The global ultrasonic cleaning market, driven by increasing demand for efficient, eco-friendly, and water-saving cleaning solutions, is experiencing robust growth. According to Grand View Research, the global ultrasonic cleaning equipment market was valued at USD 1.47 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030. This growth is fueled by advancements in cleaning technologies, rising adoption in industrial, healthcare, and consumer electronics sectors, and a growing emphasis on sustainable home appliances. As consumer interest shifts toward innovative laundry solutions that reduce water and energy consumption, ultrasonic washing machines are emerging as a disruptive alternative to traditional drum-based systems. With several manufacturers investing in scalable ultrasonic technology, the competitive landscape is evolving rapidly. The following list highlights the top 10 ultrasonic washing machine manufacturers leading this transformation, based on technology innovation, product performance, market presence, and commercial viability.

Top 10 Ultrasonic Washing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

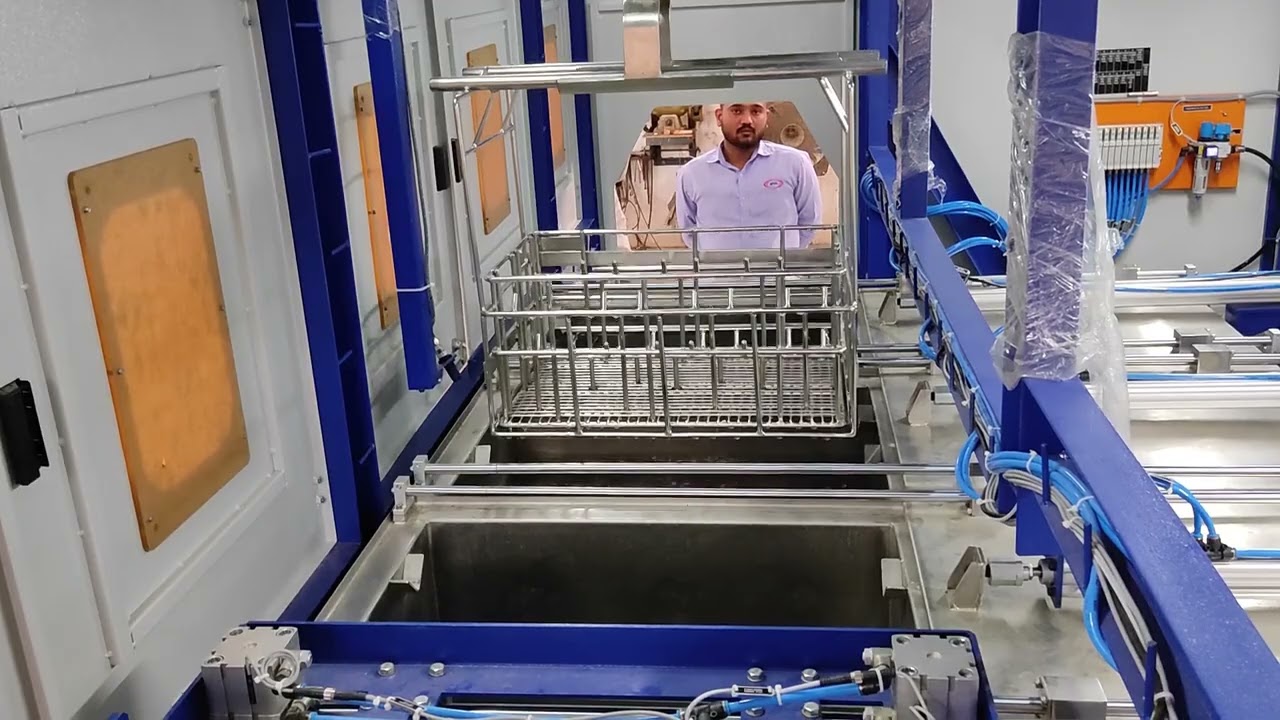

#1 Expert Ultrasonic Machine & Cleaning Machine Manufacturer

Domain Est. 2012

Website: ralsonics.com

Key Highlights: At Ralsonics, we combine ultrasonic technology and automation engineering to deliver powerful, sustainable, and tailor-made industrial cleaning and surface ……

#2 Crest Ultrasonics

Domain Est. 1996

Website: crest-ultrasonics.com

Key Highlights: Based in the U.S., Crest Ultrasonics is one of the largest private industrial ultrasonic cleaner manufacturers in the world. Call for equipment & chemicals….

