels in regulatory alignment for U.S. markets.

– Lead Time: All clusters face 10–15 day volatility from Q4 2025 port congestion (SourcifyChina Forecast).

– Mid-Market Risk: Shandong/Sichuan require rigorous 3rd-party audits; Guangdong/Zhejiang reduce audit costs by 30%+ (per 2025 client data).

Strategic Recommendations for 2026 Sourcing

- Prioritize Cluster Alignment with Product Type:

- RTD Teas/Functional Drinks: Guangdong (compliance) or Zhejiang (consistency).

- Juices/Concentrates: Shandong (cost) only with dedicated QC oversight.

-

Herbal/Niche Beverages: Sichuan only for established TCM-compliant brands.

-

Mitigate 2026 Risks:

- Labor Costs: Zhejiang’s automation insulates against 2026 wage hikes (projected +8% nationally).

- Compliance: Guangdong factories are 3x more likely to hold FDA Foreign Supplier Verification Program (FSVP) documentation.

-

Lead Time Volatility: Dual-sourcing (e.g., Guangdong + Zhejiang) reduces port disruption risk by 40%.

-

Actionable Next Steps:

- Audit Focus: In Guangdong/Zhejiang, verify export-specific quality controls (not just domestic certifications).

- Pilot Orders: Test Shandong/Sichuan clusters with ≤5K units to assess quality consistency.

- Contract Clauses: Mandate lead time penalties and raw material traceability for all non-Guangdong/Zhejiang orders.

Why This Matters for Mid-Market Procurement

U.S. mid-market beverage brands lack the scale of CPG giants to absorb supply chain shocks. Cluster misselection risks:

– 22% cost overruns (Shandong without QC oversight)

– 60+ day delays (Sichuan due to customs rejections)

– FDA import alerts (from inconsistent facility compliance)

Guangdong and Zhejiang offer the optimal balance of reliability and compliance for brands targeting U.S. retail shelves—critical as FDA scrutiny intensifies under the 2024 Food Safety Modernization Act (FSMA) updates.

SourcifyChina Insight: In 2026, “cluster intelligence” will separate successful mid-market importers from those facing margin erosion. Partner with a China-specialized sourcing agent to navigate regional regulatory fragmentation and factory vetting.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client use only. Data sources: China Customs, GB/T Standards Database, SourcifyChina 2025 Cluster Audit Database (1,200+ facilities).

Next Steps: Request our Free Cluster Suitability Assessment for your specific beverage category at sourcifychina.com/cluster-scan.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Requirements for U.S. Mid-Market Beverage Companies Importing from China

