The global adhesive tapes market has experienced steady expansion, driven by rising demand across packaging, automotive, construction, and electronics industries. According to a 2023 report by Mordor Intelligence, the market was valued at USD 64.1 billion in 2022 and is projected to grow at a CAGR of 4.8% through 2028, reaching an estimated value of over USD 85 billion. This growth is bolstered by innovations in tape formulations, increasing sustainability initiatives, and a surge in e-commerce packaging needs—factors that are reshaping competitive dynamics among manufacturers. In this evolving landscape, Tze tapes—a niche segment known for specialized industrial and labeling applications—have gained traction due to their durability and performance under extreme conditions. As demand rises, a select group of manufacturers has emerged as leaders, combining technological innovation, global distribution, and robust R&D investments to capture expanding market opportunities.

Top 4 Tze Tapes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 tesa tape, inc.

Domain Est. 1997

Website: tesa.com

Key Highlights: tesa North America is a leading manufacturer of adhesive tape solutions. We support industry partners in optimizing their processes & improving their ……

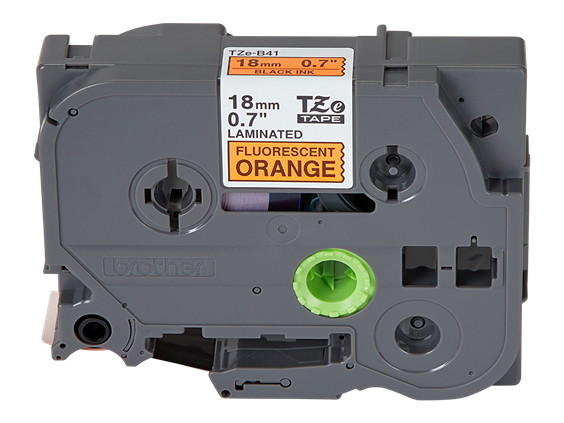

#2 P-touch Thermal Label Tapes

Domain Est. 2008

Website: brothermobilesolutions.com

Key Highlights: These Brother P-touch laminated label tapes are made with industrial pros in mind. Built to last and tested to the extreme….

#3 Brother P

Domain Est. 1997

Website: ramdcs.com

Key Highlights: Rating 2.0 (1) Abrasion Resistant: Engineered to perform in harsh environments, TZe Strong Adhesive Laminated Label Tapes can be used on items that are frequently shared, ……

#4 P

Domain Est. 2000

Website: brother-usa.com

Key Highlights: Free delivery over $50 · 30-day returnsNo matter the organizing task, Brother P-touch label tapes are up to the challenge! Choose from a variety of sizes, types, and colors to cus…

Expert Sourcing Insights for Tze Tapes

H2 2026 Market Trends Outlook for Tze Tapes

Based on current technological, regulatory, and market dynamics, the second half of 2026 is expected to present a transformative period for Tze Tapes (thermal transfer printing tapes used with Brother P-touch and similar label makers). Key trends shaping the market include:

1. Sustainability and Eco-Materials Acceleration

By H2 2026, environmental regulations and consumer demand will drive a significant shift toward biodegradable and recyclable Tze Tape materials. Leading manufacturers will likely introduce tapes using:

– Bio-based laminates (e.g., PLA substrates)

– Water-based adhesives reducing VOC emissions

– Recyclable packaging and modular refill systems

This shift will be especially pronounced in EU and North American markets due to tightening single-use plastic directives.

2. Smart Labeling Integration

Tze Tapes will increasingly support digital connectivity features. Expect:

– QR/NFC-enabled tapes for asset tracking in logistics and healthcare

– Compatibility with IoT label printers for real-time inventory management

– Mobile app integration allowing dynamic label design and cloud-based template sharing

This trend will be fueled by industrial digitization and supply chain transparency demands.

3. Expansion into Niche Verticals

Beyond consumer and office use, Tze Tapes will penetrate specialized sectors:

– Healthcare: Sterilizable, latex-free tapes for specimen and medical device labeling

– Food & Beverage: Cold-resistant, FDA-compliant tapes for freezer labeling

– Electronics Manufacturing: ESD-safe tapes for component identification

These applications will command premium pricing and drive B2B revenue growth.