#3 Industrial Ultrasonic Cleaner Manufacturer

Domain Est. 1997

Website: upcorp.com

Key Highlights: Ultrasonic Power Corp. manufactures and supplies top-of-the-line industrial and commercial ultrasonic cleaners. Contact our team for a quote today!…

#4 China Industrial Ultrasonic Cleaner & Automatic Ultrasonic Cleaner …

Domain Est. 2015

Website: m.skymenultrasonic.com

Key Highlights: Good quality Industrial Ultrasonic Cleaner from China, Automatic Ultrasonic Cleaner factories of Skymen Technology Corporation Limited….

#5 Designer/Manufacturer of ultrasonic cleaning machines

Domain Est. 1996

Website: fisa.com

Key Highlights: FISA Group has specialized in R&D, design, engineering, production, sales and technical support of custom-built ultrasonic cleaning and coating machines ……

#6 L&R Manufacturing

Domain Est. 1996

Website: lrultrasonics.com

Key Highlights: L&R, the leader in manufacturing and distribution of Ultrasonic Cleaning systems. Serving dental, medical, jewelry, watches, firearms, industrial, rescue, ……

#7 UCM Precision Cleaning

Domain Est. 1998

Website: ucm-ag.com

Key Highlights: UCM is manufacturer of ultrasonic precision parts cleaning machines. Its globally leading solutions help companies around the world in achieving highest ……

#8 Elma Ultrasonic Cleaners

Domain Est. 2009

Website: elmaultrasonic.com

Key Highlights: Elma Ultrasonic Cleaners provide the best solutions for highly sensitive lab applications and industrial/manufacturing parts cleaning….

#9 Ultrasonic LLC

Domain Est. 2011

Website: ultrasonicllc.com

Key Highlights: Save time and money with Ultrasonic LLC’s powerful ultrasonic cleaning machines for industrial, automotive, medical, and aerospace parts. Shop Now!…

#10 Ultrasonic cleaning machines

Domain Est. 2018

Website: brioultrasonics.com

Key Highlights: We design, manufacture and supply ultrasonic cleaning machines for all industrial sectors, with innovations that improve cleaning results, energy efficiency ……

Expert Sourcing Insights for Ultrasonic Washing Machine

H2: Market Trends for Ultrasonic Washing Machines in 2026

As we approach 2026, the global market for ultrasonic washing machines is poised for notable transformation, driven by technological innovation, environmental concerns, and evolving consumer expectations. These advanced appliances, which utilize high-frequency sound waves to remove dirt and contaminants without traditional agitation or extensive water use, are gaining traction beyond niche industrial and medical applications into residential and commercial domains. Below are key market trends shaping the ultrasonic washing machine industry in 2026:

1. Rising Demand for Eco-Friendly Appliances

Environmental sustainability remains a dominant force in home appliance purchasing decisions. Ultrasonic washing machines consume significantly less water and energy compared to conventional models—some using up to 90% less water and eliminating the need for hot water or harsh detergents. In 2026, increasing regulatory pressure on water conservation and carbon emissions is pushing consumers and manufacturers toward green technologies. As governments in regions like the EU and North America enforce stricter environmental standards, ultrasonic washers are emerging as a sustainable alternative, accelerating their adoption.

2. Technological Advancements and Miniaturization

In 2026, advancements in transducer efficiency, control systems, and integration with smart home ecosystems are enhancing the usability and effectiveness of ultrasonic washing technology. Manufacturers are developing compact, modular units suitable for home use—such as countertop or under-sink models—targeting urban households with limited space. Integration with IoT platforms allows users to control wash cycles via smartphone apps, monitor water and energy usage, and receive maintenance alerts, improving user experience and driving consumer interest.

3. Expansion into Niche and Specialty Markets

While still limited in handling large laundry loads, ultrasonic washing machines are finding strong applications in specialty segments. In 2026, these include:

– Delicate garment care: Ideal for cleaning silk, wool, and high-end fashion items without mechanical stress.

– Medical and laboratory settings: Used for sterilizing instruments and sensitive equipment.

– Jewelry and eyewear cleaning: Portable ultrasonic cleaners are increasingly marketed to consumers for personal use.

This diversification is broadening the market base and generating ancillary revenue streams.

4. Growing Consumer Awareness and Education

Consumer skepticism around the cleaning efficacy of ultrasonic machines has historically been a barrier. However, by 2026, increased digital marketing, product demonstrations, and third-party validation are improving consumer trust. Brands are investing in educational campaigns highlighting the science behind ultrasonic cavitation and real-world performance data, helping to shift perceptions and expand market reach.

5. Competitive Landscape and Pricing Dynamics

The ultrasonic washing machine market remains relatively fragmented, with a mix of established appliance brands (e.g., Samsung, LG exploring pilot models) and startups (e.g., Toto, P&G-backed ventures) racing to capture early-mover advantage. While prices remain high due to R&D and component costs, economies of scale and improved manufacturing processes are expected to lower consumer entry points by 2026, making these devices more accessible.