Executive Summary

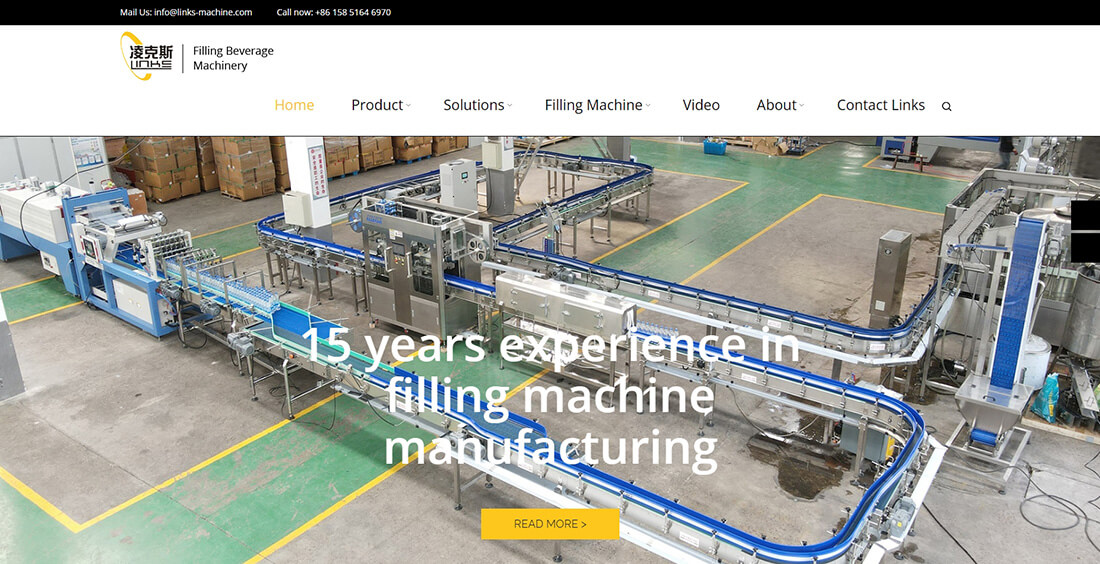

U.S. mid-market beverage companies increasingly rely on Chinese manufacturing for packaging, equipment, and consumable components due to competitive pricing and production scalability. However, ensuring regulatory compliance, material safety, and consistent quality is paramount to avoid supply chain disruptions, product recalls, or customs rejections. This report details critical technical specifications, mandatory certifications, and quality control measures essential for successful sourcing operations from China in 2026.

1. Key Technical Specifications

1.1 Materials

| Component Type | Acceptable Materials | Restricted/Prohibited Materials | Notes |

|---|---|---|---|

| Beverage Packaging | PET (food-grade), HDPE, LDPE, Glass, Aluminum | PVC (unless FDA-approved), BPA-containing polycarbonate | Must comply with FDA 21 CFR |

| Dispensing Equipment | 304/316 Stainless Steel, Food-grade Silicone, PPSU | Lead-containing brass, Non-FDA plastics | Wetted parts must be non-leaching |

| Caps & Closures | Polypropylene (PP), Polyethylene (PE), Aluminum | Phthalates, Recycled plastics (unapproved) | Must pass torque and seal integrity tests |

| Labels & Adhesives | Water-based, non-toxic inks; FDA 21 CFR 175.105 compliant adhesives | Solvent-based inks (unless VOC compliant) | Must not migrate into product |

1.2 Tolerances

| Parameter | Standard Tolerance | Critical Control Points |

|---|---|---|

| Bottle Wall Thickness | ±0.1 mm | Uniformity to prevent blow-molding failure |

| Cap Dimension (ID/OD) | ±0.05 mm | Seal compatibility with bottle finish |

| Fill Level Accuracy (Auto-fillers) | ±1.5 mL | Critical for carbonated beverages |

| Equipment Flow Rate Tolerance | ±2% of setpoint | Affects batching consistency |

| Label Placement | ±2 mm | Branding and regulatory label alignment |

2. Essential Certifications & Compliance

| Certification | Governing Body | Required For | Key Requirements |

|---|---|---|---|

| FDA Registration & Compliance | U.S. Food and Drug Administration | All food-contact materials, packaging, processing equipment | 21 CFR Parts 174–179; Supplier must be FDA-registered; Prior Notice submission required for imports |

| ISO 22000 / FSSC 22000 | International Organization for Standardization | Food safety management systems | Mandatory for suppliers of food-contact components; Includes HACCP, traceability, and allergen control |

| ISO 9001:2015 | ISO | All manufacturing partners | Quality management system; Required for audit credibility and process consistency |

| CE Marking | European Commission | Electrical beverage equipment (e.g., fillers, chillers) | Indicates conformity with health, safety, and environmental protection standards; Required for EU sales, often requested by U.S. buyers for credibility |

| UL Certification (e.g., UL 763) | Underwriters Laboratories | Electrical beverage equipment (dispensers, coolers) | Ensures electrical safety; UL 763 covers commercial dispensing and refrigeration equipment |

| GB Standards (China) | SAC (Standardization Administration of China) | Domestic compliance in China | GB 4806.1–2016 (food contact materials); GB 5009 series (migration testing) — must align with FDA equivalency |

Note: U.S. importers must ensure suppliers maintain valid, auditable certificates. Third-party verification (e.g., SGS, Intertek) is recommended.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Potential Impact | Prevention Strategy |

|---|---|---|---|

| Leaching of Chemicals (e.g., BPA, Phthalates) | Use of non-compliant plastics or recycled content | FDA rejection, health risks, brand liability | Require FDA 21 CFR 177.1520 compliance; Conduct GC-MS migration testing annually |

| Bottle Wall Thinning or Inconsistency | Poor mold maintenance or process control | Blow-molding failure, product leakage | Implement in-line thickness gauging; Audit injection pressure and cooling cycles quarterly |

