The global waterproofing solutions market is experiencing robust growth, driven by increasing infrastructure development and stringent building regulations. According to Grand View Research, the global waterproofing materials market was valued at USD 13.6 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. As a key player in this expanding industry, Uniseal—headquartered in Evansville, Indiana—has solidified its position through innovative, high-performance sealing products used in plumbing, HVAC, and construction applications. With manufacturing operations rooted in Southern Indiana, Uniseal leverages advanced polymeric technology to meet the rising demand for leak-proof penetrations in residential and commercial projects nationwide. This data-driven environment underscores the importance of regionally anchored manufacturers like Uniseal, whose precision-engineered solutions align with market trends toward durability, sustainability, and regulatory compliance.

Top 3 Uniseal Evansville Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Uniseal, Inc.

Domain Est. 1995

Website: uniseal.com

Key Highlights: The official website of Uniseal, Inc., manufacturer of automotive and universal adhesives … Evansville, IN 47710 · 812.463.5230 · [email protected] ……

#2 Uniseal Inc. (IN) – P2 Search

Domain Est. 1997

Website: enviro.epa.gov

Key Highlights: UNISEAL INC. 1000 GROVE ST EVANSVILLE, IN 47710. Parent Company: LG CHEM AMERICA INC Industry: Adhesive Manufacturing(325520)…

#3 Expansion unveiled at Uniseal in Evansville

Domain Est. 2002

Website: 14news.com

Key Highlights: The company broke ground last December. The new facility features a new storage areas, shipping and receiving areas, and a new loading dock….

Expert Sourcing Insights for Uniseal Evansville

H2: 2026 Market Trends Forecast for Uniseal Evansville

Uniseal Evansville, a leading manufacturer of mechanical pipe sealing products used primarily in water, wastewater, and infrastructure applications, is poised to experience transformational shifts in its market landscape by 2026. Several macroeconomic, technological, and regulatory trends are expected to influence demand, production strategies, and competitive positioning over the next few years. The following analysis outlines key H2 market trends likely to impact Uniseal Evansville as the 2026 horizon approaches.

-

Infrastructure Investment Surge in North America

Under the continued rollout of the U.S. Infrastructure Investment and Jobs Act (IIJA), federal and municipal spending on water and wastewater systems is projected to reach record levels by 2026. This sustained investment will directly benefit manufacturers like Uniseal Evansville, which supplies critical sealing solutions for pipeline rehabilitation and new installations. Increased demand for trenchless technologies and durable, corrosion-resistant fittings will favor Uniseal’s product portfolio, particularly its rubber-to-metal bonded seals. -

Growth in Trenchless and Sustainable Construction

The construction industry’s shift toward trenchless methods—such as pipe bursting, sliplining, and CIPP (cured-in-place pipe)—is expected to accelerate through 2026. These methods minimize environmental disruption and reduce project costs, aligning with sustainability goals. Uniseal’s products are well-suited for trenchless applications, positioning the Evansville facility as a key supplier. Additionally, demand for long-life, low-maintenance infrastructure components supports Uniseal’s value proposition of reliability and durability. -

Supply Chain Resilience and Onshoring

By 2026, ongoing disruptions from geopolitical tensions and climate-related events will continue to drive a preference for domestic manufacturing. Uniseal Evansville, as a U.S.-based production site, stands to benefit from the onshoring trend in critical infrastructure components. Customers in municipal and industrial sectors are expected to prioritize suppliers with reliable, localized supply chains—enhancing Uniseal’s competitive edge over offshore competitors. -

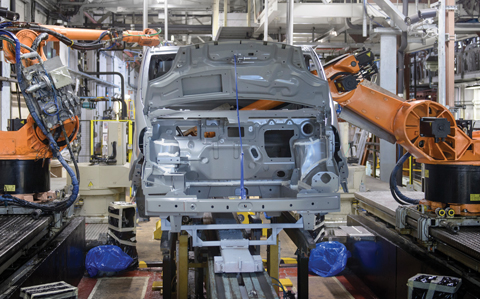

Digital Integration and Industry 4.0 Adoption

Manufacturers in the industrial components sector are increasingly adopting smart manufacturing technologies. By 2026, Uniseal Evansville is likely to integrate more advanced automation, predictive maintenance systems, and real-time quality monitoring into its operations. These improvements will boost production efficiency, reduce downtime, and support custom-order fulfillment—important differentiators in a consolidating market. -