6. Regional Market Growth Patterns

Asia-Pacific, particularly China and South Korea, leads in R&D and early adoption due to strong government support for green technologies and high urban population density. North America and Western Europe follow, driven by premium home appliance demand and sustainability trends. Emerging markets in Latin America and Southeast Asia show potential but face adoption challenges due to cost and infrastructure limitations.

Conclusion

By 2026, the ultrasonic washing machine market is transitioning from a novelty to a viable, eco-conscious alternative in the laundry appliance sector. While full-scale replacement of traditional washing machines is unlikely in the near term, continued innovation, falling prices, and growing environmental awareness are expected to drive steady market expansion—particularly in premium, specialty, and sustainable product segments.

Common Pitfalls When Sourcing Ultrasonic Washing Machines (Quality, IP)

Sourcing ultrasonic washing machines—especially for industrial, medical, or precision cleaning applications—requires careful evaluation to avoid costly mistakes. Two critical areas where buyers often encounter issues are product quality and intellectual property (IP) concerns. Here are the most common pitfalls in these areas:

Quality Pitfalls

Inconsistent or Substandard Components

Many suppliers, particularly low-cost manufacturers, use inferior materials such as thin stainless steel tanks, low-grade transducers, or unreliable generators. This leads to premature failure, reduced cleaning efficiency, and safety hazards. Always verify material specifications (e.g., SUS304 or SUS316 stainless steel) and request third-party test reports.

Overstated Performance Specifications

Suppliers may exaggerate key metrics like ultrasonic power (watts), frequency accuracy, or cleaning capacity. For instance, “40kHz” machines might operate at inconsistent frequencies, reducing effectiveness. Demand real-world performance data and request live demonstrations or customer references.

Poor Build Quality and Sealing

Inadequate sealing around transducers or tank joints can cause water leakage and electrical hazards. Poor welding or assembly compromises durability, especially in high-use environments. Inspect sample units for craftsmanship and consider on-site factory audits.

Lack of Safety Certifications

Reputable ultrasonic cleaners should comply with international safety standards such as CE, UL, or RoHS. Sourcing from suppliers who cannot provide valid certifications increases liability risks and may result in customs delays or non-compliance in your market.

Inadequate After-Sales Support and Spare Parts

Even high-quality machines require maintenance. Some suppliers fail to offer technical support, repair guidance, or accessible spare parts, leading to extended downtime. Confirm service availability and parts inventory before finalizing a purchase.

Intellectual Property (IP) Pitfalls

Risk of IP Infringement

Some manufacturers copy patented designs, control systems, or transducer configurations from established brands. Purchasing such products—even unknowingly—can expose your business to legal action, especially in regulated industries or markets with strict IP enforcement (e.g., EU, USA).

OEMs with Weak IP Compliance

When sourcing from OEMs, verify that they have legitimate licenses or original designs. Request documentation proving IP ownership or freedom-to-operate to avoid future litigation or product recalls.

Counterfeit or “Clone” Equipment

Low-cost suppliers may offer machines that closely resemble well-known brands but use counterfeit logos or packaging. These not only violate IP laws but often lack the quality and reliability of genuine products. Perform due diligence on branding and request proof of authenticity.

Lack of IP Clauses in Contracts

Failing to include IP indemnification clauses in sourcing agreements leaves buyers vulnerable. Ensure contracts specify that the supplier assumes liability for any IP disputes arising from the supplied equipment.

By addressing these quality and IP pitfalls proactively—through rigorous vetting, technical validation, and legal safeguards—buyers can source ultrasonic washing machines that are both reliable and compliant.

Logistics & Compliance Guide for Ultrasonic Washing Machine

Product Classification and Regulatory Overview

Ultrasonic washing machines, designed to clean delicate items using high-frequency sound waves, are subject to various international and regional regulations. These include electrical safety standards, electromagnetic compatibility (EMC), environmental directives, and shipping classifications. Key regulatory frameworks include the IEC 60335 series for household appliances, EU’s CE marking requirements, FCC regulations in the U.S., and RoHS/REACH compliance for hazardous substances.

Electrical Safety and Certification Requirements

Ensure the ultrasonic washing machine complies with electrical safety standards applicable in the target market:

– CE Marking (EU): Must meet Low Voltage Directive (LVD 2014/35/EU) and be tested per IEC 60335-1 and IEC 60335-2-85 (specific to ultrasonic cleaning appliances).

– UL/ETL Certification (USA & Canada): Required under UL 60745 or UL 60335 standards; products must be listed with OSHA-recognized Nationally Recognized Testing Laboratories (NRTL).

– PSE Certification (Japan): Mandatory for electrical appliances under the Electrical Appliance and Material Safety Law (DENAN).