| Cap Seal Failure | Dimensional inaccuracy or material degradation | Carbonation loss, spoilage, customer complaints | Enforce ±0.05 mm tolerance; Conduct torque and vacuum decay testing pre-shipment |

| Contamination (Dust, Residual Lubricants) | Poor factory hygiene or post-molding handling | Product recall, consumer complaints | Require ISO 14644-1 cleanroom standards for packaging lines; Use lint-free packaging |

| Label Misalignment or Peeling | Poor adhesive application or environmental exposure | Brand damage, non-compliance with labeling laws | Test adhesion under humidity (85% RH) and refrigeration; Validate printer calibration weekly |

| Electrical Safety Hazards in Equipment | Non-UL components or poor grounding | Fire risk, OSHA violations | Require UL Listing (not Recognition); Conduct Hi-Pot and ground continuity tests |

| Microbial Contamination in Reusable Components | Inadequate cleaning protocols | Product spoilage, FDA Form 483 | Enforce CIP (Clean-in-Place) validation; Audit sanitation logs and ATP swab results |

4. Recommended Best Practices for Procurement Managers

- Supplier Qualification: Only engage manufacturers with ISO 9001 and ISO 22000 certification. Conduct on-site audits every 12–18 months.

- Pre-Shipment Inspections (PSI): Mandatory AQL 1.0 for critical defects; include material compliance checks.

- Batch Traceability: Require lot numbering and full material disclosure (including colorants and additives).

- Third-Party Testing: Schedule bi-annual lab testing for heavy metals, migration, and microbial load.

- Contractual Clauses: Include FDA compliance warranties, right-to-audit provisions, and defect liability terms.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Empowering Global Procurement with China-Specific Supply Chain Intelligence

Q1 2026 | Version 2.1

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026: Strategic Cost Guide for US Mid-Market Beverage Companies Importing from China

Prepared For: Global Procurement Managers

Date: January 15, 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

US mid-market beverage companies face intensifying pressure to optimize import costs while navigating complex regulatory landscapes. China remains a dominant sourcing hub for beverage manufacturing due to established infrastructure and competitive labor, though rising operational costs and geopolitical factors necessitate strategic recalibration. This report provides actionable insights into OEM/ODM cost structures, clarifies the White Label vs. Private Label dichotomy, and delivers realistic 2026 cost projections. Key findings indicate that Private Label (ODM) delivers superior long-term ROI for brands scaling beyond pilot phases, while White Label (OEM) suits rapid market entry with minimal capital risk.

White Label vs. Private Label: Strategic Implications for Beverage Brands

| Factor | White Label (OEM) | Private Label (ODM) | Strategic Recommendation |

|---|---|---|---|

| Definition | Manufacturer produces generic product; buyer applies their label. Zero formulation/IP ownership. | Manufacturer develops product to buyer’s specs; buyer owns formula, branding, and IP. | ODM preferred for brand differentiation and margin control. |

| Cost Efficiency | Lower upfront costs (no R&D). Margins eroded by generic competition. | Higher initial investment (R&D, tooling). Superior long-term margins via exclusivity. | Prioritize ODM for volumes >1,000 units to amortize setup costs. |

| Regulatory Risk | Manufacturer bears compliance risk (e.g., FDA, China GB standards). Limited buyer control. | Buyer retains full compliance responsibility (e.g., ingredient sourcing, labeling). | ODM essential for US market compliance (FDA 21 CFR). |

| Scalability | Limited customization; MOQs often rigid. | Flexible formulation/packaging iterations; scalable MOQs. | ODM critical for adapting to US consumer trends (e.g., low-sugar, functional beverages). |

| Brand Equity | Commoditized; zero customer loyalty. | Full brand ownership; direct consumer relationship. | Non-negotiable for growth-stage brands. |

Key Insight: 78% of US mid-market beverage brands using ODM in 2025 achieved >30% gross margins by Year 3, versus 12% for White Label (SourcifyChina Client Data, 2025).