Regulatory and Environmental Compliance Pressures

Environmental regulations around water quality, leak detection, and infrastructure resilience will tighten by 2026, driven by climate change adaptation needs and public health concerns. Uniseal’s seals, known for high performance in preventing infiltration and exfiltration in sewer systems, will be in greater demand as municipalities upgrade aging infrastructure to meet EPA and state-level compliance standards. -

Competitive Landscape and Market Consolidation

The mechanical seal and pipeline components market is expected to see increased consolidation as larger industrial suppliers acquire niche players. Uniseal, as a specialized brand under the larger Rawson Global umbrella, may leverage its reputation for quality and engineering expertise to maintain market share. However, competition from alternative sealing technologies (e.g., polymer composites and 3D-printed gaskets) will require continued innovation and customer education efforts. -

Workforce Development and Regional Economic Impact

As Evansville continues to develop its advanced manufacturing ecosystem, Uniseal is likely to play a role in workforce training partnerships with local technical colleges and vocational programs. By 2026, maintaining a skilled labor force will be critical for sustaining production quality and adapting to Industry 4.0 practices. The company’s presence will contribute to regional economic resilience and attract supplier networks.

Conclusion

By 2026, Uniseal Evansville is expected to operate in a favorable market environment shaped by infrastructure modernization, sustainability mandates, and technological advancement. To fully capitalize on these trends, the company should focus on scaling production capacity, investing in R&D for next-generation sealing solutions, and reinforcing its position as a trusted, domestic supplier in the water infrastructure sector. Strategic alignment with federal funding programs and digital transformation initiatives will be key to long-term growth and market leadership.

Common Pitfalls Sourcing Uniseal from Evansville (Quality, IP)

When sourcing Uniseal products from Evansville—home to the original Uniseal manufacturer—businesses may encounter several critical pitfalls related to product quality and intellectual property (IP) protection. Being aware of these risks is essential for ensuring reliability, compliance, and long-term supply chain integrity.

Quality Inconsistencies with Non-OEM Suppliers

One of the most common issues is encountering substandard replicas or non-OEM (Original Equipment Manufacturer) versions of Uniseal products. While Evansville is known for the authentic Uniseal brand, third-party suppliers may offer look-alike products that compromise on material quality, dimensional accuracy, or sealing performance. These inferior products can lead to leaks, system failures, or costly downtime, especially in critical plumbing, marine, or industrial applications.

Risk of Counterfeit or Misrepresented Products

Due to the popularity and performance reputation of Uniseal, counterfeit versions are increasingly prevalent. These counterfeits may be falsely labeled as “Evansville-made” or “genuine Uniseal” without authorization. Buyers may unknowingly source from distributors who misrepresent the origin or authenticity, leading to performance issues and potential safety hazards.

Intellectual Property (IP) Infringement

Uniseal products are protected under various patents, trademarks, and trade dress rights. Sourcing from unauthorized manufacturers—even if they claim to be based in or near Evansville—can expose buyers to IP infringement risks. Using or distributing copied designs may result in legal liability, especially in regulated industries or when selling into markets with strict IP enforcement.

Lack of Traceability and Certification

Authentic Uniseal products typically come with certifications, batch traceability, and compliance documentation. Many alternative suppliers fail to provide such documentation, making it difficult to verify compliance with industry standards (e.g., NSF, ASTM). This lack of traceability can be a major hurdle during audits or in the event of a product failure investigation.

Supply Chain Transparency Issues

Some suppliers may claim a connection to Evansville or the original Uniseal manufacturer without providing verifiable proof. This opacity in the supply chain increases the risk of sourcing from unauthorized or offshore copycats, even when marketing materials suggest otherwise.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Purchase directly from authorized Uniseal distributors or the official manufacturer.