– KC Certification (South Korea): Required by the National Radio Research Agency (RRA) and Korea Electrotechnology Research Institute (KETI).

Electromagnetic Compatibility (EMC) Compliance

Ultrasonic devices generate high-frequency signals that may interfere with other electronics. Compliance with EMC standards is mandatory:

– EU: EMC Directive 2014/30/EU; test to EN 55014 (emissions) and EN 61000-3-2/3-3 (harmonics and flicker).

– USA: FCC Part 15 Subpart B for unintentional radiators; Class B limits apply for residential environments.

– Other Markets: Refer to local EMC regulations such as ICES-003 (Canada), VCCI (Japan), and CNS 13438 (Taiwan).

Environmental and Chemical Regulations

Adherence to environmental directives ensures the product is safe and sustainable:

– RoHS (EU): Restricts use of lead, mercury, cadmium, and other hazardous substances. Ensure component suppliers provide RoHS-compliant declarations.

– REACH (EU): Requires disclosure of Substances of Very High Concern (SVHC); conduct supply chain due diligence.

– WEEE (EU): Register the product with national WEEE authorities and provide end-of-life take-back options.

– Proposition 65 (California, USA): Warn consumers if the product contains listed carcinogens or reproductive toxins.

Packaging, Labeling, and Marking Requirements

Proper labeling ensures regulatory compliance and user safety:

– Include CE, UKCA, FCC, or other required certification marks visibly on the product and packaging.

– Provide multilingual user manuals and safety instructions for target markets.

– Label input voltage, frequency, power consumption, and IP rating (if applicable) on the nameplate.

– Use recyclable packaging materials compliant with local waste regulations (e.g., EU Packaging Directive 94/62/EC).

Shipping and Transportation Logistics

Plan logistics based on product specifications and international shipping standards:

– UN Classification: Most ultrasonic washing machines are non-hazardous (UN 3481, PI 966 for lithium batteries if included). Confirm with testing lab if power banks or rechargeable units are integrated.

– Packaging: Use shock-absorbent materials and secure internal bracing to prevent damage during transit. Follow ISTA 3A or similar standards for drop and vibration testing.

– Documentation: Prepare commercial invoice, packing list, bill of lading, and certificates of compliance (CE, FCC, etc.). Include HS code (e.g., 8509 80 00 for electromechanical domestic appliances).

– Import Duties and Taxes: Research tariff rates and VAT/GST requirements in destination countries; consider using Incoterms (e.g., DDP, FOB) to clarify responsibilities.

Import/Export Controls and Customs Clearance

Facilitate smooth customs processing:

– Verify export licensing requirements, especially for dual-use technologies (rare for consumer ultrasonic washers, but confirm).

– Ensure accurate product descriptions and Harmonized System (HS) code classification to avoid delays.

– Retain technical files, test reports, and declarations of conformity for audit purposes.

– Comply with EU’s Market Surveillance Regulation (2019/1020) requiring an EU Responsible Person for non-EU manufacturers.

Post-Market Surveillance and Compliance Monitoring

Maintain compliance after product launch:

– Register products with national market surveillance bodies where required.

– Monitor for field failures and report serious incidents under EU RAPEX or U.S. CPSC guidelines.

– Keep technical documentation updated and available for at least 10 years post-manufacture.

– Conduct periodic compliance audits of suppliers and manufacturing facilities.

Summary

Successfully distributing an ultrasonic washing machine globally requires proactive planning across regulatory certification, environmental compliance, accurate labeling, and efficient logistics. Partner with accredited testing laboratories, stay informed on evolving regulations, and maintain thorough documentation to ensure market access and consumer safety.

Conclusion on Sourcing an Ultrasonic Washing Machine:

Sourcing an ultrasonic washing machine presents a promising and innovative solution for efficient, eco-friendly, and gentle cleaning of delicate items such as jewelry, eyewear, medical instruments, and precision components. These machines utilize high-frequency sound waves to generate microscopic bubbles that remove contaminants without the need for harsh scrubbing or excessive water and detergent, offering significant advantages in terms of cleaning effectiveness and operational sustainability.

When sourcing ultrasonic washing machines, it is essential to consider factors such as frequency, tank capacity, material quality, safety features, and brand reliability. Whether for industrial, medical, or household use, selecting a machine that aligns with specific cleaning requirements ensures optimal performance and longevity. Additionally, sourcing from reputable suppliers with technical support and warranty services enhances value and reduces operational risks.

Overall, investing in an ultrasonic washing machine supports cleaner, faster, and more sustainable cleaning processes. With proper due diligence in sourcing, organizations and individuals can achieve superior cleaning results while minimizing environmental impact and long-term maintenance costs.