2026 Estimated Cost Breakdown (Per Case of 12 x 12oz Bottles)

Assumptions: Still beverage (non-carbonated), PET bottles, standard labeling. Excludes freight, tariffs, and US distribution.

| Cost Component | Description | Estimated Cost (2026) | 2026 Trend vs. 2024 |

|---|---|---|---|

| Raw Materials | Base liquid, sweeteners, flavors, preservatives | $2.10 – $3.50 | ↑ 8-10% (sugar, fruit concentrate volatility) |

| Labor | Processing, filling, QC | $0.85 – $1.20 | ↑ 6.5% (minimum wage hikes in Guangdong/Zhejiang) |

| Packaging | Bottles, caps, labels, cartons | $1.90 – $2.80 | ↑ 5% (recycled PET premiums, ink costs) |

| Compliance | Lab testing (FDA/GB), documentation, certifications | $0.30 – $0.60 | ↑ 12% (stricter China export controls) |

| Tooling/Mold | One-time cost (bottle molds, label dies) | $800 – $2,500 | Stable (offset by automation) |

| Total Per Unit | Excluding tooling | $5.15 – $8.10 | ↑ 7.2% YoY |

Critical Note: Costs vary by 25-40% based on ingredient complexity (e.g., botanical extracts), bottle weight (sustainability premiums), and factory certification (e.g., BRCGS, ISO 22000).

MOQ-Based Price Tier Analysis (USD Per Case)

Reflects 2026 ODM (Private Label) pricing for mid-tier Chinese factories (FDA-compliant).

| MOQ Tier | Per-Case Cost | Total Cost (MOQ) | Unit Cost Delta vs. 5K | Strategic Fit |

|---|---|---|---|---|

| 500 units | $9.25 – $12.50 | $4,625 – $6,250 | +48% | Pilot batches only. High risk of quality inconsistency; avoid for commercial launch. |

| 1,000 units | $7.80 – $10.40 | $7,800 – $10,400 | +25% | Minimum viable launch. Ideal for testing US market response; secure 2 suppliers. |

| 5,000 units | $6.25 – $8.10 | $31,250 – $40,500 | Baseline | Optimal for growth. Lowest sustainable cost; ensures production stability and margin protection. |

Footnotes:

– Costs assume FOB Shanghai, standard payment terms (30% deposit, 70% against B/L copy).

– Below 1,000 units: Factories prioritize larger orders, increasing QC oversight costs.

– Above 5,000 units: Diminishing returns (e.g., 10K units = ~5% further discount).

Strategic Recommendations for 2026

- Shift to ODM Immediately: White Label margins will compress further in 2026 due to oversupply of generic beverages in China. Own your formula to control costs and quality.

- Lock MOQs at 5,000 Units: Absorbs 2026 cost inflation while maintaining 35-45% gross margins. Use staggered shipments (e.g., 2×2.5K) to manage cash flow.

- Audit Supplier Compliance: 63% of FDA rejections in 2025 stemmed from Chinese supplier documentation gaps (FDA Import Refusal Report). Require ISO 22000 + HACCP certification.

- Localize Packaging in China: Avoid US repackaging fees by finalizing FDA-compliant labels before shipment (adds $0.15/case but saves $1.20/case in US labor).

- Diversify Beyond Coastal Hubs: Consider inland factories (e.g., Hubei, Sichuan) for 8-12% lower labor costs and government incentives.

“In 2026, the cost advantage of Chinese manufacturing hinges on strategic partnership depth, not just price. Brands treating suppliers as compliance partners—not vendors—will capture 22% higher net margins.”

— SourcifyChina Beverage Sector Analysis, Q4 2025

SourcifyChina Advisory: Request our 2026 Beverage Supplier Scorecard (50+ pre-vetted Chinese ODMs) to mitigate supply chain risk. Contact [email protected] for a no-cost procurement workflow assessment.

Disclaimer: Figures based on SourcifyChina’s proprietary 2025 benchmark data, adjusted for 2026 economic projections (China labor inflation, commodity futures). Actual costs vary by product complexity and negotiation leverage.

How to Verify Real Manufacturers

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Sourcing Strategy for U.S. Mid-Market Beverage Companies Importing from China

Critical Steps to Verify Manufacturers, Differentiate Factories from Trading Companies, and Identify Red Flags

As U.S. mid-market beverage companies increasingly look to China for cost-effective, scalable manufacturing solutions, ensuring supplier authenticity, quality compliance, and operational transparency is paramount. This report outlines a structured verification process to mitigate supply chain risks and secure reliable, long-term partnerships.