4. Market Consolidation and Competitive Pressure

The Tze Tape ecosystem will experience consolidation as:

– Third-party manufacturers face stricter IP enforcement from Brother

– Private-label brands from retail giants (e.g., Amazon, Staples) capture price-sensitive segments

– Innovation focus shifts to proprietary materials and printer compatibility

This will pressure margins but incentivize R&D in durability and print quality.

5. AI-Driven Design and Customization

H2 2026 will see widespread adoption of AI-powered labeling platforms, enabling:

– Automated label template generation based on product data

– Voice-to-label workflows for hands-free operation

– Predictive tape usage analytics to prevent shortages

This enhances productivity, particularly in warehouse and retail environments.

Strategic Implications

Companies in the Tze Tape space should prioritize sustainable innovation, vertical-specific solutions, and digital ecosystem integration to capitalize on H2 2026 opportunities. Partnerships with industrial IoT providers and compliance with regional ESG standards will be critical for market leadership.

Common Pitfalls When Sourcing TZE Tapes (Quality, IP)

Sourcing TZE tapes—commonly used in Brother label printers—can present several challenges, particularly concerning product quality and intellectual property (IP) issues. Being aware of these pitfalls helps ensure reliable performance and legal compliance.

Poor Print Quality and Durability

One of the most frequent issues with third-party TZE tapes is inconsistent print quality. Low-cost alternatives may use substandard ink or ribbon materials, resulting in faded, smudged, or illegible text over time. Additionally, adhesive performance can degrade, causing labels to peel or fall off surfaces—especially in extreme temperatures or humid environments. This compromises labeling integrity in critical applications such as asset tracking, inventory management, and safety signage.

Non-Compliance with Environmental and Safety Standards

Many generic TZE tapes are manufactured without adherence to environmental regulations like RoHS (Restriction of Hazardous Substances) or REACH. This not only raises sustainability concerns but may also pose health risks in enclosed or sensitive environments. Furthermore, tapes not tested for UV, chemical, or heat resistance can fail prematurely when used in industrial or outdoor settings.

Misrepresentation of Compatibility

Some suppliers falsely claim compatibility with Brother P-touch printers. While a tape may physically fit, differences in tape core dimensions, adhesive formulation, or protective laminate thickness can lead to printer jams, misfeeds, or damage to internal components over time. Always verify compatibility through trusted distributors or technical specifications.

Intellectual Property Infringement

TZE is a trademarked format developed by Brother International. Unauthorized production and sale of TZE-compatible tapes can infringe on Brother’s IP rights, particularly when packaging, branding, or product design closely mimics genuine Brother products. Sourcing from vendors involved in IP violations may expose your organization to legal risks, supply chain disruptions, or reputational damage.

Lack of Traceability and Warranty Support

Counterfeit or unbranded TZE tapes often lack batch traceability and manufacturer warranties. If a product fails, there’s little recourse for replacement or support. Genuine Brother tapes, on the other hand, come with quality assurance and customer service, minimizing operational downtime.

Conclusion

To avoid these pitfalls, prioritize sourcing TZE tapes from authorized resellers or reputable manufacturers who provide transparency about materials, compliance, and IP legitimacy. Investing in high-quality, legally compliant tapes ensures long-term reliability, protects your equipment, and reduces overall operational risk.

Logistics & Compliance Guide for Tze Tapes

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legal handling, transportation, and distribution of Tze Tapes. Adherence to these guidelines ensures product integrity, regulatory compliance, and customer satisfaction.

Product Handling & Storage

Tze Tapes must be handled and stored under controlled conditions to maintain adhesive performance and structural integrity.

- Temperature Control: Store tapes in a cool, dry environment with temperatures between 15°C and 25°C (59°F–77°F). Avoid exposure to extreme heat or freezing conditions.

- Humidity Levels: Maintain relative humidity below 65% to prevent moisture absorption, which can degrade adhesive properties.

- Protective Packaging: Keep tapes in original sealed packaging until ready for use. Protect from direct sunlight and UV exposure, which may weaken adhesives.

- Shelf Life Management: Observe expiration dates and follow FIFO (First-In, First-Out) inventory practices. Do not distribute expired products.

Packaging & Labeling Standards

Ensure consistent, compliant, and informative packaging for all shipments.

- Primary Packaging: Use durable, tamper-evident packaging that protects tapes from dust, moisture, and physical damage.