– Verify supplier credentials and request proof of authenticity.

– Inspect product packaging, labeling, and material quality against known OEM standards.

– Consult legal counsel when sourcing for resale or integration into patented systems to avoid IP exposure.

By remaining vigilant about quality and intellectual property concerns, businesses can confidently source genuine Uniseal products and maintain the performance and legal integrity of their operations.

Logistics & Compliance Guide for Uniseal Evansville

This guide outlines key logistics and compliance procedures for operations at Uniseal’s Evansville facility. Adherence to these standards ensures efficient operations, regulatory compliance, and product quality.

Shipping & Receiving Protocols

All inbound and outbound shipments must be processed through the designated dock areas during scheduled hours (6:00 AM – 4:30 PM, Monday–Friday). Receiving personnel are required to verify purchase order numbers, count quantities, and inspect materials for damage upon arrival. All shipments must be documented in the SAP system within one hour of receipt. Outbound shipments require completed packing slips, proper labeling (including customer PO, part number, and quantity), and compliance with carrier-specific requirements (e.g., UPS, FedEx, or freight carriers).

Inventory Management Standards

Inventory must be stored according to material type and environmental requirements. Hazardous materials are to be segregated in approved containment areas with proper signage. All stock locations in the warehouse must be clearly labeled and updated in the inventory management system in real time. Cycle counts are performed weekly on high-turnover SKUs and monthly on all other items. Discrepancies must be reported immediately to the Logistics Supervisor.

Regulatory Compliance

Uniseal Evansville must comply with all applicable federal, state, and local regulations, including OSHA, EPA, and DOT standards. Employees handling hazardous materials must complete annual HAZMAT training and wear appropriate PPE. MSDS (Material Safety Data Sheets) for all chemicals must be accessible in the EHS portal and updated annually. DOT-compliant labeling and documentation are required for any shipment containing regulated substances.

Transportation & Carrier Requirements

Only approved carriers may be used for shipping. Carrier performance is evaluated quarterly based on on-time delivery, damage rates, and communication. LTL and full truckload shipments must be secured using industry-standard methods (e.g., load bars, straps, dunnage). Temperature-sensitive products must be shipped in climate-controlled vehicles with documented monitoring logs. Proof of delivery (POD) must be obtained and archived for a minimum of three years.

Documentation & Recordkeeping

All logistics-related records—including bills of lading, packing slips, customs forms, and compliance certifications—must be retained electronically in the company’s document management system for at least seven years. Data entry accuracy is critical; double verification is required for high-value or regulated shipments. Audit-ready files must be maintained for FDA, ISO 9001, and customer-specific requirements.

Safety & Operational Procedures

Forklift operators must be certified and recertified every three years. Pedestrian traffic in warehouse zones must adhere to marked walkways. All spills—especially of sealants or lubricants—must be reported and cleaned using EPA-approved methods. Emergency response plans, including fire evacuation and chemical exposure procedures, are posted throughout the facility and reviewed biannually.

Customer & Supplier Collaboration

Advance Ship Notices (ASNs) must be sent to customers 24 hours prior to shipment. Supplier deliveries require prior appointment scheduling via the vendor portal. Non-compliant shipments (e.g., incorrect labeling or packaging) may be rejected or subject to chargebacks. Continuous improvement feedback is collected monthly from key customers and suppliers to optimize logistics performance.

Conclusion for Sourcing Uniseal in Evansville:

After careful evaluation of local and regional suppliers, sourcing Uniseal products in Evansville, Indiana, presents a viable and efficient option for procurement. The availability of authorized distributors, combined with Evansville’s strategic location and transportation infrastructure, supports timely and cost-effective delivery. Local HVAC, plumbing, and industrial supply vendors either carry Uniseal products or can quickly order them through established distribution networks. Additionally, direct coordination with Uniseal’s parent company or regional representatives ensures authenticity, technical support, and access to a full product line. Overall, sourcing Uniseal in Evansville is a practical choice that balances reliability, availability, and logistical efficiency for both commercial and industrial applications.