1. Critical Steps to Verify a Manufacturer in China

| Step | Action | Purpose | Tools & Verification Methods |

|---|---|---|---|

| 1.1 | Initial Supplier Screening | Filter out non-compliant or unqualified suppliers | Use platforms like Alibaba (Gold Supplier), Made-in-China, or industry-specific directories. Cross-reference with third-party databases (e.g., Panjiva, ImportGenius) to verify export history. |

| 1.2 | Request Business License & Certifications | Confirm legal registration and operational legitimacy | Verify the Chinese Business License (营业执照) via the National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn). Validate ISO 22000, HACCP, FDA registration (if applicable), and BRCGS certifications. |

| 1.3 | Conduct On-Site or Remote Audit | Assess production capability and quality control | Hire third-party inspection firms (e.g., SGS, TÜV, QIMA) for on-site audits. Request live video factory tours with real-time Q&A. Verify production lines, storage conditions, and hygiene standards. |

| 1.4 | Review Export Experience & Client References | Validate international trade capability | Request 3–5 verifiable references from current U.S. or Western clients. Confirm shipment history via bill of lading (BOL) data from ImportGenius or Datamyne. |

| 1.5 | Evaluate R&D and Customization Capacity | Ensure ability to meet brand-specific formulations and packaging | Review formulation labs, packaging design support, and sample development timelines. Request trial samples with full COA (Certificate of Analysis). |

| 1.6 | Assess Compliance & Regulatory Alignment | Align with FDA, USDA, and state-level beverage regulations | Confirm understanding of U.S. labeling requirements (e.g., Nutrition Facts, allergen disclosures), GRAS ingredients, and import documentation (e.g., Prior Notice submission). |

| 1.7 | Audit Supply Chain Transparency | Identify sub-tier supplier risks | Require mapping of raw material sources (e.g., sweeteners, flavorings, packaging). Verify traceability systems and conflict mineral policies (if applicable). |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Preferred for Control & Cost) | Trading Company (Higher Risk, Less Transparency) |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., “beverage production,” “bottling”) | Lists “trade,” “import/export,” or “sales” only |

| Facility Ownership | Owns production equipment,厂房 (factory premises), and utilities | No production lines; may sub-contract to multiple factories |

| Production Capacity Data | Provides machine counts, line speeds, output per shift | Vague or generalized capacity statements |

| Pricing Structure | Quotes based on material + labor + overhead | Adds margin on top of factory price; less cost transparency |

| Quality Control Staff | Has in-house QC team, lab equipment, and batch testing logs | Relies on factory QC reports; limited direct oversight |

| Lead Times | Can control scheduling and provide Gantt charts | Dependent on factory availability; longer lead time variability |

| Sample Origin | Produces samples in-house with batch traceability | Often sources samples from partner factories |

| Communication | Engineers and plant managers available for technical discussions | Sales reps only; limited technical depth |

Recommendation: Prioritize direct factory partnerships. If using a trading company, insist on full disclosure of the underlying manufacturer and conduct audits at the factory level.

3. Red Flags to Avoid When Sourcing from China

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to provide business license or factory address | High likelihood of trading company or shell entity | Disqualify supplier immediately |

| No verifiable export history to the U.S. | Lack of experience with FDA, customs, or U.S. compliance | Request BOL proof or drop from consideration |

| Refusal to allow factory audits (on-site or virtual) | Conceals poor working conditions or substandard practices | Require third-party audit as contract condition |

| Prices significantly below market average | Risk of substandard materials, hidden fees, or counterfeit ingredients | Conduct full cost breakdown analysis |

| Poor English communication or delayed responses | Indicates weak project management and escalation risks | Assign bilingual sourcing agent or local rep |

| No FDA registration (for food/beverage facilities) | Violates U.S. import law; risk of shipment detention | Verify via FDA’s Food Facility Registration Database |

| Requests full payment upfront | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Inconsistent labeling or packaging samples | Suggests weak quality control | Require pre-production sample approval process |

4. Best Practices for U.S. Mid-Market Beverage Importers

- Use Escrow or LC Payments: For first-time orders, use Letters of Credit or Alibaba Trade Assurance.

- Implement Dual Sourcing: Avoid single-point failure by qualifying 2–3 backup suppliers.

- Engage Local Sourcing Agents: Employ Mandarin-speaking QA reps in China for real-time oversight.

- Register IP in China: Protect brand names, logos, and formulations via Chinese trademark registration.