- Labeling Requirements:

- Product name and SKU

- Batch/lot number

- Manufacturing and expiration dates

- Net weight or length

- Handling symbols (e.g., “Keep Dry,” “Do Not Stack”)

- Safety warnings (if applicable)

- Compliance Labels: Include required regulatory markings based on destination (e.g., CE, UKCA, RoHS where applicable).

Transportation & Shipping

Follow best practices for domestic and international shipments to prevent damage and comply with carrier regulations.

- Carrier Selection: Use reputable carriers experienced in handling industrial goods. Ensure alignment with delivery timelines and tracking capabilities.

- Palletization & Securing Loads: Stack cartons uniformly on pallets. Use stretch wrap and corner boards to prevent shifting. Max stack height: 6 cartons or as per product specification.

- Hazard Classification: Tze Tapes are typically non-hazardous (UN3082, environmentally hazardous, if solvent-based). Confirm classification per SDS. Most variants are non-regulated for transport.

- Documentation: Provide accurate shipping manifests, commercial invoices, packing lists, and Material Safety Data Sheets (SDS) for international shipments.

- Cold Chain Considerations: If transporting in extreme climates, use climate-controlled vehicles or insulated packaging as needed.

Regulatory Compliance

Adhere to international and regional regulations governing product safety, environmental impact, and trade.

- REACH & RoHS (EU/UK): Confirm tapes are free from restricted substances (e.g., SVHCs). Maintain compliance documentation for chemical content.

- Proposition 65 (California): Ensure labeling compliance if applicable based on adhesive composition.

- Customs Compliance: For cross-border shipments, provide accurate HS codes (e.g., 3919.10 for self-adhesive tapes of plastics), country of origin, and declared values.

- Import/Export Documentation: Include certificates of origin, export declarations, and any required import permits depending on destination.

Quality Assurance & Traceability

Implement systems to ensure product consistency and enable rapid traceability in case of recalls.

- Batch Tracking: Assign unique batch numbers and maintain detailed logs of production, testing, and distribution.

- Inspection Protocols: Conduct pre-shipment inspections to verify packaging integrity, labeling accuracy, and product condition.

- Recall Preparedness: Maintain a recall response plan including communication protocols, stock quarantine procedures, and regulatory reporting.

Sustainability & Environmental Responsibility

Support eco-friendly logistics practices and comply with waste directives.

- Recyclable Packaging: Use minimal, recyclable materials for shipping and primary packaging.

- Waste Management: Provide guidance for proper disposal of used tapes and packaging. Comply with WEEE or local waste regulations if applicable.

- Carbon Reduction: Optimize shipping routes and consolidate shipments to reduce emissions.

Training & Documentation

Ensure all logistics and warehouse personnel are trained and up to date.

- Staff Training: Regularly train staff on handling procedures, safety data, labeling, and compliance updates.

- Record Retention: Maintain shipping records, compliance certifications, and audit trails for a minimum of 5 years.

By following this Logistics & Compliance Guide, Tze Tapes operations will remain efficient, legally compliant, and aligned with industry best practices. Regularly review and update procedures to reflect changes in regulations or business needs.

Conclusion for Sourcing TZE Tapes

Sourcing TZE tapes requires a strategic approach that balances quality, cost, availability, and supplier reliability. As essential components for labeling in various industries—ranging from manufacturing and logistics to healthcare and retail—ensuring a consistent supply of genuine, high-performance TZE tapes is critical for operational efficiency.

After evaluating various sourcing options, it is evident that prioritizing authorized suppliers or manufacturers such as Brother—the brand that produces TZE tapes—ensures authenticity, compatibility, and durability. While third-party or generic alternatives may offer lower prices, they often come with risks related to print quality, longevity, and potential damage to label printers.

Additionally, building relationships with reliable distributors, considering bulk purchasing for cost savings, and maintaining inventory buffers can mitigate supply chain disruptions. Evaluating environmental conditions for label use (e.g., resistance to heat, moisture, or abrasion) further informs the selection of appropriate TZE tape types.

In conclusion, an effective sourcing strategy for TZE tapes involves verifying supplier credibility, assessing total cost of ownership—not just upfront price—and ensuring product specifications meet application requirements. By doing so, organizations can maintain labeling accuracy, reduce downtime, and support seamless daily operations.