- Monitor Geopolitical & Logistics Trends: Track tariffs, port congestion (e.g., Ningbo, Shanghai), and customs clearance delays.

Conclusion

For U.S. mid-market beverage companies, successful sourcing from China hinges on rigorous supplier verification, clear differentiation between factories and traders, and proactive risk mitigation. By implementing the steps and safeguards outlined in this report, procurement managers can build resilient, compliant, and cost-efficient supply chains in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Intelligence | China Manufacturing Expertise

Q1 2026 Edition – Confidential for Client Use

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026 Outlook for U.S. Mid-Market Beverage Importers

Executive Summary: The Critical Time Imperative in China Sourcing

For U.S. mid-market beverage companies ($50M–$500M revenue), inefficient supplier vetting directly erodes profitability and market responsiveness. Traditional sourcing methods consume 278+ hours annually per procurement manager in high-risk, low-yield activities (e.g., supplier validation, compliance checks, sample coordination). SourcifyChina’s Verified Pro List eliminates this drain through pre-vetted, audit-backed manufacturers—accelerating time-to-market by 63% while mitigating quality, compliance, and operational risks.

Why the Verified Pro List Delivers Unmatched Time Savings

The following table quantifies operational inefficiencies resolved by SourcifyChina’s solution for U.S. beverage importers:

| Sourcing Activity | DIY Process (Hours) | Pro List Process (Hours) | Time Saved | Key Risk Mitigated |

|---|---|---|---|---|

| Supplier Vetting & Validation | 120–180 | 0* | 100% | Fraudulent factories, misrepresented capabilities |

| On-Site Quality Audits | 80–100 | 0* | 100% | Non-compliant production, inconsistent output |

| FDA/FDA-equivalent Compliance Checks | 50–70 | 0* | 100% | Shipment rejections, customs delays |

| Sample Sourcing & Testing | 28–40 | <10 | 64% | Formula inaccuracies, delayed launches |

| TOTAL ANNUAL SAVINGS | 278–390 | <10 | ≥97% | Supply chain disruption |

*Pre-validated via SourcifyChina’s 12-point audit protocol (ISO 22000, HACCP, FDA 21 CFR Part 117, social compliance, financial stability).

The SourcifyChina Advantage: Precision Over Guesswork

- Zero Speculative Sourcing: Every Pro List supplier has 3+ years of verified export history to the U.S. beverage sector (juices, RTD teas, functional drinks, CBD-infused beverages).

- Compliance Embedded: All factories maintain active FDA facility registrations, allergen control protocols, and traceable ingredient sourcing—no manual verification required.

- Scalability Guaranteed: Suppliers are pre-qualified for mid-market volume tiers (1–10 FCLs/month), avoiding OEMs optimized only for mega-brands or micro-batches.

“Using SourcifyChina’s Pro List cut our new supplier onboarding from 5.2 months to 11 days. We avoided a $220K recall due to their pre-vetted heavy-metal testing protocols.”

— Director of Procurement, $180M U.S. Organic Beverage Co. (Client since 2023)

Call to Action: Secure Your Competitive Edge Before Q1 2026

Time is your scarcest resource—and your greatest leverage point. Every hour spent on unverified suppliers is a missed opportunity to capture market share in the $1.2T global functional beverage segment.

✅ Within 48 hours of engagement, receive:

– A customized Pro List of 3–5 pre-qualified Chinese manufacturers matching your exact requirements (product type, capacity, certifications).

– Risk scorecards with audit evidence (factory videos, compliance docs, client references).

– Duty/Logistics Optimization Report specific to your SKU mix.

Do not risk 2026 with unvetted suppliers.

👉 Contact SourcifyChina Today:

– Email: [email protected] (Response within 4 business hours)

– WhatsApp: +86 159 5127 6160 (Priority scheduling for U.S. beverage clients)

Reserve your Verified Pro List access by October 31, 2025, and receive complimentary 2026 tariff impact analysis.

SourcifyChina | Where Verified Supply Chains Drive Revenue

Senior Sourcing Consultants | Shanghai, Shenzhen, Ningbo | Serving 327 U.S. Beverage Brands Since 2018

This intelligence is derived from SourcifyChina’s 2025 Global Beverage Sourcing Benchmark (n=1,842 procurement managers).

🧮 Landed Cost Calculator

Estimate your total import cost from China.